Drying main unit of continuous grain drying device

A kind of drying equipment and continuous technology, which is applied in the direction of dryers, dryers for static materials, drying, etc., can solve problems such as troubles, achieve convenient control, convenient drying time, and realize the effects of dumping and returning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

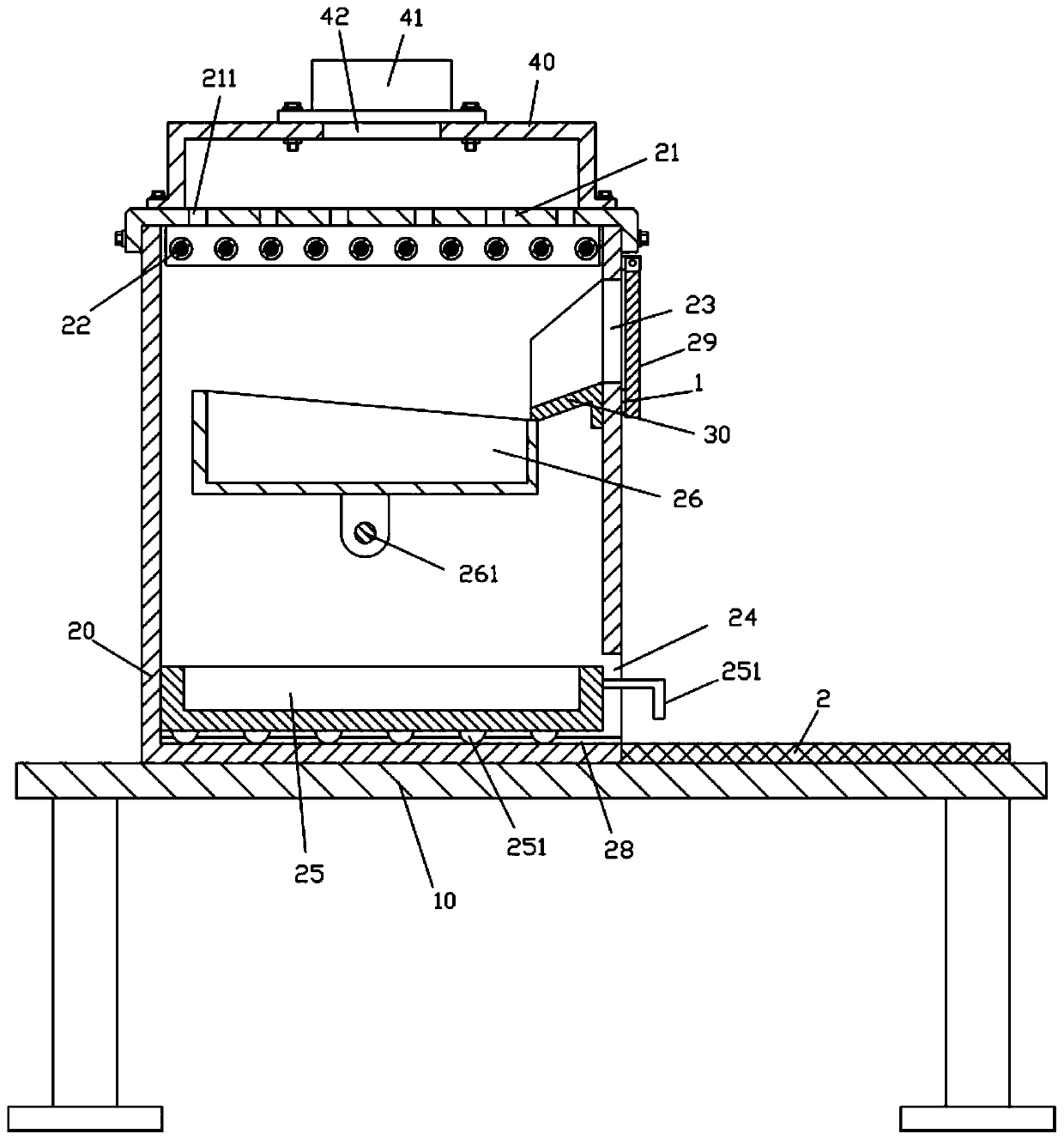

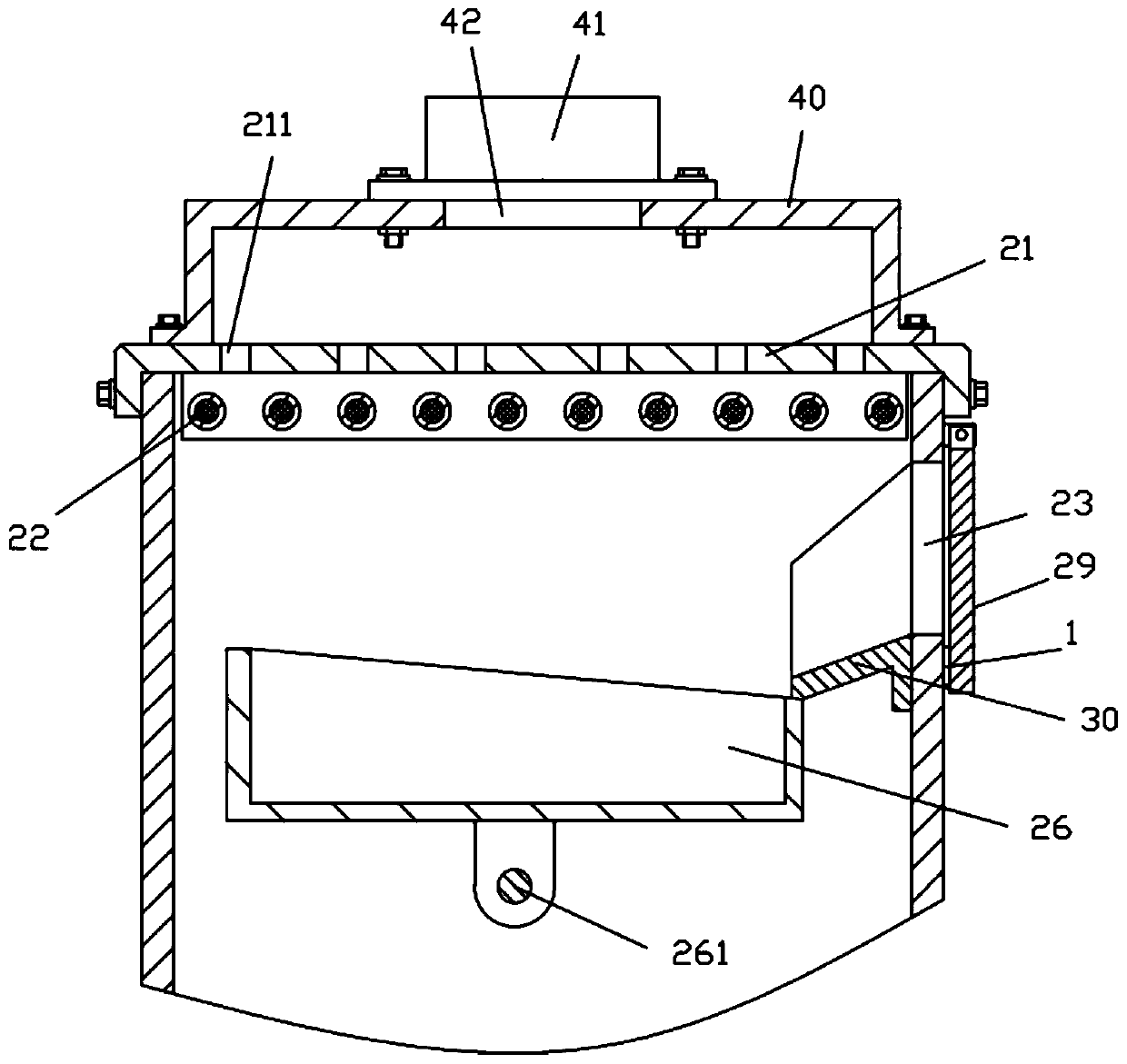

[0018] Examples, see e.g. Figure 1 to Figure 3 As shown, a drying host of a grain continuous drying equipment includes a main frame 10, a main box body 20 is fixed on the top surface of the top plate of the main frame 10, and an upper top plate 21 is fixed on the top of the main box body 20, A plurality of heating rods 22 are fixed on the bottom surface of the upper top plate 21;

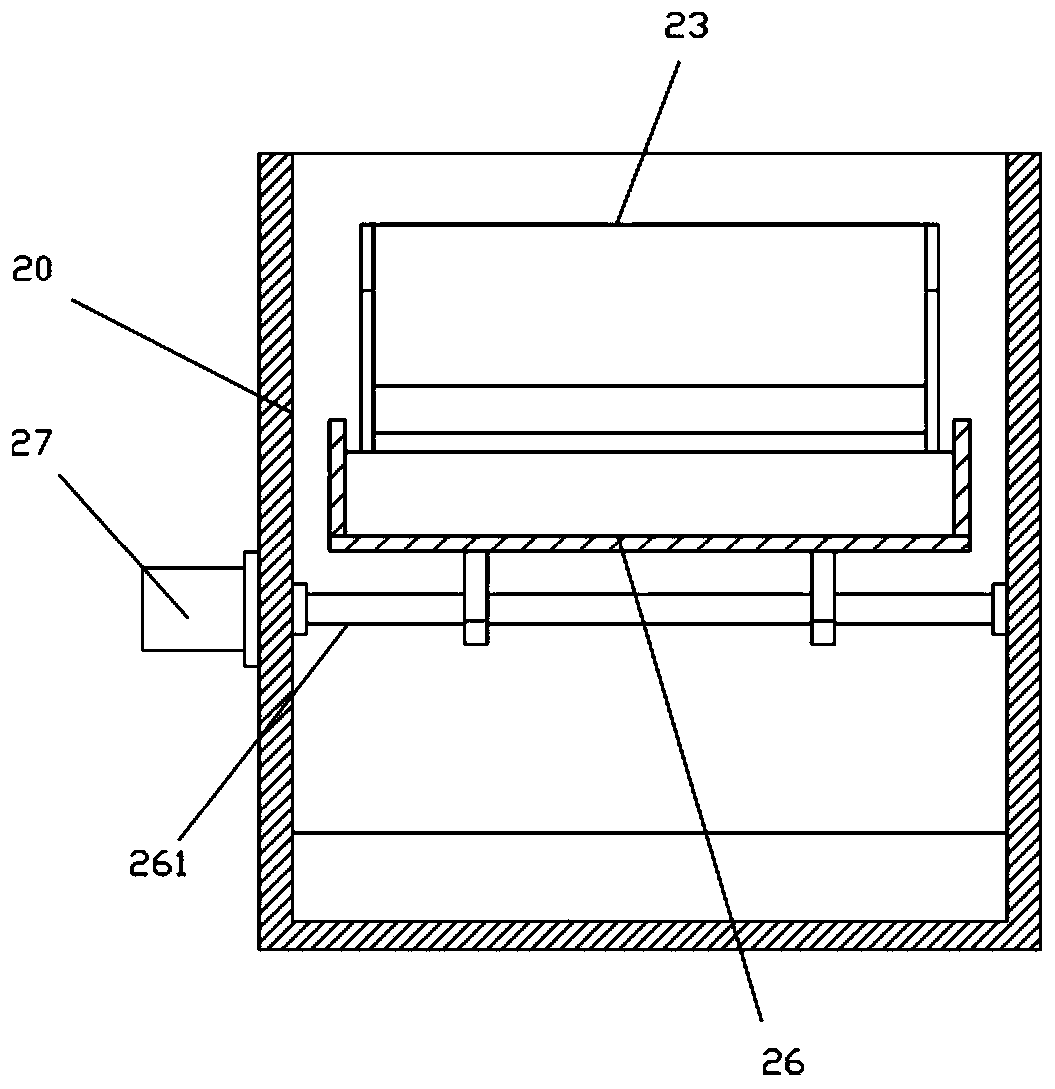

[0019] The upper part of the right side plate of the main box body 20 is formed with a feeding channel 23, the lower part of the right side plate of the main box body 20 is formed with a discharge channel 24, and the material receiving channel body 25 is located on the bottom plate of the main box body 20. On the top surface of the top surface, a handle 251 is fixed on the right side wall of the material receiving tank body 25, and the handle 251 is inserted and sleeved in the discharge channel 24;

[0020] The upper part of the main box body 20 is provided with a middle drying tank 26, the middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com