Patents

Literature

49results about How to "Realize return" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

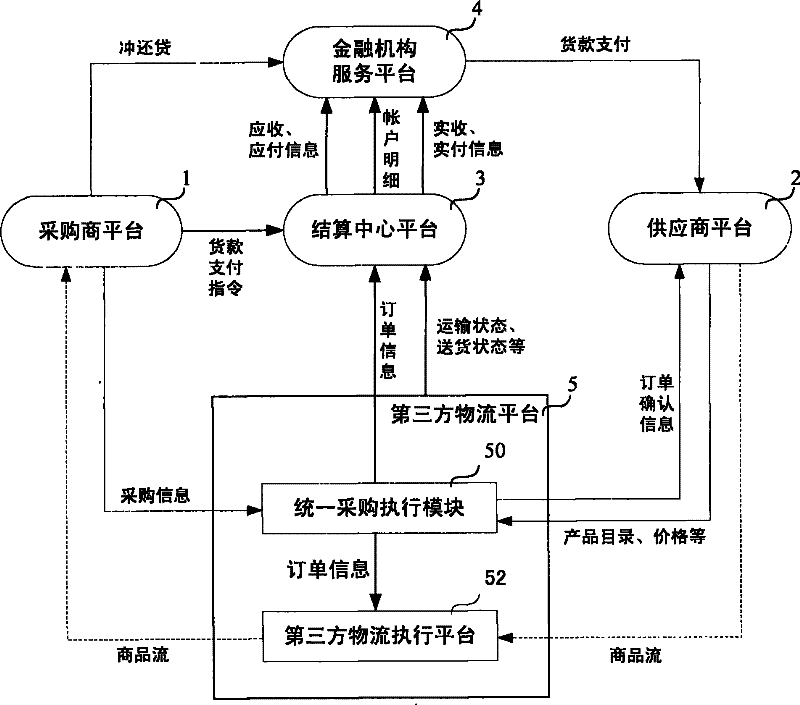

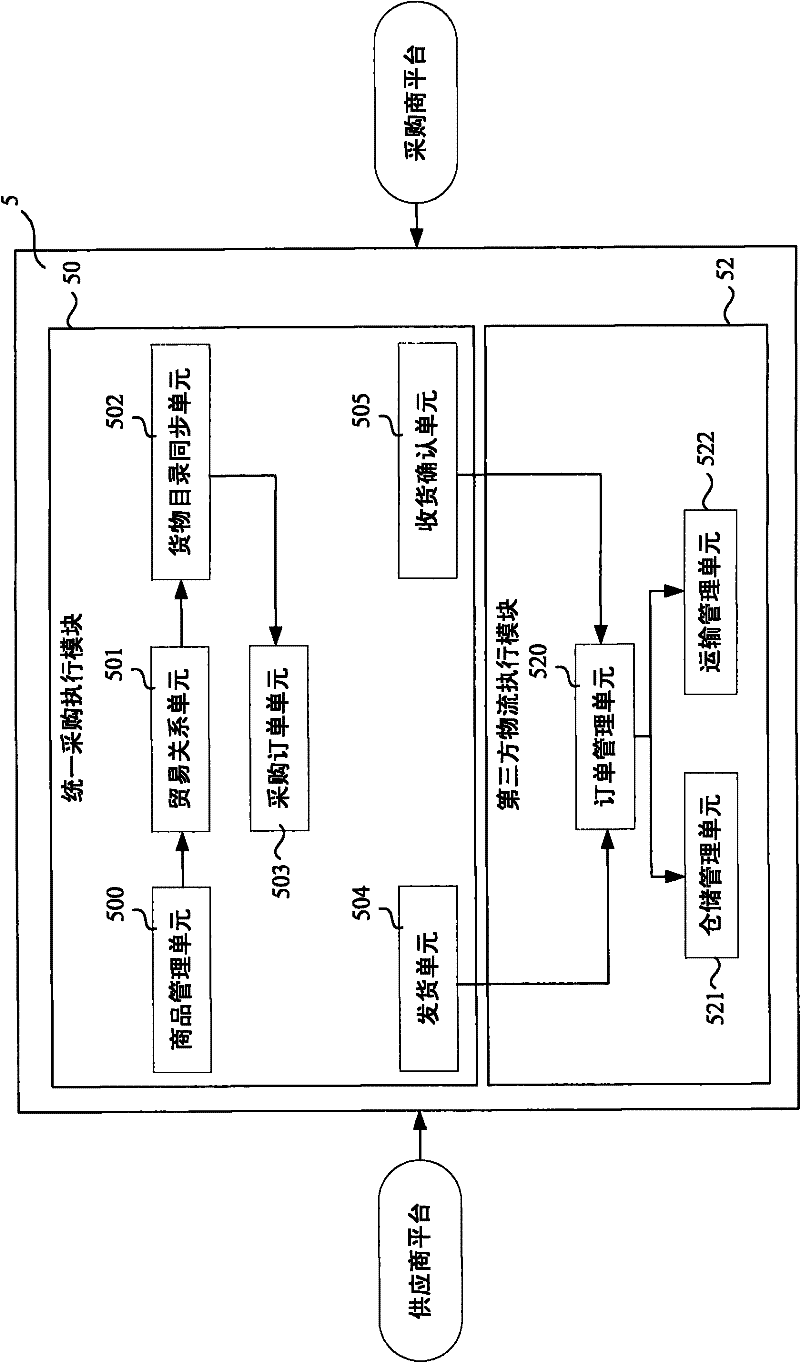

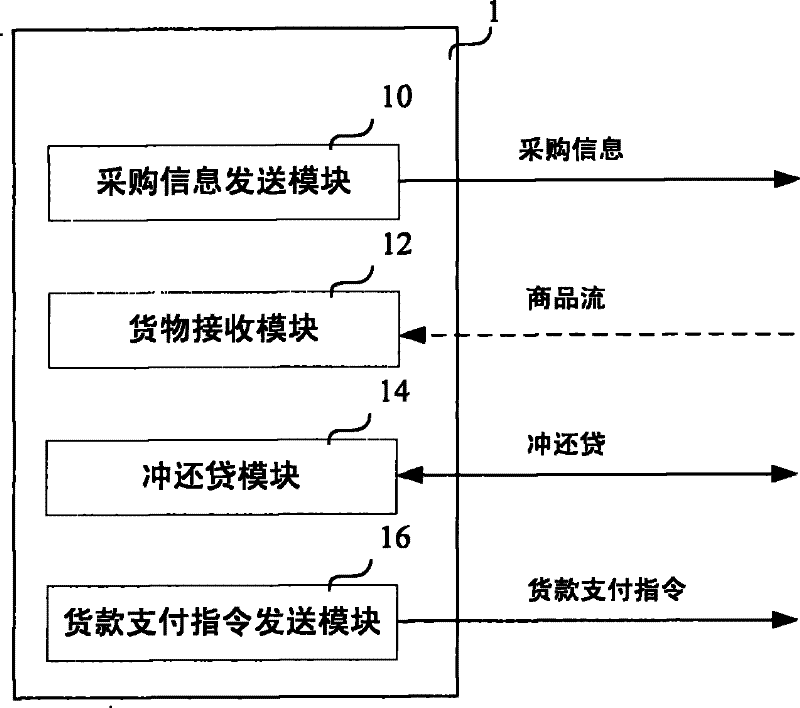

Commodity transaction settlement method and system

The invention discloses a commodity transaction settlement method and system, which can effectively solve the two problems of difficulty in financing and settlement of small and medium enterprises in the field of commodity transaction settlement. The technical scheme is as follows: a settlement center is introduced besides a supplier, a purchaser and a third-party logistics (TPL), thus integrating the purchaser, the supplier, the TPL and the settlement center tightly and organically as a common body. A triangular circular flow chain is formed among the settlement center, the supplier and the purchaser, namely, the settlement pays the supplier in advance, and then the purchaser repays the delayed factoring goods payment to the settlement center in a preset period. Under the pattern, a whole supplying chain financial system is controlled by an electronic business information system, thus removing all anthropic factors, being capable of realizing rapid payment return of the supplier by realizing real transaction and delivery only if commodities are good for sales, and thoroughly solving the dilemma of difficulty in payment settlement.

Owner:上海钧宸投资有限公司

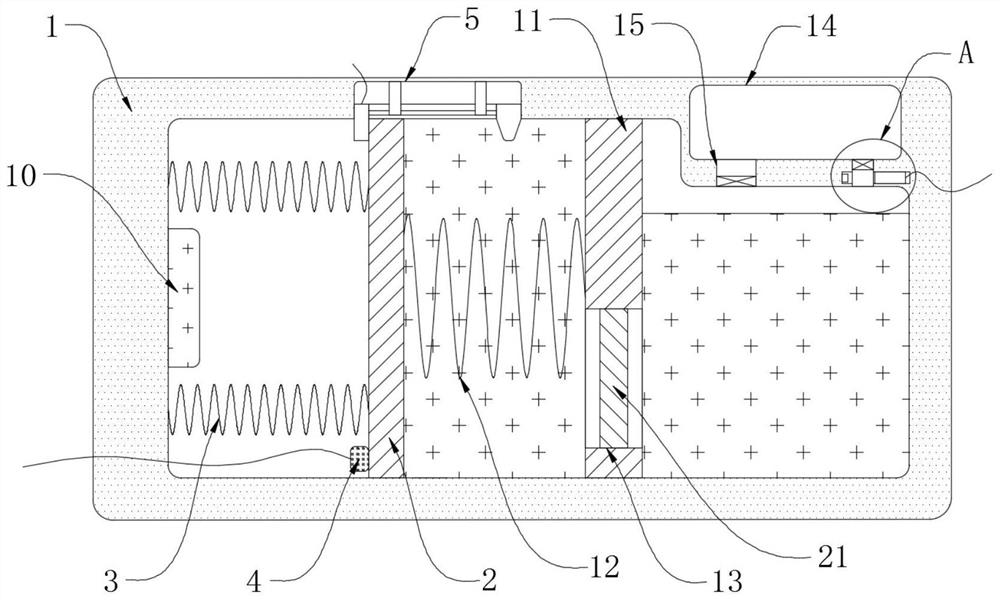

Adjusting device

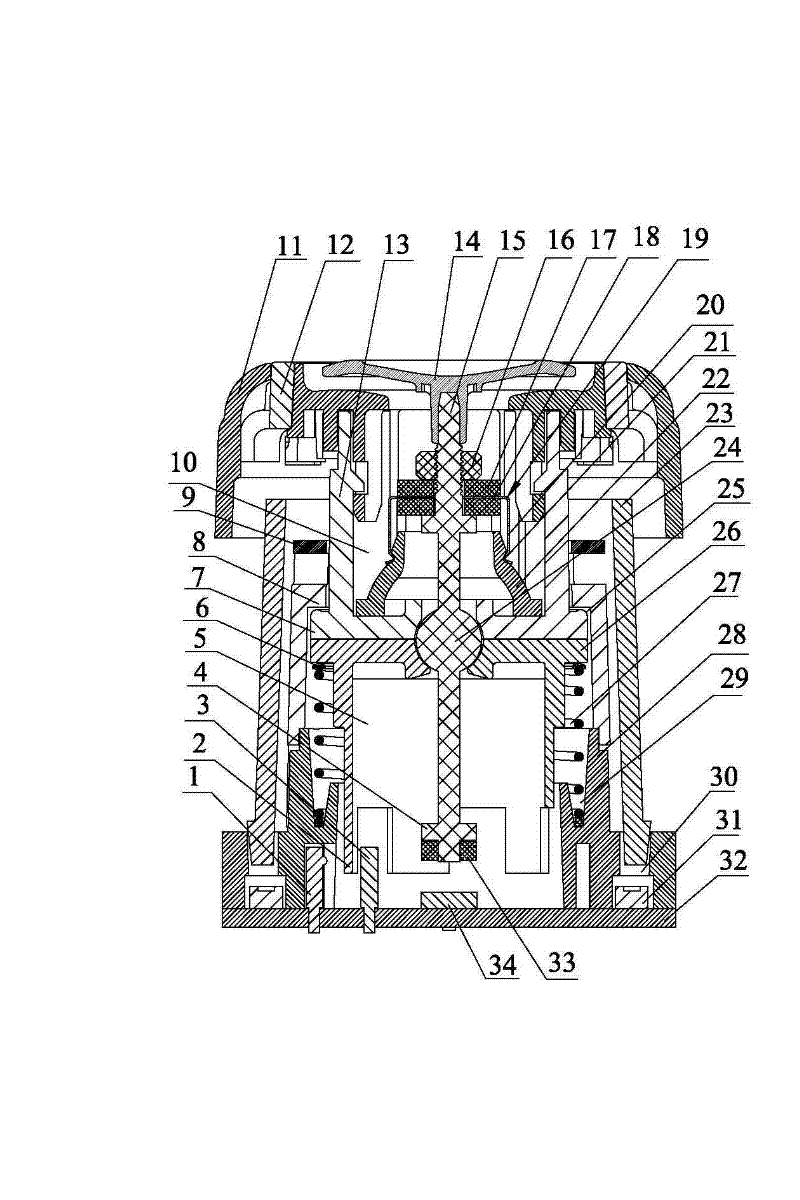

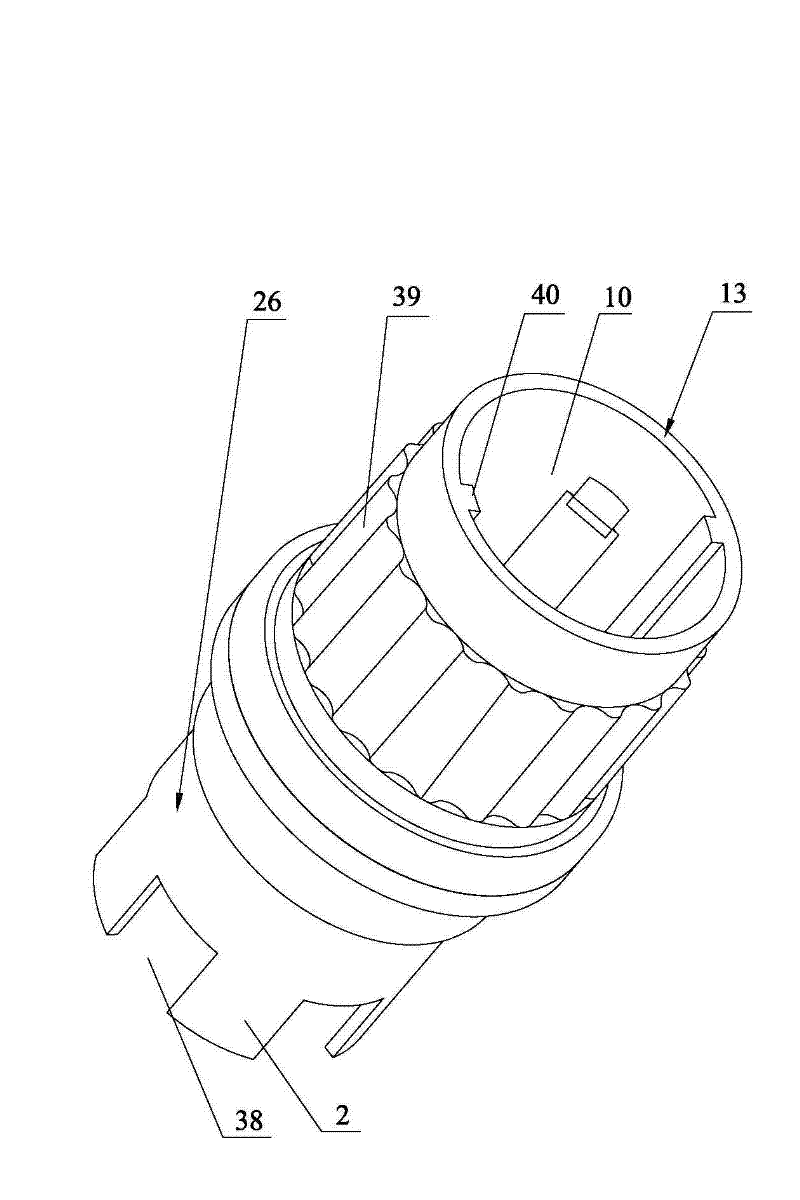

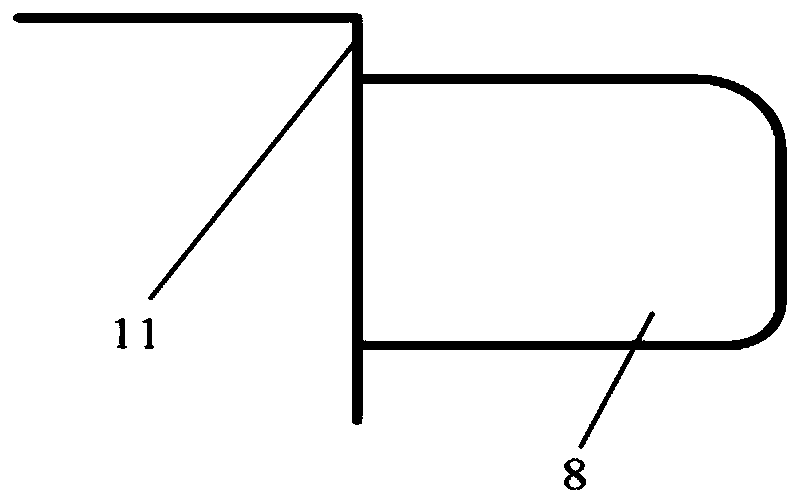

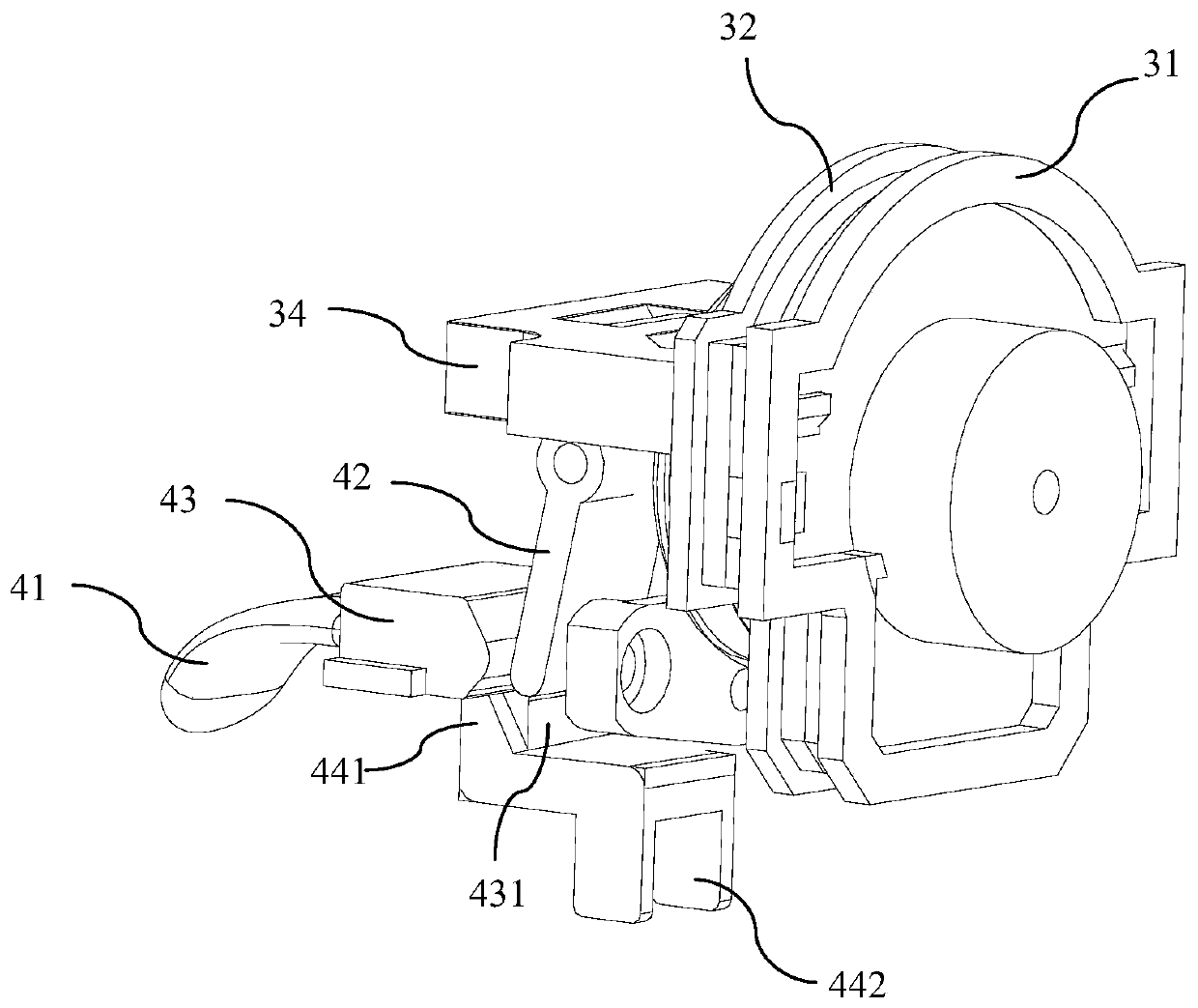

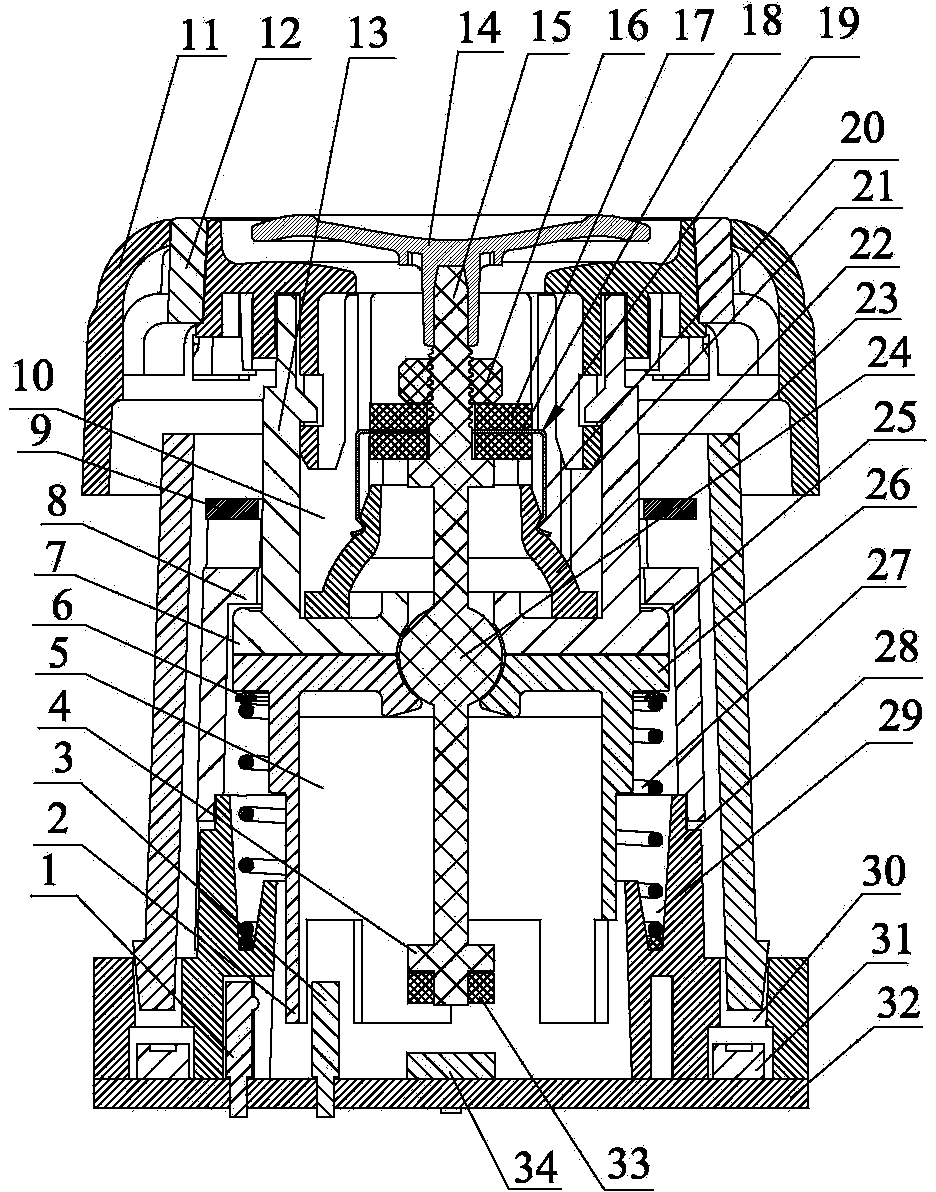

An adjusting device comprises a bottom plate, at least two signal transmitting units, a magnetic element, a Hall element, a base, a limit element, a first cover, a second cover, a knob, a button, a rocker, a first return unit and a second return unit, wherein the first return unit is used for axially returning the rocker, and the second return unit is used for obliquely returning the rocker. As the adjusting device is provided with the rocker and a ball, button functions in a vertical direction and in other directions can be realized, namely the adjusting device is capable of realizing omnidirectional button functions. Besides, the adjusting device is provided with the magnetic element and the Hall element which are opposite, the magnetic element is driven to move by the rocker, the Hall element is capable of sensing different signals, and the operation of the whole adjusting device can be judged by the aid of the signals. By means of coordination of a baffle plate of the first cover and the signal transmitting units, turning directions of the knob can be judged, so that omnidirectional output can be realized.

Owner:BYD CO LTD

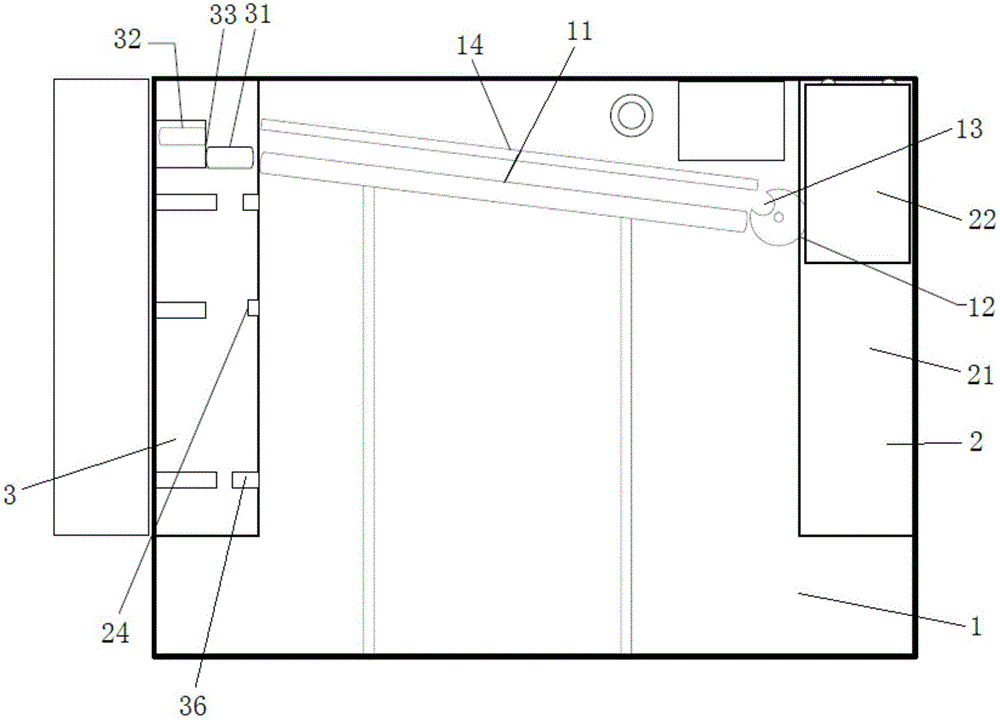

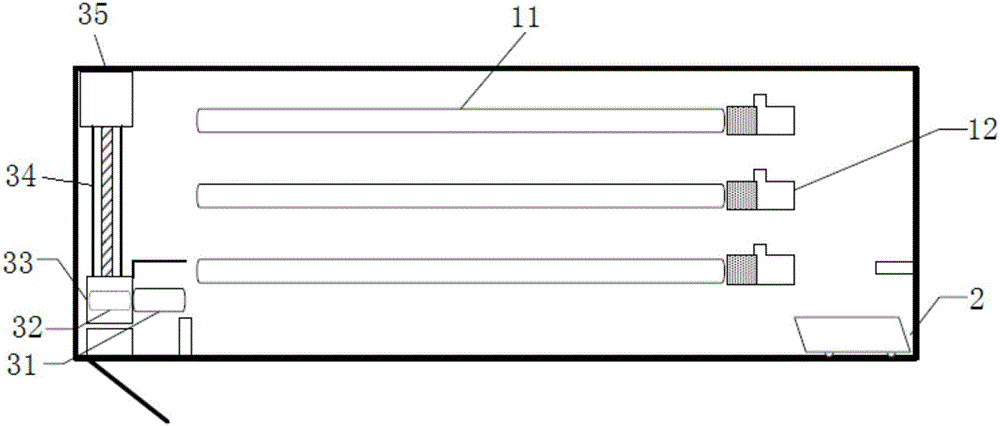

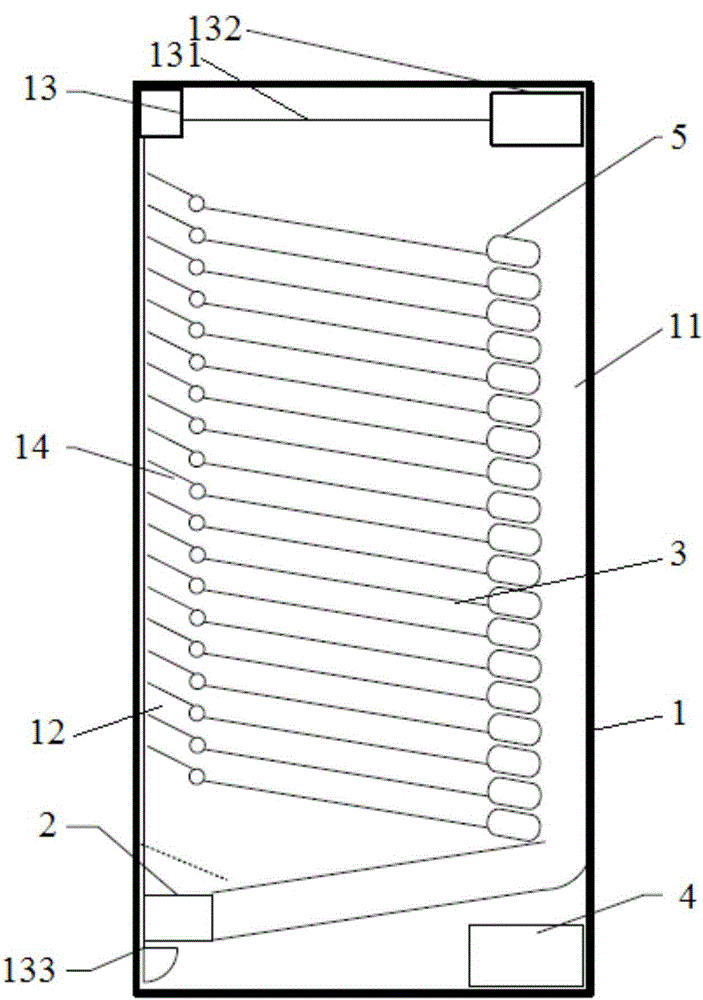

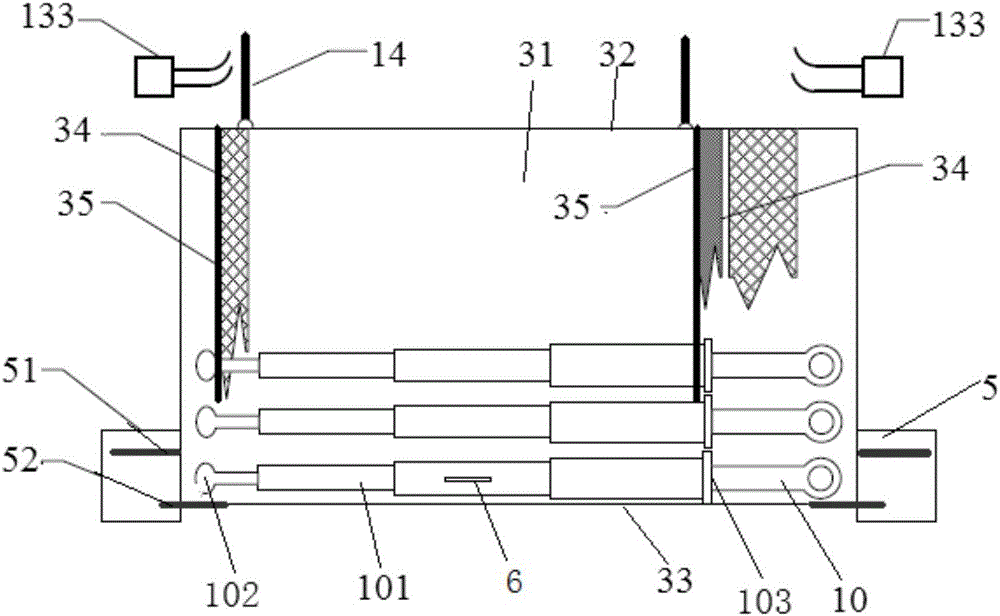

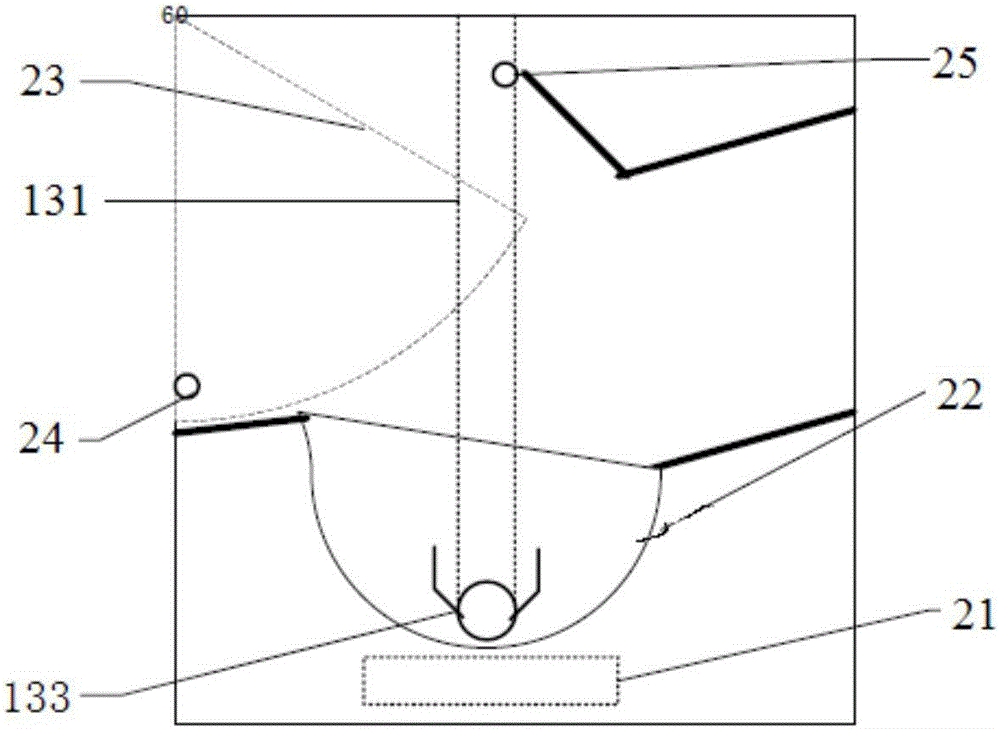

Rod-hanging type automatic umbrella borrowing machine and control method thereof

InactiveCN106355773AEfficiently provideRealize automatic collectionApparatus for meter-controlled dispensingEngineering

The invention relates to a rod-hanging type automatic umbrella borrowing machine and a control method thereof. The rod-hanging type automatic umbrella borrowing machine comprises a cabinet body, an umbrella taking port and an umbrella returning port, wherein the cabinet body is internally provided with a sliding track piece with a suspended umbrella; one or more than one sliding track piece is arranged; the umbrella is suspended on the sliding track piece and is provided with a label; the umbrella taking port is arranged at the side of the cabinet, comprises a transparent panel, and is internally provided with an umbrella-label reader for recording umbrella taking; and the umbrella returning port is arranged at one side of the cabinet body, far away from the umbrella taking port, and is internally provided with an umbrella returning label reader for recording umbrella returning. The rod-hanging type automatic umbrella borrowing machine and the control method have the beneficial effects that (1) the umbrella is effectively provided in time, a user can use the umbrella instantaneously after taking the umbrella, the use is reliable and convenient, a special person is not needed for management, the operation is convenient and the use prospect is wide; (2) the umbrella storage amount is large and the occupied space is saved; (3) the product is simple and practical in structure and simple in maintenance; and (4) the full-automatic operation is achieved, and the umbrella borrowing and returning experience of the user is good.

Owner:上海飞翰信息科技有限公司

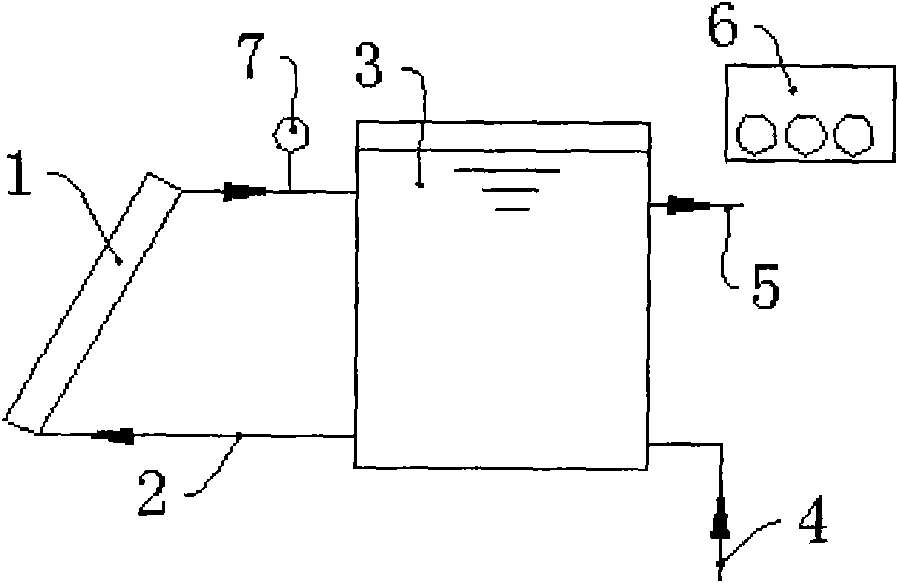

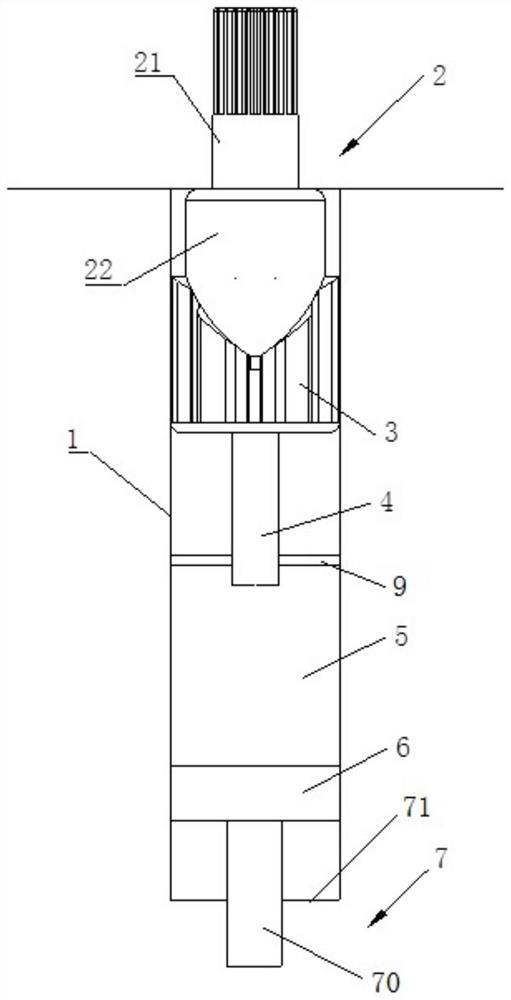

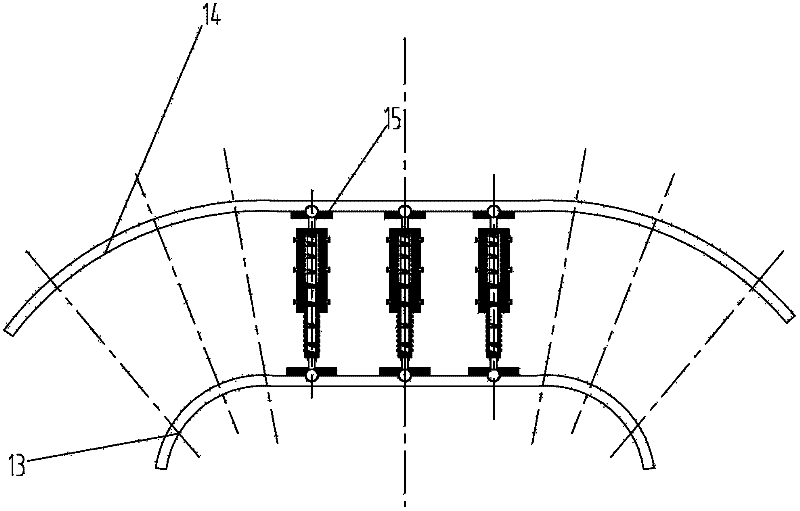

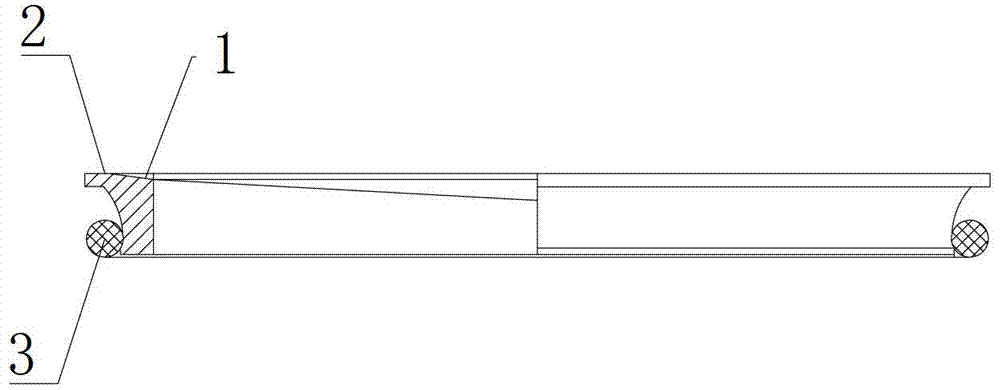

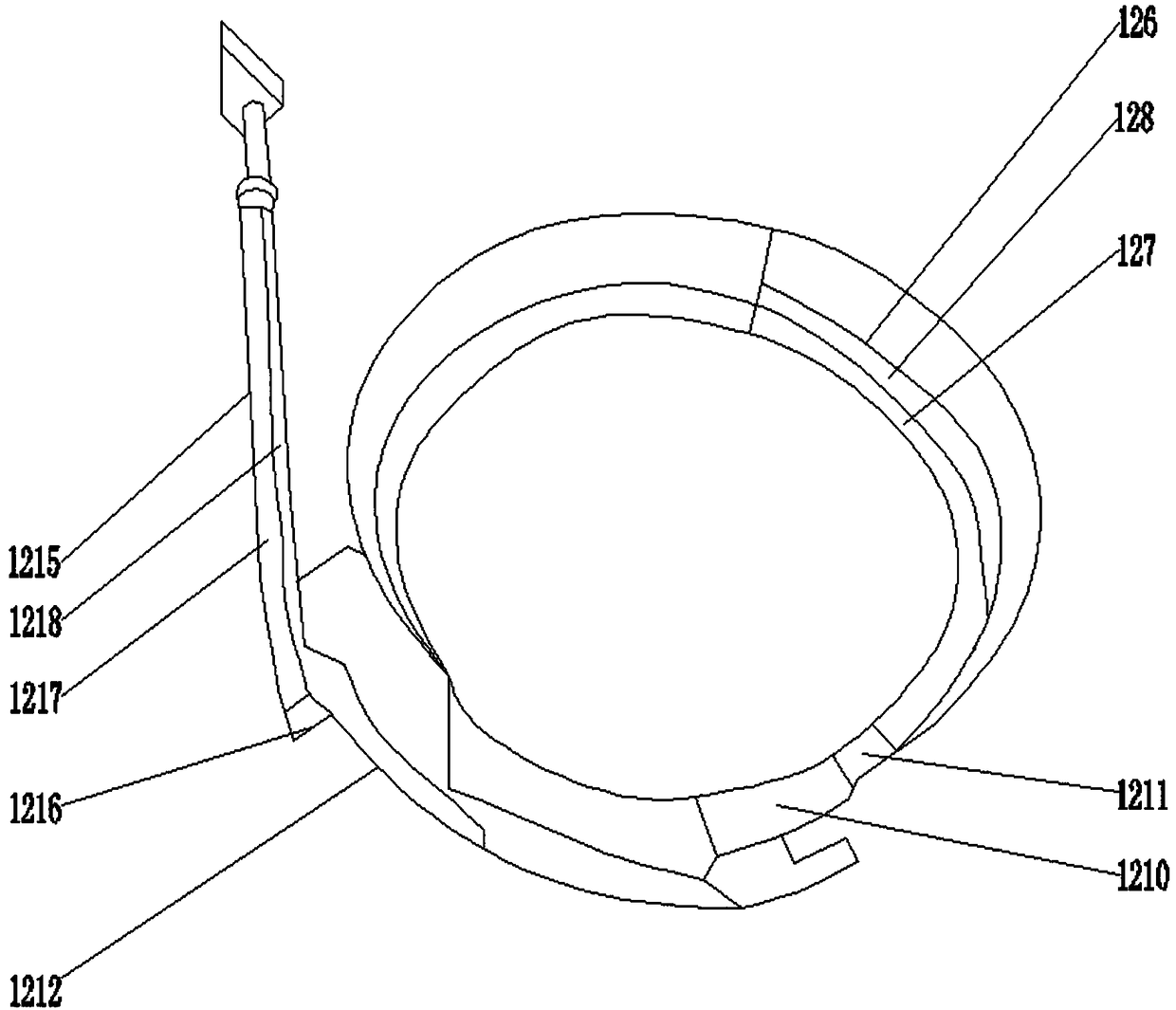

Sunshade device for large solar heat collector

InactiveCN101782286AAdjustable water temperatureRealize returnSolar heating energySolar heat devicesCollector deviceEngineering

The invention relates to a sunshade device for a large solar heat collector. The sunshade device is arranged above the heat collector and comprises a sunshade curtain, a rotating shaft, a rotating drum, a pulling rope, a line rolling wheel and fixed pulleys. The rotating drum is sheathed on the rotating shaft in a spacing way. The rotating drum and a group of fixed pulleys are respectively arranged at the two ends of the heat collector. The line rolling wheel is fixedly installed on the rotating shaft at the two ends of the rotating drum. One end of the sunshade curtain is connected and wound on the rotating drum and the other end of the sunshade curtain is connected with the pulling rope. After the direction of the pulling rope is turned through the fixed pulleys, the pulling rope is wound on the line rolling wheel. A hard pull rod is connected at the end part of the sunshade curtain. The number of the fixed pulleys is two. The two fixed pulleys are respectively arranged on the two sides of one end of the heat collector. At least one horizontal a support lever horizontally supporting the sunshade curtain is arranged below the sunshade curtain. Supports arranged at the two ends of the support lever are connected with the frame of the heat collector or the installing supports of the heat collector. The sunshade device is manually driven or driven by a motor. The invention has the advantages that the sunshade device can be used to shade sunshine to the solar heat collector, the price is low and the popularization and the application are easy.

Owner:潘戈

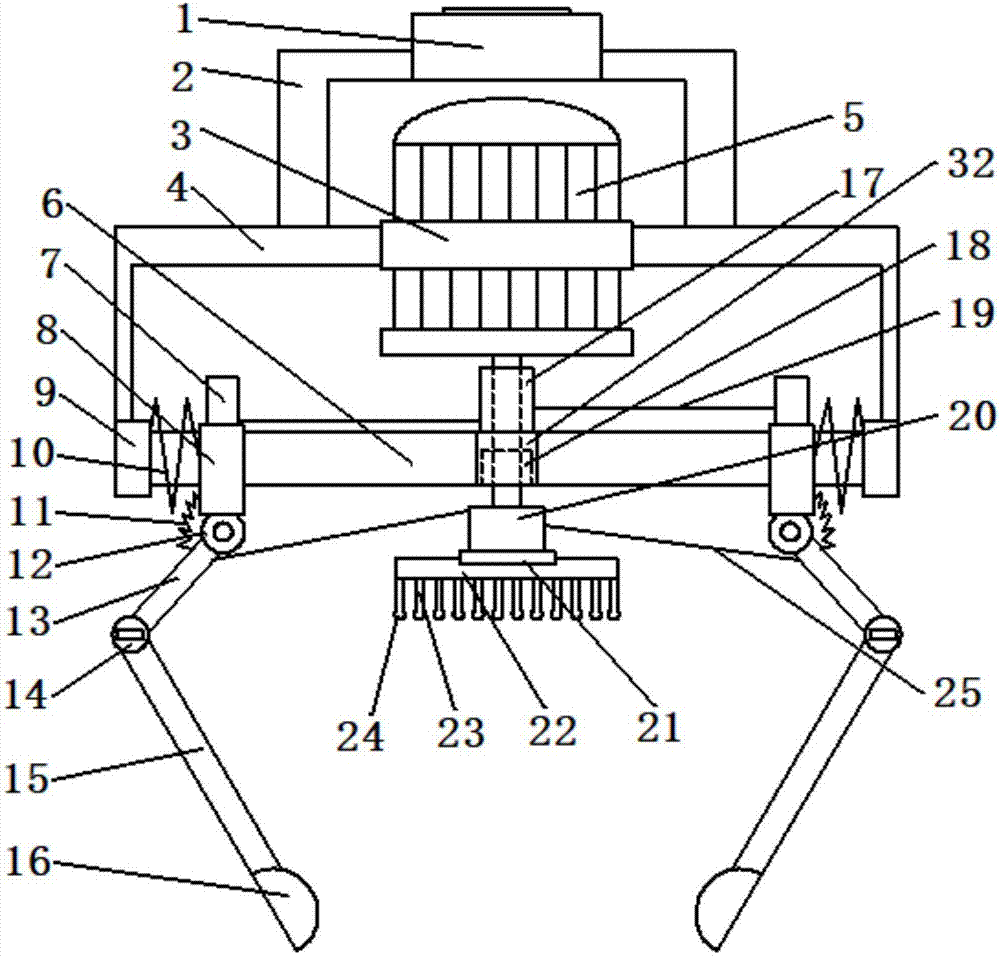

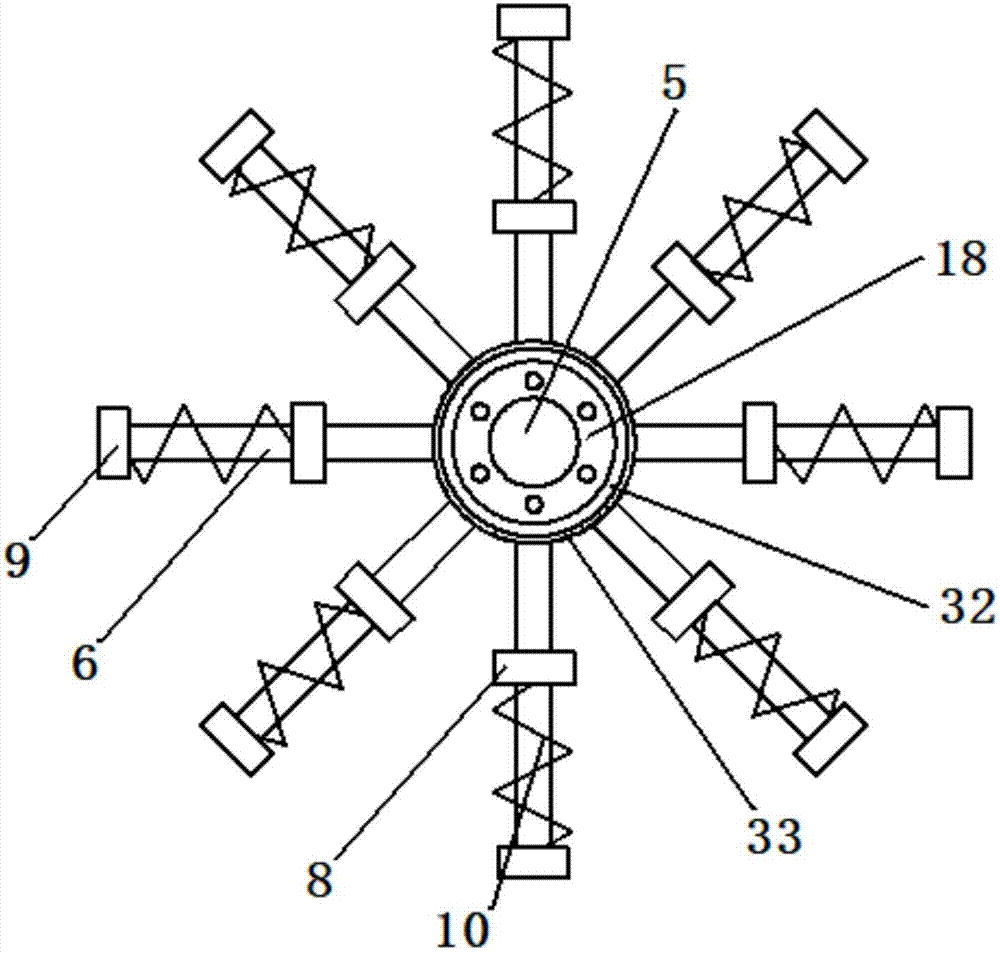

Driving device for robot gripper

PendingCN107471236AKeep the position fixedGuaranteed resetGripping headsElectric machineryEngineering

The invention discloses a driving device for a robot gripper. The driving device comprises a mounting flange, a first bracket, a second bracket, a motor, a first lantern ring, a second lantern ring, a third lantern ring and a fourth lantern ring. A first spring is arranged between the first lantern ring and the limiting block; the third lantern ring winds the top of the first lantern ring through a first connecting rope; the bottom of the first lantern ring is hinged to a first gripper and a second gripper; a second slide bar is inserted onto the fourth lantern ring; a wedge block is connected to the inner side of the slide bar and an arc-shaped plate is fixedly connected to the outer side; the shaft of the motor is inserted into the fourth lantern ring; a base plate is also fixedly connected below the fourth lantern ring; the shaft of the motor is fixed below the base plate through a fixed bolt; a fourth spring sleeves the fixed bolt; the fourth spring is located between the motor shaft and the base plate; and the first gripper is wound on the arc-shaped plate through a second connecting rope. The driving device disclosed by the invention can improve the defects in the prior art and can be applied to a plant which is not driven by compressed air, and the gripper is more conveniently adjusted.

Owner:宁夏巨能机器人股份有限公司

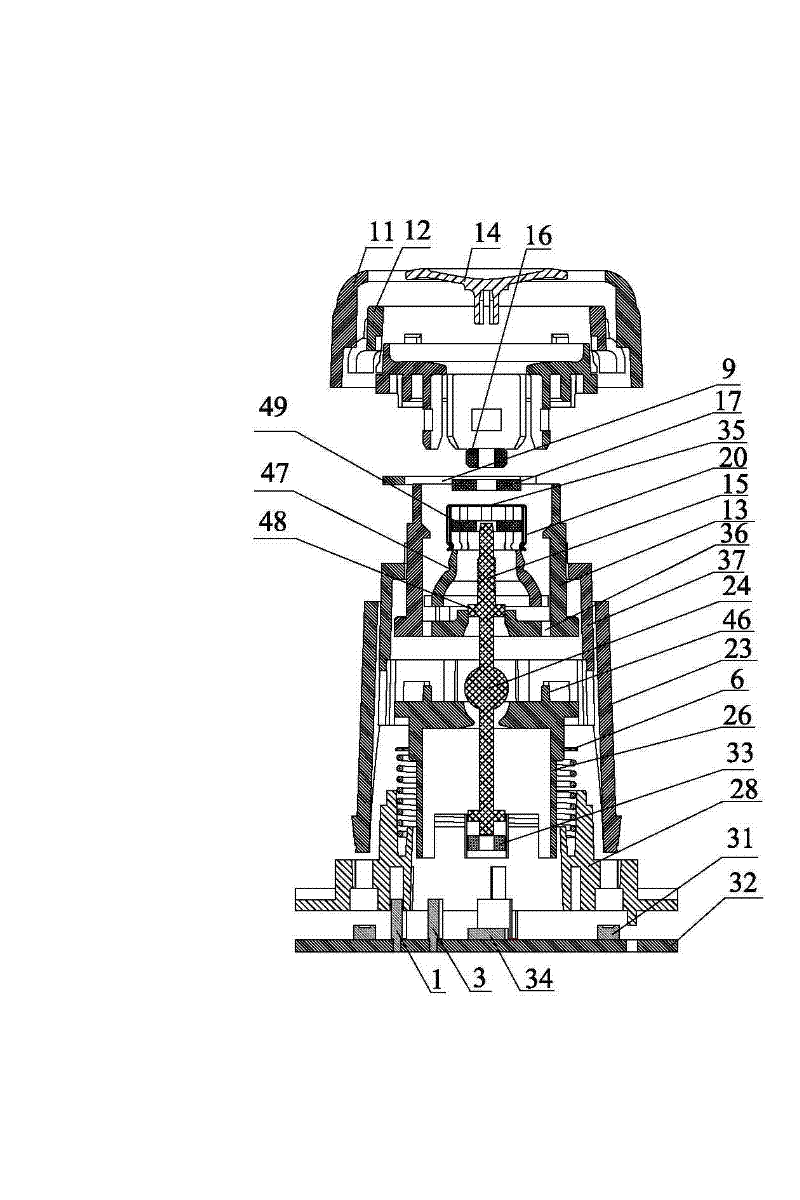

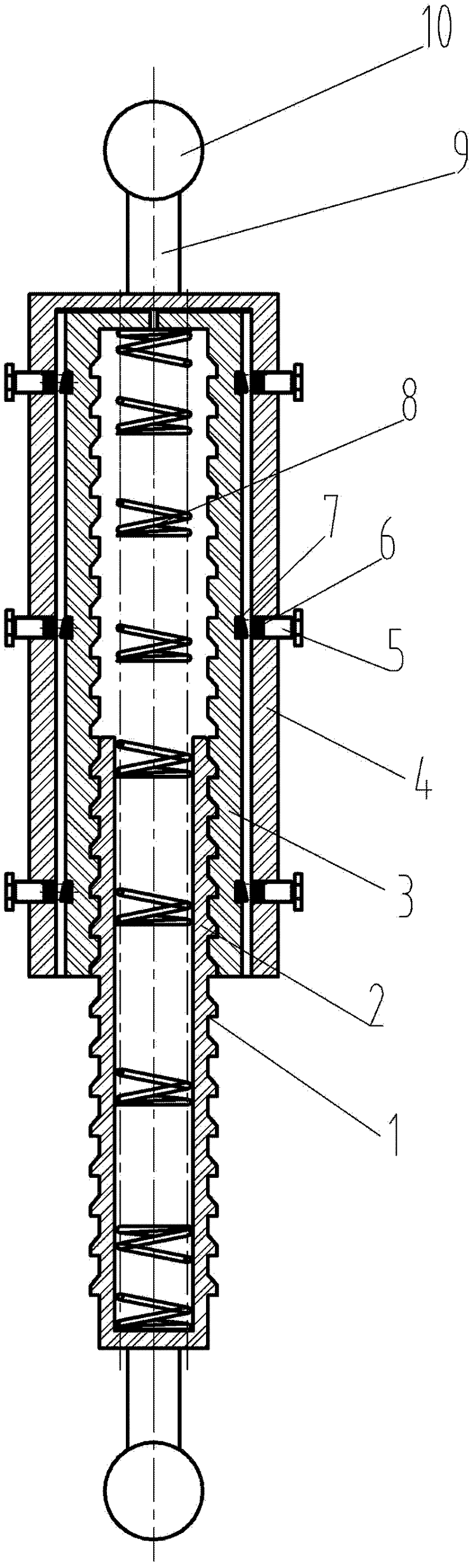

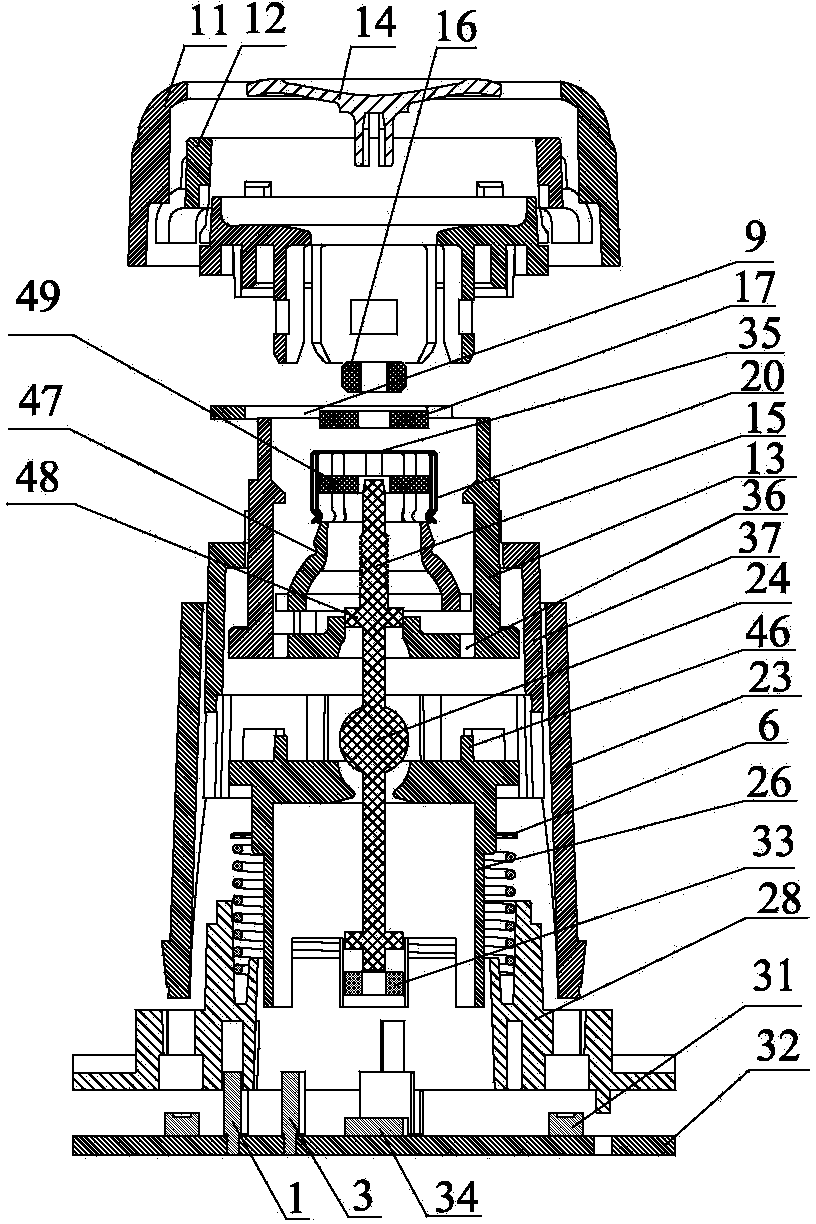

Pneumatic automatic return device

ActiveCN113047719AImprove experienceGood creativityBuilding braking devicesEngineeringHigh pressure gas

The invention provides a pneumatic automatic return device. The problem that in the prior art, the return speeds of doors with different weights are different is solved. The pneumatic automatic return device comprises a shell, an upper convex shaft, a lower convex shaft, a piston, a sealed air chamber and an adjusting device, wherein the shell is of a hollow structure, the upper convex shaft is arranged in a gear sleeve, one end of the upper convex shaft extends outwards from the end part of the gear sleeve, the upper convex shaft only rotates in the gear sleeve, the lower convex shaft is also arranged in the gear sleeve and does reciprocating rectilinear motion only in the length direction of the gear sleeve, the upper convex shaft is in contact with the lower convex shaft, acting force always exists between the upper convex shaft and the lower convex shaft, the rotating motion of the upper convex shaft is synchronous with the rectilinear motion of the lower convex shaft, one end of the piston is used for continuously propping the lower convex shaft against the upper convex shaft, the sealed air chamber is a sealed cavity formed by an upper sealing piece and a lower sealing piece in the shell, high-pressure air is arranged in the sealed cavity, the other end of the piston extends into the sealed cavity, and the adjusting device is used for adjusting the volume of the sealing cavity.

Owner:WEIFANG ZHENGXIN PNEUMATIC TECH CO LTD

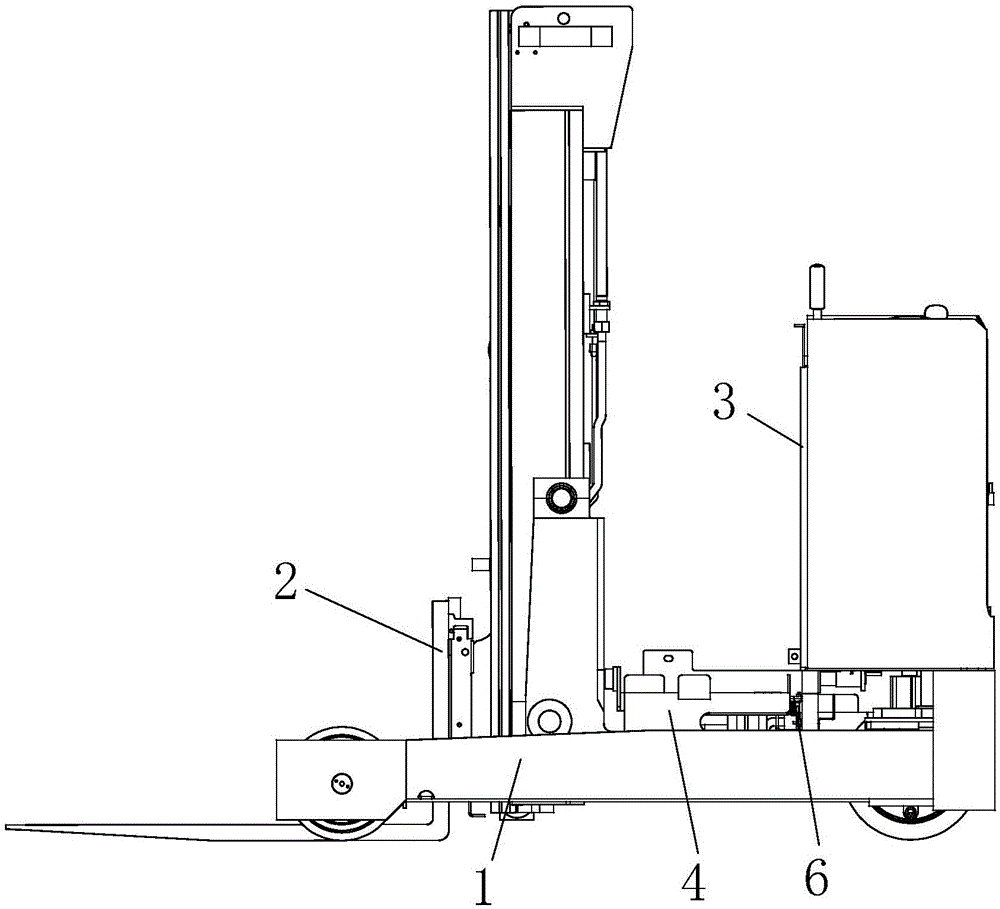

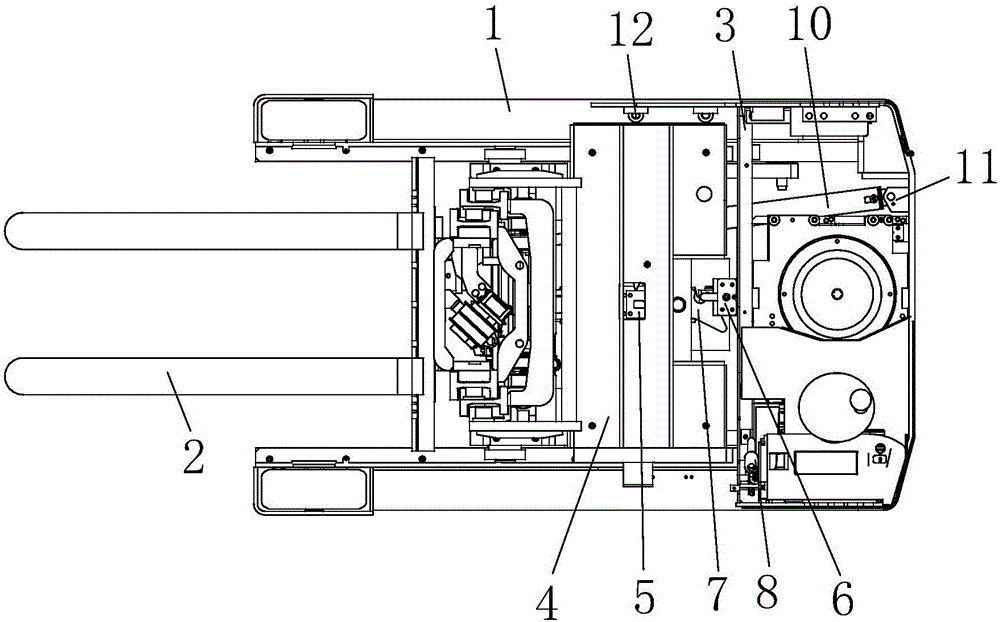

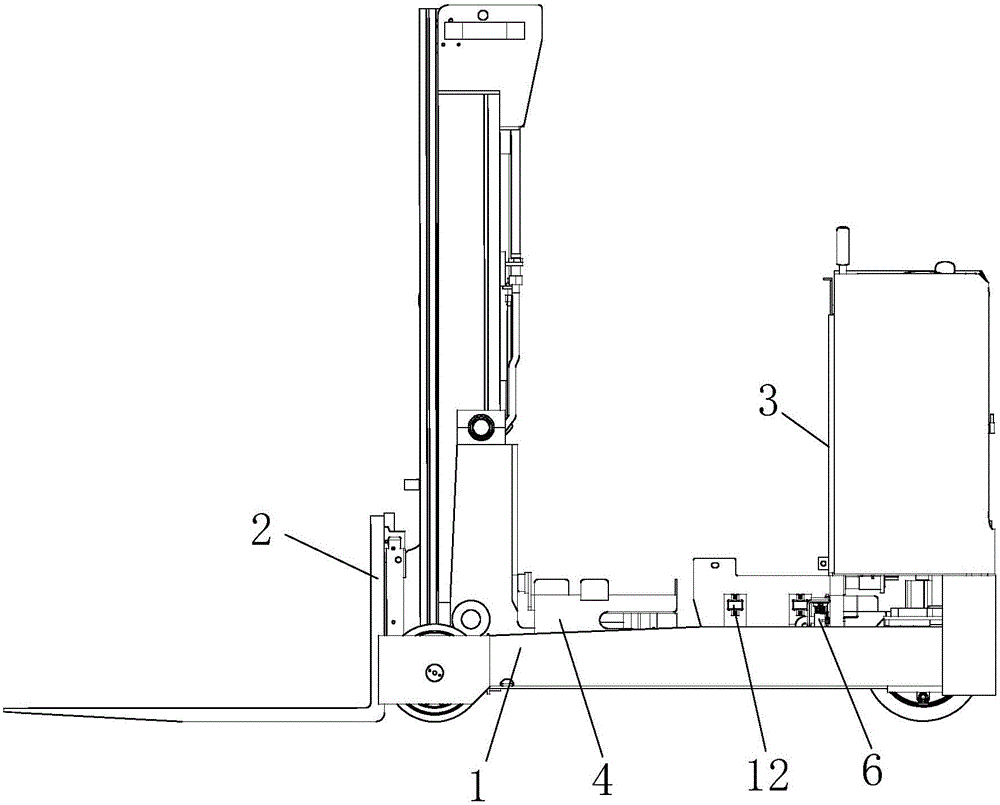

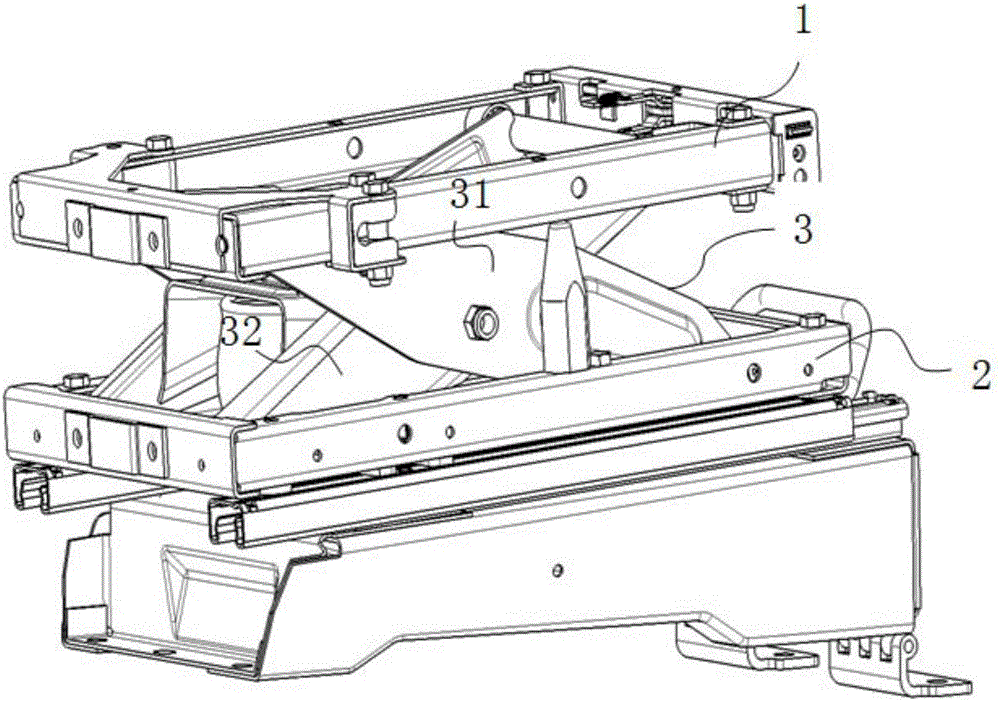

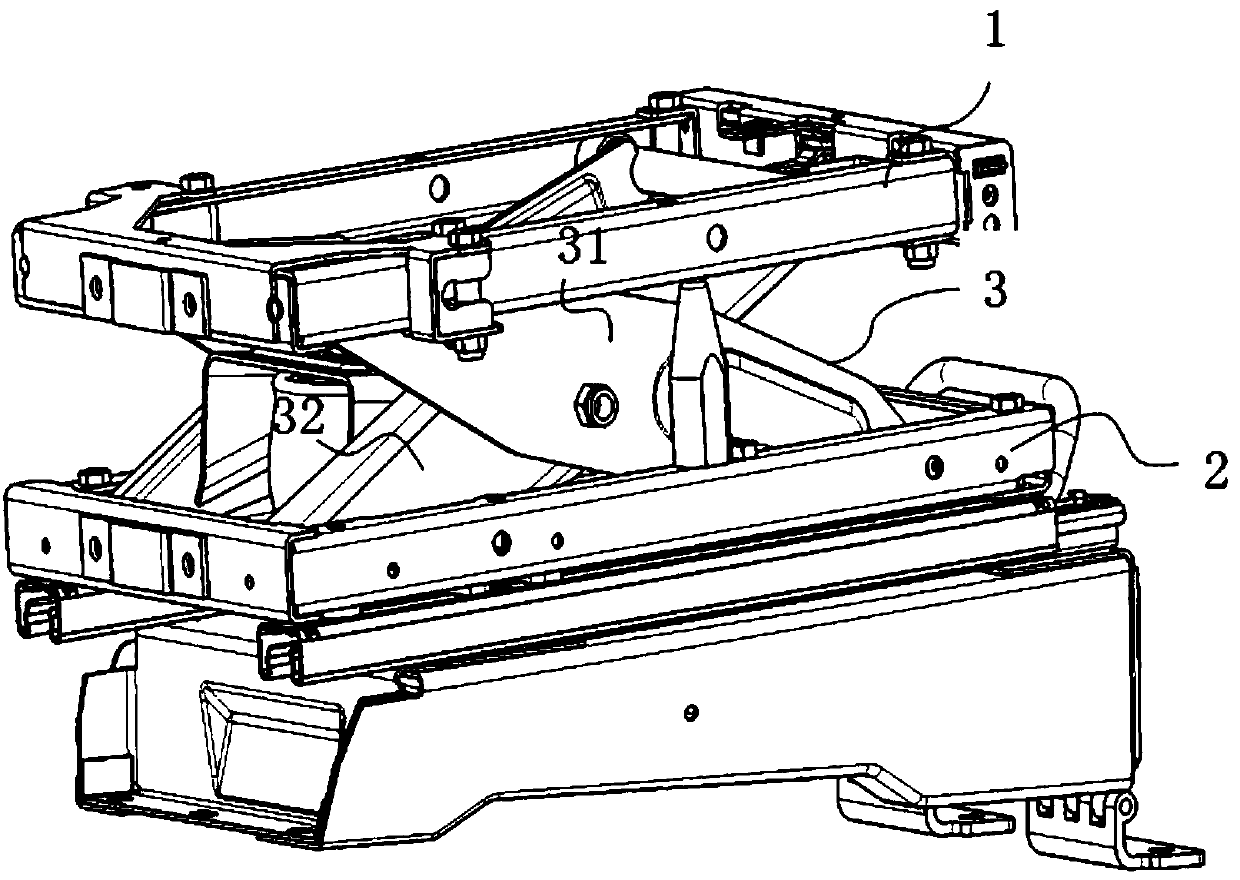

Forward-moving type forklift storage battery unhooking device

ActiveCN105967108ARealize connection fixationRealize moving forwardLifting devicesVehicle frameEngineering

The invention relates to a forward-moving type forklift storage battery unhooking device which comprises a vehicle frame, a gantry, a vehicle frame middle plate and a storage battery supporting frame. The lower end of the gantry is provided with a lock block, the vehicle frame middle plate is provided with a lock mechanism, the lower end of the storage battery supporting frame is provided with a lock hook, the lock hook comprises a first hook head matched with the lock block and a second hook head matched with the lock mechanism, when the first hook head and the lock block are locked in a matched mode, the second hook head and the lock mechanism are in the unlocking state, and under the state, the storage battery supporting frame and the gantry are fixed relative to each other; when the second hook head and the lock mechanism are locked in a matched mode, the first hook head and the lock block are in the unlocking state, and under the state, the storage battery supporting frame and the vehicle frame are fixed relative to each other. It is known through the forward-moving type forklift storage battery unhooking device that connection and fixation between the storage battery supporting frame and the gantry and between the storage battery supporting frame and the vehicle frame are achieved through different matches between the lock hook and the lock block and between the lock hook and the lock mechanism, therefore forward movement and return of a storage battery are achieved, and maintenance, adjustment, assembling and disassembling of the storage battery become simple and convenient.

Owner:ANHUI HELI CO LTD

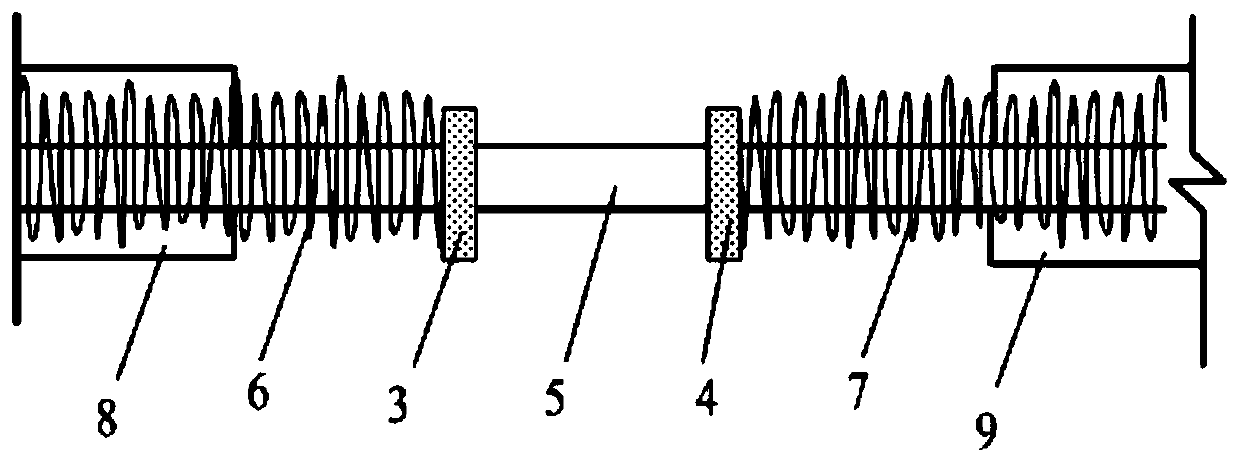

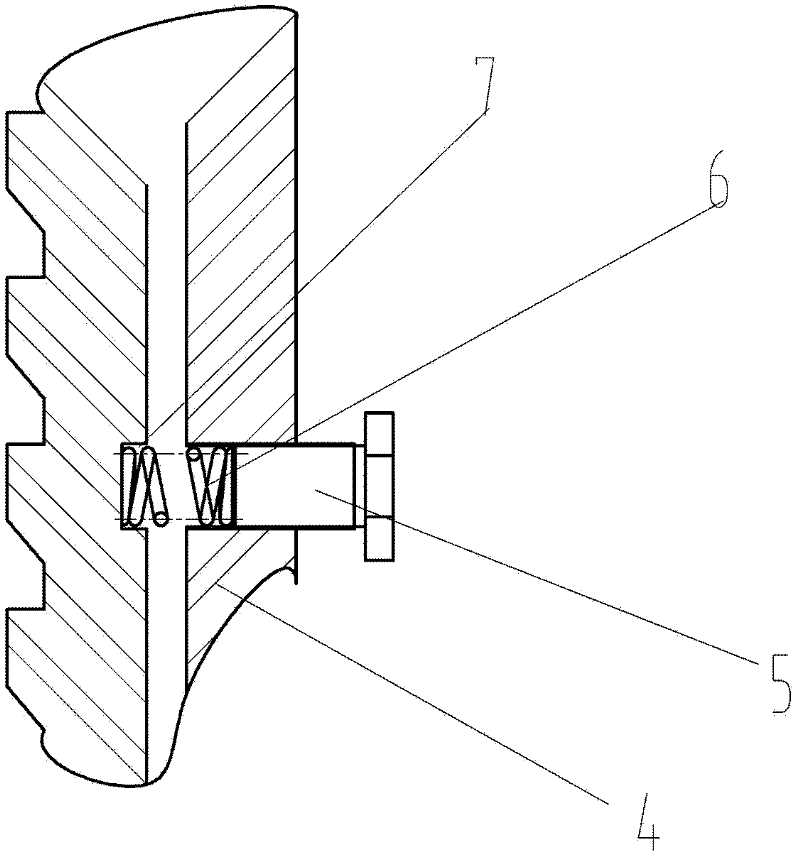

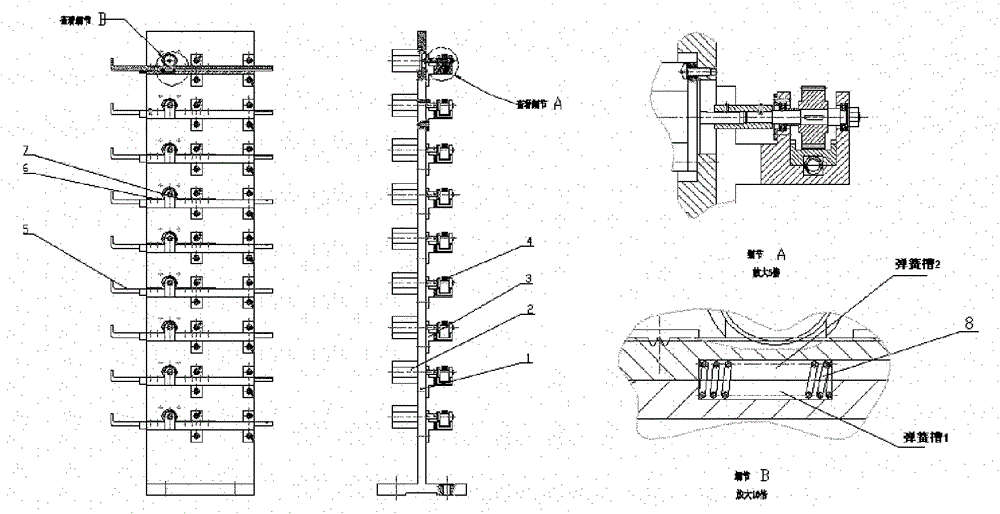

Energy consumption connecting structure for connecting frame and swing wall

PendingCN109779064ARealize returnControl shock damageWallsProtective buildings/sheltersEarthquake resistanceResidual deformation

The invention discloses an energy consumption connecting structure for connecting a frame and a swing wall and belongs to the technical field of civil engineering earthquake resistance and shock absorption. The energy consumption connecting structure for connecting the frame and the swing wall comprises a screw rod, a nut I and a nut II are symmetrically arranged in the middle of the screw rod. The end, close to the first nut, of the screw rod is sleeved by a first spring, the end, close to the second nut, of the screw rod is sleeved by a second spring, one end of the first spring makes contact with the first nut, the other end of the first spring is located in a first sleeve, one end of the second spring makes contact with the second nut, and the other end of the second spring is locatedin a second sleeve. The energy consumption connecting structure for connecting the frame and the swing wall is simple in structure, convenient to construct and operate, easy to replace and low in cost, the structure can be reset, part of earthquake energy in an input structure can be dissipated, the bearing capacity of the frame-swing wall structure can be improved, and the structure shock loss and residual deformation can be effectively controlled.

Owner:LIAONING TECHNICAL UNIVERSITY

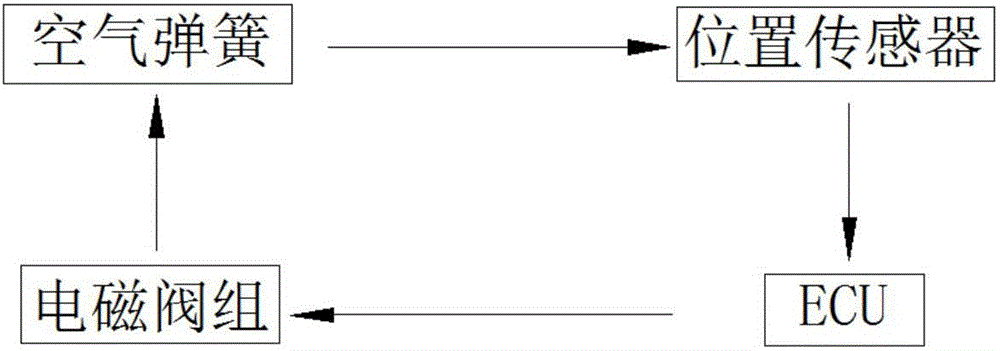

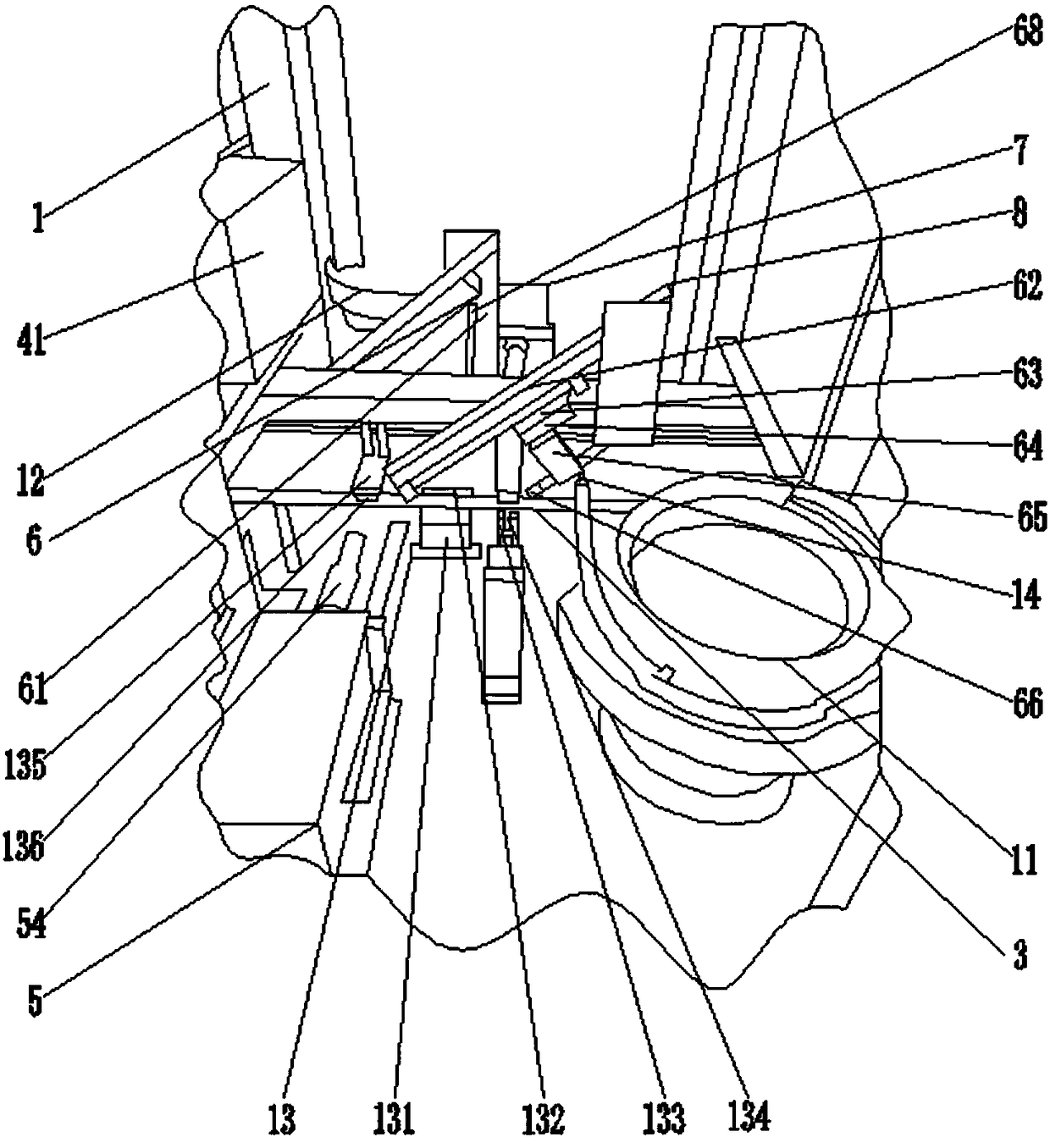

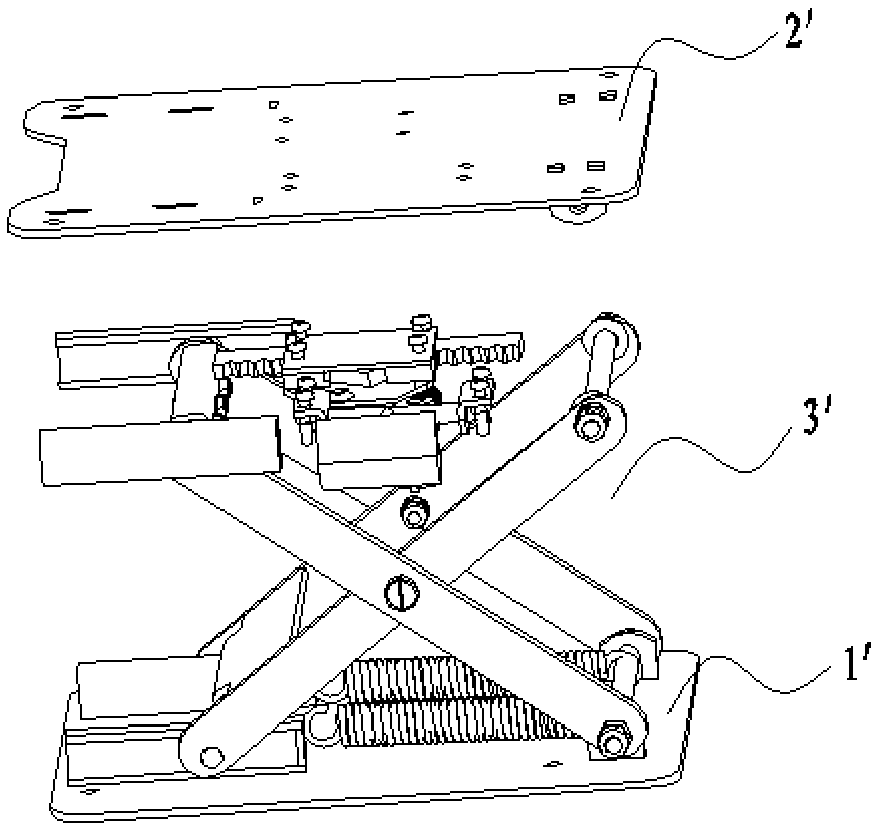

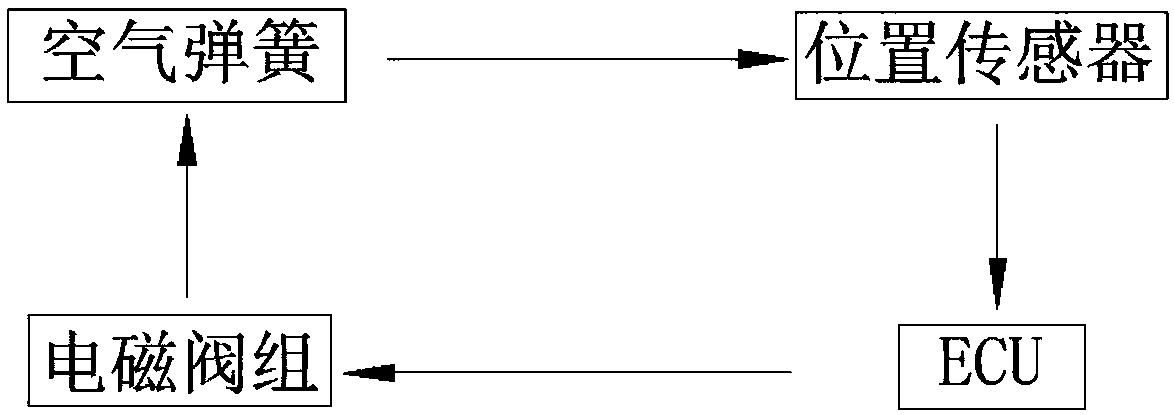

Controlling system for air-suspending seat and air-suspending seat

ActiveCN106218453AFunction increaseHigh degree of automationMovable seatsSeat suspension devicesControl signalAir spring

The invention relates to the controlling system field, in particular to a controlling system for an air-suspending seat and the air-suspending seat. The controlling system for the air-suspending seat comprises a position sensor, an electronic controlling unit (ECU), an electromagnetic valve set and a man-machine interface; the position sensor is connected with the ECU, used for detecting changing quantity of positions, obtains position signals according to the changing quantity of the positions, and transmits the position signals to the ECU; the ECU is used for receiving the position signals transmitted by the position sensor and / or controlling signals transmitted by the man-machine interface, obtains corresponding controlling orders according to the position signals and / or the controlling signals, and transmits the controlling orders to the electromagnetic valve set; and the electromagnetic valve set is connected with the ECU and an air spring, receives the controlling orders transmitted by the ECU, and control the air spring according the controlling orders to enable the air spring to inflate or deflate. The air-suspending seat is controlled to conduct lifting, fast landing, returning, remembering and suspending according to the different controlling orders. The controlling system for the air-suspending seat and the air-suspending seat have the beneficial effects that functions are various, and automation degree is higher.

Owner:西安光华荣昌汽车部件有限公司

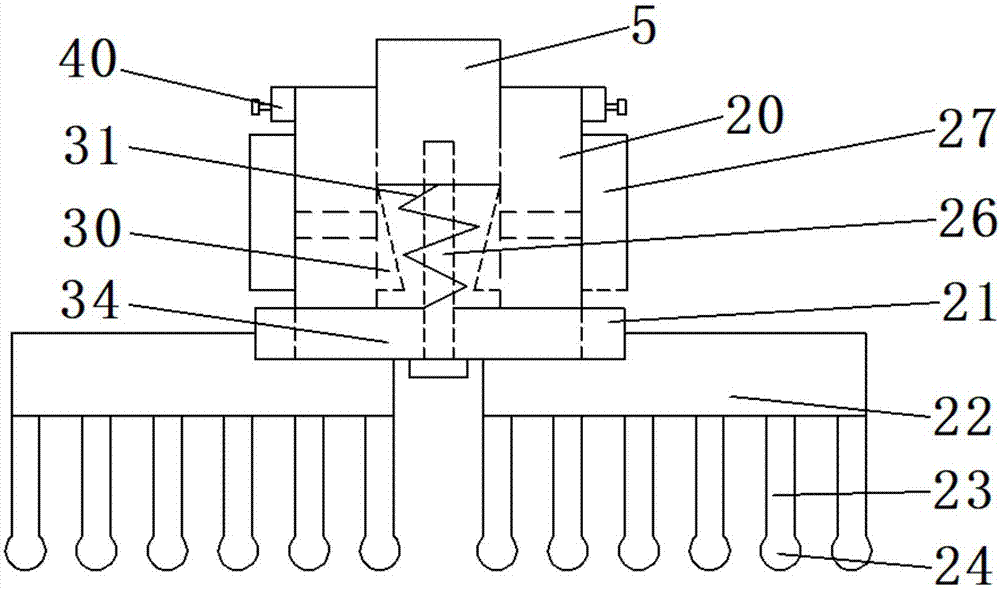

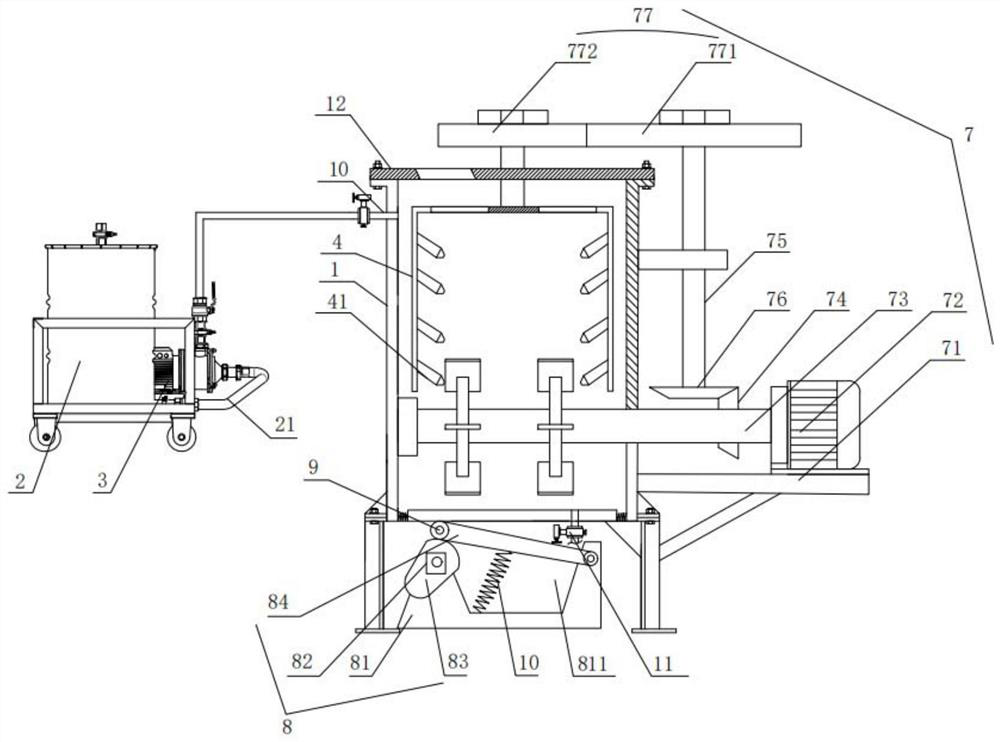

Semiconductor material cleaning device

InactiveCN112435918AImprove stabilityImprove securitySemiconductor/solid-state device manufacturingCleaning using toolsSemiconductor materialsLiquid storage tank

The invention discloses a semiconductor material cleaning device, which comprises: a cleaning box capable of hierarchically cleaning a semiconductor material in the height direction, a vibrating plateis arranged at the bottom of the cleaning box, and the vibrating plate is elastically arranged at the bottom of the cleaning box; a liquid storage tank which is used for storing cleaning liquid, wherein the cleaning liquid is pumped into the cleaning tank through a pump body, so that the semiconductor material is flushed by layers in a circumferential array manner; a circulating material stirringbarrel which is in a thin-plate cylindrical shape, the top and the bottom of the circulating material stirring barrel are open, wherein a plurality of material stirring rods are arranged on the circumferential inner side wall of the circulating material stirring barrel; cleaning pipeline assemblies which are distributed on the inner side wall of the cleaning box in an annular array mode; a cleaning roller assembly which is located at the bottom of the cleaning box and conducts rolling cleaning on the semiconductor material; a driving part which can simultaneously control the circulating material stirring barrel body and the cleaning roller assembly to synchronously rotate; and a vibration assembly which generates periodic vibration on the vibration plate, wherein overturning and positionreplacement of the semiconductor material are realized by matching with a material stirring rod, and therefore, the semiconductor material can be flushed more cleanly and cleaned more thoroughly, andthe cleaning efficiency and effect are improved.

Owner:江西舜源电子科技有限公司

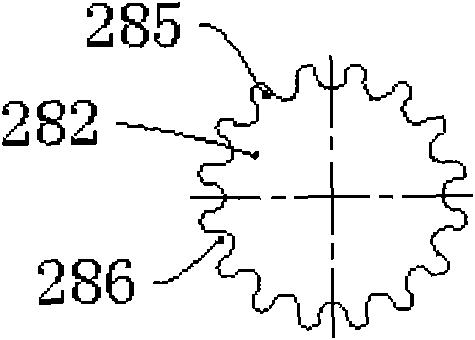

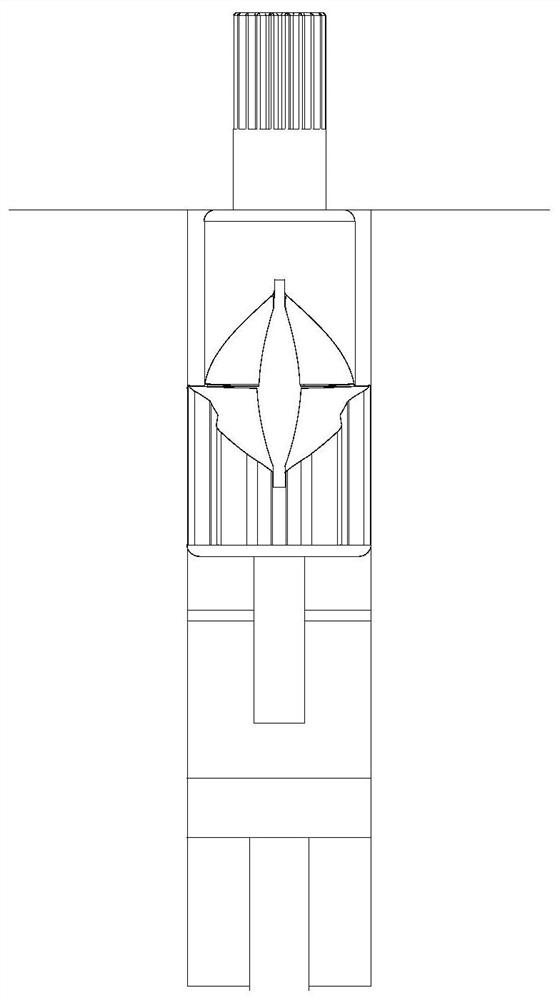

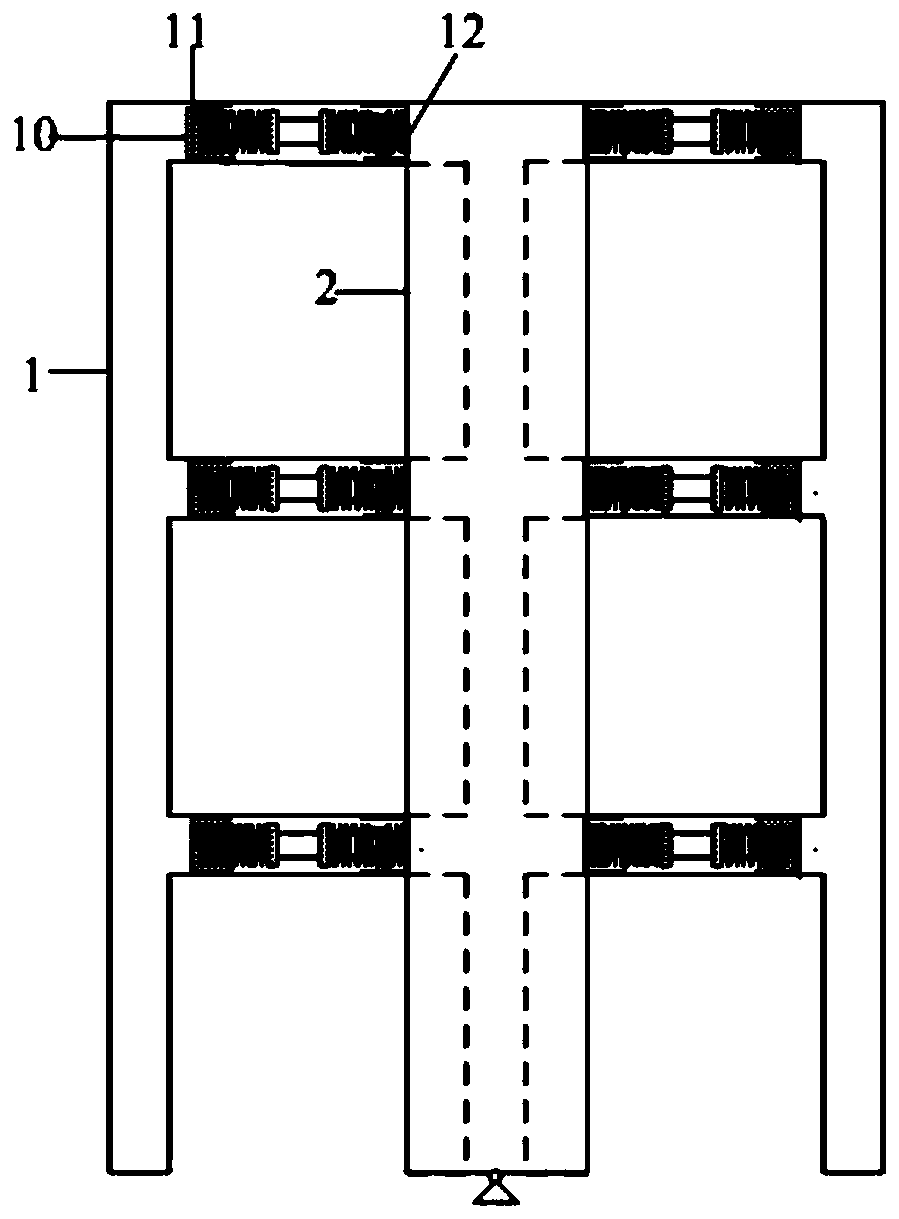

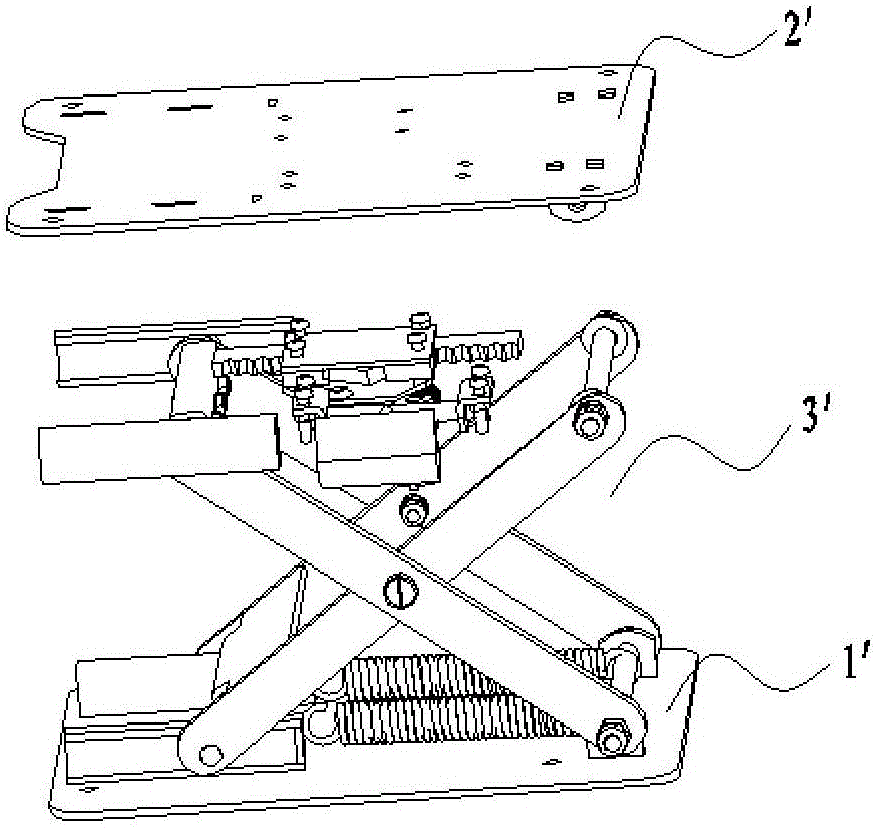

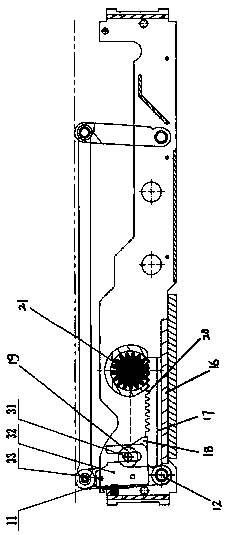

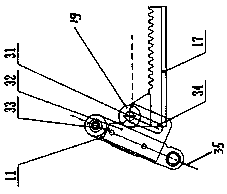

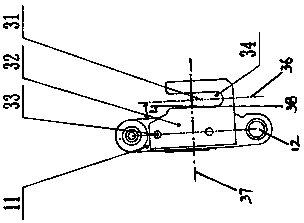

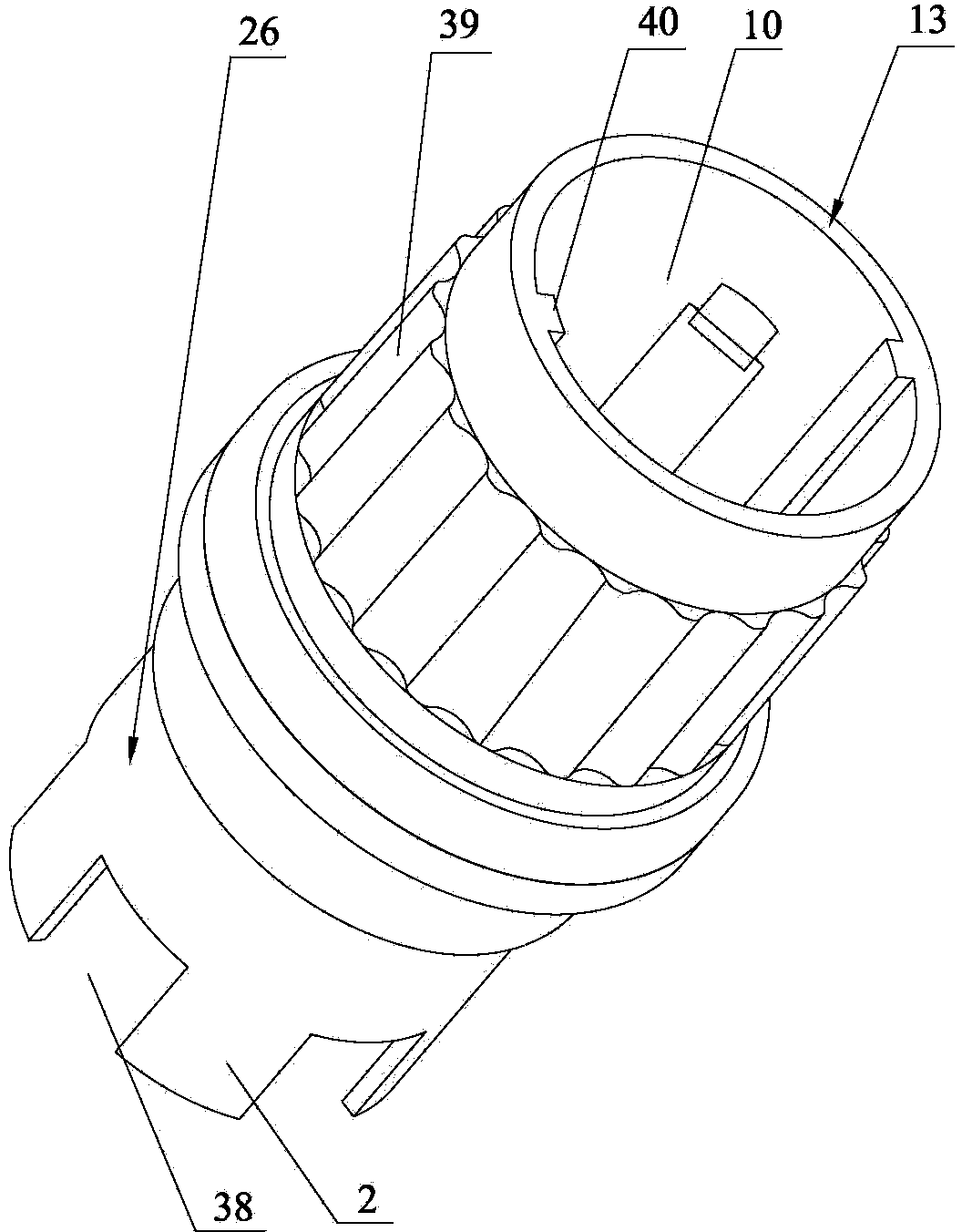

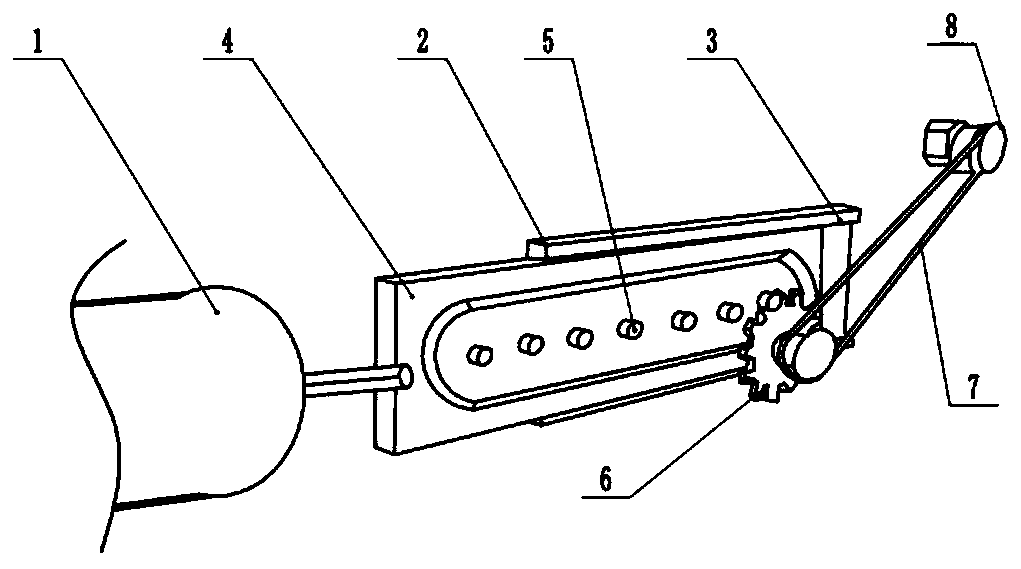

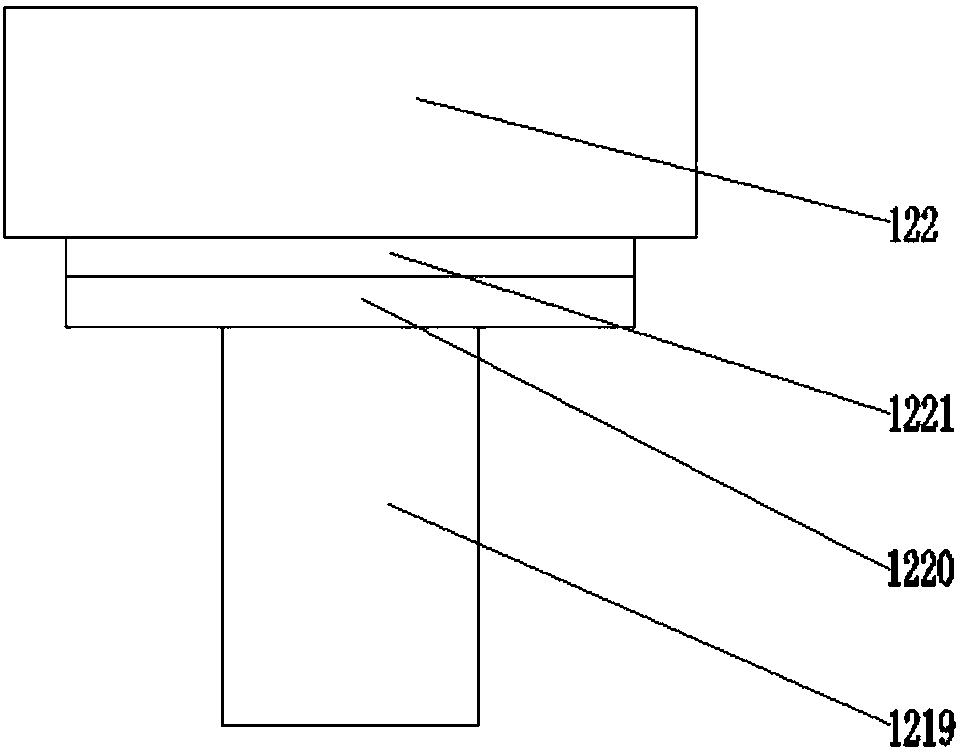

Follow-up hooks on tray lifting mechanism of shuttling car

ActiveCN110615378APrevent falling backRealize returnLifting framesStorage devicesAcute angleEngineering

The invention discloses follow-up hooks on a tray lifting mechanism of a shuttling car. The technical problem of achieving automatic returning of two swinging rods in a four-connecting-rod swinging rod mechanism is solved. A four-connecting-rod mechanism shaped like a parallelogram serves as a lifting mechanism and replaces a traditional eccentric wheel lifting mechanism, a frame of the shuttlingcar serves as the bottom edge of the four-connecting-rod mechanism, the top edge of the four-connecting-rod mechanism serves as an executing mechanism of a top connecting tray, parallel left and rightswinging vertical rods are pushed by a gear-rack mechanism, when lifting is conducted, the gear-rack mechanism pushes the two parallel swinging vertical rods to pass through the perpendicular position which has 90 degrees with a car plate of the shuttling car and then be limited by fixed limiting blocks, the follow-up hooks are arranged between swinging rods and pushing and lifting sliding blocks, the swinging rods and the pushing and lifting sliding blocks are connected in a hooked manner through the follow-up hooks when the sliding blocks push the swinging rods leftwards to lift the tray, the pushing and lifting sliding blocks pull the swinging rods to the acute-angle position with the frame of the shuttling car from the over position through the follow-up hooks, and returning of the swinging rods is achieved.

Owner:SHANXI ORIENTAL MATERIAL HANDLING

Repeatedly usable self-locking energy-absorbing automobile bumper

InactiveCN102416918AEffective absorption of collision energyNo reboundBumpersUniversal jointEngineering

The invention discloses a repeatedly usable self-locking energy-absorbing automobile bumper, which comprises two parallel bumpers and a plurality of self-locking energy-absorbing spring components. The two ends of each self-locking energy-absorbing spring component are fixed between the two parallel bumpers through universal joint connection. In the bumper structure provided by the invention, the motion of the compression springs is limited in a sleeve to prevent the springs from torsion due to stress and from becoming invalid; therefore, when an automobile come into incidental collision, the springs can move in preset tracks to effectively absorb energy in the collision of the automobile.

Owner:郑小军

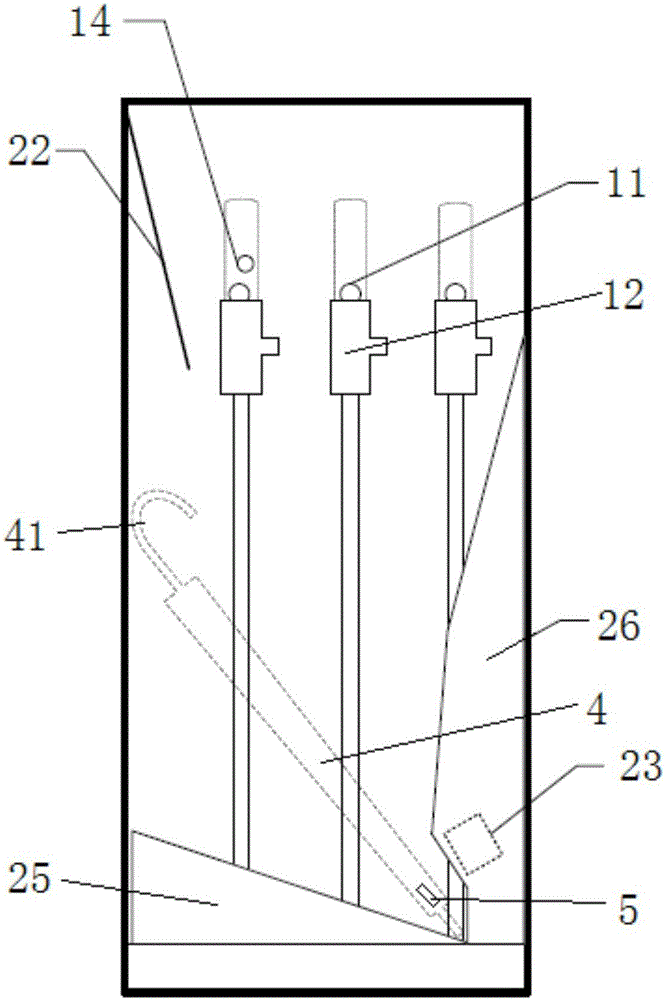

Tumbling type automatic umbrella borrower and control method thereof

InactiveCN106530505AEfficiently provideRealize automatic collectionApparatus for meter-controlled dispensingEngineering

The invention relates to a tumbling type automatic umbrella borrower and a control method thereof; the tumbling type automatic umbrella borrower comprises a cabinet body, a multi-layered umbrella storing module stored with an umbrella is arranged on the cabinet body; a label is arranged on the umbrella; both sides of the umbrella storing module are respectively provided with an umbrella falling channel and an umbrella folding channel; the umbrella folding channel is provided with a lifting mechanism for recycling the umbrella; an umbrella outlet is arranged at the front side of the cabinet body, a label reader for recording the umbrella state is arranged in the umbrella outlet; the label reader can read the label on the umbrella, and store the label information in the database. The tumbling type automatic umbrella borrower has the beneficial effects that (1) umbrella is effectively and timely provided, users can take and use the umbrella reliably and conveniently, and the borrower needs not to manage by a special person, thus the operation is convenient and the using prospect is wide; (2) the umbrella storage amount is big, and the floor space is saved; (3) the product structure is simple and practicable, and simple to maintain; (4) the borrow is automatically operated, and the user has good experience in borrowing and returning the umbrella.

Owner:上海飞翰信息科技有限公司

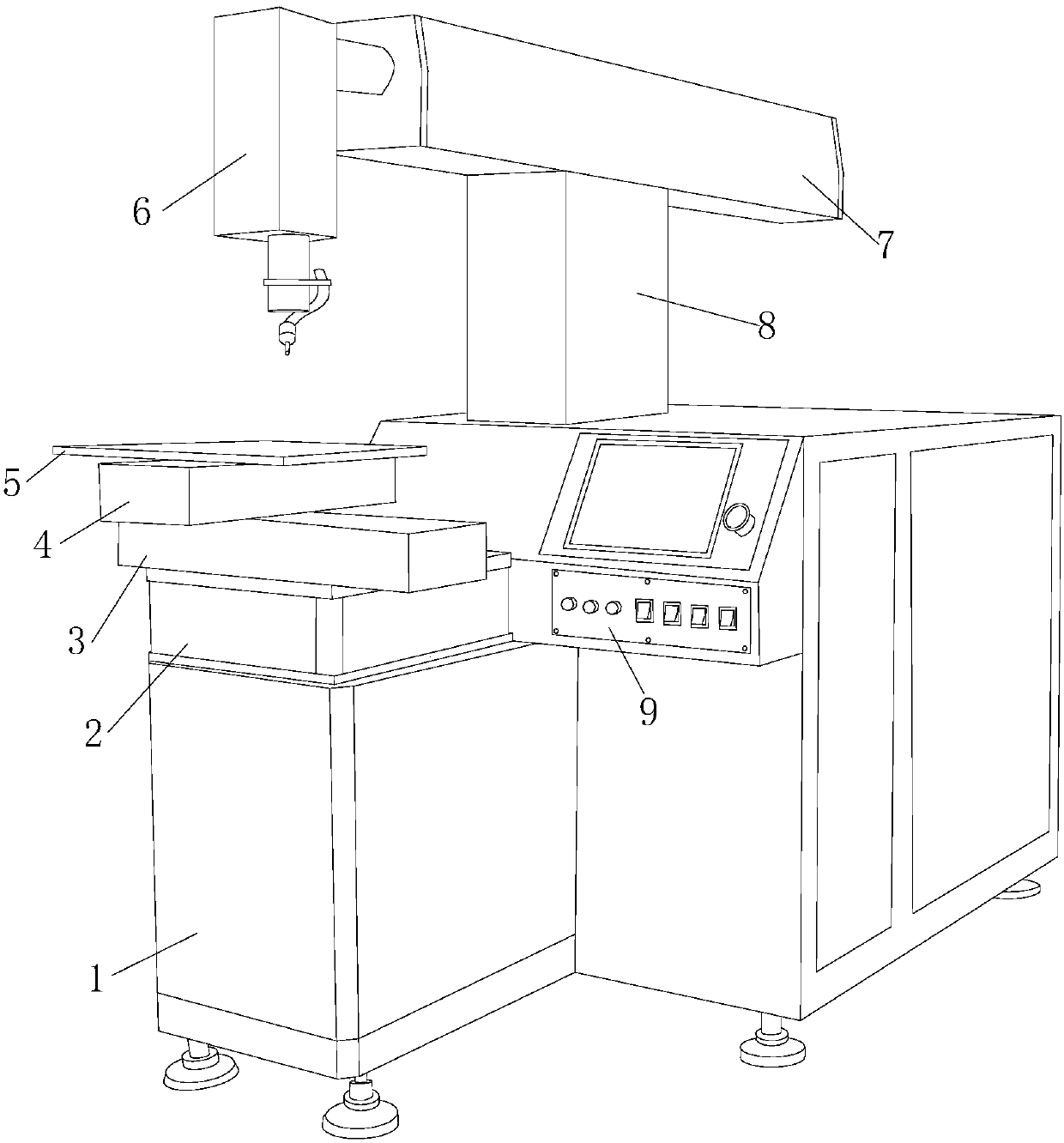

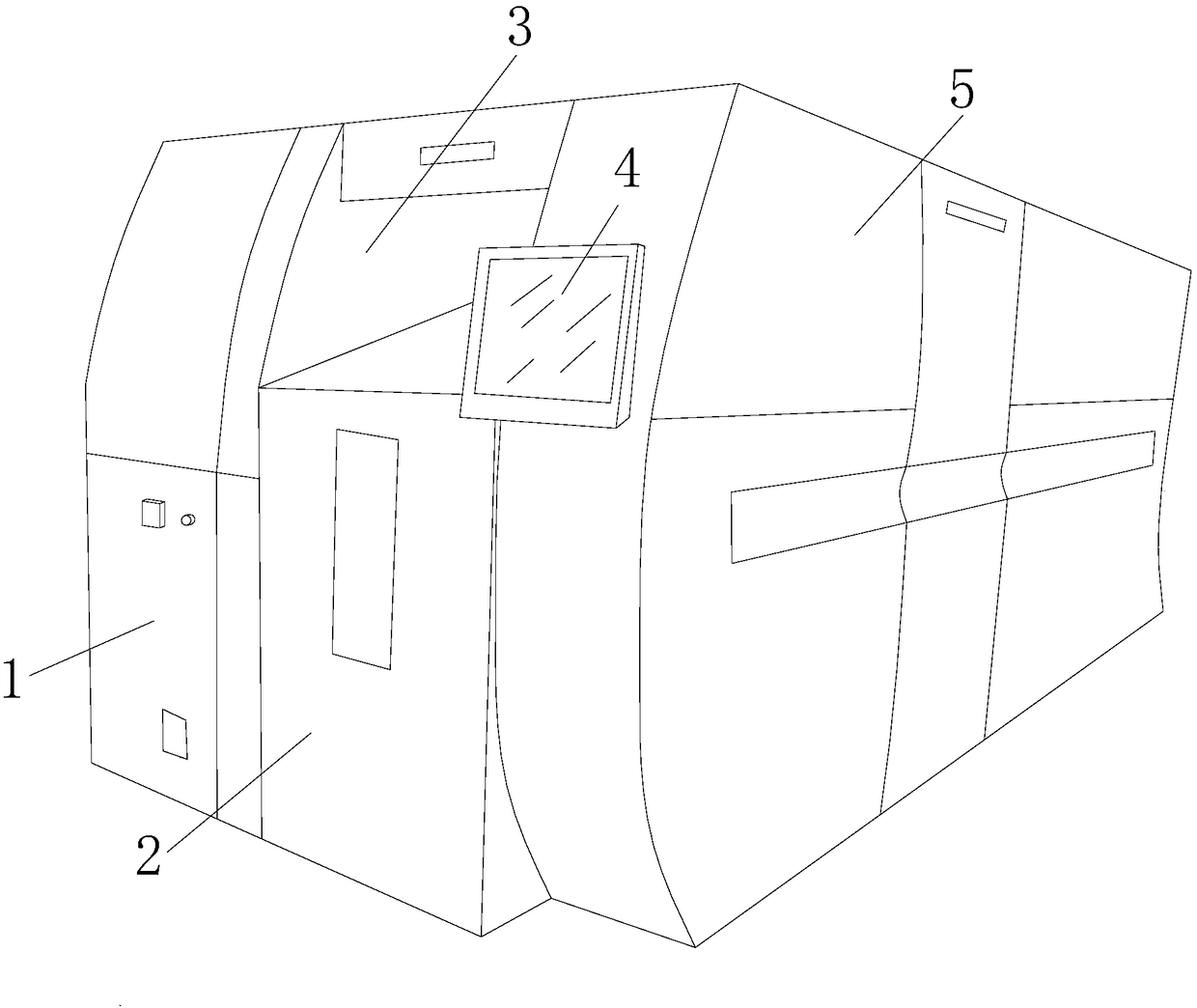

Novel laser welding machine for automobile part machining

InactiveCN108015416AReduce labor costsWelding speed blockLaser beam welding apparatusHead movementsMotor vehicle part

The invention discloses a novel laser welding machine for automobile part machining. The novel laser welding machine structurally comprises a welding machine body, an ascending-descending movement machine, a front-back movement machine, a left-right movement machine, a positioning plate, a welding machine head, a machine head movement rack, a machine head ascending-descending rack, a data consoleand a welding machining mechanism, wherein the ascending-descending movement machine is mounted on the upper portion of the position, located on one side of the data console, of the welding machine body; the ascending-descending movement machine, the front-back movement machine, the left-right movement machine and the positioning plate are arranged from bottom to top; the front-back movement machine is movably connected with the left-right movement machine; and the data console is disposed on the side, close to the ascending-descending movement machine, of the welding machine body. Movements are achieved during equipment running by performing data setting on the shapes of parts, manual auxiliary fixing operation is not needed during the procedures of spot welding, butt welding, stitch welding, seal welding and the like, the labor cost is reduced, welding is fast and accurate, the welding smoothness and attractiveness are further improved, the safety is guaranteed, welding for the different parts is achieved, and welding is convenient.

Owner:叶宝义

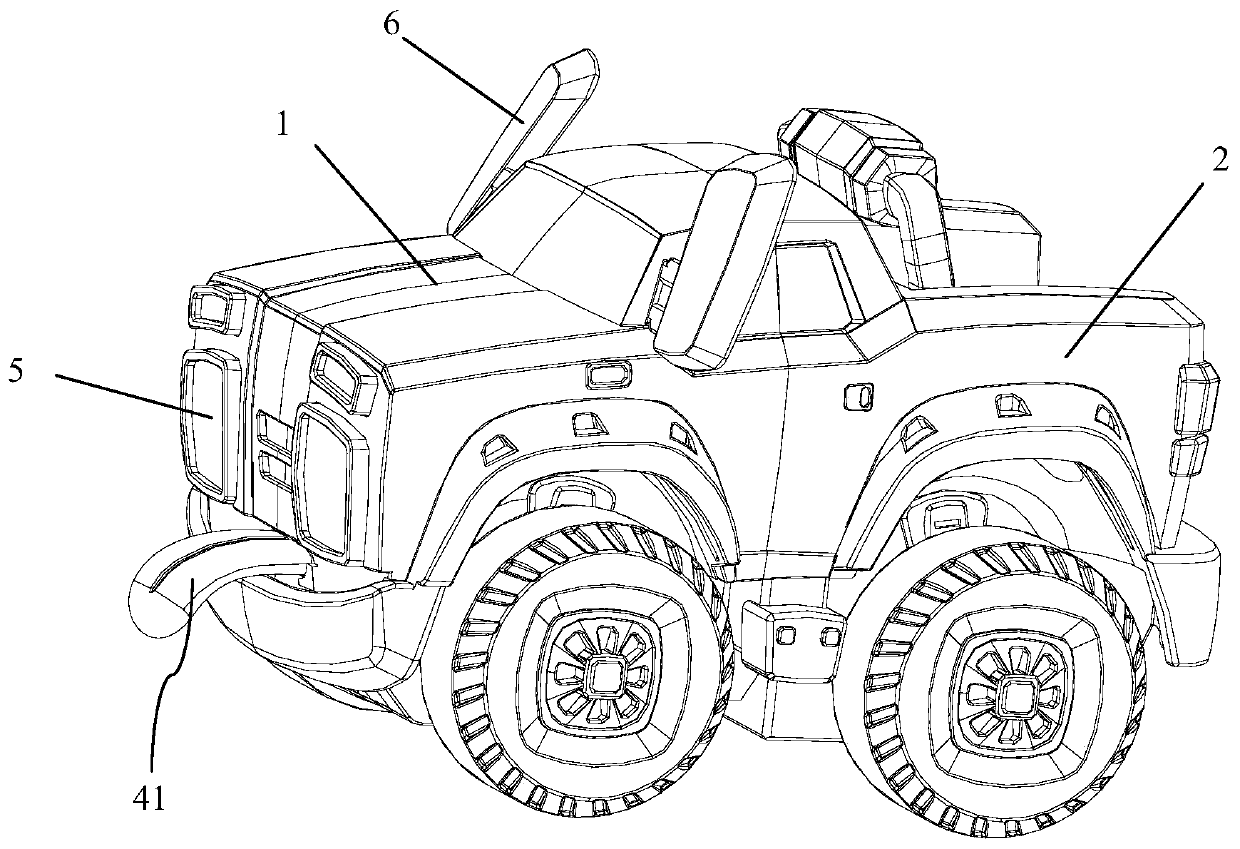

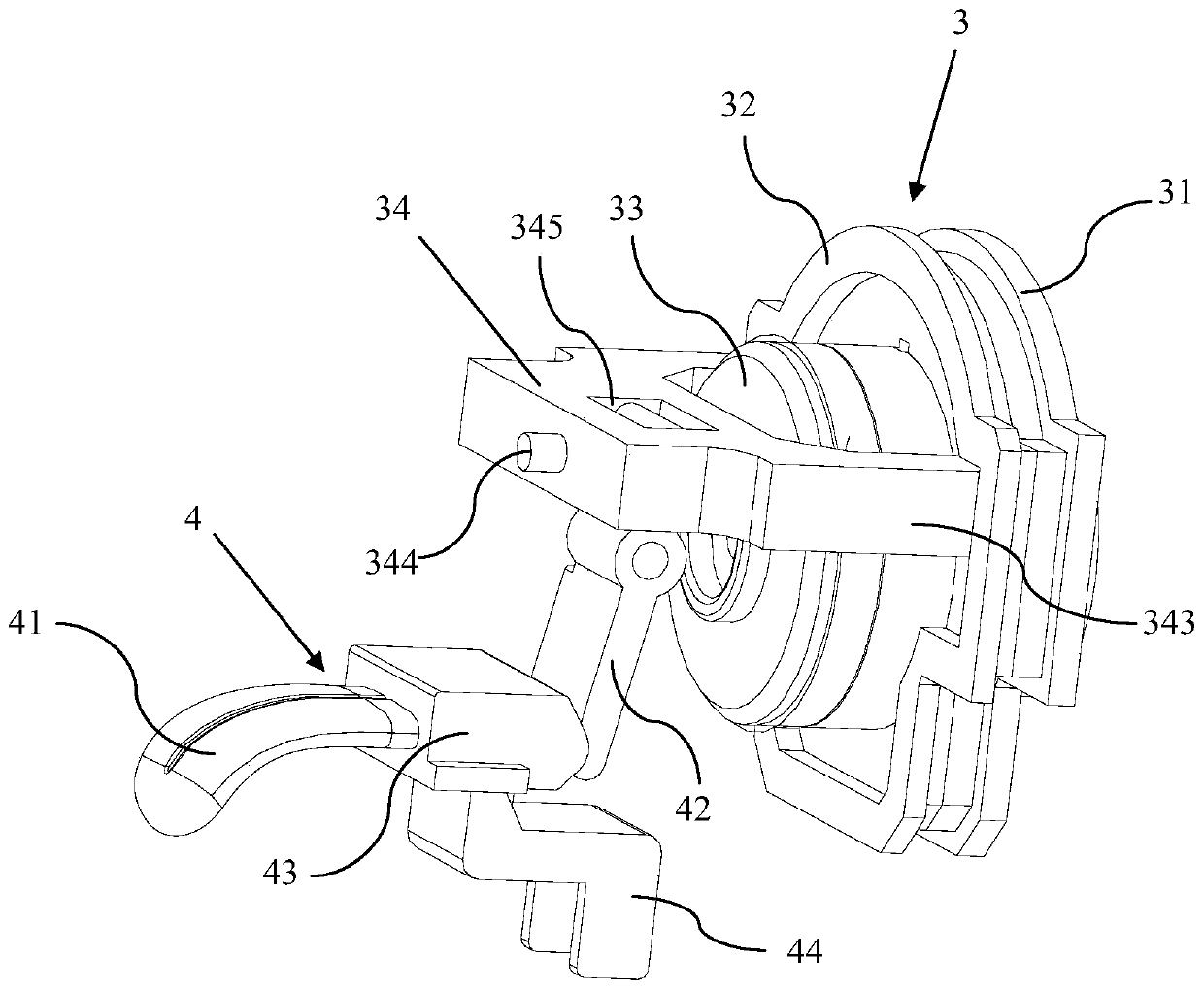

Twisted toy car

The invention discloses a twisted toy car. The twisted toy car comprises a car head and a car body and further comprises a rotating assembly and a triggering assembly, wherein the car head and the carbody can rotate relatively through the rotating assembly; the rotating assembly rotates forwardly when the car head and the car body are twisted relatively; the triggering assembly triggers the rotating assembly to rotate reversely when the triggering assembly is triggered, and thus, the car head and the car body are driven to rotate reversely relatively and return. According to the twisted toy car, the car head and the car body can be twisted relatively through the rotating assembly, and the rotating assembly can be driven to rotate reversely through the triggering assembly to achieve the returning of the car head and the car body. When the triggering assembly is contacted, the car head and the car body relatively reversely rotate and jump up, the playing method is novel, and the playability is relatively high.

Owner:ALPHA GRP CO LTD +1

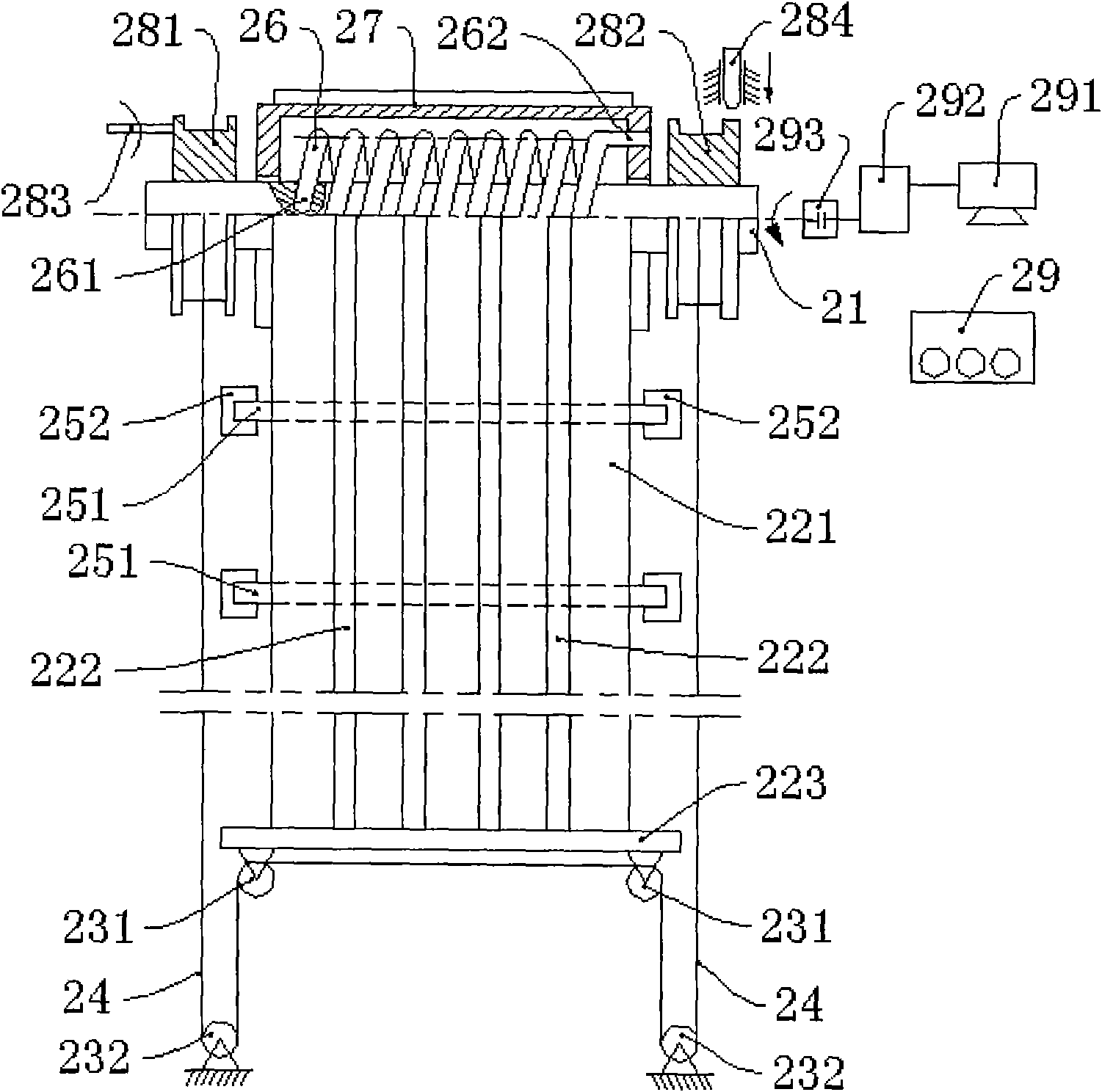

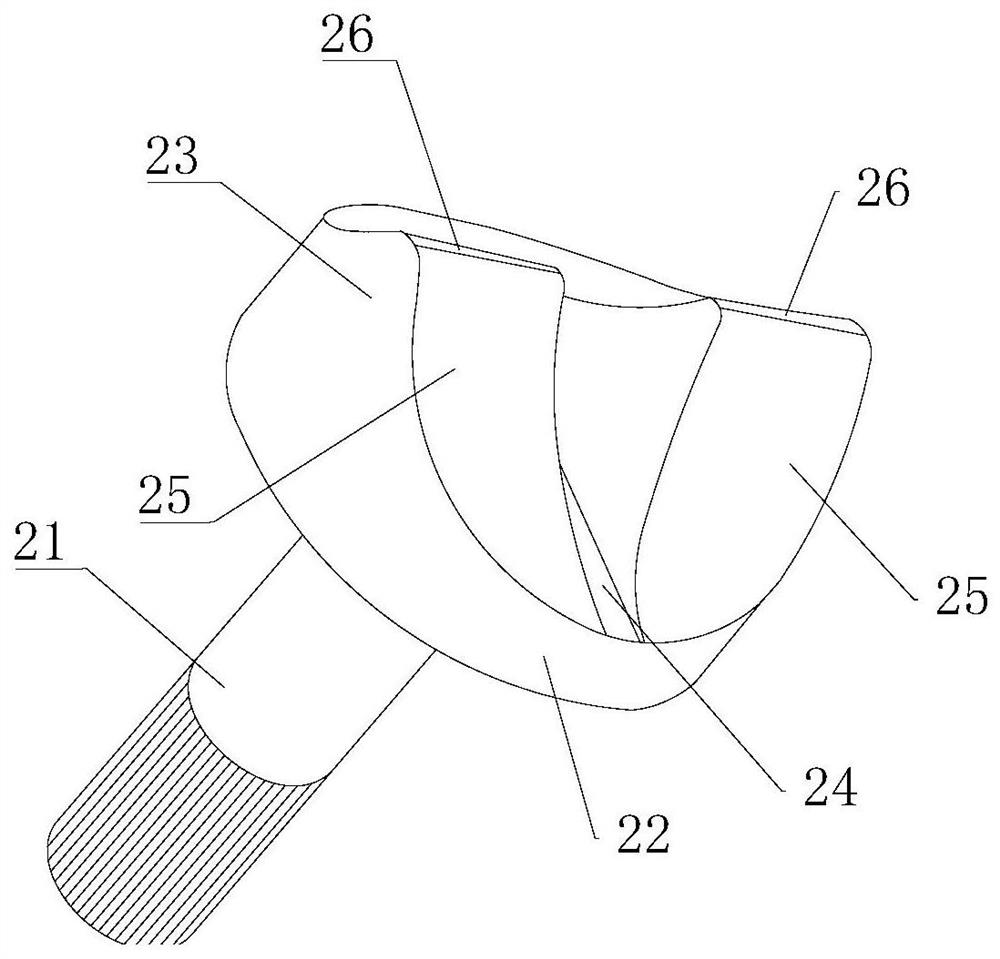

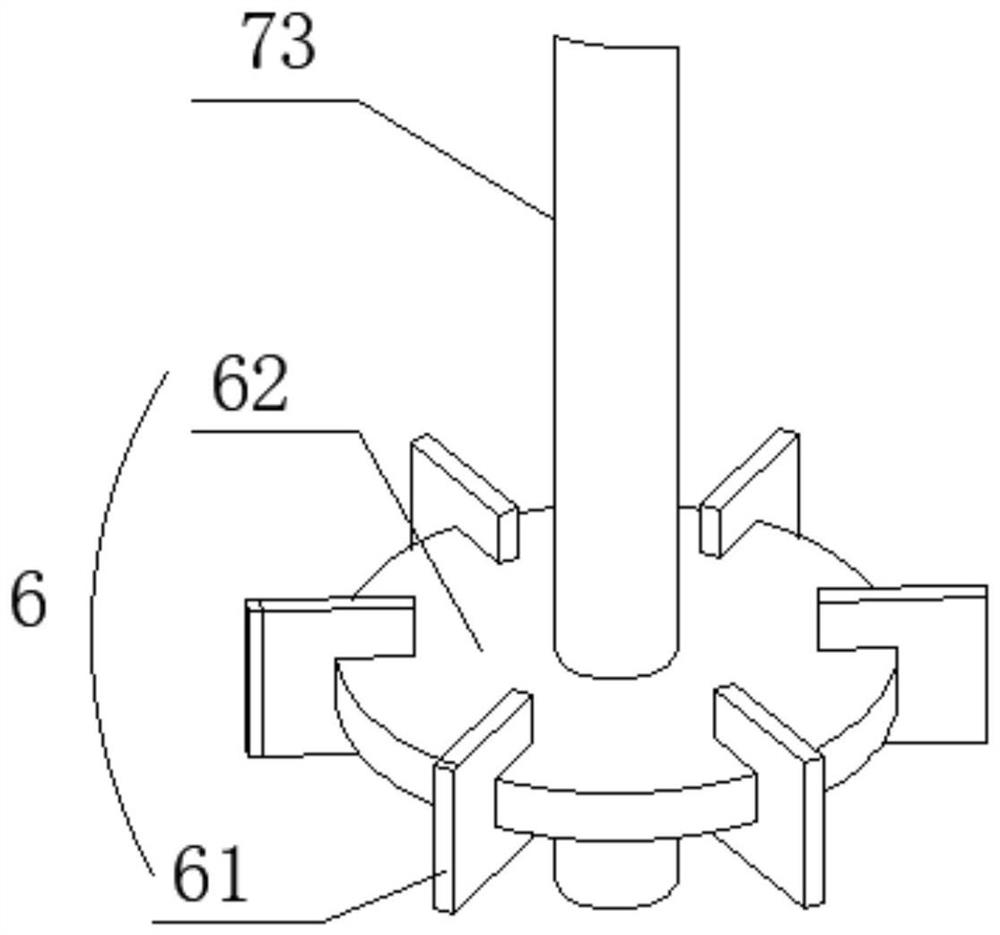

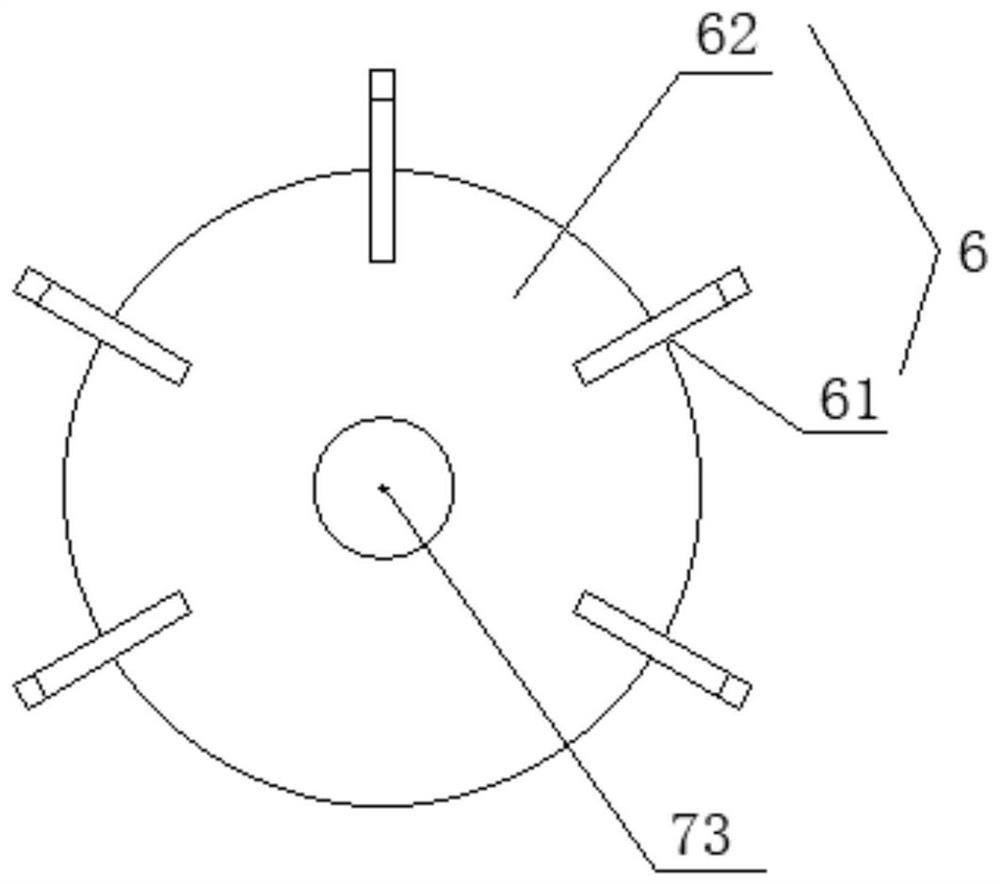

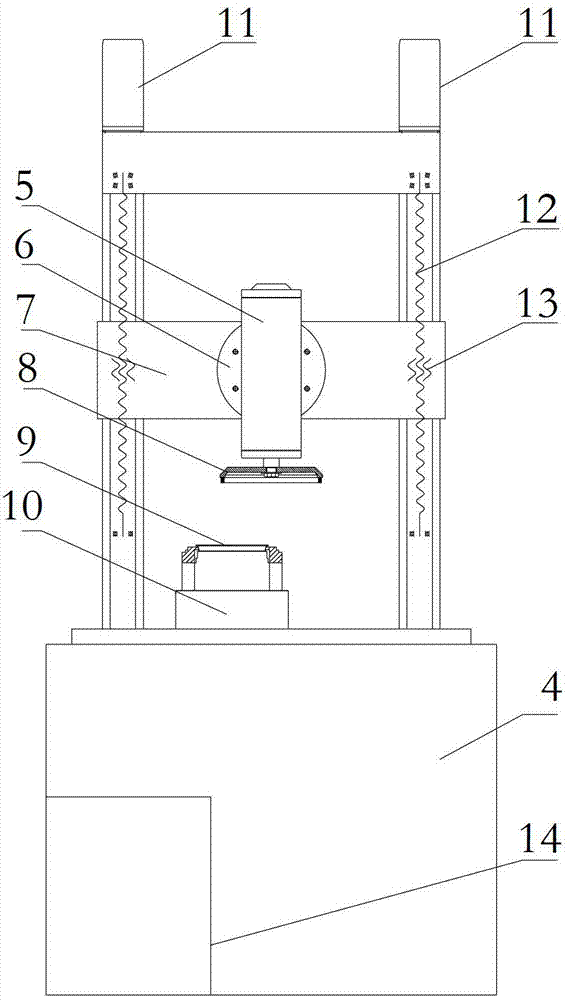

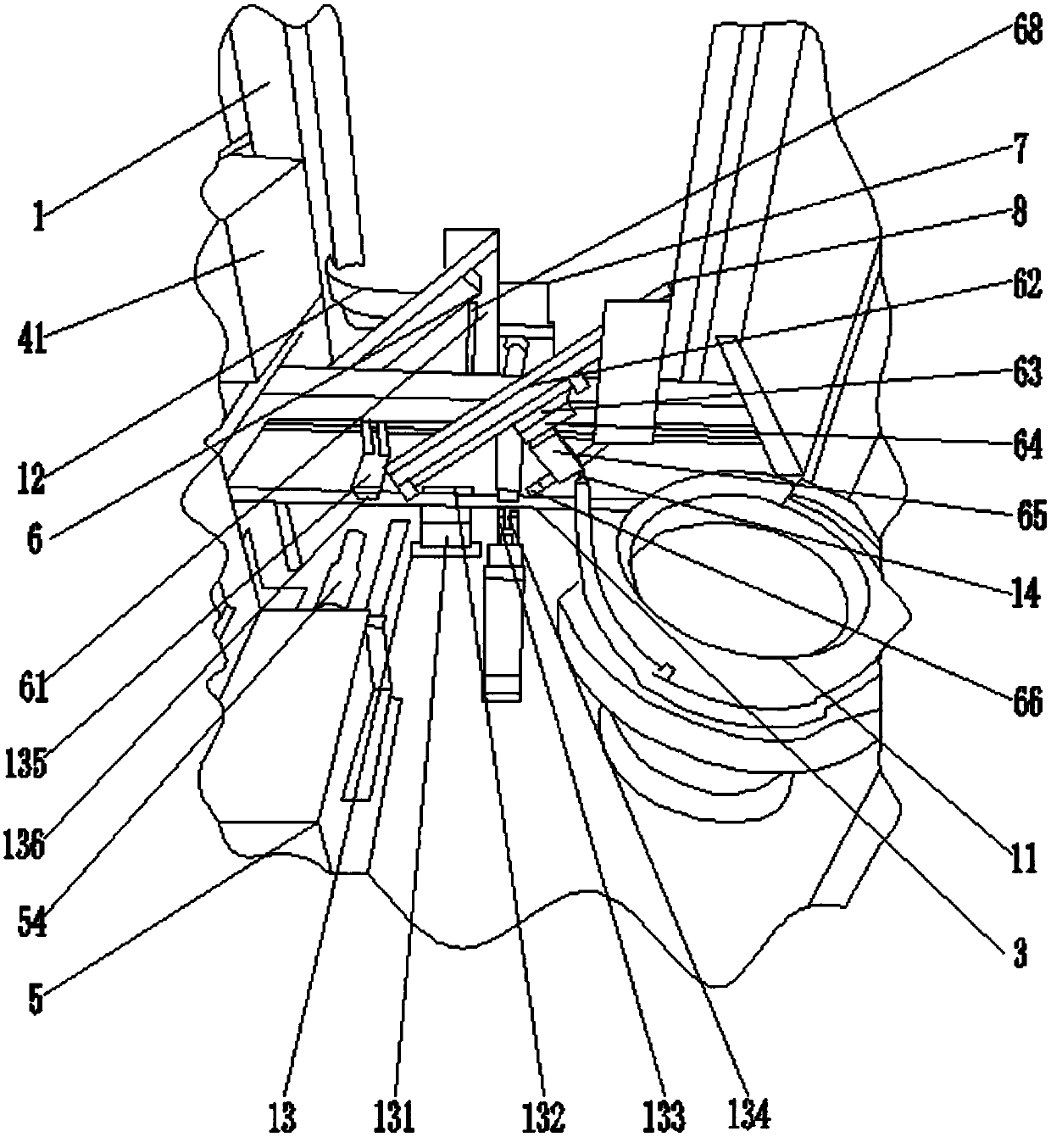

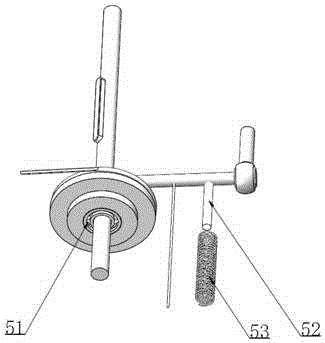

Floating oil seal inner spherical surface automatic grinding and polishing machine

InactiveCN103084951AImprove processing efficiencyRemoval of processing volumeGrinding carriagesGrinding drivesEngineeringProcess efficiency

This invention provides a floating oil seal inner spherical surface automatic grinding and polishing machine which can effectively improve processing efficiency of a floating oil seal inner spherical surface on the premise that processing accuracy of the floating oil seal inner spherical surface is ensured. The automatic grinding and polishing machine comprises a rack, a clamping mechanism, a feeding mechanism and a grinding mechanism, wherein the clamping mechanism and the feeding mechanism are installed on the rack, the feeding mechanism comprises two vertically arranged lead screws which are respectively provided with lead screw nuts matched with the lead screws, a movable plate is fixed between the two lead screw nuts, and the two lead screws are respectively driven by corresponding servo motors; and the grinding mechanism is installed on the movable plate and is controlled by the feeding mechanism to grind work pieces on the clamping mechanism. After quenching for the work pieces is finished, the floating oil seal inner spherical surface automatic grinding and polishing machine can be fixed on the clamping mechanism to grind, producing efficiency is greatly improved, product quality is improved, energy consumption is reduced, and production period of a floating oil seal is shortened.

Owner:YANTAI SHUANGYUAN GENERAL PARTS

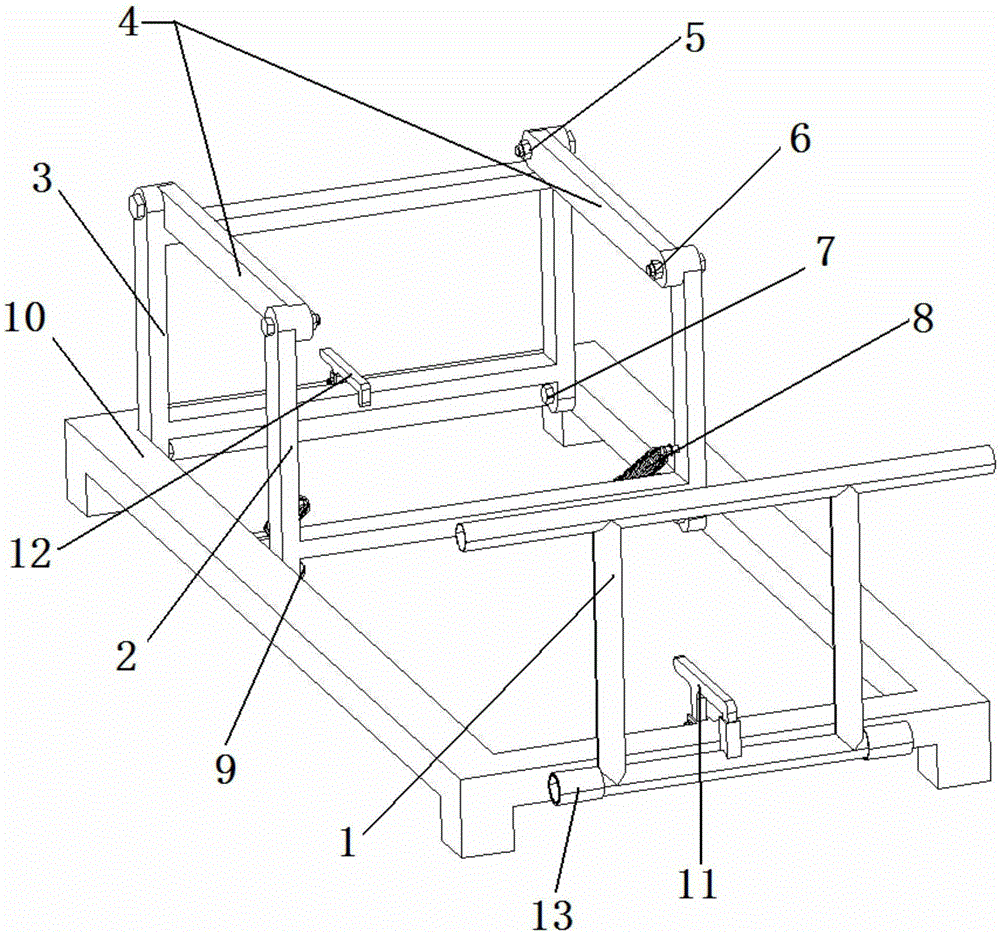

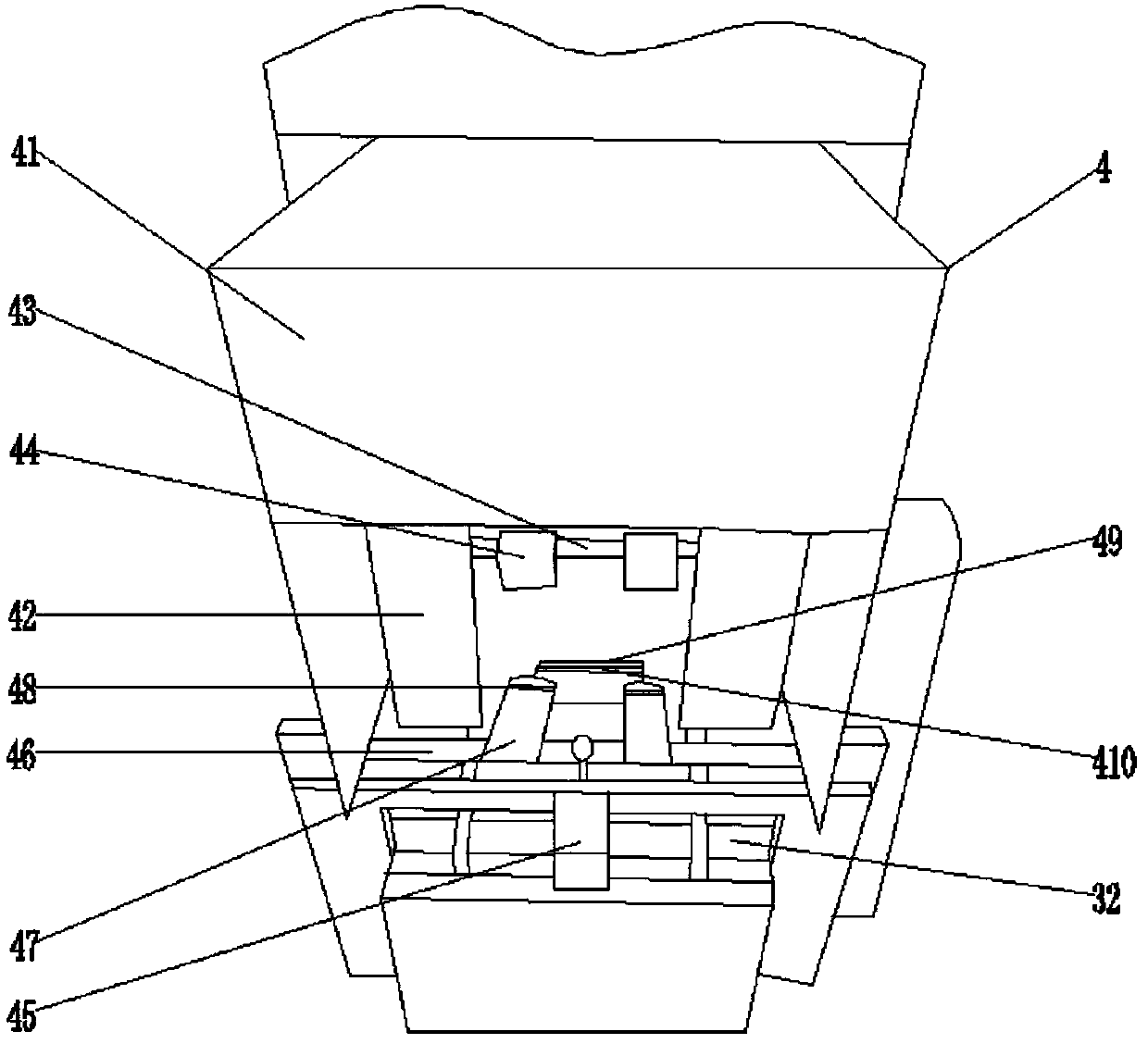

Pre-assembly workbench for motor tricycle

InactiveCN105269537AEasy to installReduce labor intensityWork benchesMetal working apparatusLocking mechanismEngineering

A pre-assembly workbench for a motor tricycle comprises a base, a first support, a second support, a third support, bearing connecting rods, a first locking mechanism and a second locking mechanism. The lower end of the first support is connected to the front end of the base through a first revolute pair. The lower end of the second support is connected to the middle of the base through a second revolute pair. The lower end of the third support is connected to the rear end of the base through a third revolute pair. One end of each bearing connecting rod is connected to the upper end of the second support through a fourth revolute pair, and the other end of each bearing connecting rod is connected to the upper end of the third support through a fifth revolute pair. The first locking mechanism is installed on the base and the first support. The second locking mechanism is installed on the base and the third support. The pre-assembly workbench further comprises springs. One end of each spring is connected to the second support, and the other end of each spring is connected to the base. By means of the pre-assembly workbench for the motor tricycle, the installation of motor tricycle wheels is facilitated; in addition, by utilizing the characteristic of working procedures, the labor intensity for transferring a tricycle body away from the workbench is relieved, and the working efficiency is improved.

Owner:广西银钢南益制造有限公司

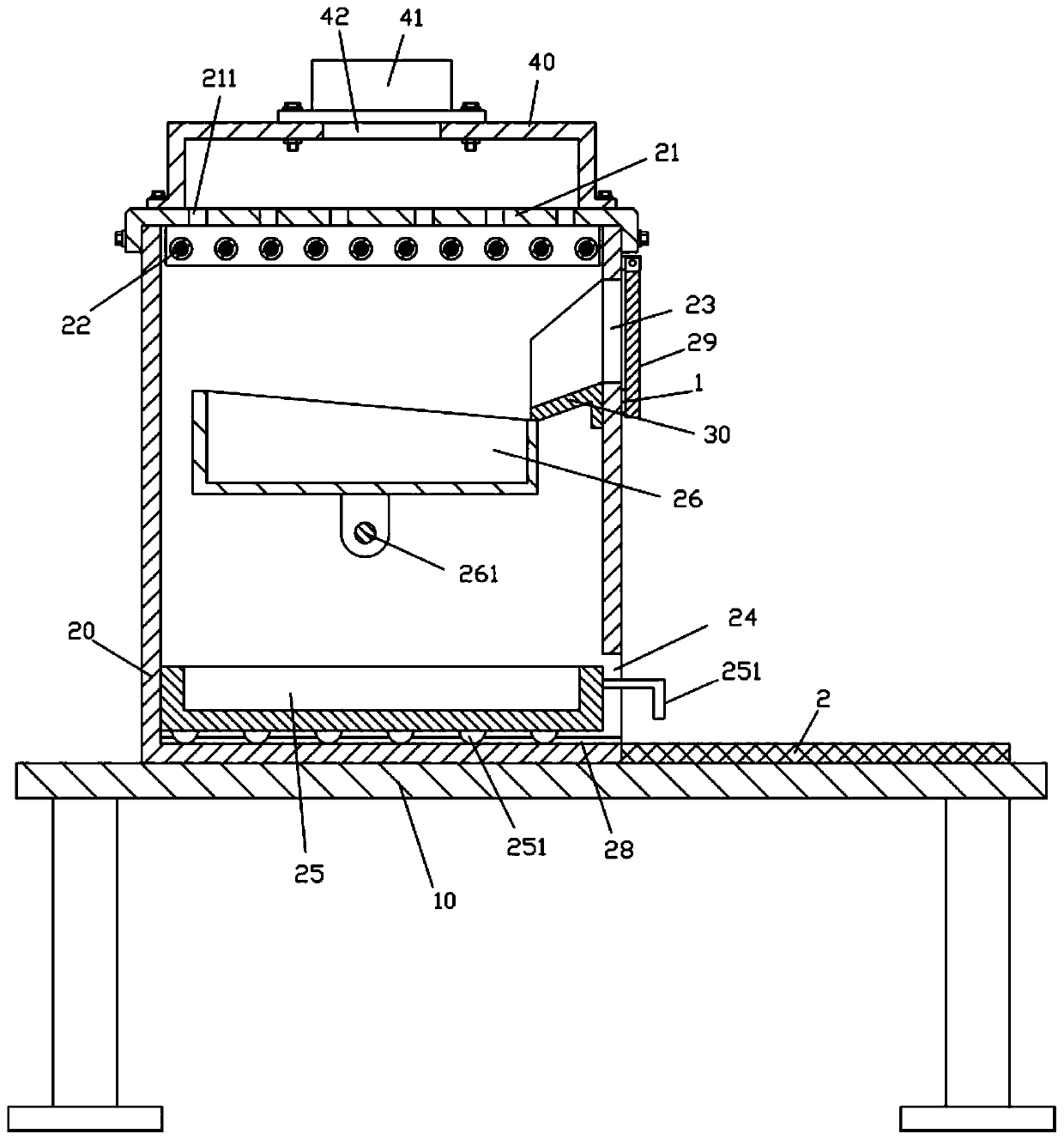

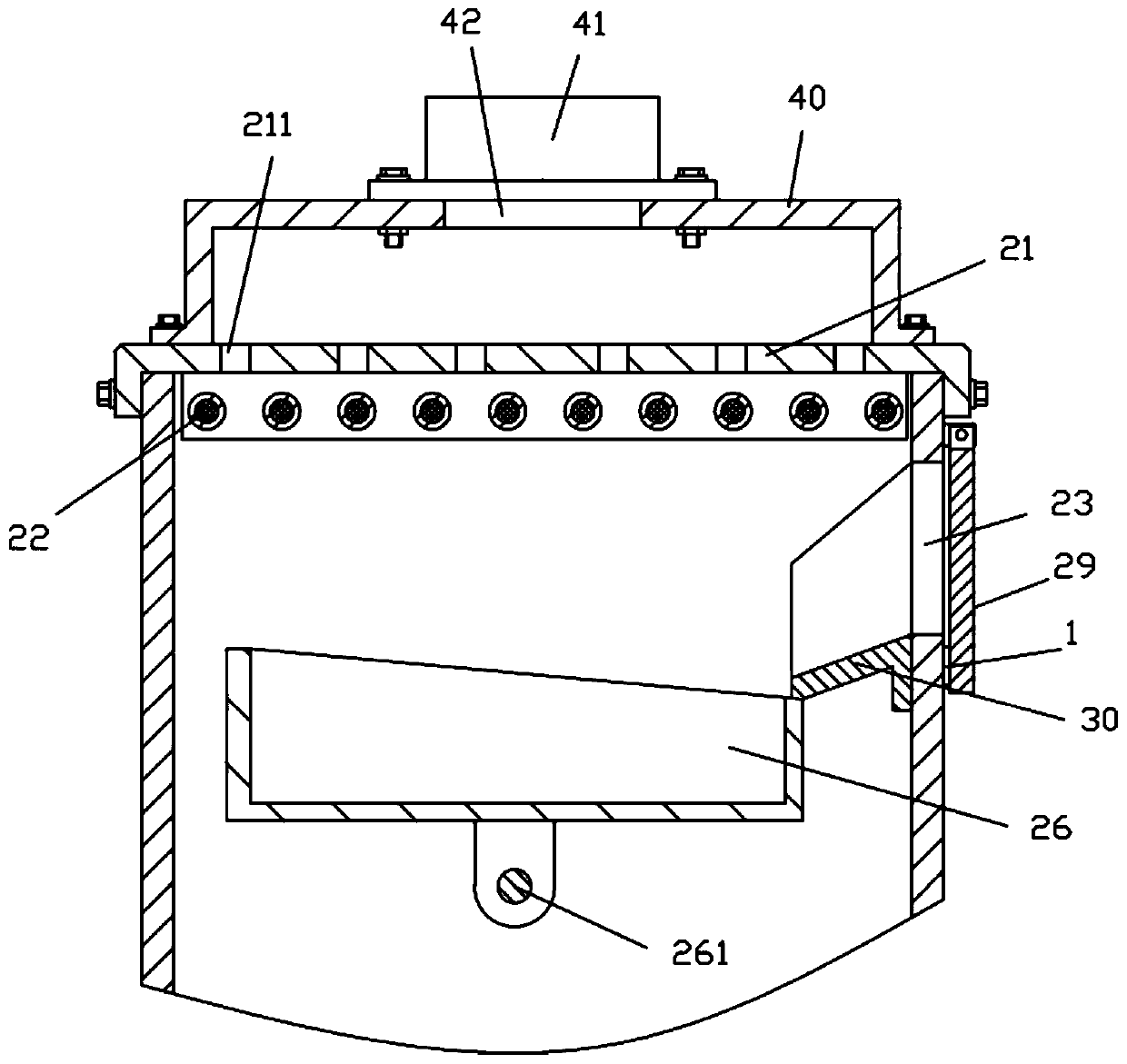

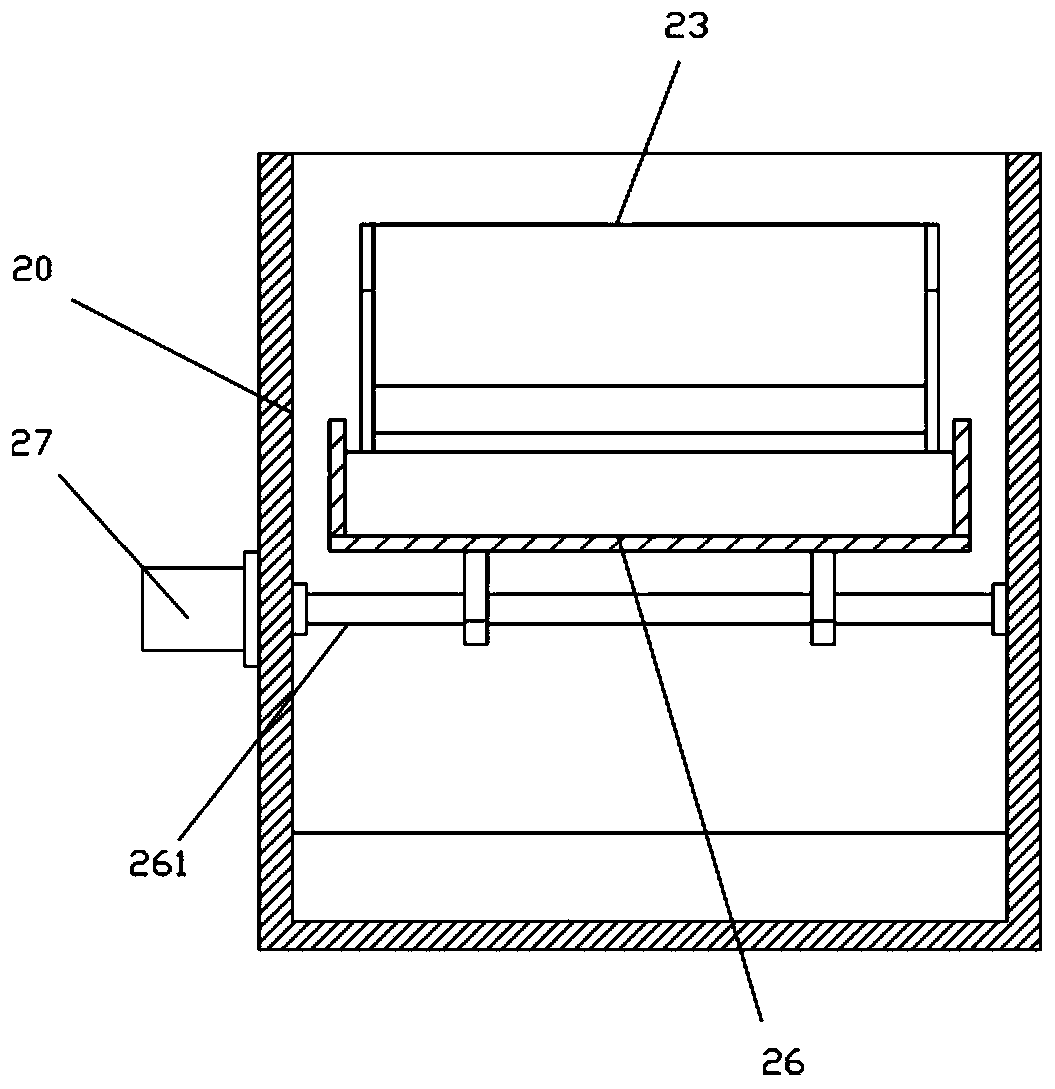

Drying main unit of continuous grain drying device

InactiveCN111595118AConvenient drying time controlAchieve dumpingDrying gas arrangementsDrying chambers/containersControl engineeringHeater Rod

The invention discloses a drying main unit of a continuous grain drying device. The drying main unit comprises a main unit frame, a main box is fixed to the top surface of a top plate of the main unitframe, an upper top plate is fixed to the top of the main box, and a plurality of heating rods are fixed to the bottom surface of the upper top plate; and a feeding through groove is formed in the upper portion of a right side plate of the main box, a discharging through groove is formed in the lower portion of the right side plate of the main box, a receiving tank is located on the top surface of a bottom plate of the main box, a handle is fixed to the right side wall of the receiving tank, and the handle is inserted in the discharging through groove in a sleeved manner. According to the drying main unit, materials such as grains or nuts can be poured into a middle drying tank to be dried, after drying is completed, the middle drying tank can turn over and pour the materials into the receiving tank through operation of a driving servo motor, discharging can be achieved by pulling out the receiving tank, and the process is very convenient; and as the middle drying tank is independently controlled by the driving servo motor, the drying time of the middle drying tank is convenient to control, and pouring and returning can be achieved just by controlling the operation and stop of thedriving servo motor.

Owner:TAIZHOU LEYAN AUTOMATION SCIEN-TECH CO LTD

Self-recovery type circuit protection fuse

ActiveCN113066688AReduce damageGuaranteed service lifeAir-break switch detailsCircuit protectionStructural engineering

A self-recovery type circuit protection fuse disclosed by the present invention comprises a protection box; the inner wall of the protection box is in sealed sliding connection with a power connection plate, the power connection plate is connected with the inner wall of the protection box through a plurality of reset springs, the side wall of the power connection plate is provided with a first power connection block, and the top in the protection box is provided with a sliding cavity. The inner walls of the two ends of the sliding cavity are slidably connected with a second power connection block and a protruding block correspondingly, the second power connection block abuts against the power connection plate, the second power connection block is connected with the protruding block through a connecting plate, and a plurality of guide columns are welded to the inner wall of the sliding cavity and are slidably connected with the connecting plate in a penetrating mode. The fuse has the advantages that when current in a circuit is too large, the magnetic sliding plate jacks up the convex block, so the second power connection block can be separated from the power connection plate, the fuse is in a disconnected state, the circuit can be protected, the fuse can be disconnected without heat, and damage to the circuit caused by the heat can be reduced.

Owner:诸暨市东白电力安装工程有限公司 +1

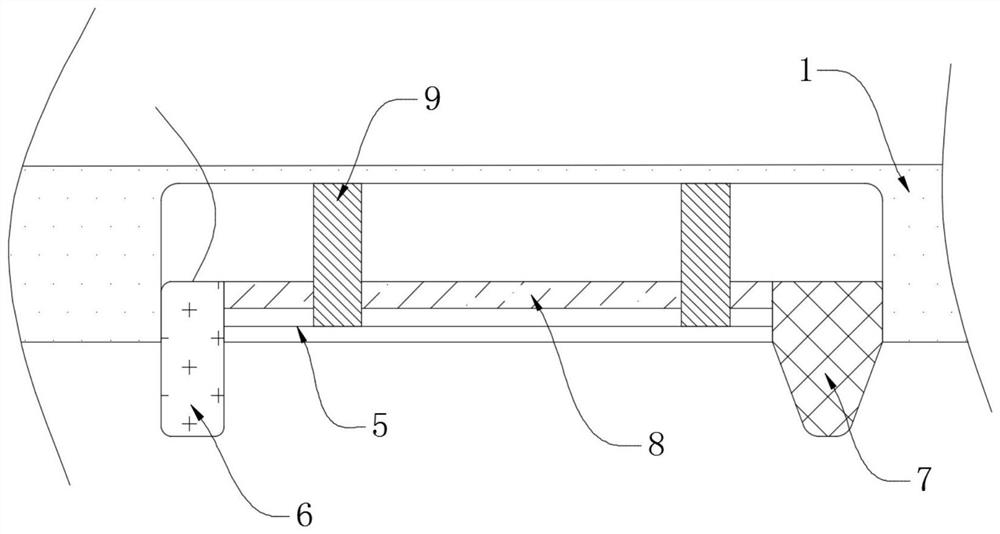

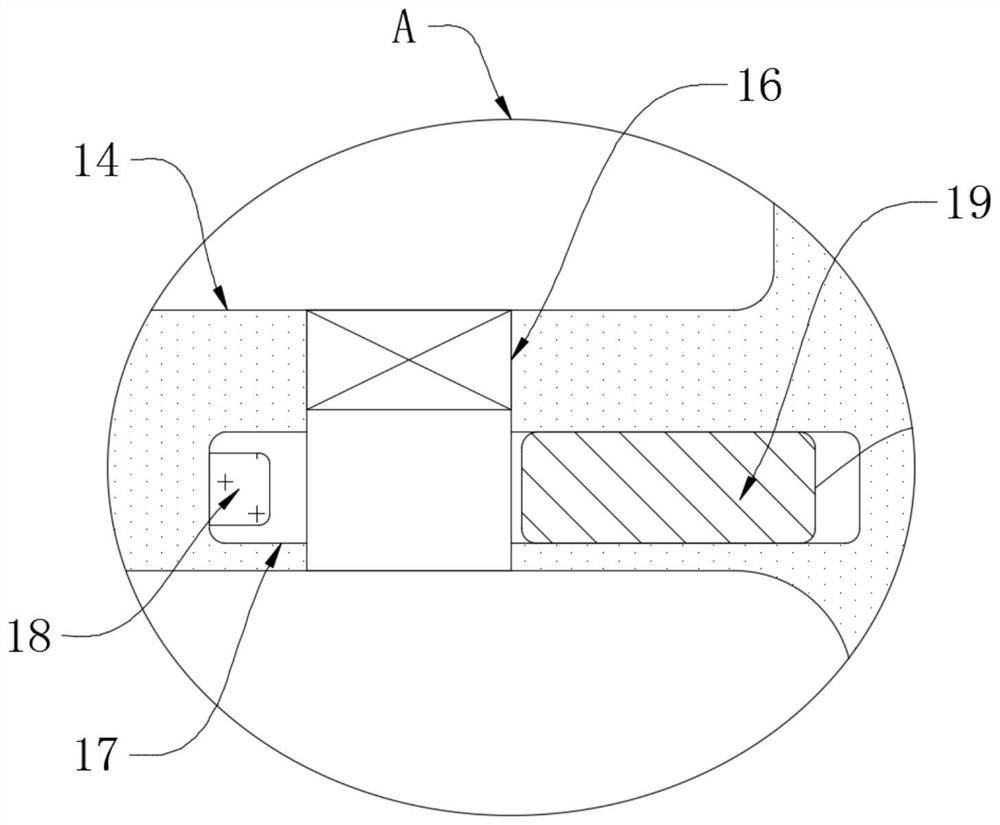

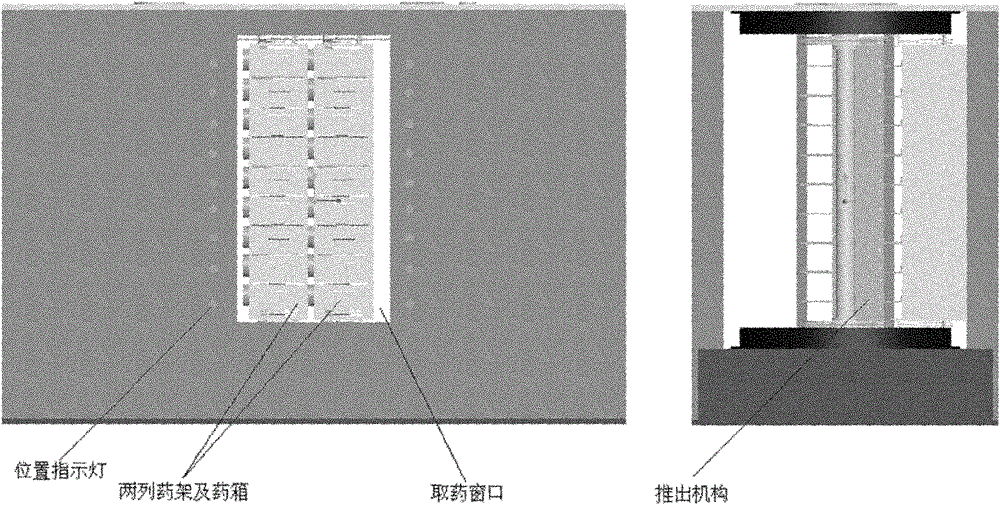

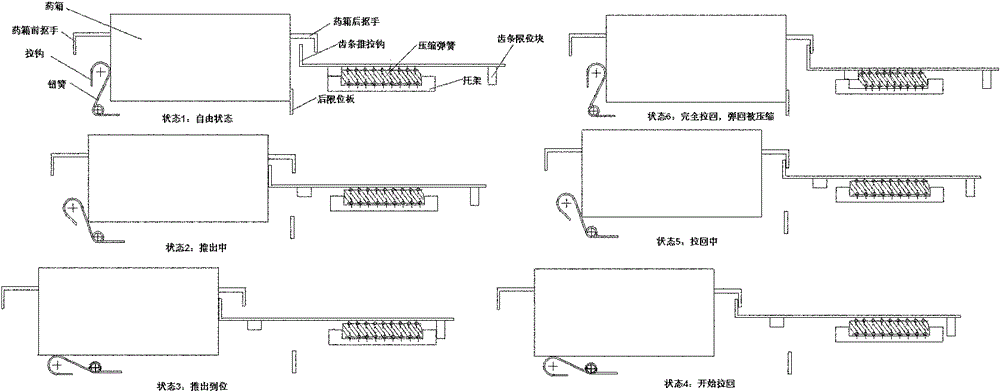

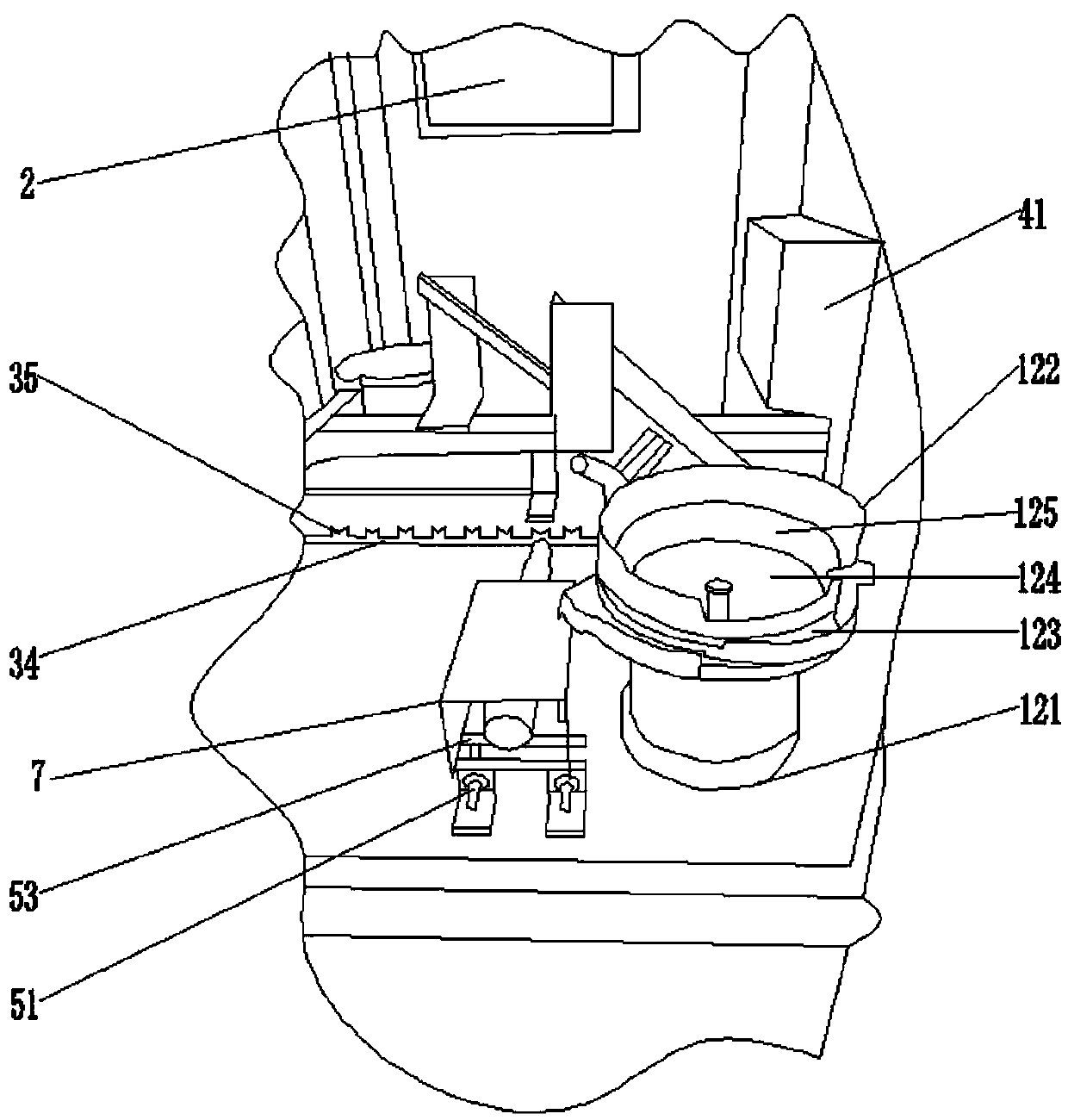

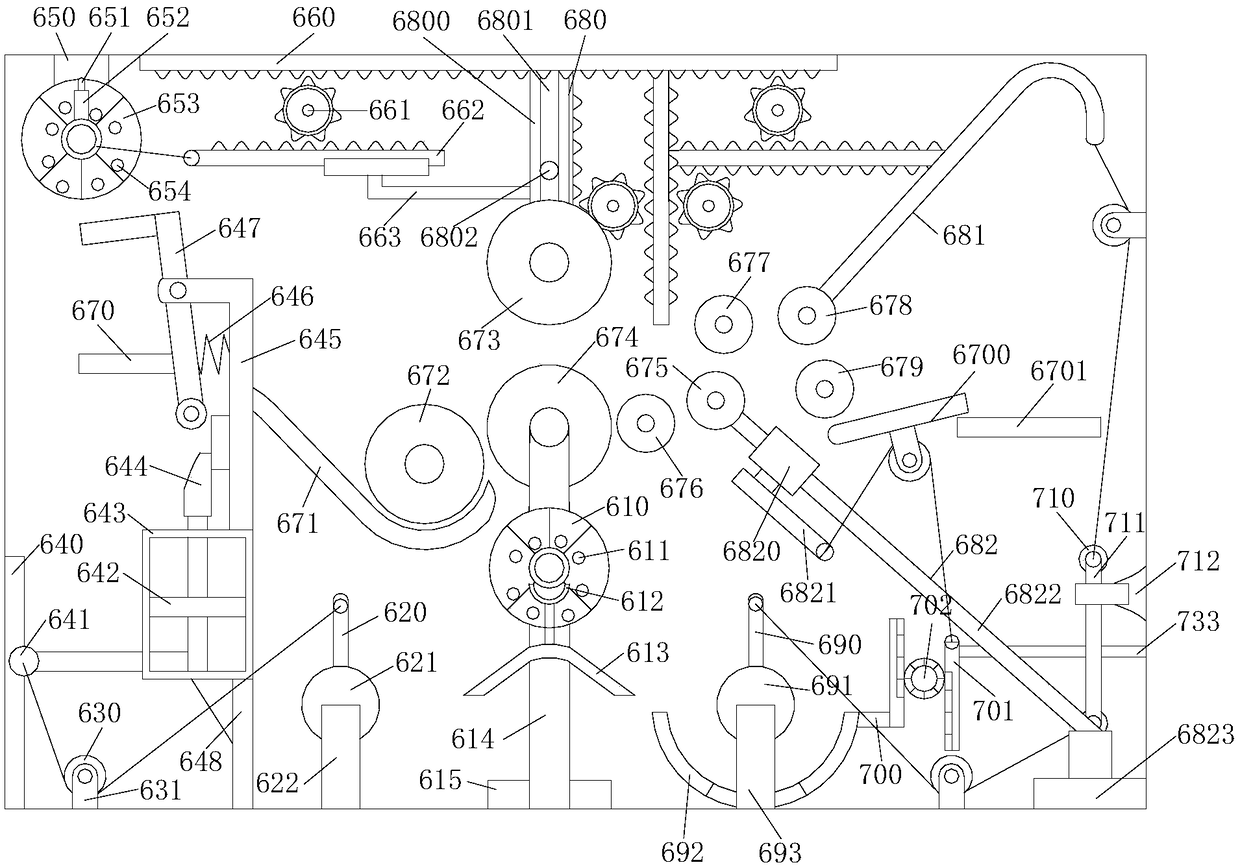

A horizontal rotary cabinet type intelligent medicine dispensing system automatic medicine dispensing mechanism

ActiveCN102673930BIncrease the speed of taking medicineGuaranteed stabilityStorage devicesPush pullMechanical design

Owner:SHANGHAI VIEW VALLEY TECH +1

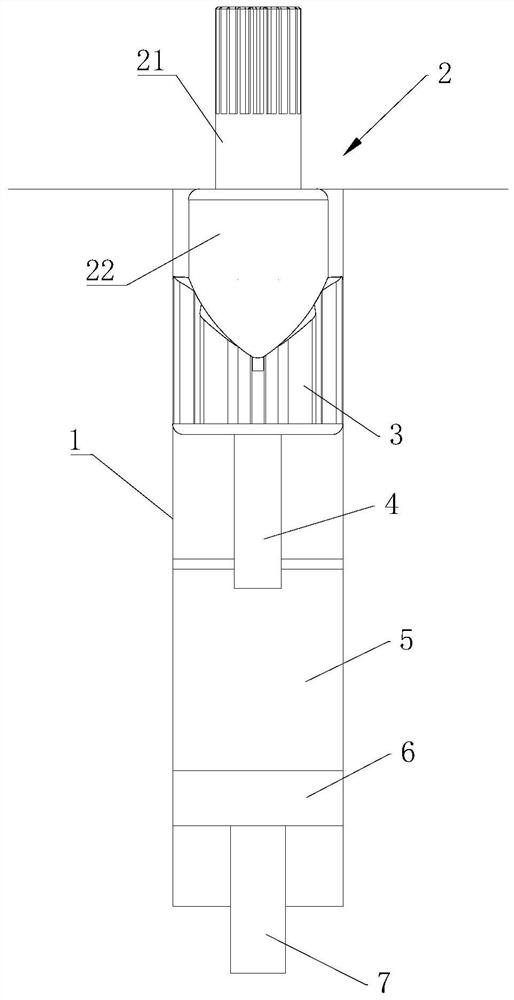

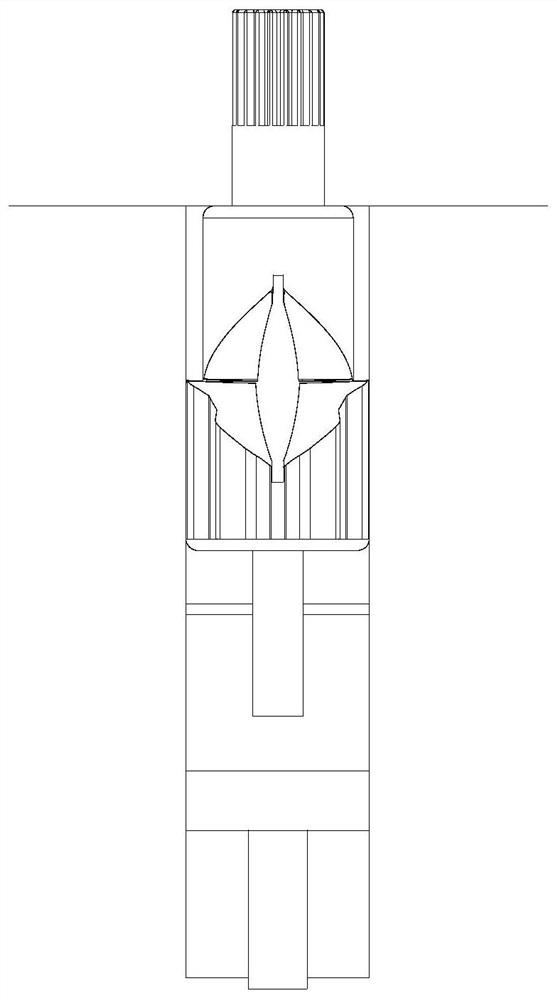

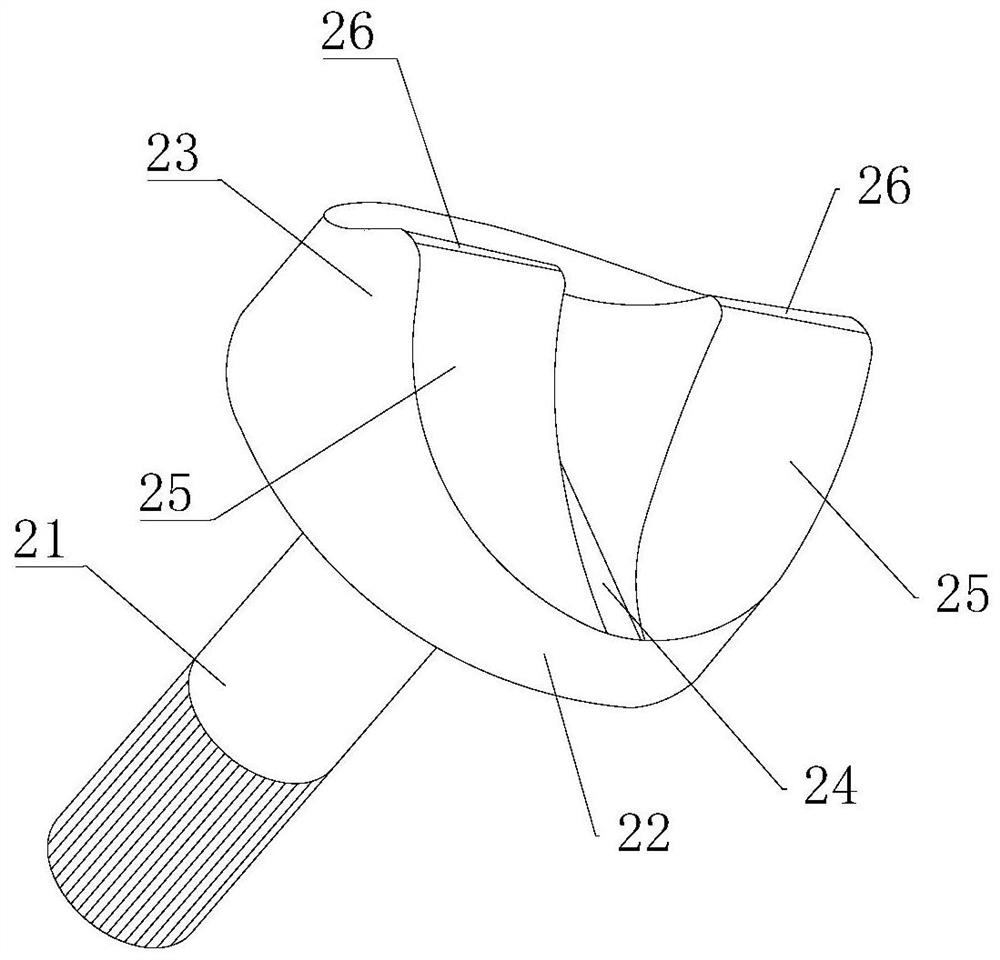

Full-automatic ultrasonic welding mechanism for serological pipettes

ActiveCN108672915AEfficient weldingSave human effortWelding/cutting auxillary devicesAuxillary welding devicesPipetteUltrasonic welding

The invention relates to the technical field of biological medical instruments, and particularly discloses a full-automatic ultrasonic welding mechanism for serological pipettes. The full-automatic ultrasonic welding mechanism comprises a machine frame, a controller and a conveying mechanism, wherein a first feeding mechanism, a second ultrasonic welding assembly and a first grabbing mechanism aresequentially arranged on the machine frame along the conveying direction of the conveying mechanism, a second feeding mechanism is arranged on the position, located on the side on which the first grabbing mechanism is located, of the machine frame, and a lifting mechanism is arranged on the machine frame; the first feeding mechanism comprises a hopper and a discharging rail; the second ultrasonicwelding assembly comprises a first pushing air cylinder and a supporting plate; the first grabbing mechanism comprises a fixing plate and a rodless air cylinder; the second feeding mechanism comprises a second vibrating mechanism and a second material plate; and the lifting mechanism comprises a lifting air cylinder and an I-shaped lifting plate. The full-automatic ultrasonic welding mechanism has the characteristics of being high in automation degree, good in welding air tightness, high in production efficiency and low in production cost.

Owner:ZHEJIANG SORFA MEDICAL PLASTIC

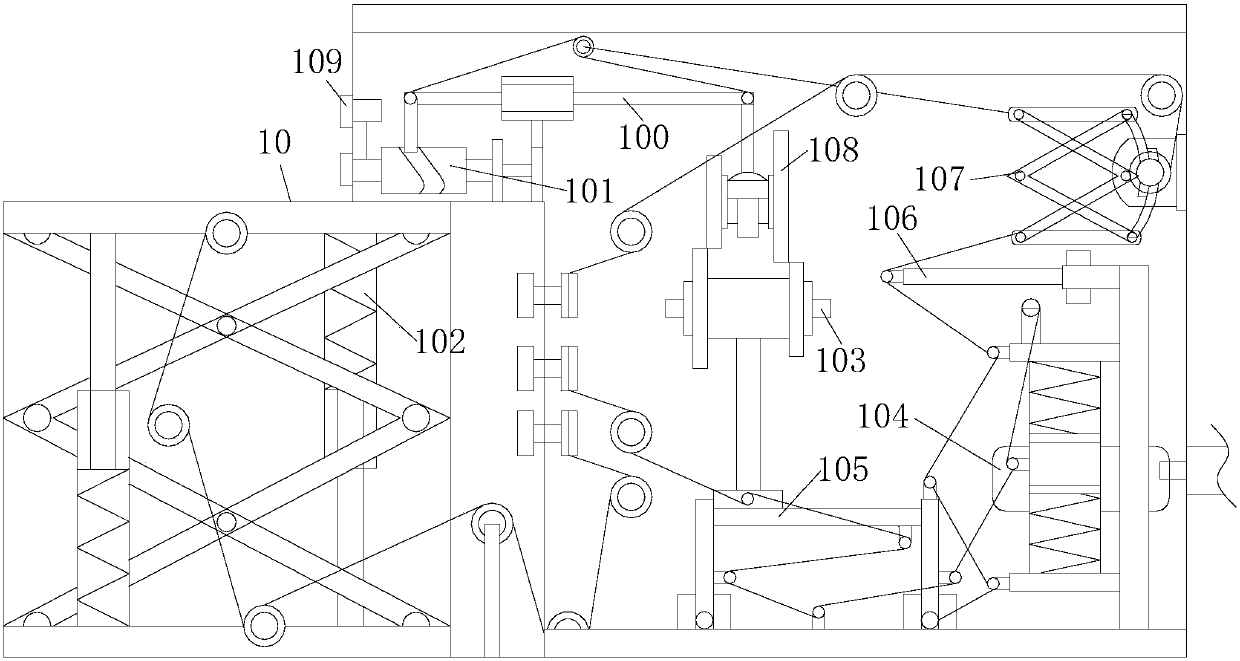

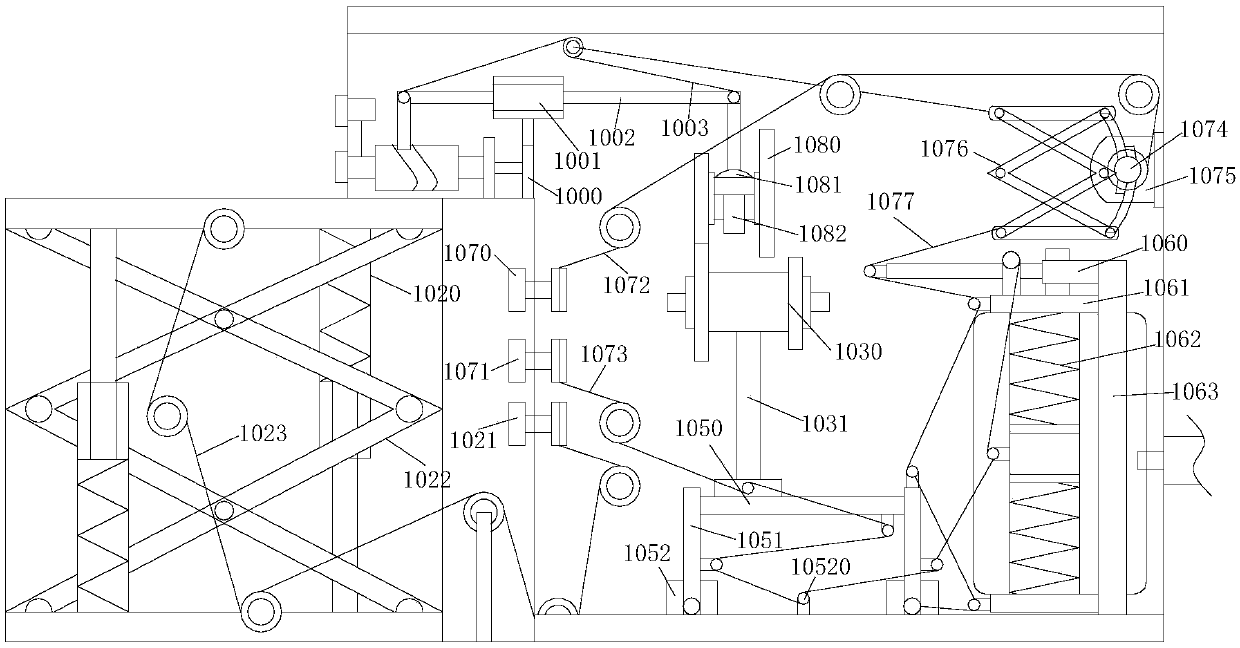

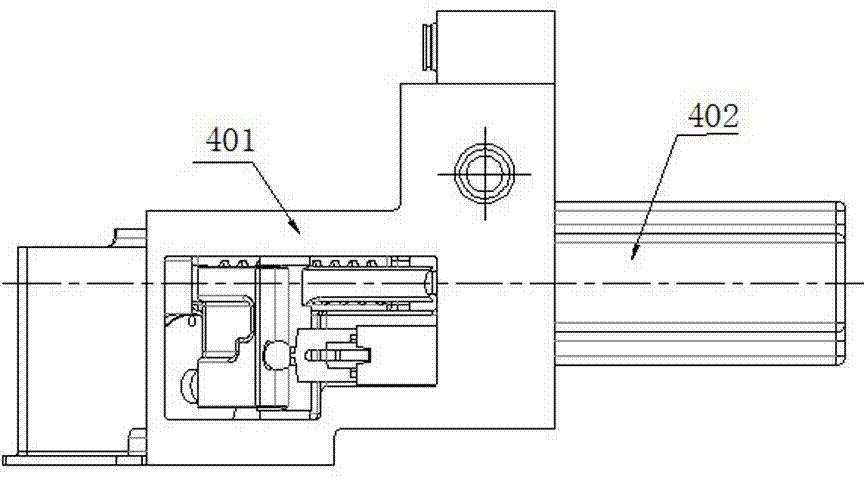

Adjusting device

An adjusting device comprises a bottom plate, at least two signal transmitting units, a magnetic element, a Hall element, a base, a limit element, a first cover, a second cover, a knob, a button, a rocker, a first return unit and a second return unit, wherein the first return unit is used for axially returning the rocker, and the second return unit is used for obliquely returning the rocker. As the adjusting device is provided with the rocker and a ball, button functions in a vertical direction and in other directions can be realized, namely the adjusting device is capable of realizing omnidirectional button functions. Besides, the adjusting device is provided with the magnetic element and the Hall element which are opposite, the magnetic element is driven to move by the rocker, the Hall element is capable of sensing different signals, and the operation of the whole adjusting device can be judged by the aid of the signals. By means of coordination of a baffle plate of the first cover and the signal transmitting units, turning directions of the knob can be judged, so that omnidirectional output can be realized.

Owner:BYD CO LTD

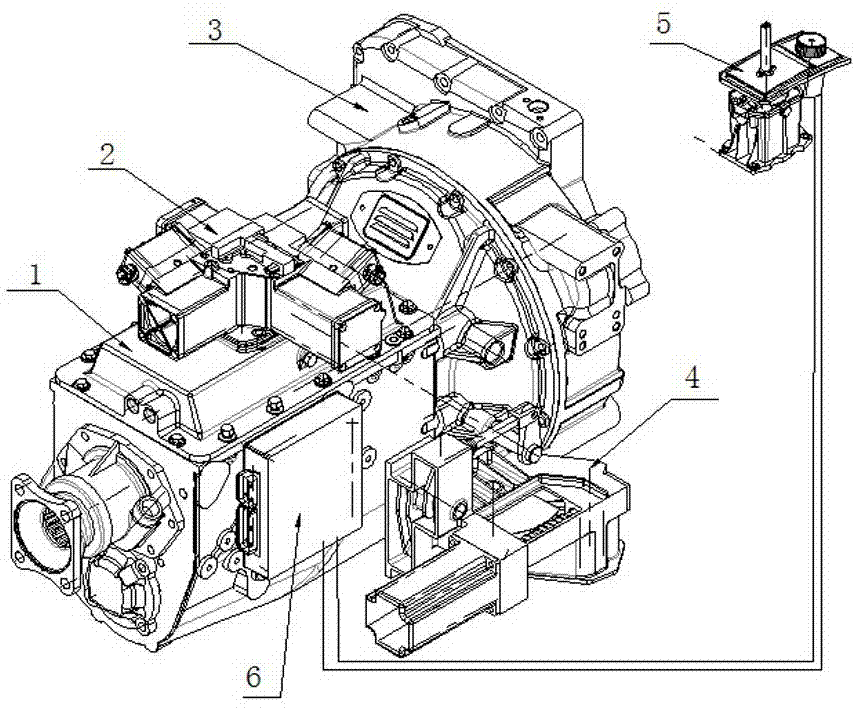

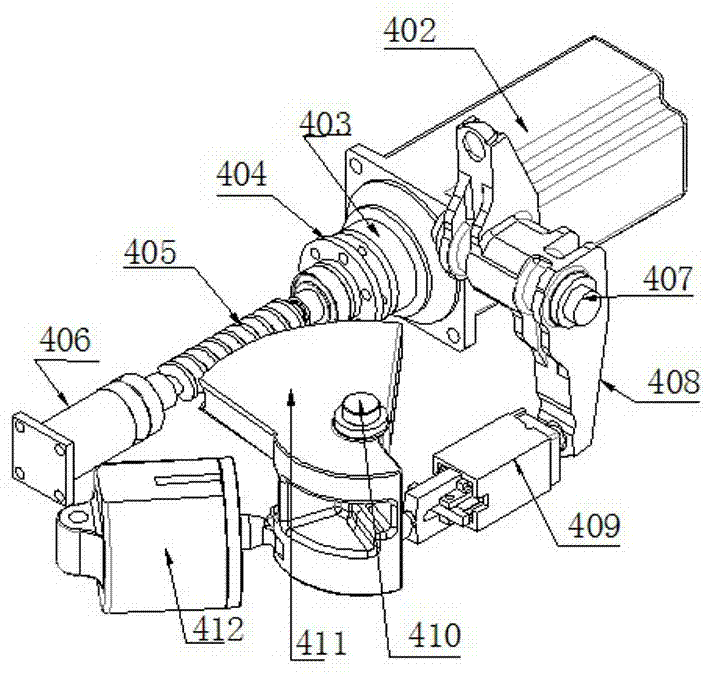

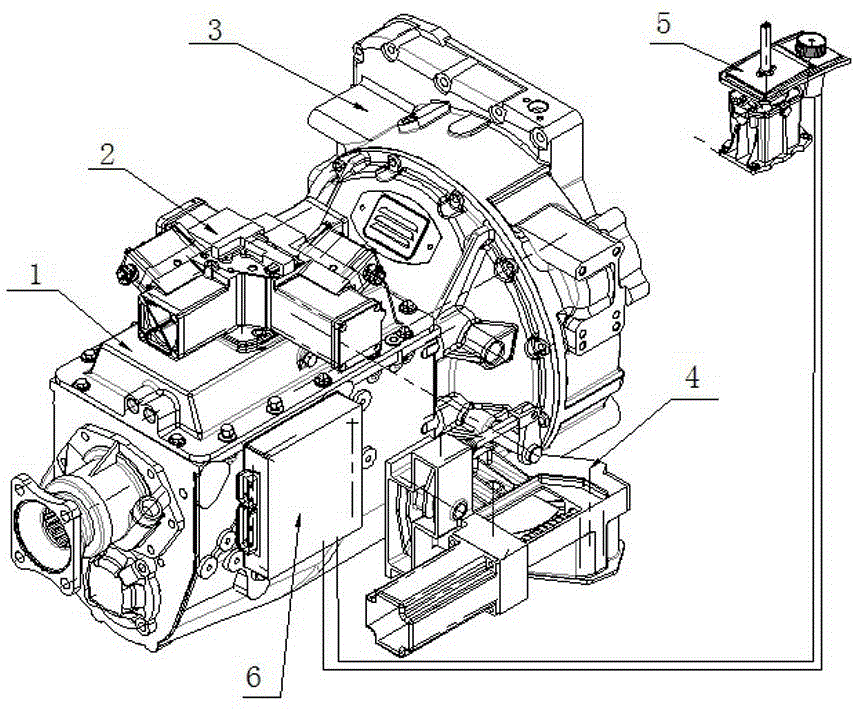

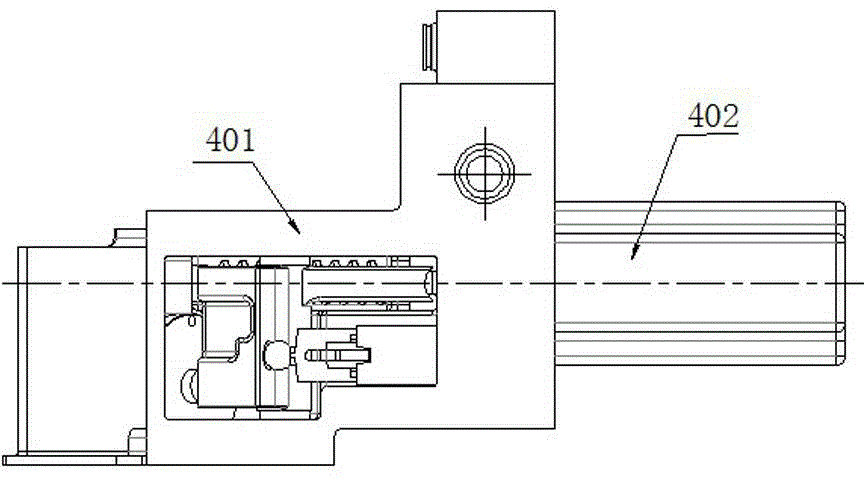

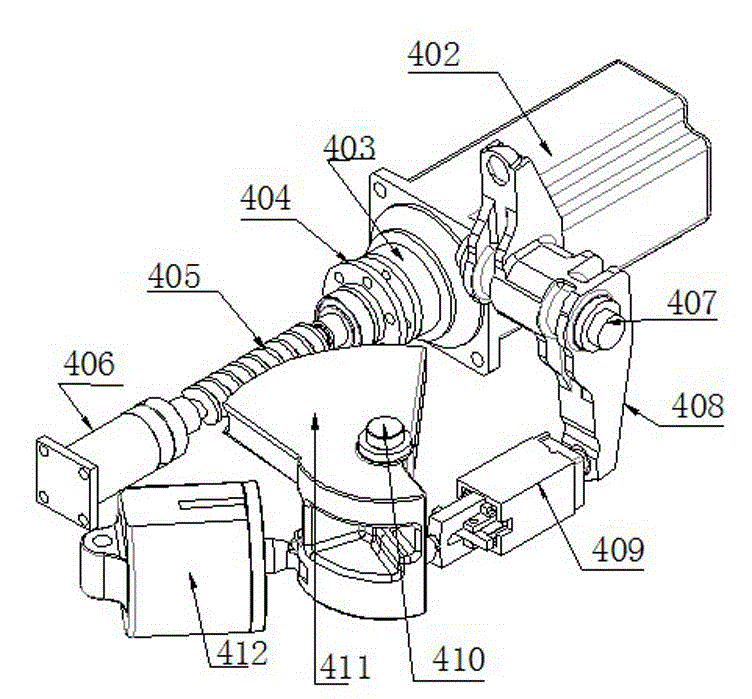

Automatic transmission execution system of automobile

The invention provides an automatic transmission execution system of an automobile. The automatic transmission execution system comprises a transmission box. An automatic transmission box gear selecting and shifting execution mechanism is arranged at the top of the transmission box, a clutch is arranged on the front portion of the transmission box, a clutch execution mechanism and a TCU are arranged on the lateral face of the transmission box, and a manual-automatic integrated gear shifting controller is arranged in a cab. The clutch execution mechanism is a pneumatic assistance electric clutch execution mechanism, the manual-automatic integrated gear shifting controller comprises a shell, a gear shifting rod performs electronic control over triggering of a Hall element control switch, the TCU comprises a master control MCU, and a Freescale 32 high performance processor MPC5633M serves as the master control MCU. According to the automatic transmission execution system, the clutch execution mechanism, the TCU and the manual-automatic integrated gear shifting controller are organically combined, and technical supports are provided for achieving manual-automatic integration of middle-sized trucks, passenger cars, special cars and the like.

Owner:湖北禹步机电科技有限公司

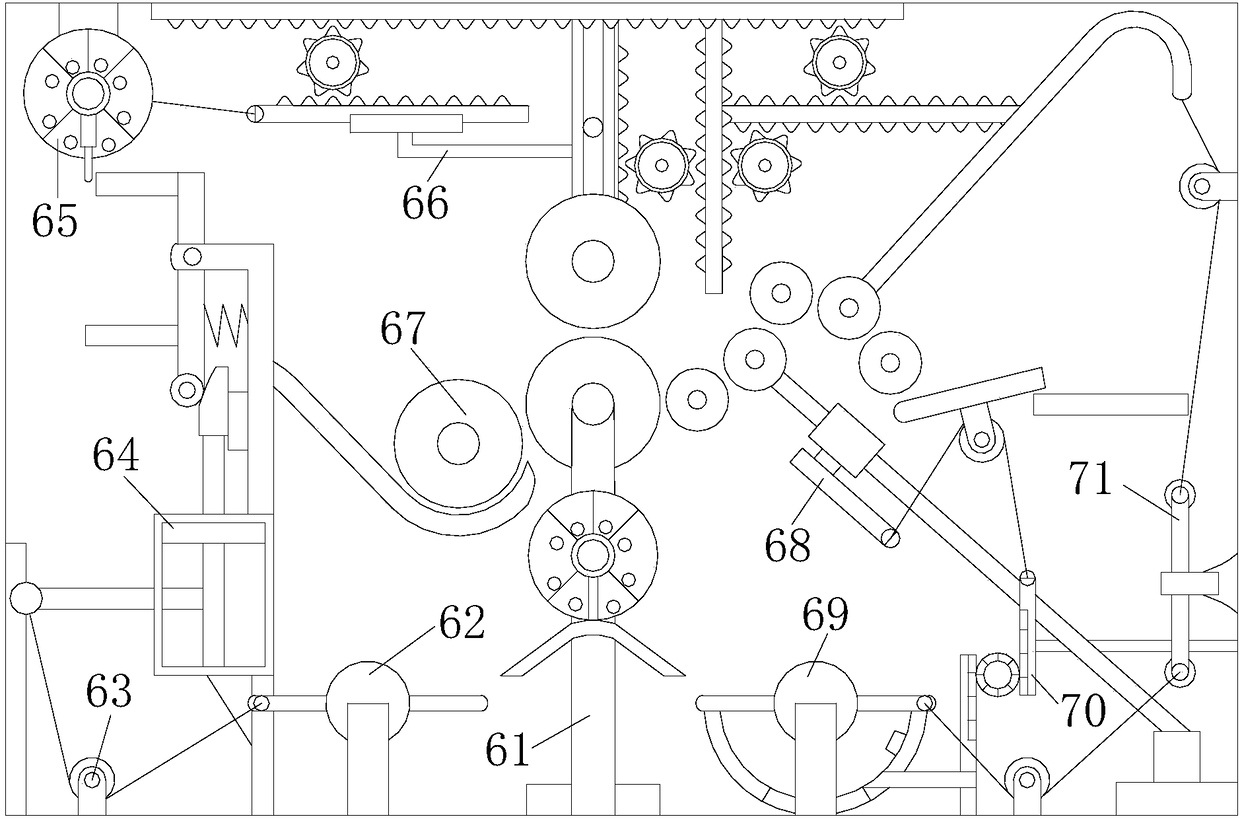

Automatic double-sided printing device

PendingCN108582991ALow failure rateImprove efficiencyPrinting press partsDrop structurePrinting press

The invention discloses an automatic double-sided printing device which structurally comprises an overhaul bin, an inner inspection bin, a paper outlet, an intelligent control panel, a printer, and anautomatic repair device for paper jam inside. The overhaul bin is adjacent to the inner inspection bin; the paper outlet is located above the inner inspection bin; the inner inspection bin and the paper outlet form an integrated structure; the intelligent control panel is arranged on the side surface, on which the paper outlet is formed, of the printer; the paper outlet is adjacent to the intelligent control panel; and the automatic repair device for paper jam inside is arranged in the printer and is formed by a bead dropping structure, a turnover structure, a wire wheel structure, a pushingmechanism, a rolling structure and a multidirectional reciprocating transmission mechanism. According to the automatic double-sided printing device provided by the invention, when a paper jam phenomenon occurs during a printing process, the transmission mechanism in the equipment can maintain automatically, so that the failure rate of the equipment is reduced, the printing production efficiency isimproved, and meanwhile, the labor cost of maintenance personnel is reduced.

Owner:陈泳伶

Pneumatic automatic return device

The invention provides a pneumatic automatic return device which solves the problem that return speeds of doors with different weights are different in the prior art. The pneumatic automatic return device comprises a gear sleeve, an upper convex shaft, a lower convex shaft, a piston, a closed air chamber and an adjusting rod. The gear sleeve is of a hollow structure; the upper convex shaft is arranged in the gear sleeve, one end of the upper convex shaft extends outwards from the end part of the gear sleeve, and the upper convex shaft only rotates in the gear sleeve; the lower convex shaft isalso arranged in the gear sleeve and does reciprocating rectilinear motion only in the length direction of the gear sleeve, the upper convex shaft and the lower convex shaft are in contact and alwayshave acting force, and the rotating motion of the upper convex shaft is synchronous with the rectilinear motion of the lower convex shaft; one end of the piston is used for continuously propping the lower convex shaft against the upper convex shaft; the other end of the piston extends into the closed air chamber, and the closed air chamber is provided with a movable end face used for adjusting thespace size of the closed air chamber; and the adjusting rod is arranged on the gear sleeve in a matched manner and abuts against the movable end face.

Owner:WEIFANG ZHENGXIN PNEUMATIC TECH CO LTD

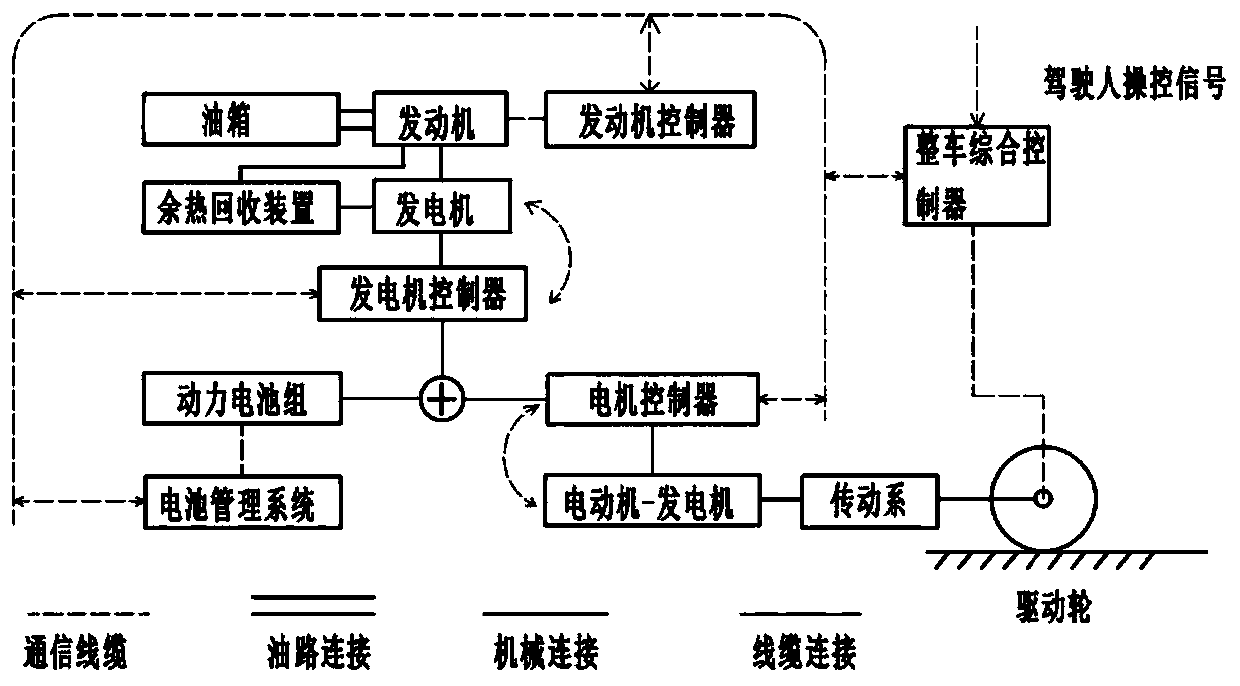

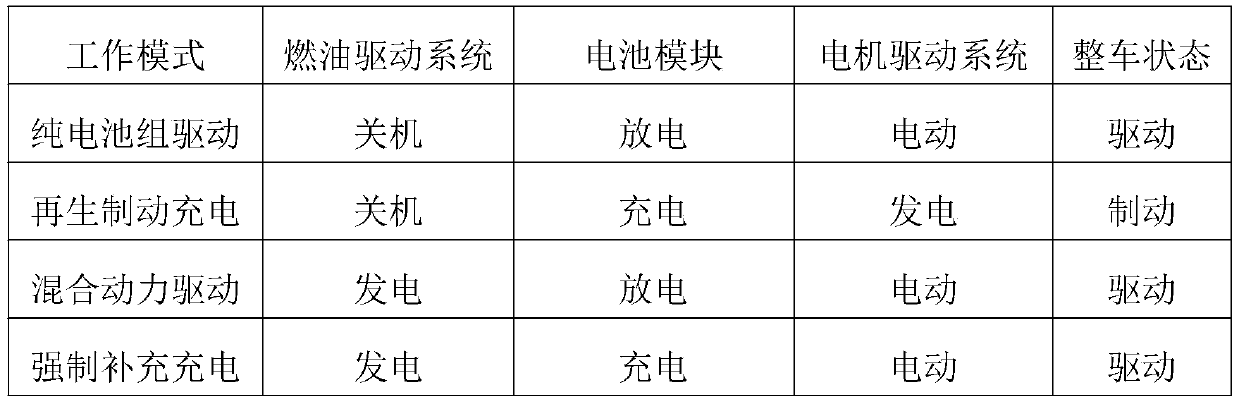

Power system of hybrid electric vehicle

PendingCN111409439AEmission reductionIncrease profitHybrid vehiclesInternal combustion piston enginesElectric machineryFuel oil

The invention discloses a power system of a hybrid electric vehicle. The power system comprises a driving system and a transmission system, wherein the power system is characterized in that the driving system comprises a motor driving system and a fuel oil driving system which are connected in series, a waste heat recovery system is arranged between the fuel oil driving system and the transmissionsystem, the waste heat recovery system comprises an energy storage device and an air cylinder for receiving waste gas heat of an engine, and the energy storage device is in power connection with theair cylinder. The power system is advantaged in that a problem of power acceleration in the prior art is solved, and the advantages of environmental protection and heat energy utilization rate are reserved.

Owner:XIJING UNIV

Nozzle feeding mechanism in serum pipette welding equipment

InactiveCN108526683AEasy to adjustReasonable quantityNon-electric welding apparatusPipetteEngineering

The invention relates to the technical field of biomedical instruments and particularly discloses a nozzle feeding mechanism in serum pipette welding equipment. The nozzle feeding mechanism comprisesa frame and a third feeding mechanism. The third feeding mechanism comprises a third vibrating mechanism and a third material tray. A third spiral conveying plate is arranged on the inner wall of a third inner tray part. The output end of the third spiral conveying plate is connected with a first arc conveying rail. The output end of the first arc conveying rail is connected with a second slide rail. A baffle is arranged on the third material tray. A gap is formed between the baffle and the output end of the first arc conveying rail. The output end of the second slide rail is connected with athird arc conveying rail. The output end of the third arc conveying rail is connected with a fourth linear conveying rail. The nozzle feeding mechanism in the serum pipette welding equipment has the beneficial effects of being higher in automation degree, higher in production efficiency and lower in production cost.

Owner:ZHEJIANG SORFA MEDICAL PLASTIC

Air suspension seat control system and air suspension seat

ActiveCN106218453BFunction increaseHigh degree of automationMovable seatsSeat suspension devicesControl systemAir spring

The invention relates to the controlling system field, in particular to a controlling system for an air-suspending seat and the air-suspending seat. The controlling system for the air-suspending seat comprises a position sensor, an electronic controlling unit (ECU), an electromagnetic valve set and a man-machine interface; the position sensor is connected with the ECU, used for detecting changing quantity of positions, obtains position signals according to the changing quantity of the positions, and transmits the position signals to the ECU; the ECU is used for receiving the position signals transmitted by the position sensor and / or controlling signals transmitted by the man-machine interface, obtains corresponding controlling orders according to the position signals and / or the controlling signals, and transmits the controlling orders to the electromagnetic valve set; and the electromagnetic valve set is connected with the ECU and an air spring, receives the controlling orders transmitted by the ECU, and control the air spring according the controlling orders to enable the air spring to inflate or deflate. The air-suspending seat is controlled to conduct lifting, fast landing, returning, remembering and suspending according to the different controlling orders. The controlling system for the air-suspending seat and the air-suspending seat have the beneficial effects that functions are various, and automation degree is higher.

Owner:西安光华荣昌汽车部件有限公司

Automobile automatic transmission system

Owner:湖北禹步机电科技有限公司

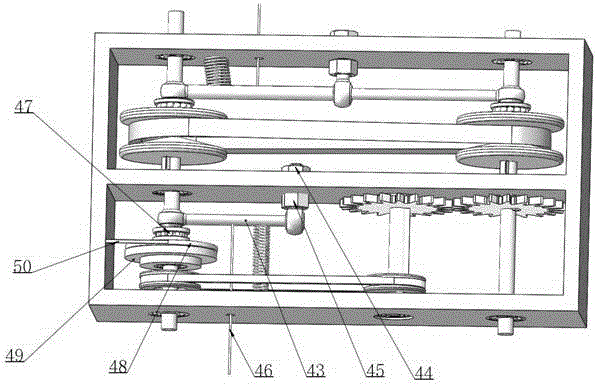

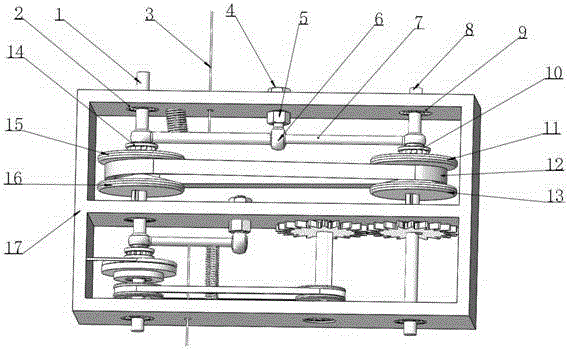

Buffer energy-storage stepless speed changer applied to two-wheeled vehicle

The invention discloses a buffer energy-storage stepless speed changer applied to a two-wheeled vehicle, which aims at realizing the advantages of steplessly changing the speed, buffering the brake, storing the brake energy, releasing the energy and outputting power after the brake is stopped by virtue of the cooperation of a speed changing assembly, a synchronous assembly and a buffer energy storage assembly, and overcomes the weaknesses of the stepped speed changer that the energy consumption is great, the speed changing is unsmooth, the energy is wasted and the emergent brake is easy to be out of control. The speed changing assembly realizes the stepless speed changing by continuously changing a transmission ratio, the synchronous assembly is connected with the speed changing assembly and the buffer energy storage assembly, the buffer energy storage assembly plays a buffer role and stores the energy in braking and releases the stored energy to be used as power when the brake is released. The buffer energy-storage stepless speed changer is low in energy consumption, high in comfirt and safety, and wide in market application prospect. The buffer energy-storage stepless speed changer comprises a speed changing assembly, a synchronous assembly and a buffer energy storage assembly.

Owner:QINGDAO UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com