Semiconductor material cleaning device

A cleaning device and a technology for semiconductors, which can be applied to cleaning methods using liquids, manufacturing of semiconductor/solid-state devices, cleaning methods using tools, etc., can solve the problems of low cleaning efficiency, poor cleaning effect, and inability to rinse semiconductor materials, etc. To achieve the effect of improving stability and security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

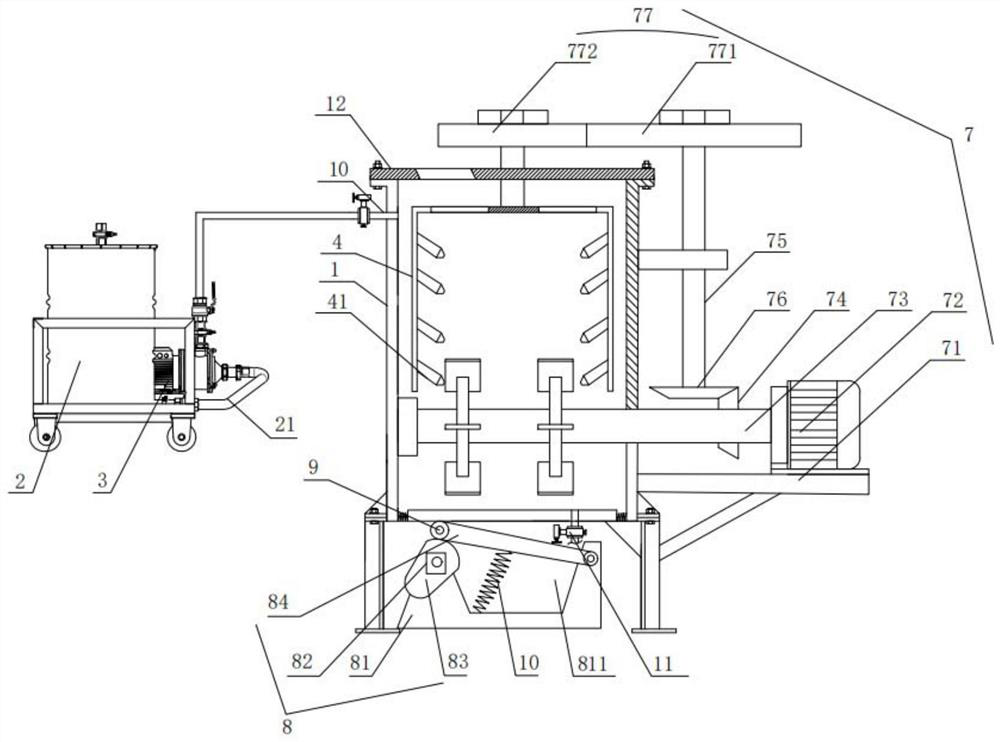

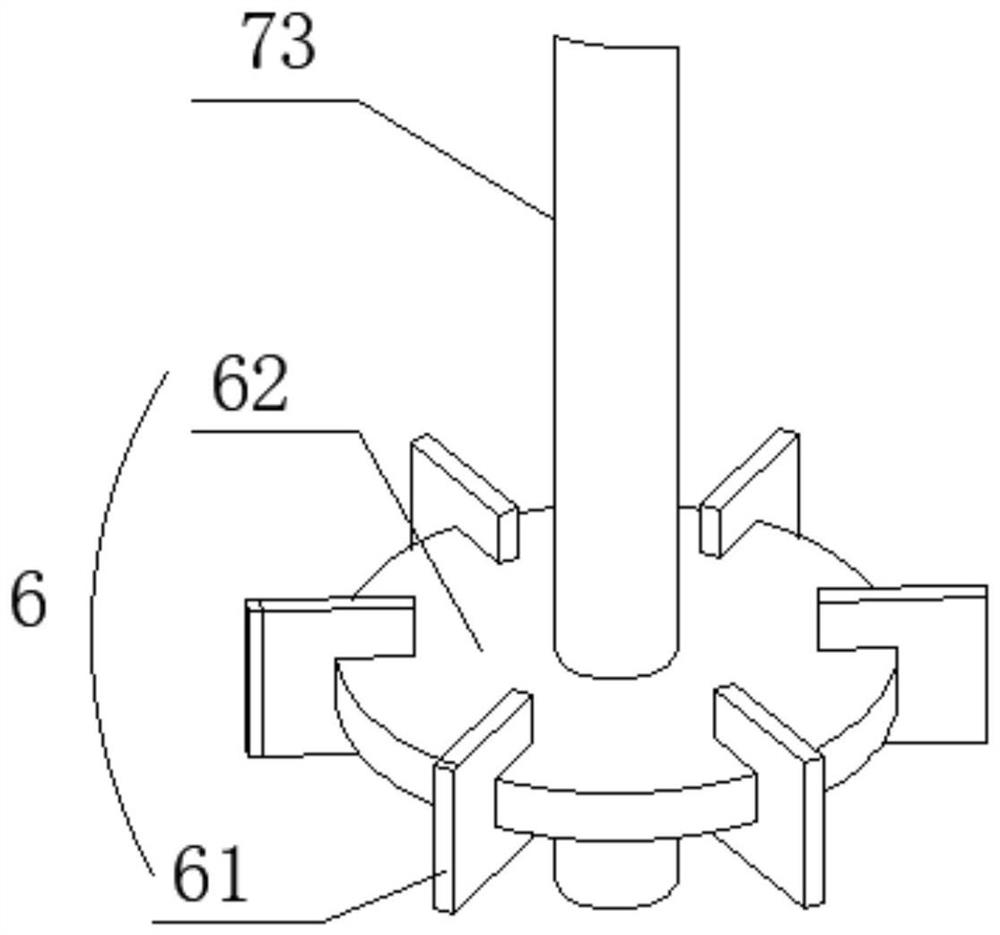

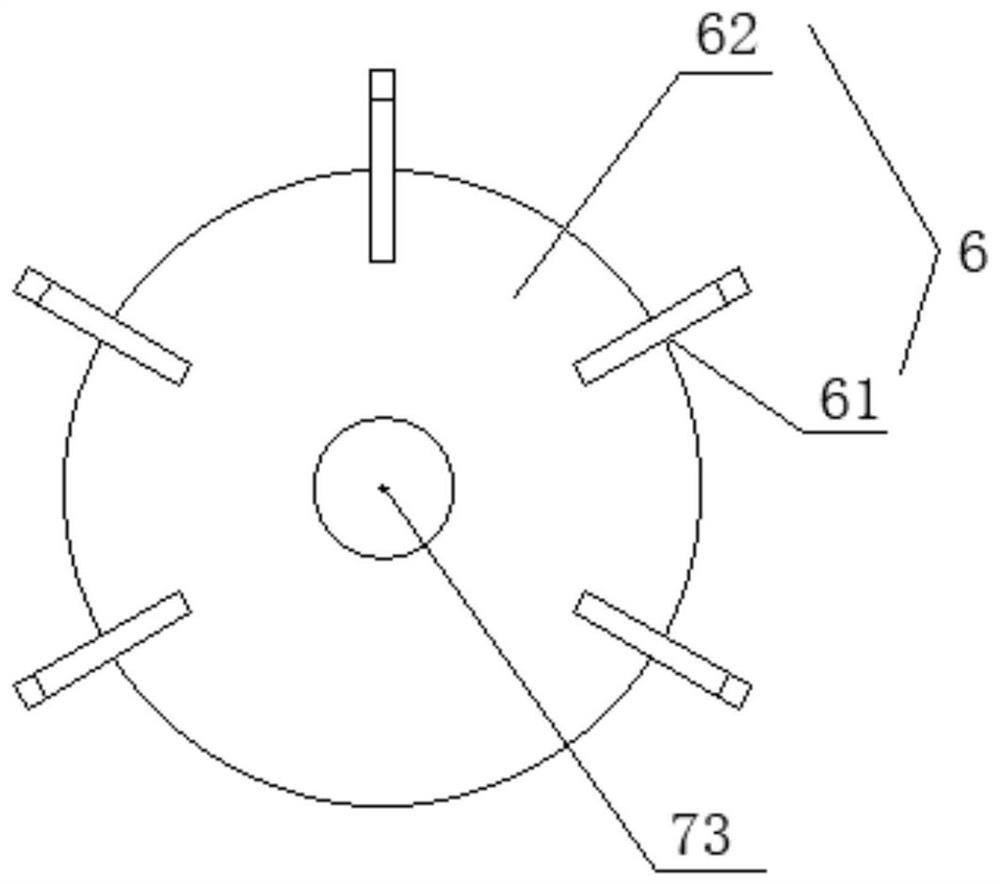

[0040] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0041] Figure 1-2 Shown, a cleaning device for semiconductor materials, comprising:

[0042] Cleaning box 1, the cleaning box 1 can clean the semiconductor material layer by layer in the height direction; the bottom of the cleaning box 1 is provided with a vibration plate 11; the vibration plate 11 is elastically arranged at the bottom of the cleaning box 1;

[0043] The liquid storage tank 2 is used to store the cleaning liquid, and pump the cleaning liquid into the cleaning tank 1 through the pump body 3, so as to realize the circular array to wash the semiconductor material layer by layer;

[0044] Circulation dial cylinder body 4 is in the shape of a thin plate cylinder, its top and bottom are open, and a plurality of feed rods 41 are provided on its circumferential inner wall;

[0045] The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com