Neodymium iron boron waste continuous blanking device and method

A blanking device, NdFeB technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problem of inability to precisely control the amount of NdFeB waste blanking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

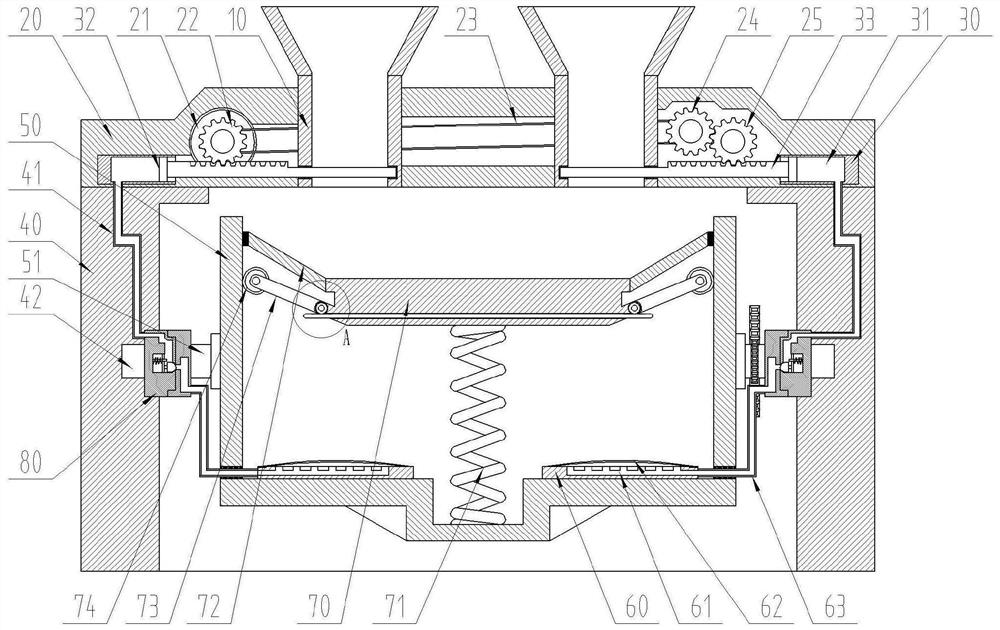

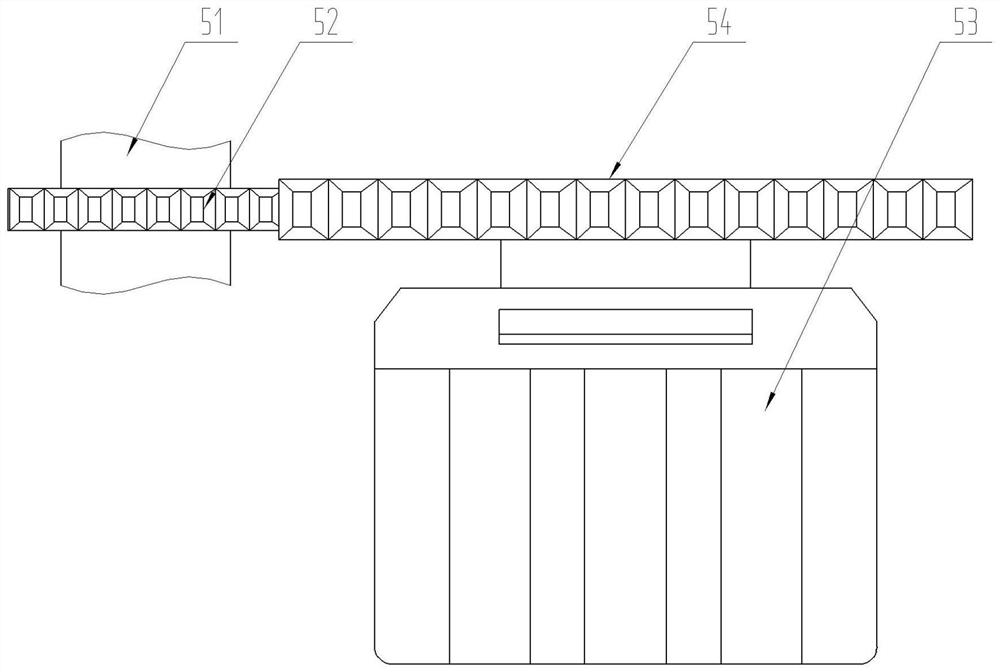

[0065] A continuous blanking device for NdFeB waste, wherein, such as figure 1 , 2 As shown, it includes: a blanking hopper 10 , a transmission mechanism 20 , a blocking mechanism 30 , a support body 40 , a suspension frame 50 , a rotator 80 , a trigger mechanism 60 , and a loading mechanism 70 .

[0066] There are at least two dropping hoppers 10 arranged along the left and right directions.

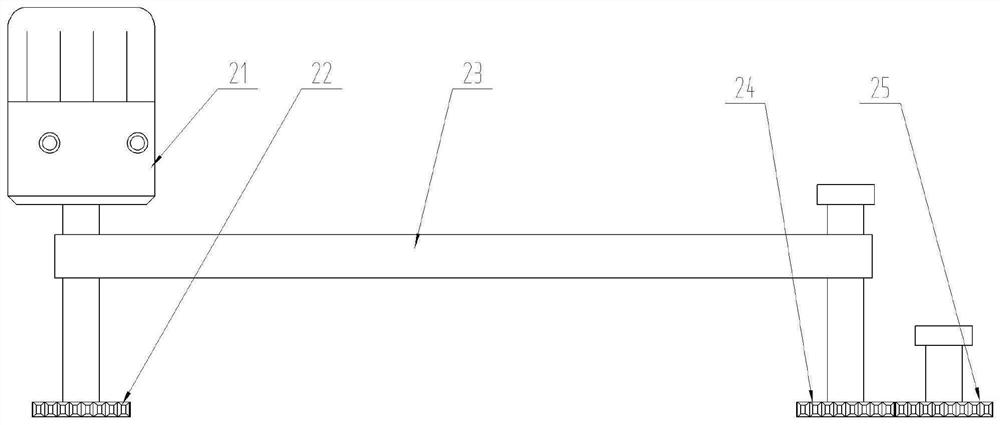

[0067] The blanking hopper 10 is embedded in a transmission mechanism 20 , and the transmission mechanism 20 has: a transmission motor 21 , a first transmission gear 22 , a second transmission gear 24 , a transmission belt 23 , and a third transmission gear 25 .

[0068] The first transmission gear 22 is connected with the power end of the transmission motor 21 . The second transmission gear 24 is disposed at the right end of the first transmission gear 22 . The transmission belt 23 connects the power end of the transmission motor 21 and the second transmission gear 24 . The third t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com