Automatic pouring system of rare earth metal casting molding machine

A technology of casting and forming rare earth metals, which is applied in the field of automatic pouring system of rare earth metal casting and forming machinery, which can solve the problems of non-dumping of rare earth metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

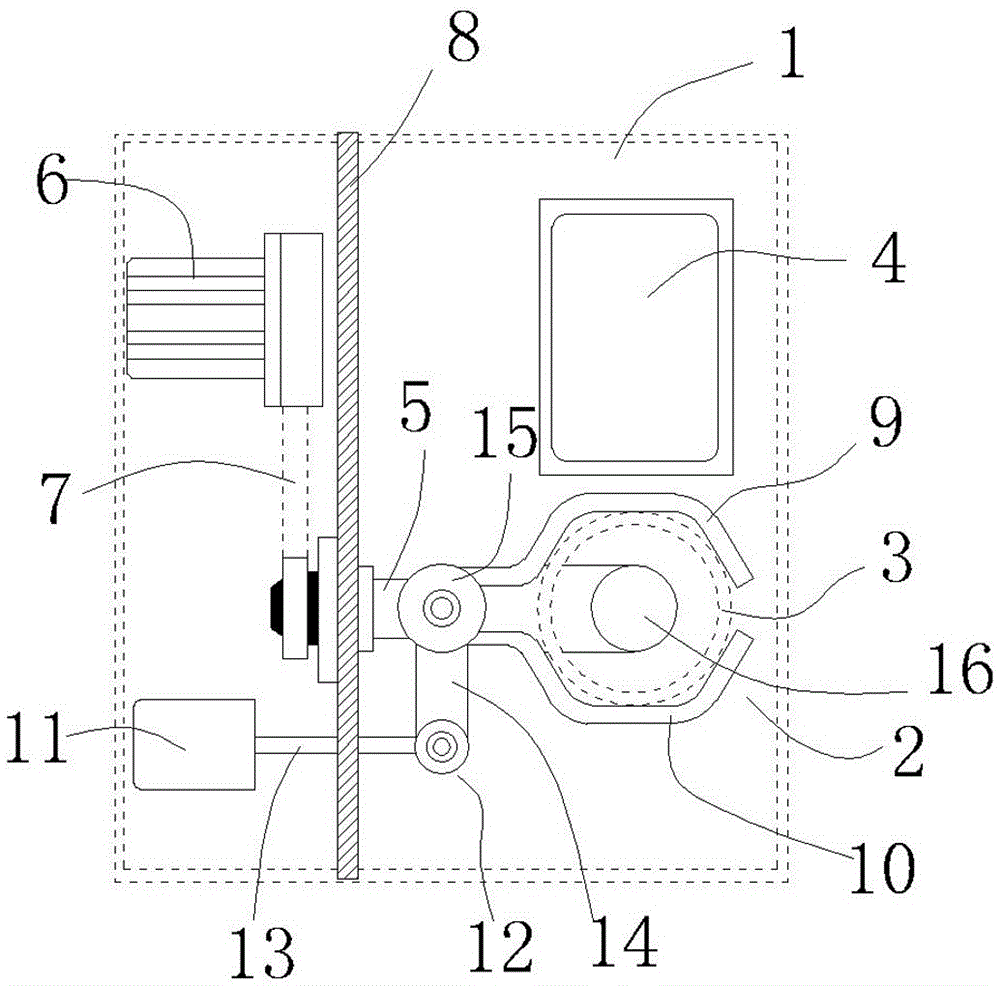

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0017] refer to figure 1 , the automatic pouring system for rare earth metal casting and molding machinery, including a base 1, and a clamping device 2 for clamping the pot body, the base 1 is provided with a dumping driving device, and the dumping driving device is connected to the The above-mentioned clamping device 2 is connected, and the tipping drive device can drive the described clamping device 2 to roll over. When in use, the electrolytic pot body 3 is clamped in the clamping device 2, and after the tipping drive device drives the clamping device 2 to roll over, the rare earth metal in the electrolytic pot body 3 is poured into the mold 4 for casting.

[0018] In this embodiment, the base 1 is provided with a rotating shaft 5, and the clamping device 2 is provided on the rotating shaft 5; the tilting driving device includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com