Pneumatic automatic return device

An automatic return and adjustment device technology, which is applied to switches with braking devices, buildings, door/window accessories, etc., can solve the problems of rotor and shaft falling off, affecting normal use, and different return speeds. High operation precision, wide application range, and smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

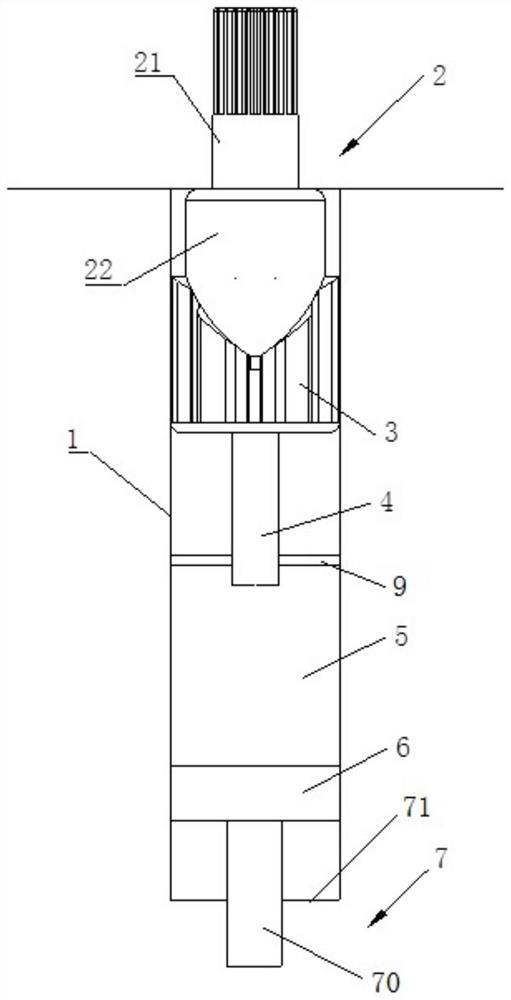

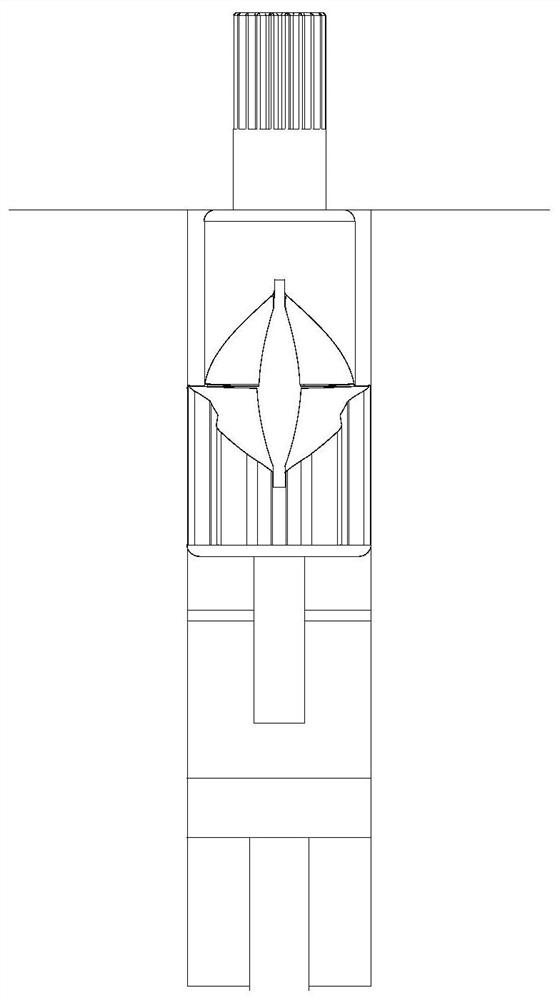

[0204] Such as figure 1 with figure 2 As shown, it is a schematic diagram of two different states of the pneumatic automatic return device of the present invention, and is a schematic diagram of two limit states, which is used to mount on the door, and the automatic return of the door is realized. At the time of installation, the rotation center of the door is mounted on the connecting shaft 21 of the upper convex shaft 2 in the drawing, and between the door and the connecting shaft 21 are synchronously rotated. figure 1 In the state shown, the door is closed, and when the door and the connecting shaft 21 rotate 90 °, it is figure 2 The state shown, the door is opened to the largest, after the door can be figure 2 Automatically returned in the state shown figure 1 The state shown, the automatic shutdown of the door is realized.

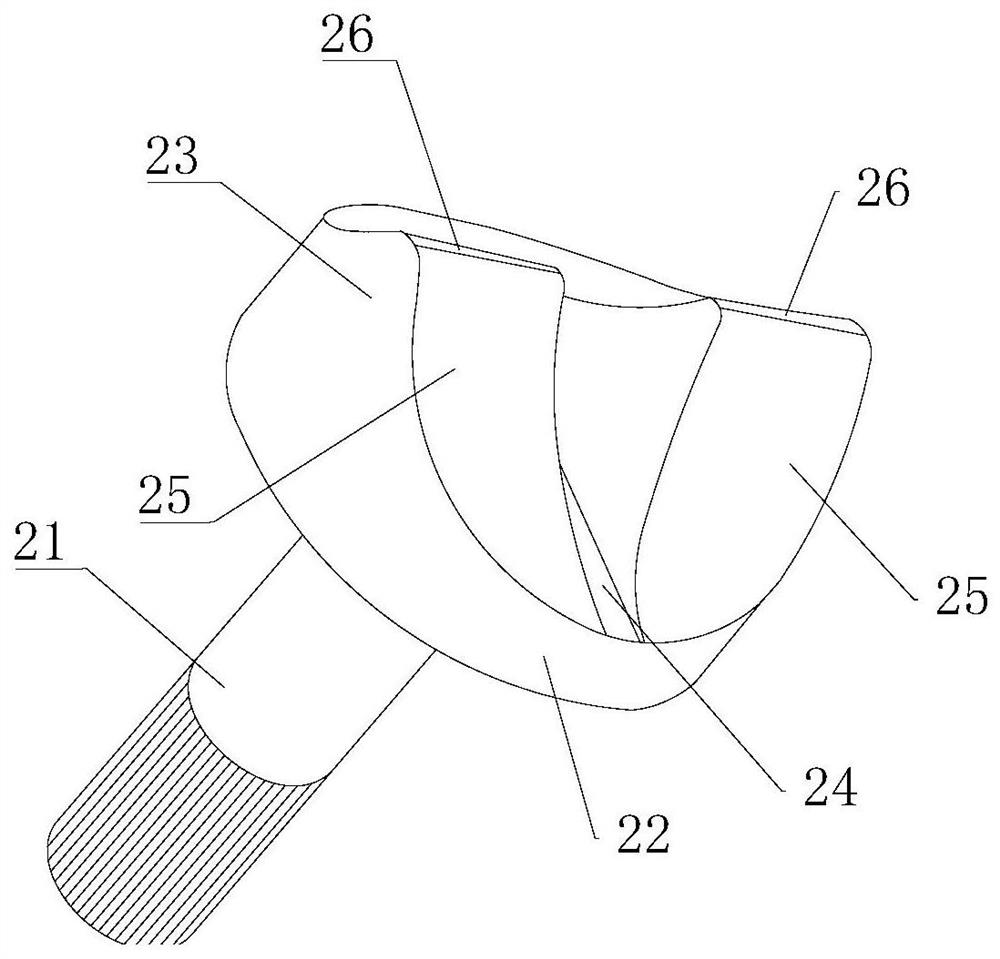

[0205] This embodiment first includes a hollow structure of the housing 1, the overall shape of the housing 1 is cylindrical, and the upper convex shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com