Movable type filter cloth cleaning device of rotary disc filter

A technology of cleaning device and mobile device, applied in the direction of mobile filter element filter, filtration separation, membrane filter, etc., can solve the problems such as the decline of filter cloth filtration efficiency, incomplete washing of filter cloth, dead filter cloth mesh, etc. The effect of reducing cleaning water consumption, reducing work intensity and improving production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

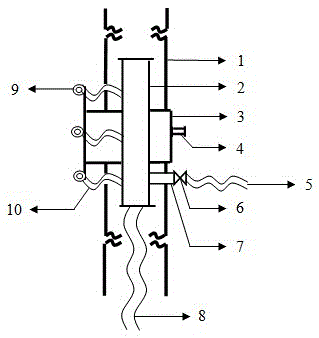

[0019] Such as figure 1 As shown, a mobile filter cloth cleaning device for a turntable filter includes several nozzles 9 installed, and a stainless steel guide rail cover plate as a mobile device 3, wherein the nozzles 9 are connected to the nozzle main water pipe 2 through a nozzle hose 10, and the nozzles are always The water pipe 2 is connected to the nozzle water flexible main pipe 8, and the guide rail cover plate 3 is set on the stainless steel guide rail 1 fixed on the top of the filter turntable, the length is greater than the radius of the fan of the filter disc, and the bolt is used as the locking device 4, the guide rail cover plate Several stainless steel pipes are welded perpendicular to the direction of the turntable of the filter for installing the nozzle 9;

[0020] The installation steps of this invention are as follows:

[0021] Step 1: According to the size of the filter, make a stainless steel guide rail 1 whose length is greater than the radius of the fa...

Embodiment 2

[0027] Such as figure 1 As shown, a mobile filter cloth cleaning device for a turntable filter includes an electronically controlled automatic trolley as a mobile device 3 equipped with several nozzles 9, wherein the nozzles 9 are connected to the nozzle main water pipe 2 through a nozzle hose 10, and the nozzles are always connected to each other. The water pipe 2 is connected to the water flexible main pipe 8 of the nozzle, and the electronically controlled automatic trolley 3 is installed on the stainless steel guide rail 1 above the filter turntable, whose length is greater than the radius of the fan of the filter disc, and bolts are provided as the locking device 4, and the electronically controlled automatic trolley The trolley is welded with several stainless steel pipes perpendicular to the direction of the turntable of the filter for installing the nozzle 9;

[0028] The installation steps of this invention are as follows:

[0029] Step 1: According to the size of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com