A smart cleaning food processor

A food processing machine and intelligent cleaning technology, which is applied in the direction of tableware washing machine/rinsing machine, tableware washing machine/rinsing and rinsing machine parts, cleaning equipment, etc., can solve the problem of bloated crushing chamber cover structure, easy breeding of bacteria, and easy existence Cleaning dead corners and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

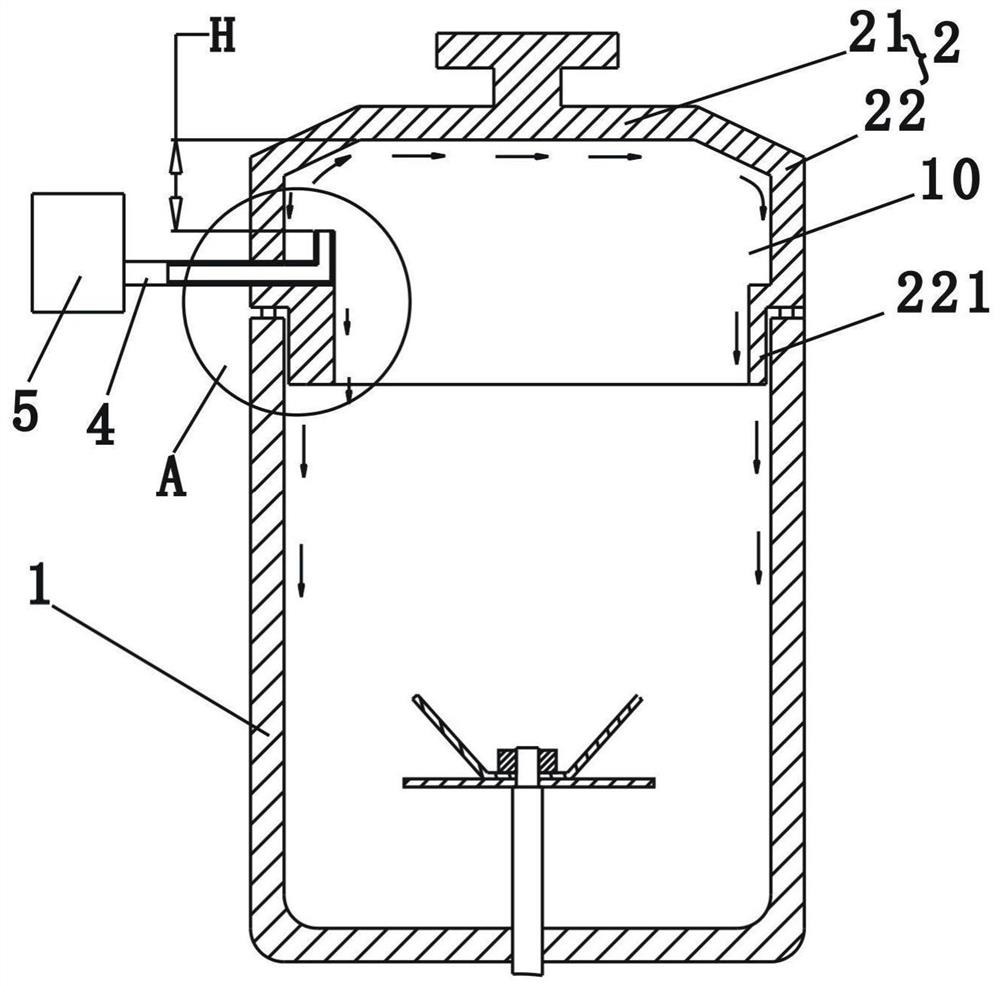

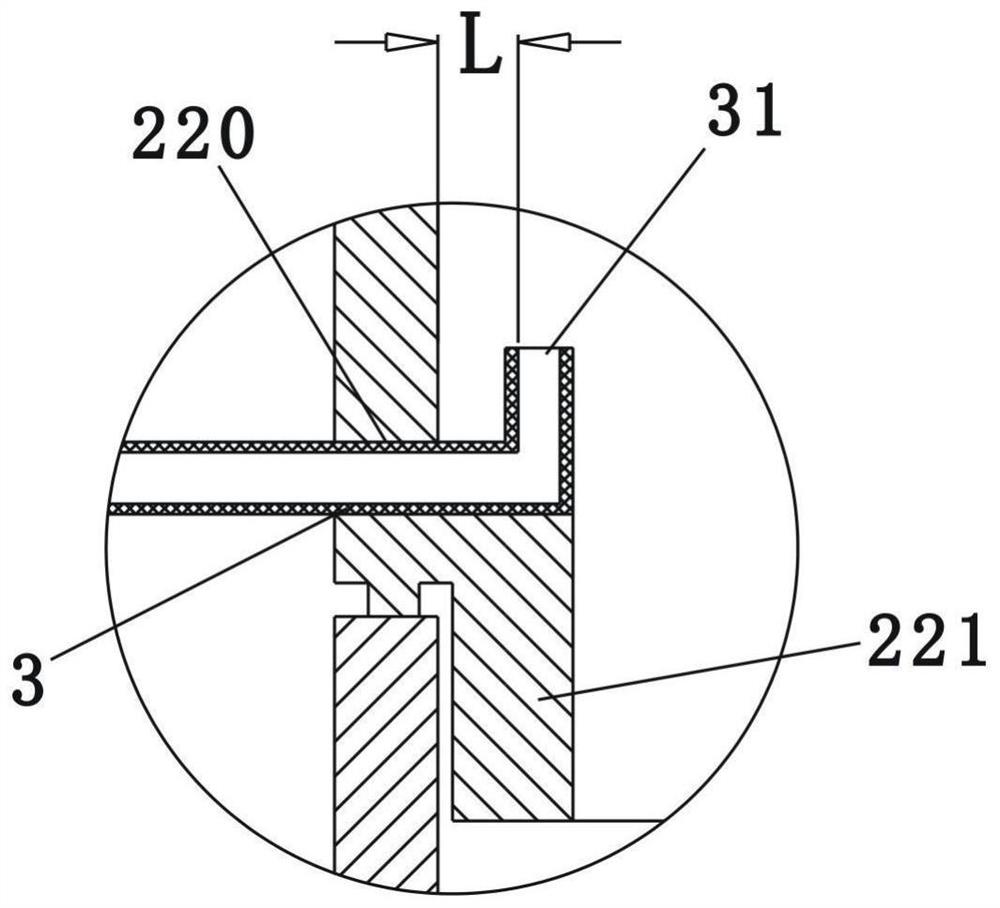

[0036] Such as figure 1 , figure 2 Shown is a schematic structural diagram of the first embodiment of the present invention. A food processor, comprising a cup body 1, a cup cover 2 mounted on the top of the cup body 1, the cup cover 2 has a top wall 21 and a peripheral wall 22 extending downward from the top wall 21, inside the cup body 1 A crushing device (not marked in the figure) for crushing materials is provided, the cup cover 2 is formed with an accommodation chamber 10, and the peripheral wall 22 of the cup cover is provided with a nozzle 3, and the nozzle 3 transversely penetrates the peripheral wall 22 of the cup cover and extend into the housing cavity 10 formed by the cup cover 2, and the nozzle 3 has an upper spout 31 arranged upwards, and the upper spout 31 sprays cleaning liquid toward the inner surface of the top wall 21 of the cup cover, and the sprayed water from the upper spout 31 The cleaning liquid washes along the inner surface of the cup cover 2, and ...

Embodiment 2

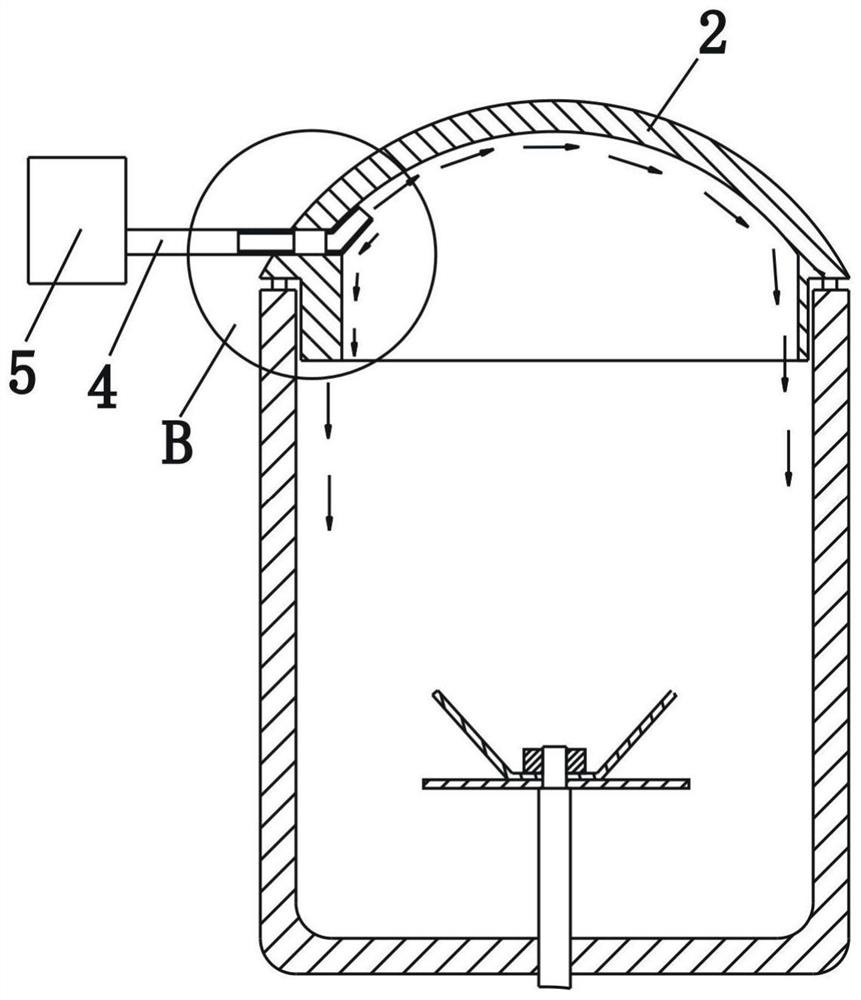

[0048] Such as image 3 , Figure 4 Shown is a schematic structural diagram of the second embodiment of the present invention. This embodiment differs from Embodiment 1 in that: in this embodiment, the inner surface contour of the cup cover 2 is spherical, and the nozzle includes a through hole 220 that runs through the wall of the cup cover 2 transversely, and the through hole 220 The water outlet is communicated with the upper nozzle 31, and the other end of the through hole 220 is communicated with the water supply system 5 through the connecting pipe 4, so that the water supply system 5 can supply water to the nozzle. Simultaneously, in the present embodiment, the upper spout 31 is close to the inner surface of the cup cover 2, and the cleaning water ejected from the upper spout 31 is sprayed obliquely relative to the vertical plane, and the spraying inclination formed by the sprayed cleaning water and the vertical plane is α1, and the angle formed by the tangent of the ...

Embodiment 3

[0053] Such as Figure 5 Shown is a schematic structural view of the third embodiment of the present invention. The difference between this embodiment and Embodiment 2 is that in this embodiment, the nozzle is a through hole 220 that runs through the cup cover laterally, and the through hole 220 is arranged obliquely toward the top of the cup cover, and the outlet end of the through hole 220 It is the upper spout 31, and, in this embodiment, the wall of the cup cover is provided with a plurality of nozzles around a circle, and the plurality of nozzles cross-spray the inner surface of the cup cover, so as to realize the full-coverage flushing and cleaning of the cup cover, and there is no cleaning blind spot.

[0054] It should be pointed out that, in this embodiment, the cup lid has a single-layer wall structure. Of course, the cup lid can also have a double-wall structure with an outer wall and an inner wall, and a cup can be formed between the outer wall and the inner wall....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com