Patents

Literature

194results about How to "Will not affect work efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

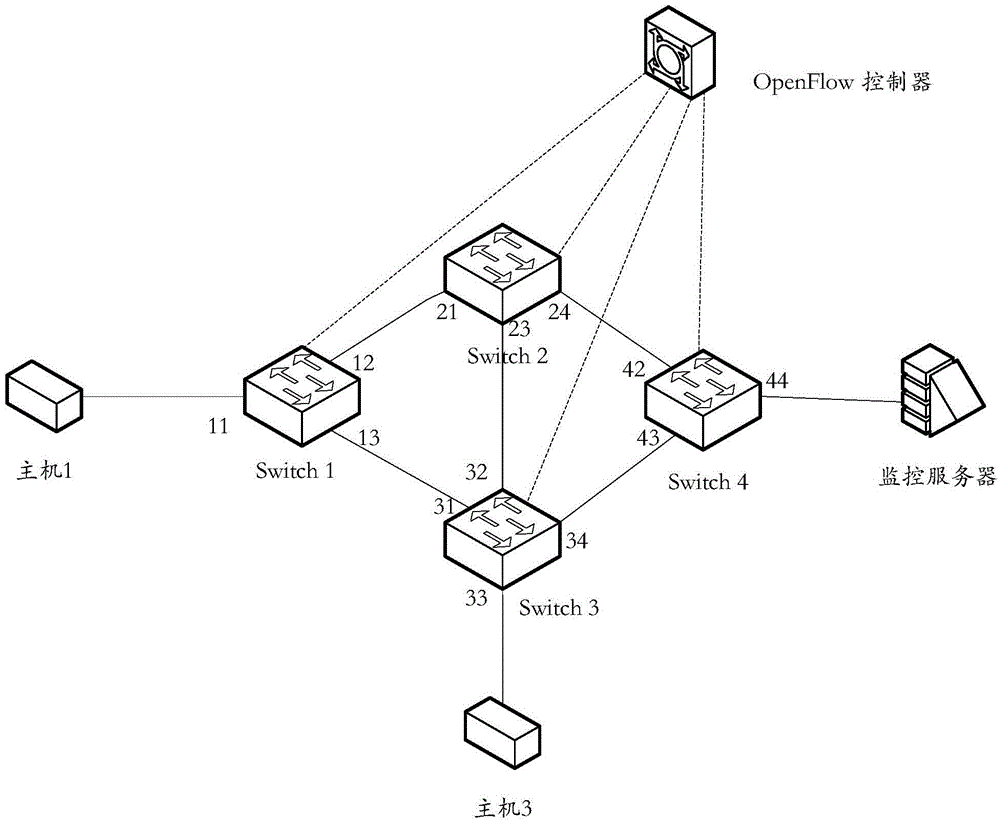

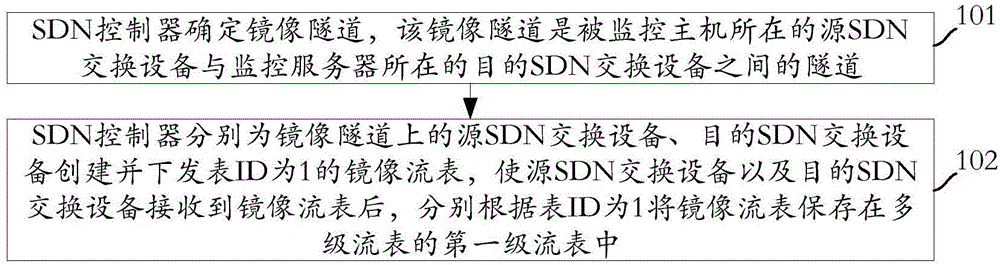

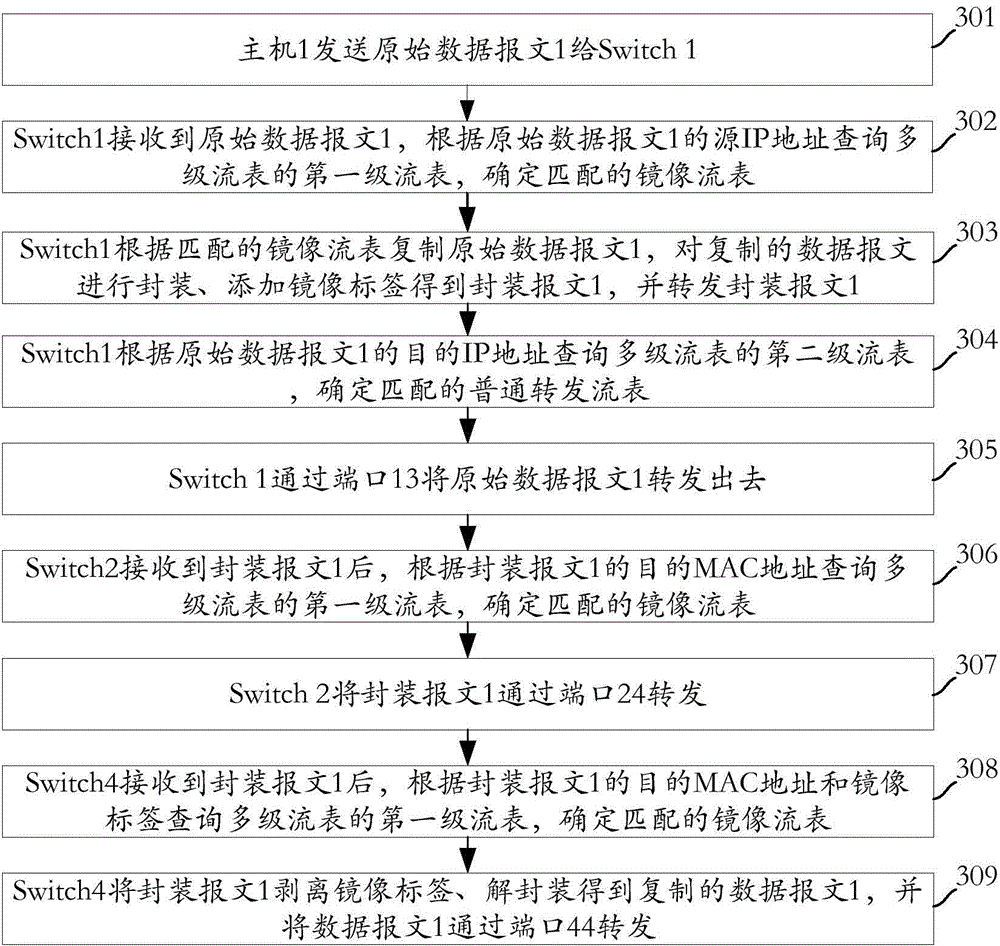

Software definition network message monitoring method, SDN controller and switching devices

ActiveCN104618194AImplement traffic monitoringWill not affect work efficiencyData switching networksSoftwareComputer engineering

The invention discloses a software definition network message monitoring method, an SDN controller and switching devices. The method includes: the SDN controller defines a mirror tunnel which is between a source SDN switching device where a monitoring host locates and a purpose SDN switching device where a monitoring server locates; and the SDN controller respectively establishes and sends a mirror flow table whose ID is 1 for the source SDN switching device and the purpose SDN switching device of the mirror tunnel. Therefore, the mirror flow table is saved in a first-level flow table of multi-level flow tables according to the fact that the table ID is 1 after being received by the source SDN switching device and the purpose SDN switching device.

Owner:NEW H3C TECH CO LTD

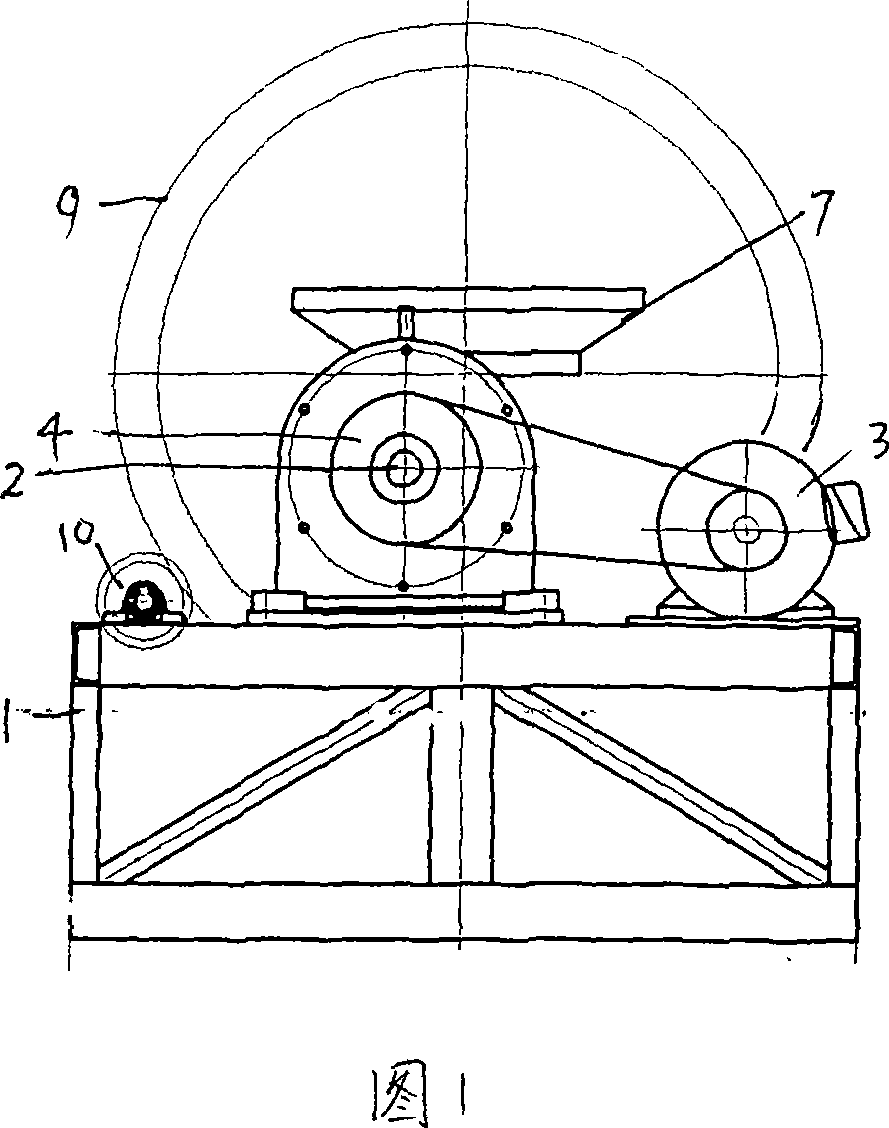

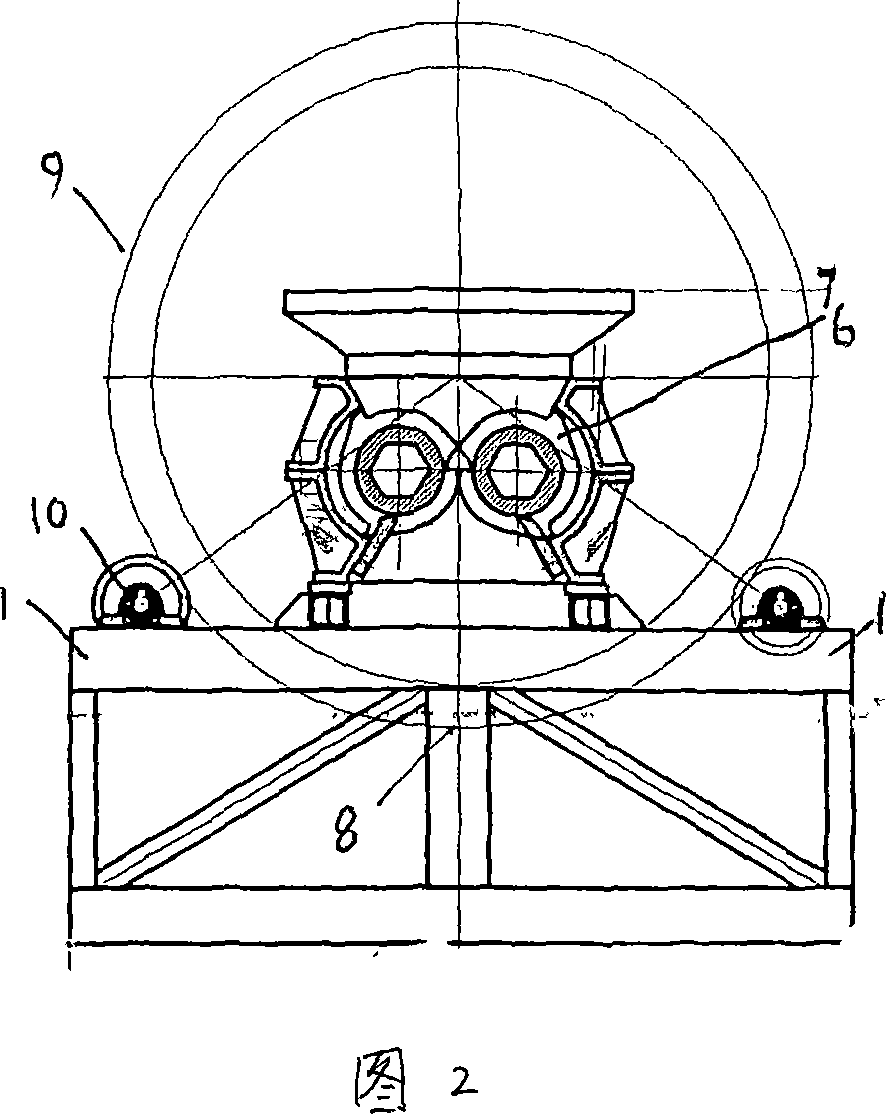

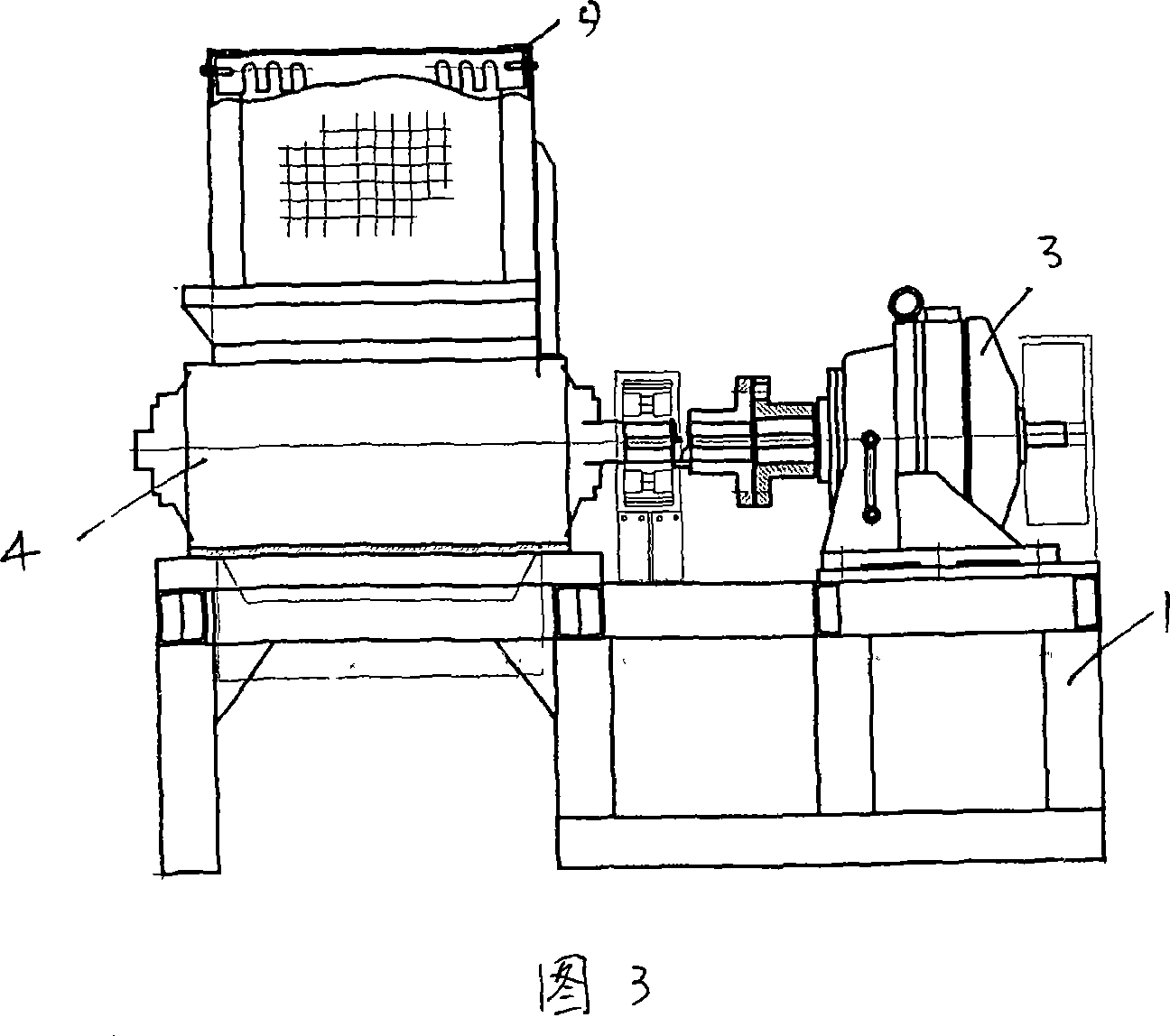

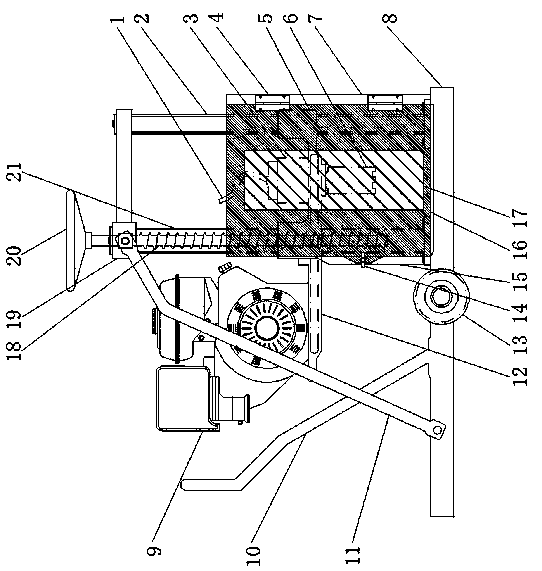

Method and apparatus for crushing waste tyre

InactiveCN101073787AReduce extrusionAvoid depolymerizationPlastic recyclingGrain treatmentsElectric machineryEngineering

The invention is concerned with a kind of rubber disintegrator. There are two roller canisters set in type of revolving on axis seat and they move inside of the roller. The axis of roller canister is fixed on frame of machine through the bearing seat, and the motor and reducer is droved by the revolving on axis seat and they move inside of the roller. The axis of roller canister is fixed on frame of mach axis of the two roller canisters. The said roller canister is made up of some slice type of drills on the axis with lengthways congruence and the drills of two roller canisters are interleaving. The roller canisters move to different directions and send the top of rubber block between the two roller canisters into the drills for cutting. The structure to exit of stuff is outer screen; with exit of stuff and the main part wrapped by the outer screen is the main body of the two roller canisters. The outer screen is a column and the side of it is the screen, the two bottom of it has circumferential rim and the bottom of each rim on the revolving axis seat is driven by transmission framework.

Owner:顾洪 +1

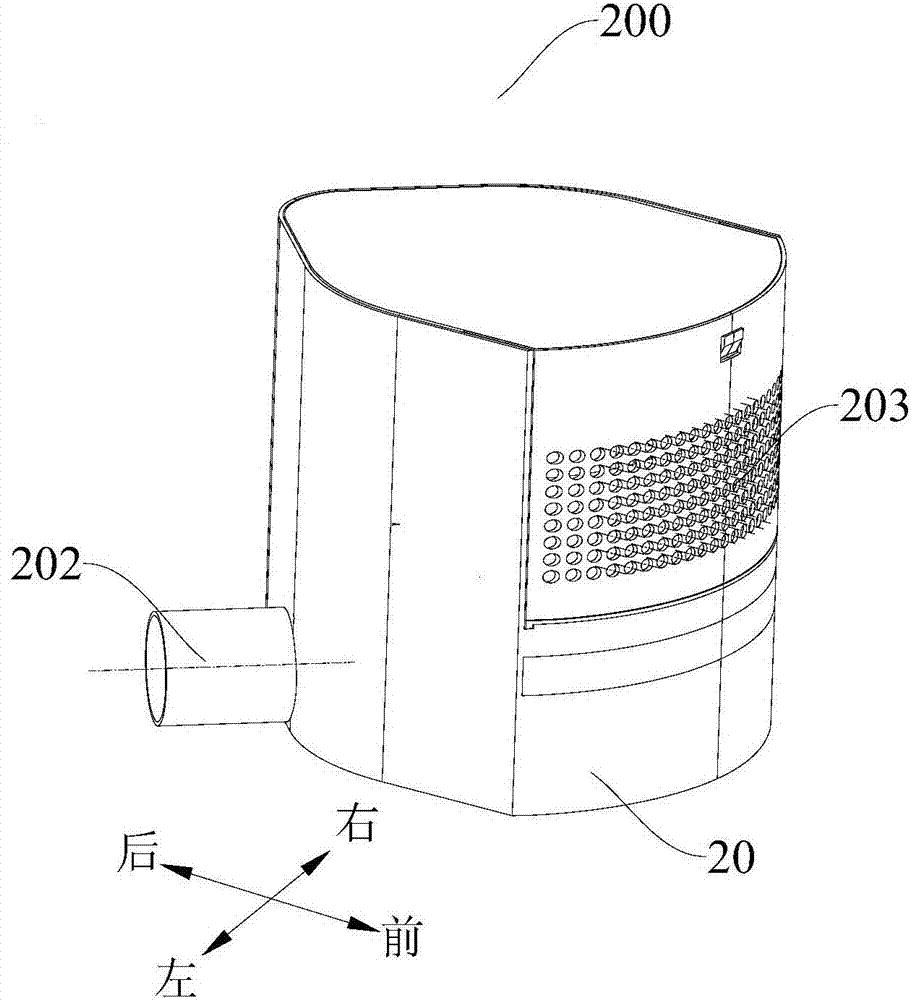

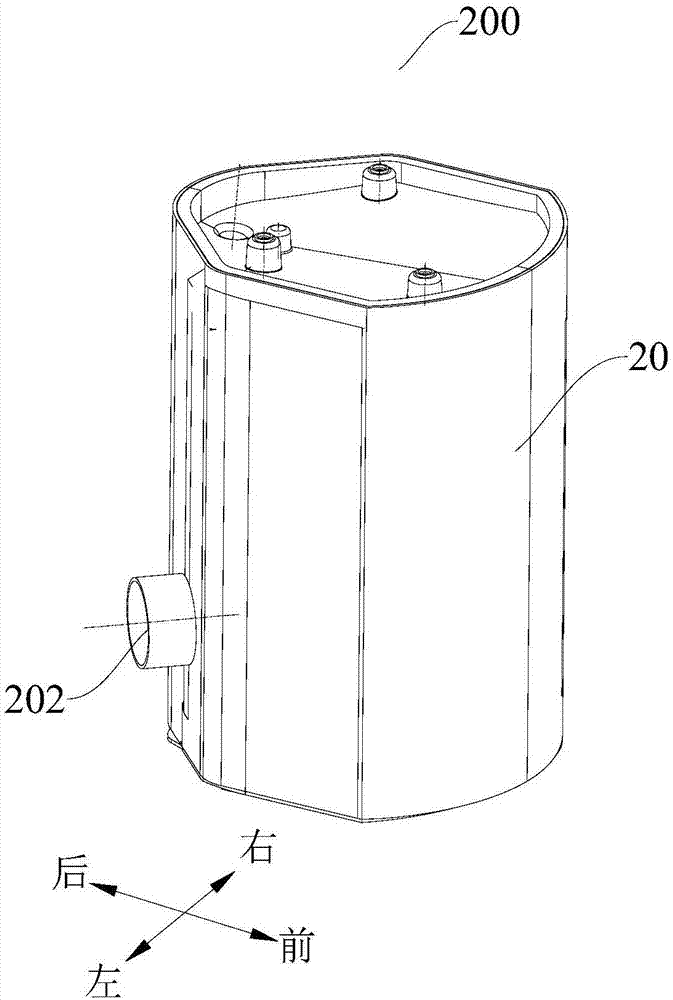

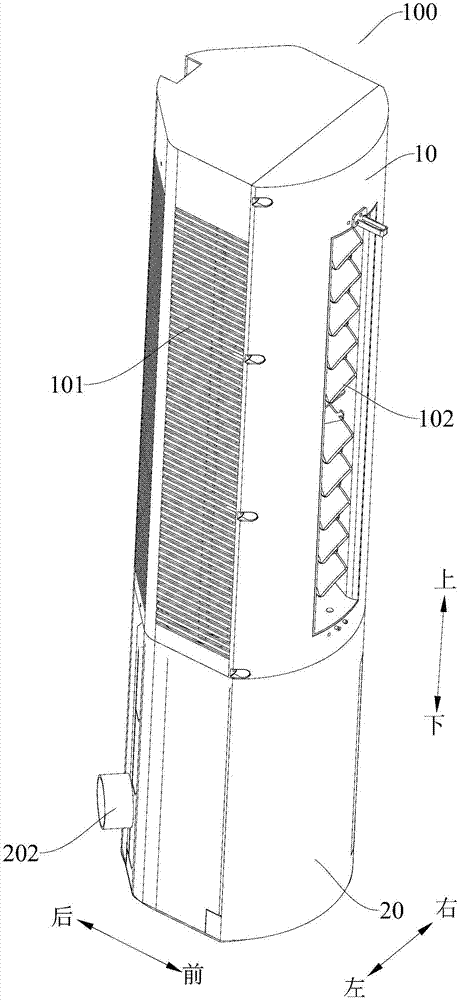

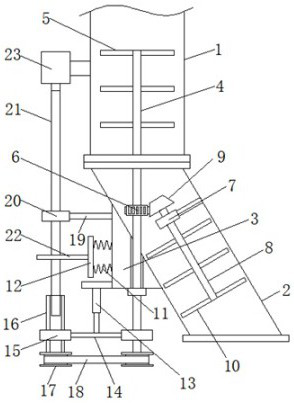

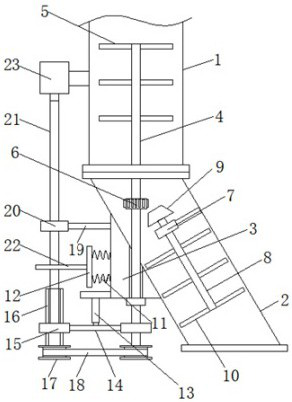

Vertical air conditioner indoor unit and air conditioner

InactiveCN107327944AWill not affect work efficiencyCompact structureMechanical apparatusLighting and heating apparatusFresh airEngineering

The invention discloses a vertical air conditioner indoor unit and an air conditioner. The vertical air conditioner indoor unit comprises a machine shell, an indoor heat exchanger, an indoor draught fan and an air processing device; the machine shell is provided with a first indoor air inlet and a first air outlet, and a heat exchange air flue communicated with the first indoor air inlet and the first air outlet is defined in the machine shell; the indoor heat exchanger and the indoor draught fan are arranged in the machine shell; the air processing device is arranged below the machine shell and comprises a shell, a humidification module and a guide draught fan, the shell is provided with a second indoor air inlet, a fresh air inlet and a second air outlet, an air processing air flue isolated from the heat exchange air flue is arranged in the shell, and the air processing air flue is communicated with the second indoor air inlet, the fresh air inlet and the second air outlet. According to the vertical air conditioner indoor unit in the embodiment, the function is complete, and the performance is good.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

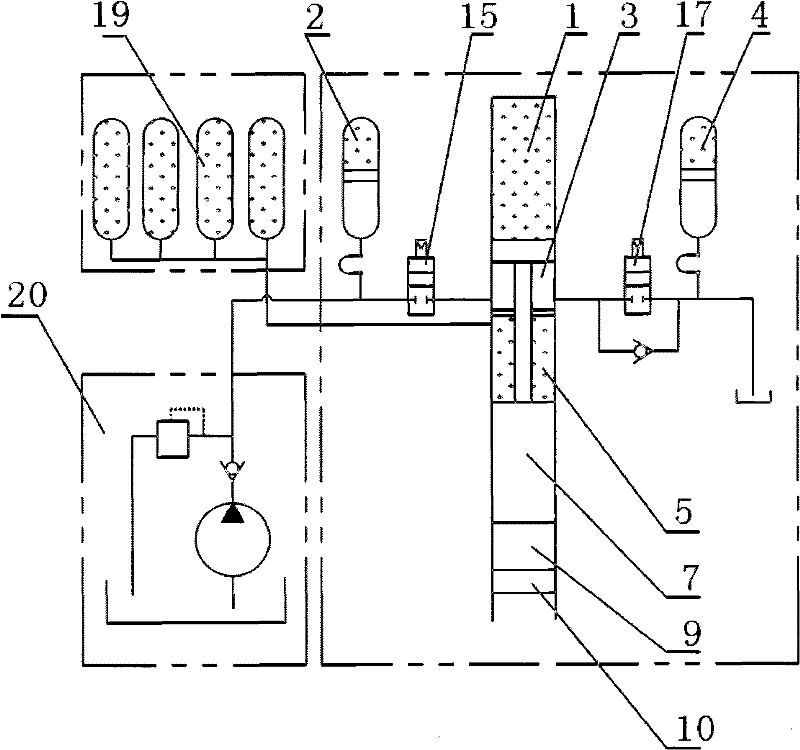

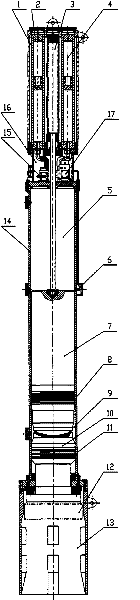

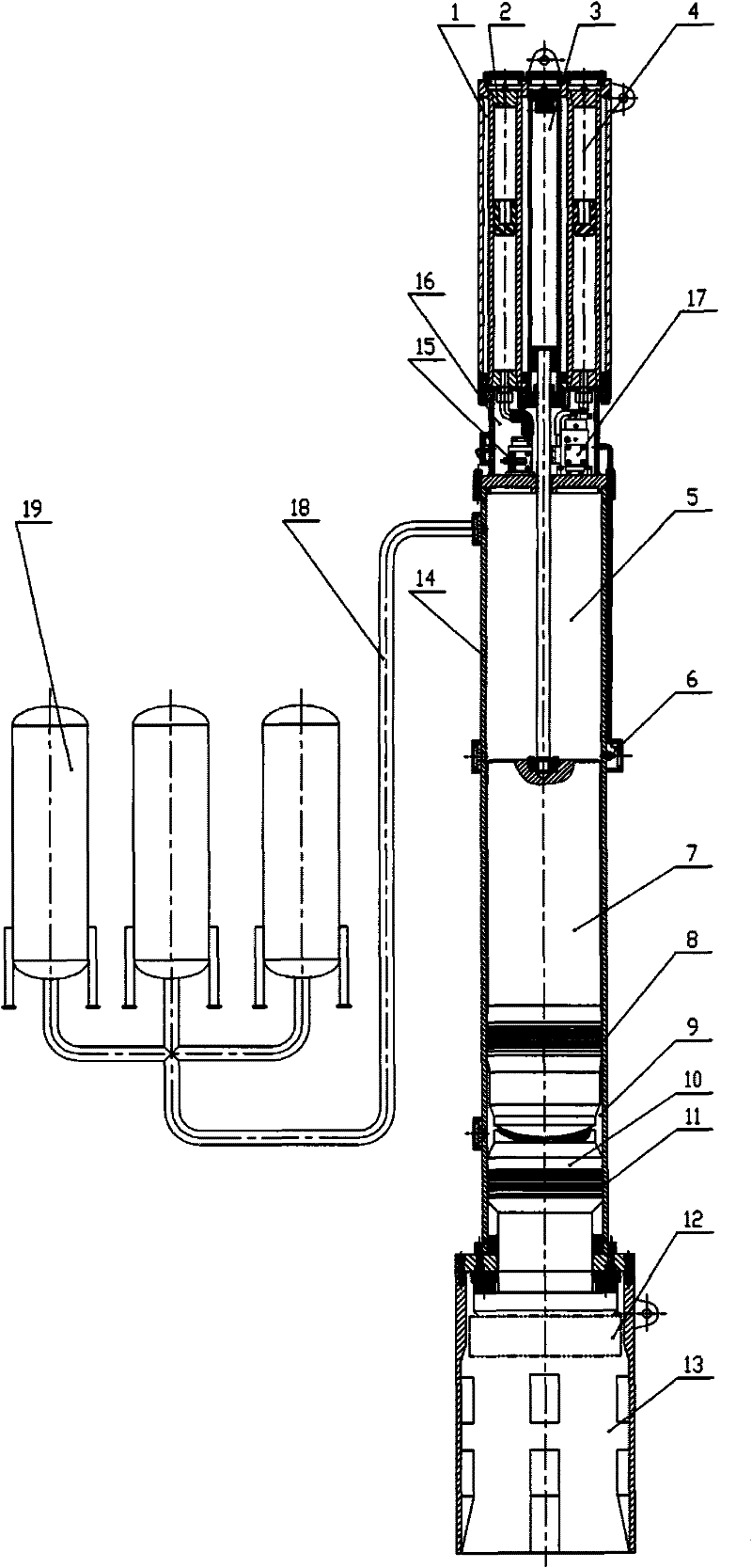

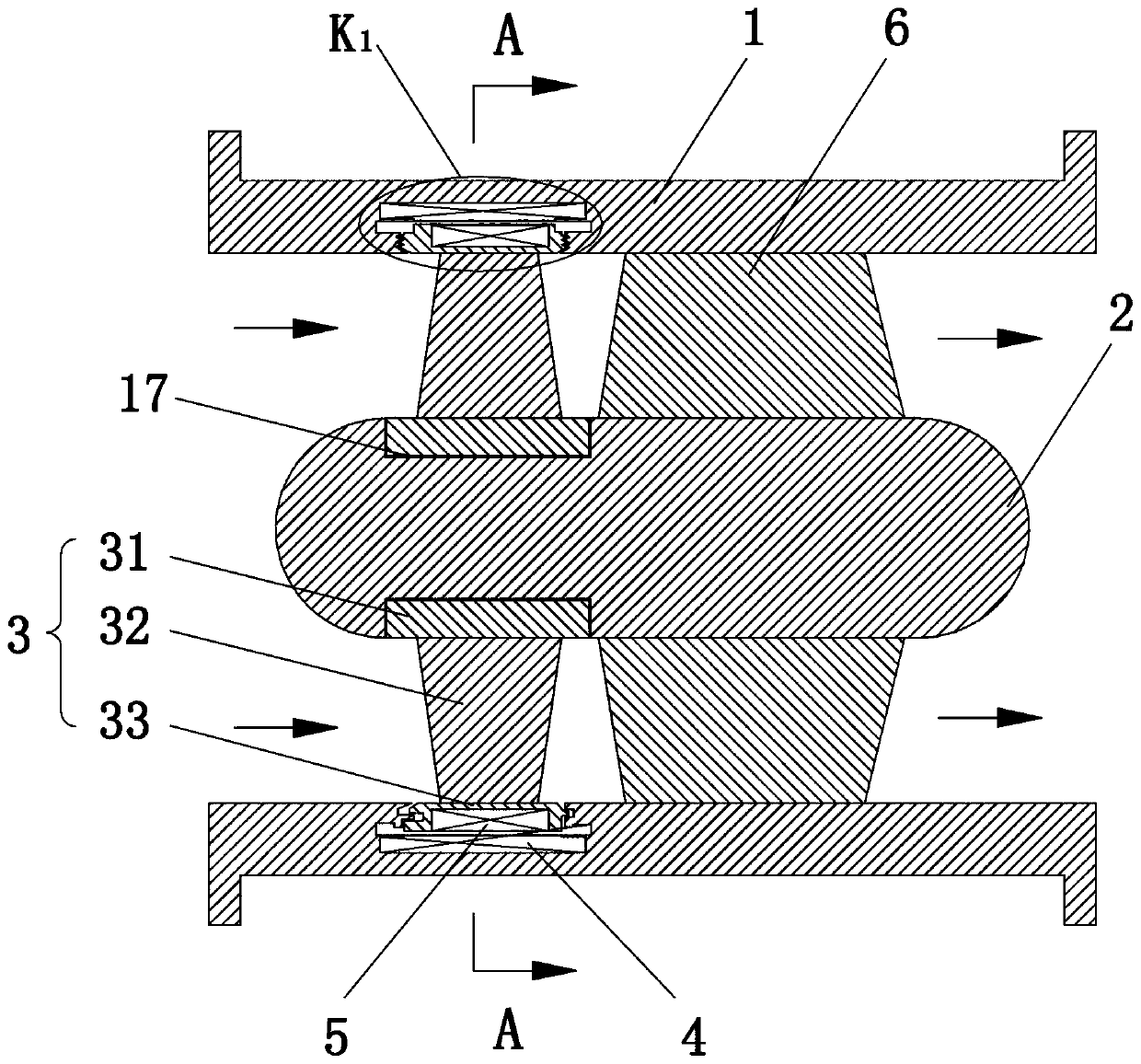

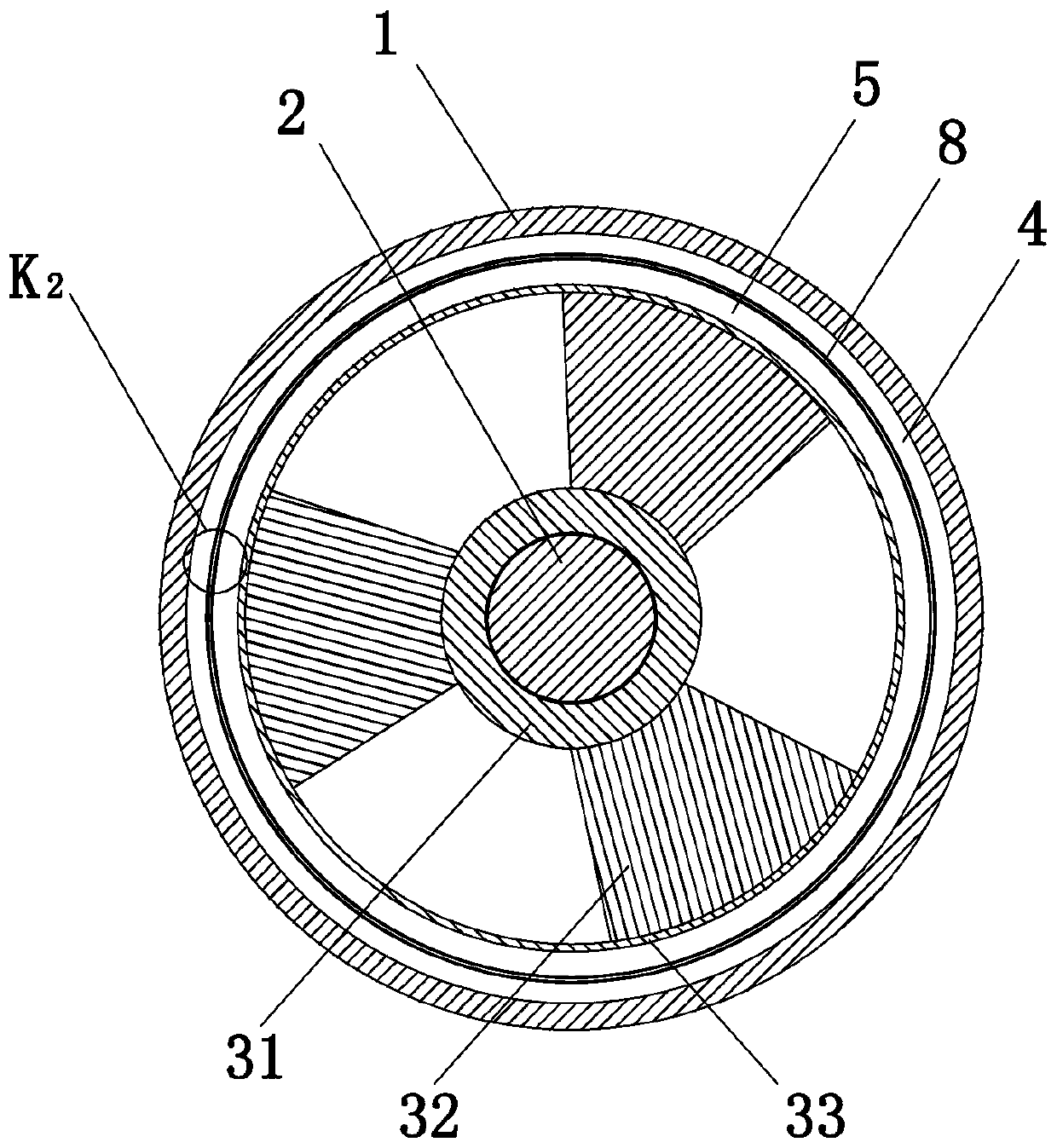

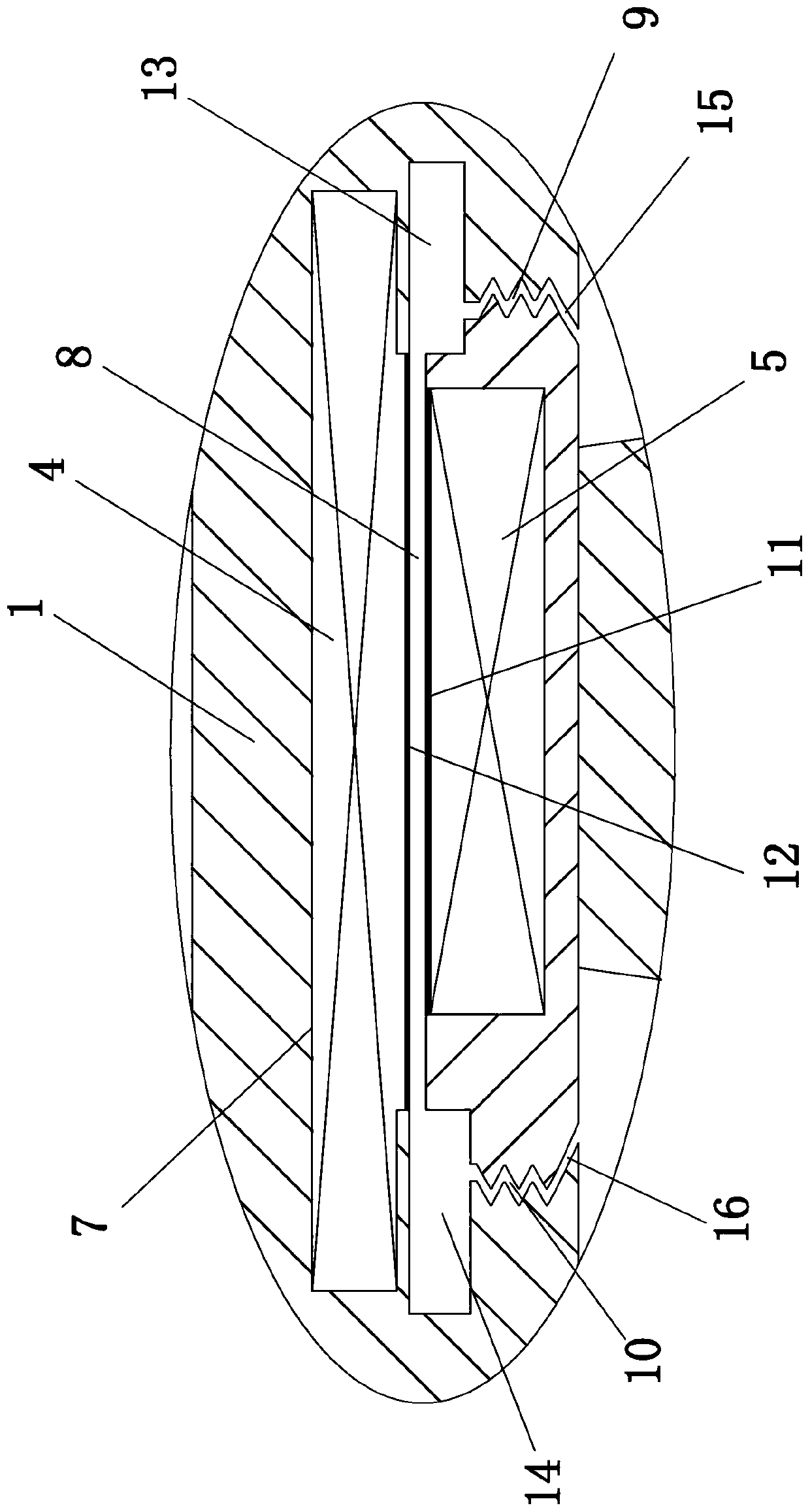

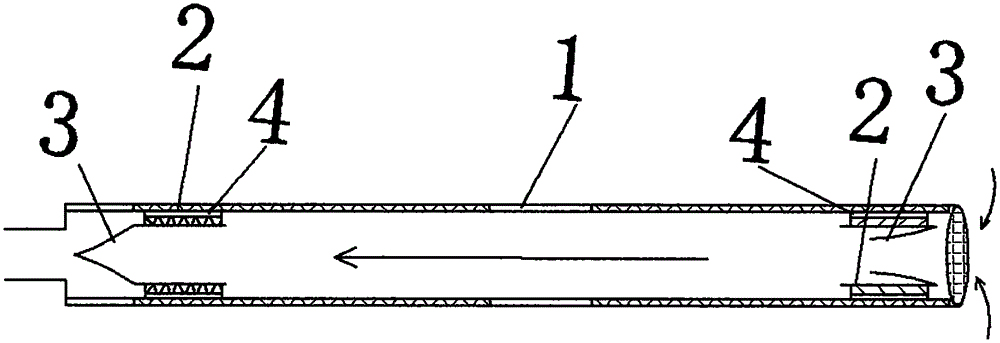

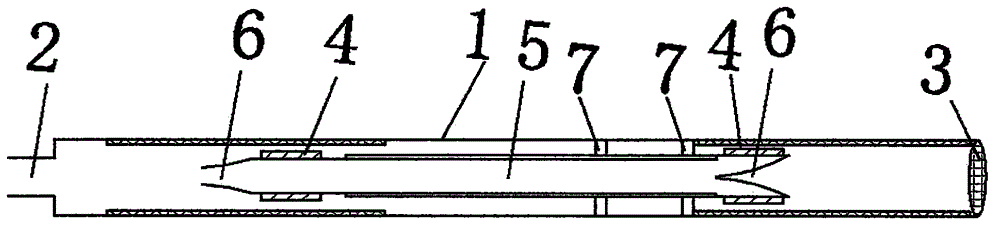

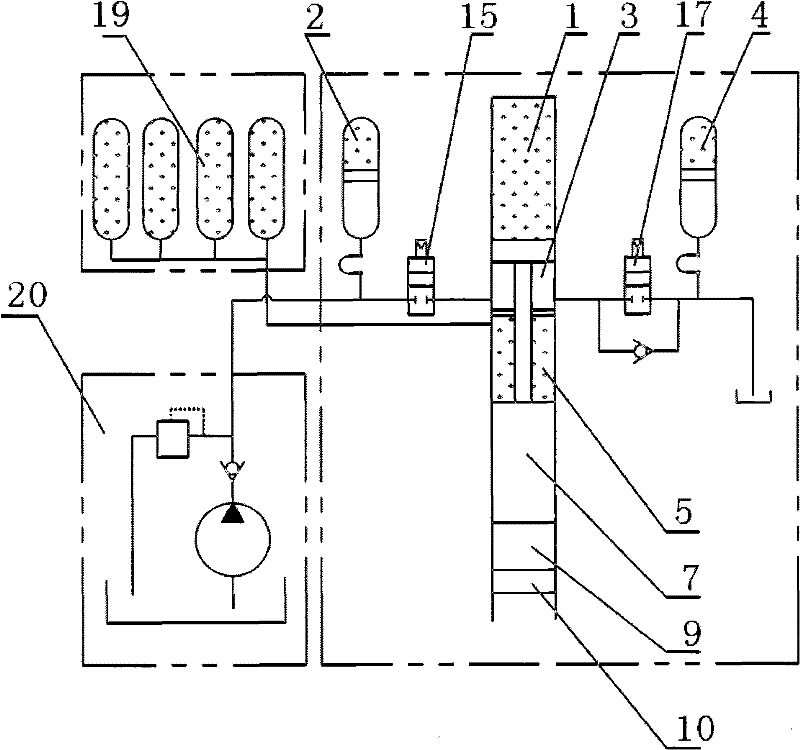

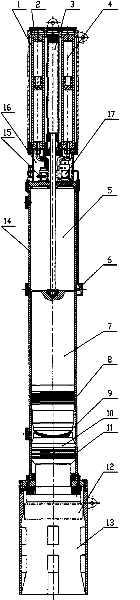

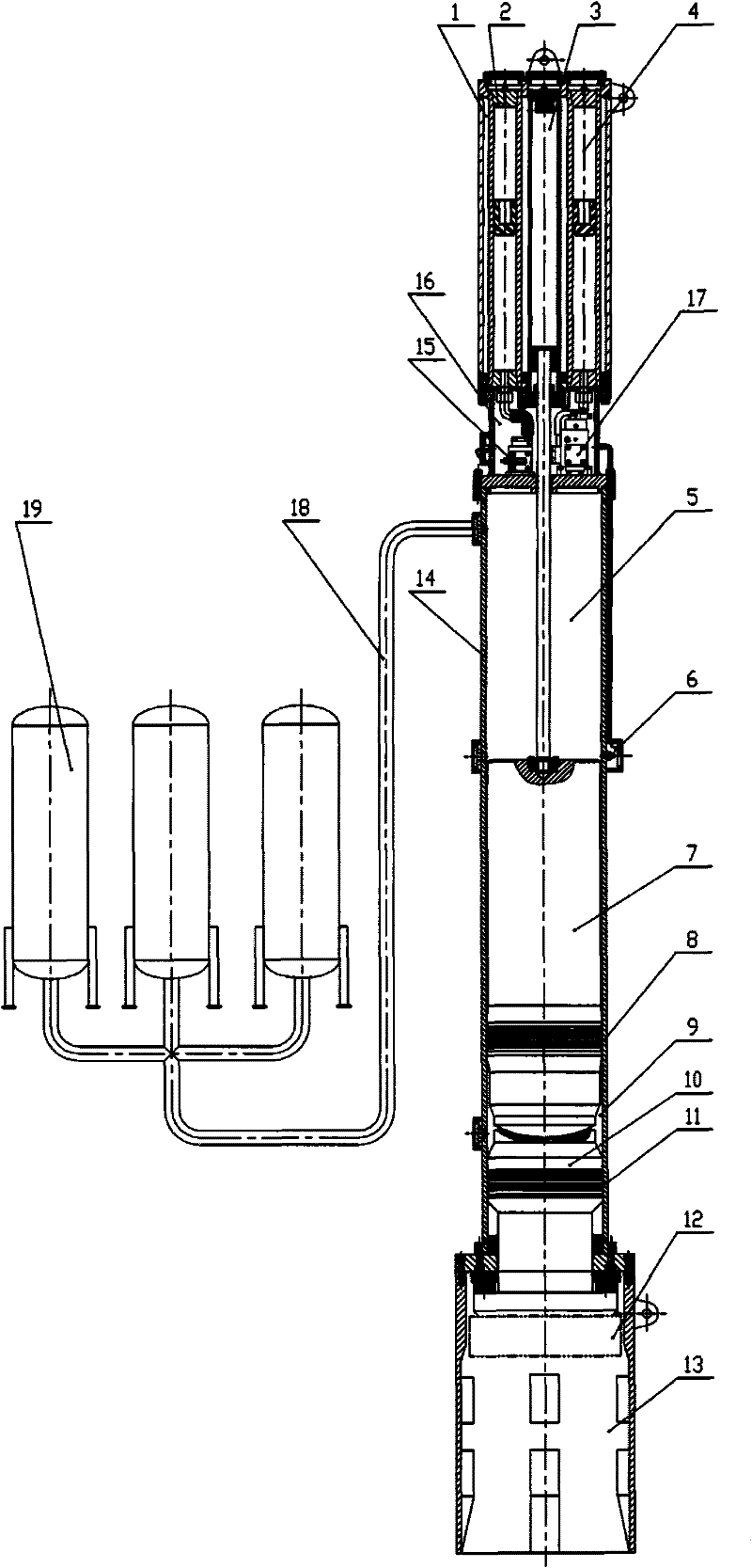

Multi-function closed cylinder type hydraulic piling hammer

InactiveCN101748730AIncreased fall accelerationWill not affect work efficiencyBulkheads/pilesEngineeringGas chamber

The invention relates to a multi-function closed cylinder type hydraulic piling hammer. The technical scheme is as follows: the multi-function closed cylinder type hydraulic piling hammer is mainly formed by connecting an upper hammer body, a middle hammer body, a lower hammer body and a bottom hammer body, wherein, the three parts of the upper hammer body, the middle hammer body and the lower hammer body respectively form the respective closed structures; the lower hammer body mainly consists of a hammer cylinder barrel, an upper hammer core, an upper hammer core sealing device and a gas chamber, the hammer cylinder barrel and the upper hammer core form the gas chamber which is positioned at the upper part of the upper hammer core, when the upper hammer core moves downward, the pressure of the gas chamber provides the downward thrust for the hammer core, and the upper hammer core sealing device and an alternate hitting block which is connected with the bottom hammer body are arranged at the bottom of the hammer cylinder barrel. The multi-function closed cylinder type hydraulic piling hammer has the benefits that the action force in the same direction of the downward motion is increased at the upper part and the lower part of the upper hammer core, thereby improving the falling acceleration of the hammer core, improving the hitting energy under the premise of not increasing the weight of the hammer body; meanwhile, due to the adoption of the closed cylinder type structure, the working efficiency can not be affected during underwater operation.

Owner:高天宝 +1

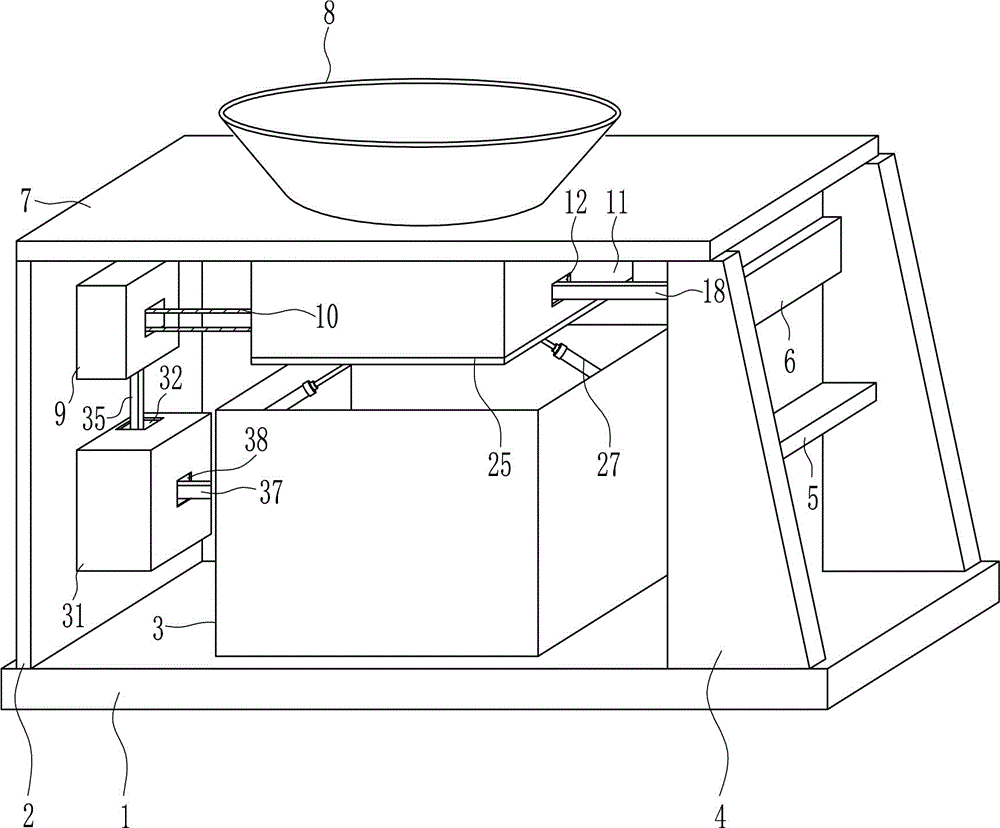

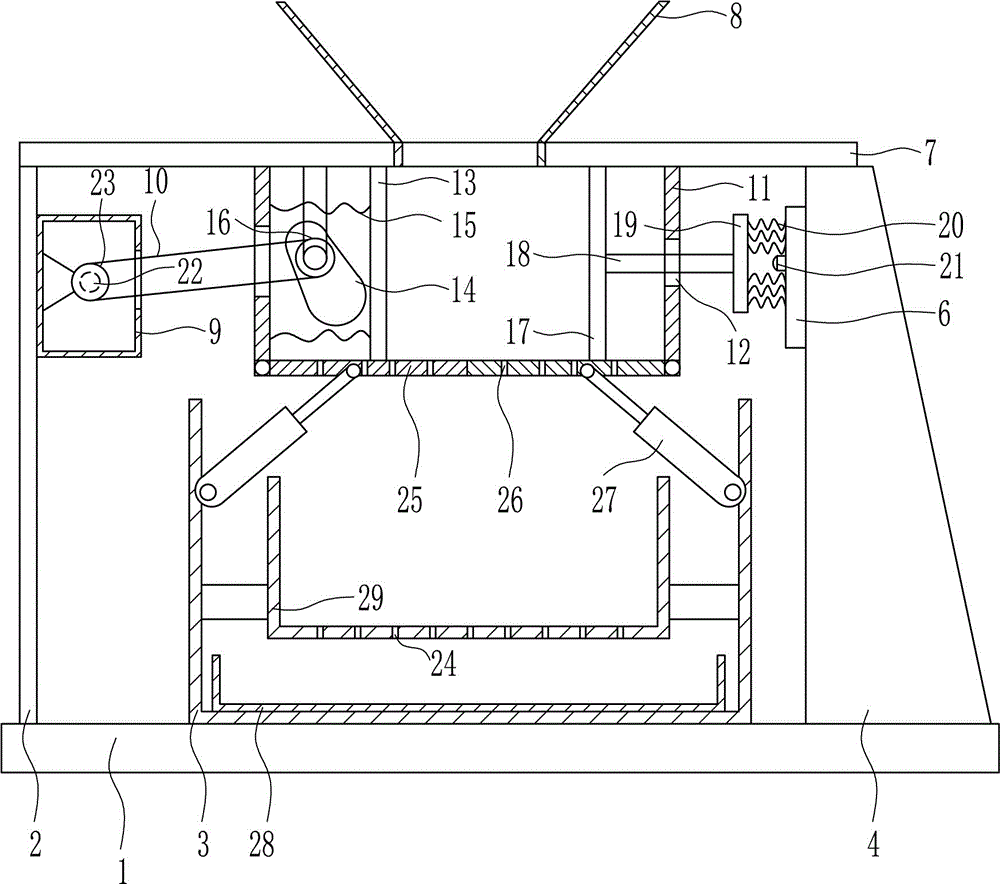

Efficient dewatering device used for rare earth waste recovery

ActiveCN106595232AEasily brokenEnsure hygieneDrying solid materials without heatRare earthEngineering

The invention relates to a rare earth dewatering device, in particular to an efficient dewatering device used for rare earth waste recovery. The efficient dewatering device used for rare earth waste recovery is good in dewatering effect, easy to operate, high in work efficiency and short in waiting time, and comprises a base plate, a left side plate, a first box, supporting plates, a first connecting rod, a mounting plate, a top plate, a discharge hopper, a second box, a flat belt, a treatment box, a first movable plate and the like. The left side plate, the first box and the supporting plates are sequentially welded to the top of the base plate from left to right, and the supporting plates are symmetrically arranged front and back. According to the efficient dewatering device used for rare earth waste recovery, a first motor is adopted for driving the first movable plate to reciprocate left and right so as to dewater rare earth wastes in the treatment box through squeezing.

Owner:滕州市产品质量监督检验所

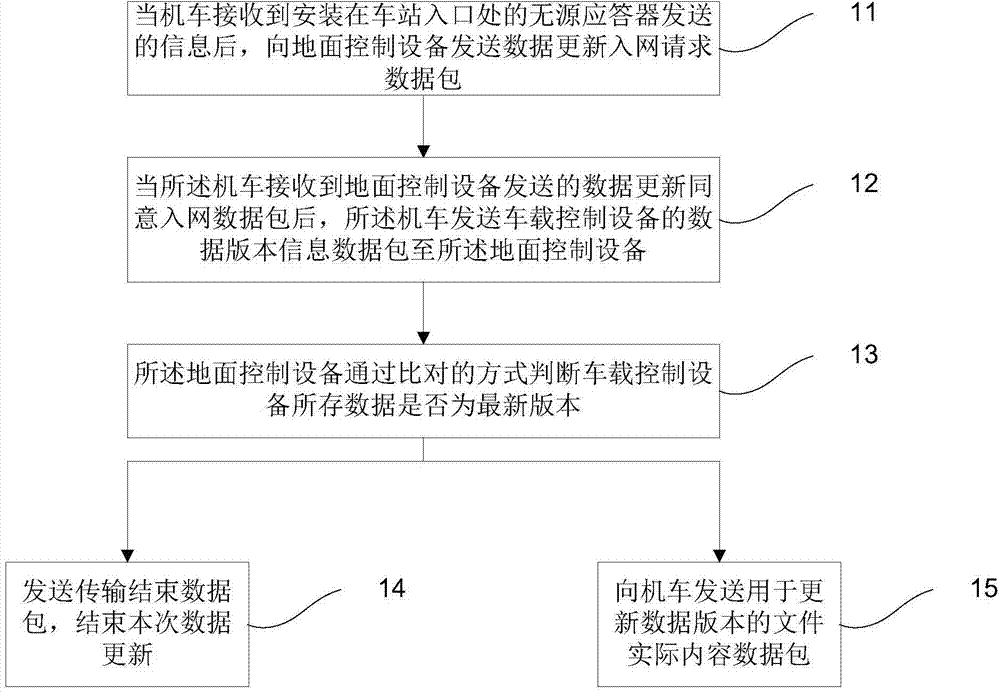

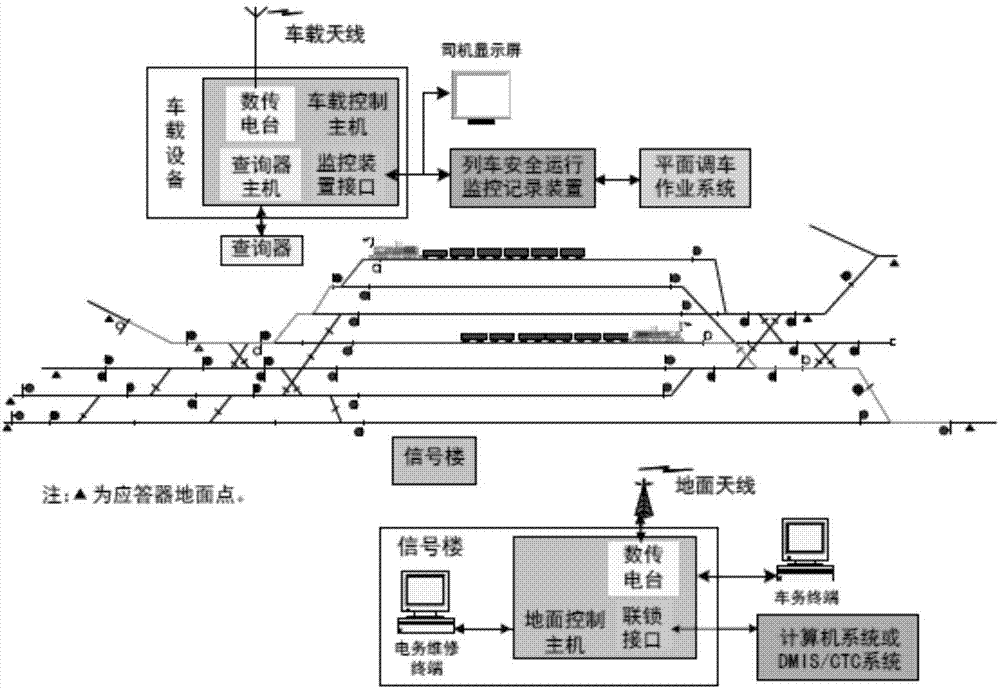

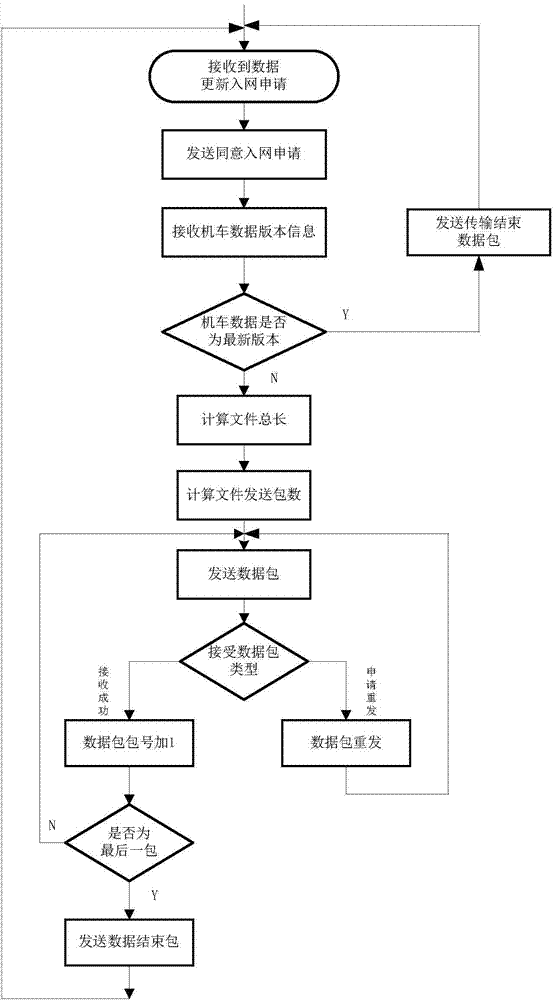

Wireless communication based vehicle-mounted data intelligent and safe updating method

InactiveCN103685534APrevent mispassPrevent leakage and other phenomenaTransmissionNetwork packetInformation data

The invention discloses a wireless communication based vehicle-mounted data intelligent and safe updating method. The method comprises the steps of: after a locomotive receives a message sent from a passive responder which is mounted at an entrance of a station, sending a data updating networking request data packet to a ground control device; after the locomotive receives a data updating networking agreement data packet sent from the ground control device, sending a data version information data packet of a vehicle-mounted control device to the ground control device by the locomotive; judging whether the data of the vehicle-mounted control device are in the latest version through a comparison way by the ground control device; if so, sending transmission ending data packet to end the data updating; otherwise, sending a file practical content data packet used for updating the data version to the locomotive. With the adoption of the method disclosed by the invention, fault caused by delayed station yard data updating of the vehicle-mounted control device is avoided, and accordingly the safety is improved.

Owner:CHINA ACADEMY OF RAILWAY SCI CORP LTD +3

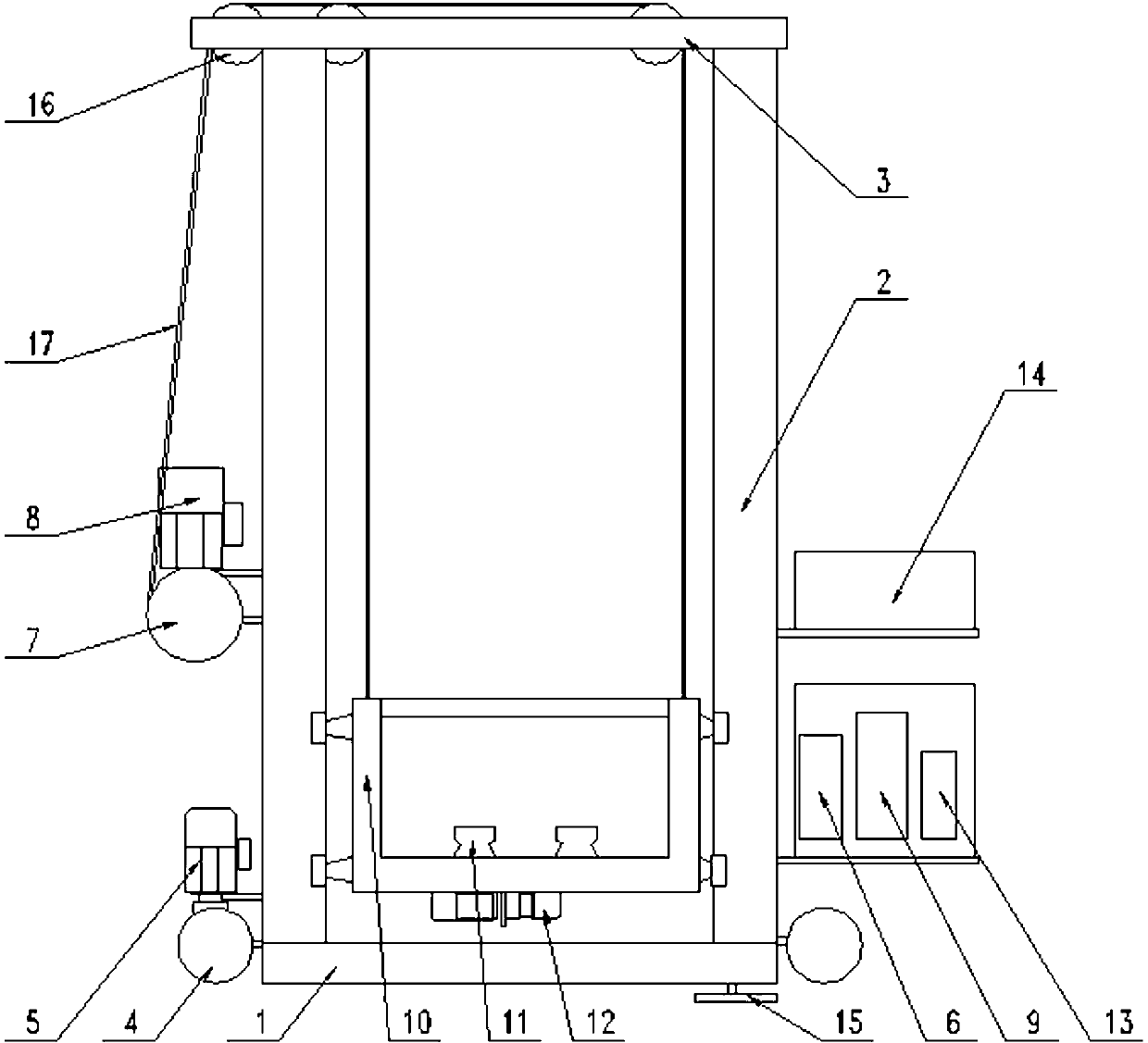

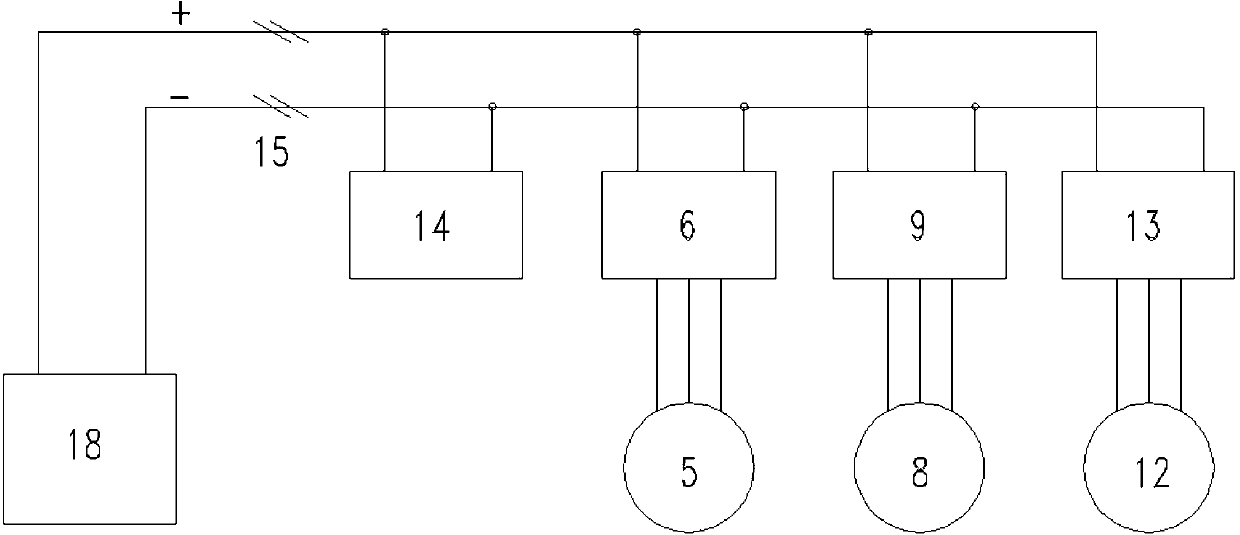

Energy-saving roadway stacker

InactiveCN102826487AWill not affect work efficiencySave powerLifting devicesSprocketMotor controller

The invention relates to an energy-saving roadway stacker; according to the energy-saving roadway stacker, a winch and a loading platform are connected through a cable or a strand chain (17) which spans on a pulley or a sprocket component (16); a walking motor controller (6) which is electrically connected with a walking motor, a lifting motor controller (9) which is electrically connected with a lifting motor and a fork motor controller (13) which is electrically connected with a fork motor are respectively arranged; the walking motor controller, the lifting motor controller and the fork motor controller are respectively connected with an electric energy storage device (14) to acquire electric energy; and the electric energy storage device is electrically connected with a ground charging system (18) through a charging boot (15) for charging. According to the energy-saving roadway stacker, the electric energy storage device is adopted to supply power, the electric energy storage device can also absorb the braking energy of the roadway stacker, so that the energy consumption can be effectively reduced and various environments with difficulty in power supply are adapted to.

Owner:YUNNAN KUNMING SHIPBUILDING DESIGN & RESEARCH INSTITUTE

Safety helmet with dust prevention and cooling function based on internet of things

ActiveCN108272159AReduce the temperatureAdd practical functionsHelmetsHelmet coversThe InternetEngineering

The invention relates to a safety helmet with a dust prevention and cooling function based on the internet of things. The safety helmet comprises a main body and further comprises a face mask, a cooling mechanism and a dedusting mechanism, the cooling mechanism comprises a cooling assembly and a jetting assembly, and the dedusting mechanism comprises a roller and two movable assemblies. By means of the safety helmet with the dust prevention and cooling function based on the internet of things, through the cooling mechanism, heat inside the safety helmet can be absorbed and taken away, thus thetemperature inside the safety helmet is lowered, the wearing comfort of workers is improved, the body fatigue of the workers is mitigated, cooled air is made full use of for dedusting, dust is prevented from covering the surfaces of the safety helmet and the face mask, thus the vision is not blurred, and the respiratory tract and the eyes of the workers are not influenced; through the dedusting mechanism, the surface of the face mask keeps clean, the visual effect is improved, the workers conveniently observe the surrounding environment during work, and the practicability and the functionality of the safety helmet are improved.

Owner:HUNAN KANGDEJIA FORESTRY TECH CO LTD

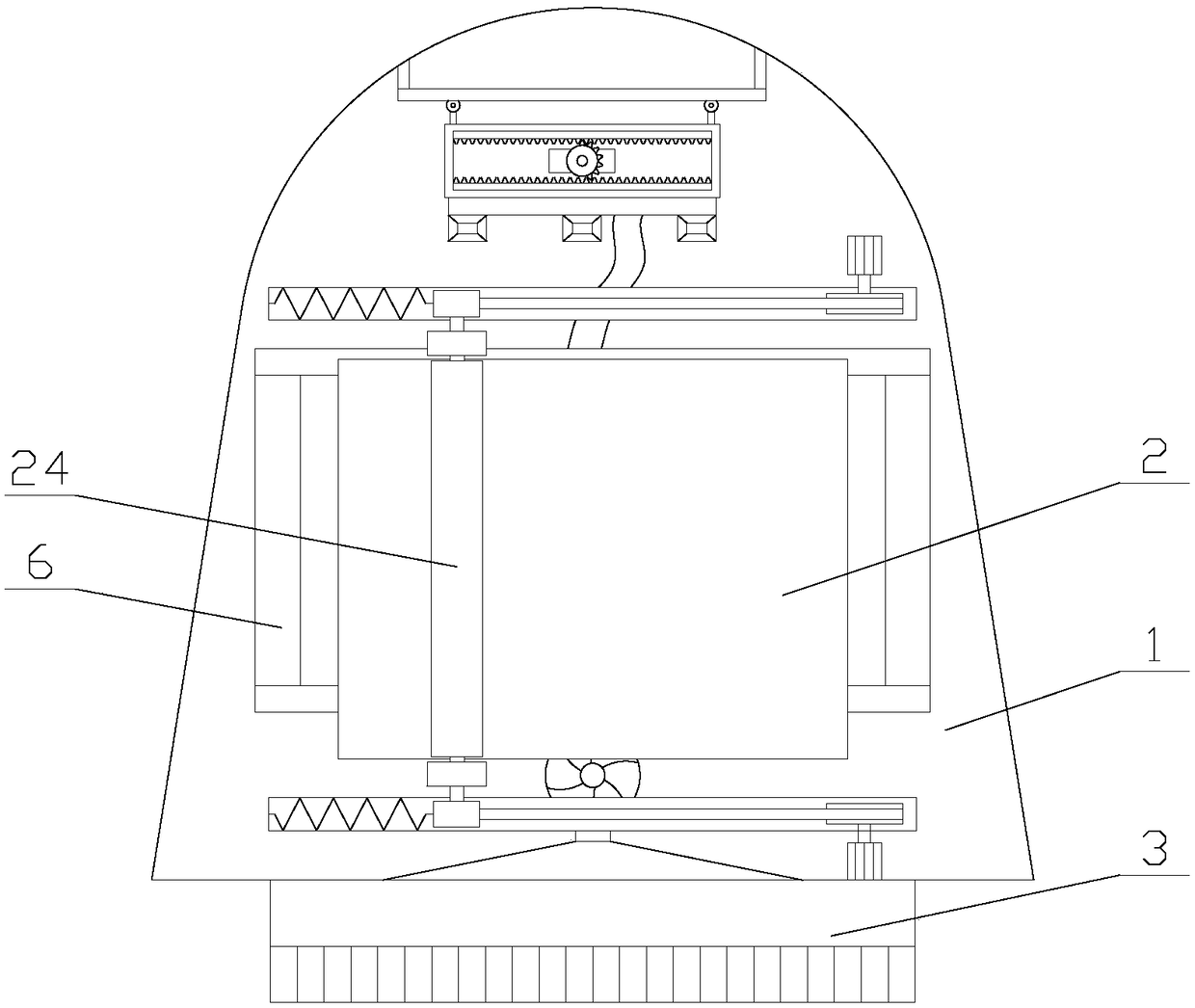

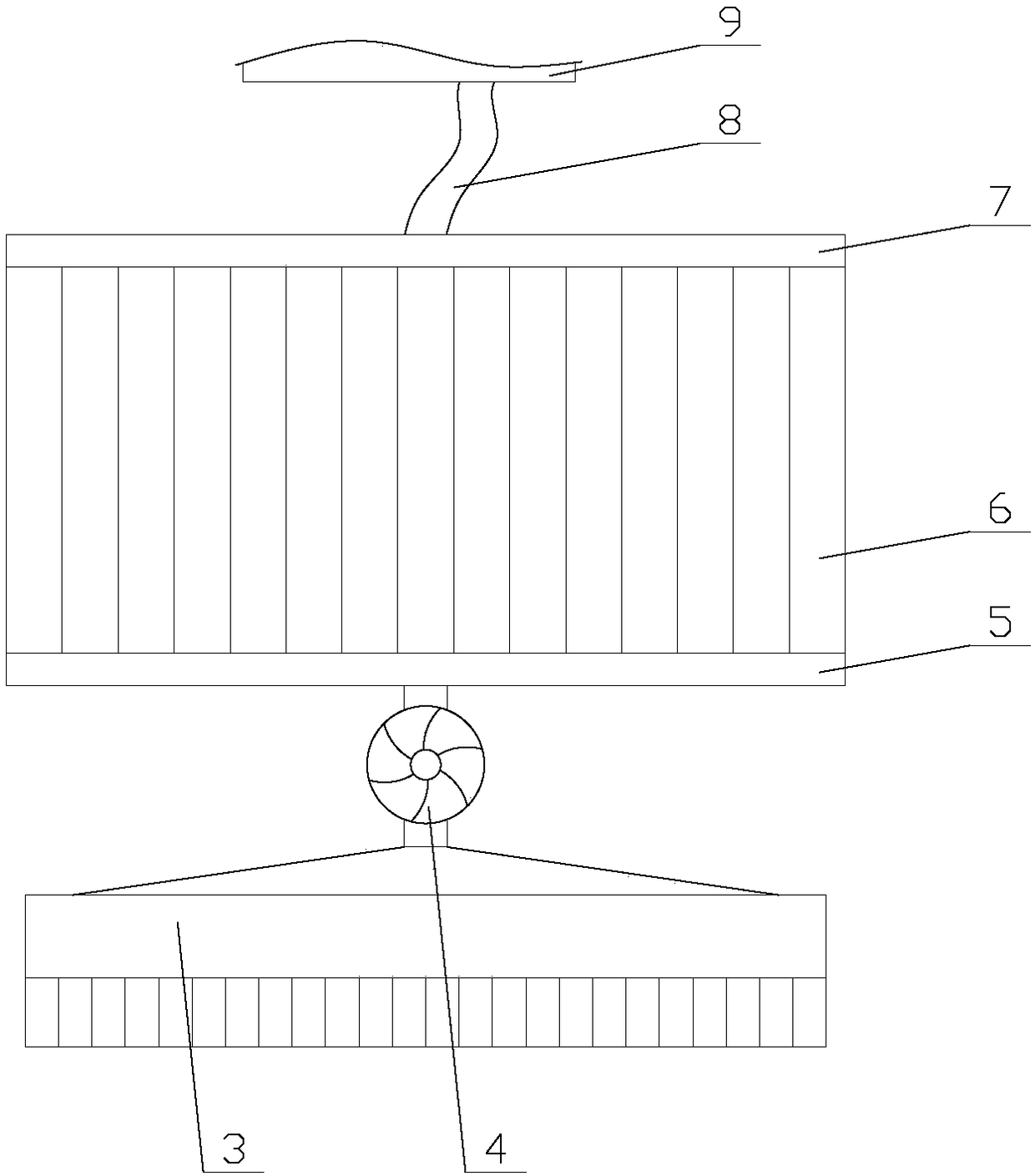

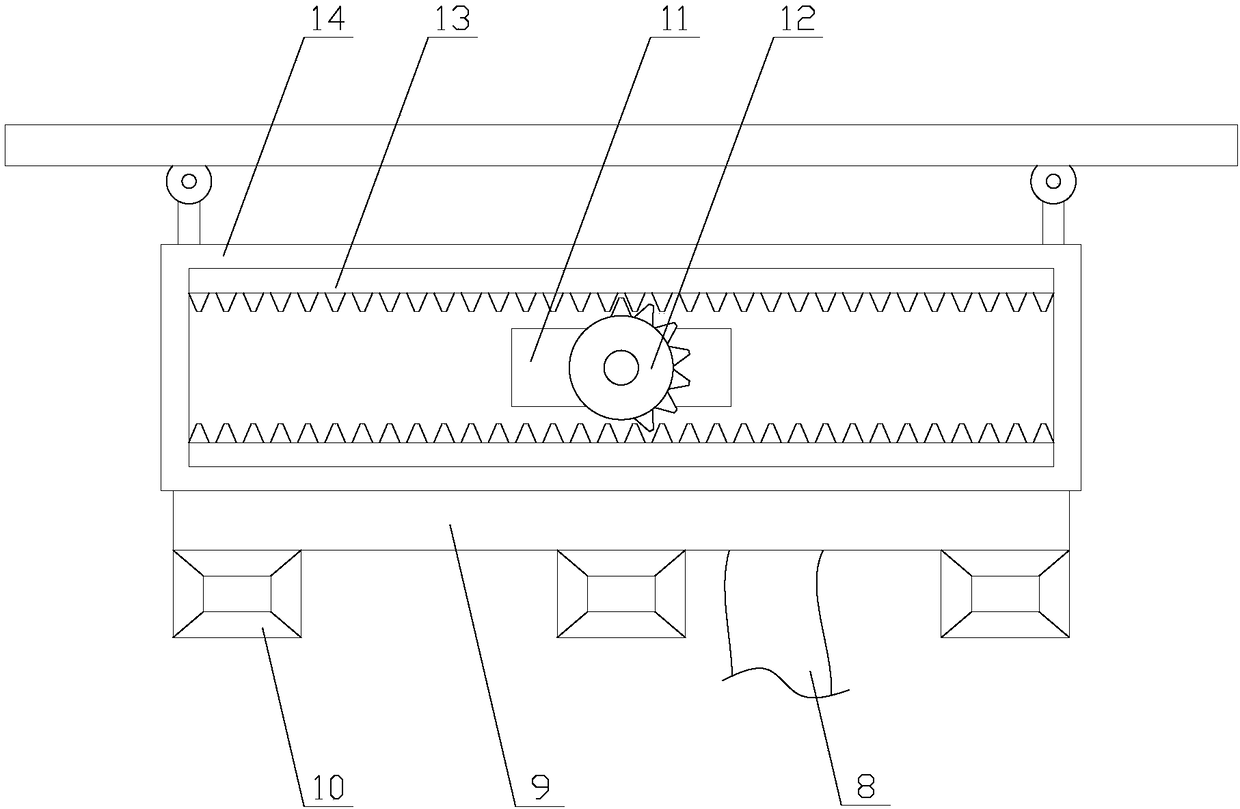

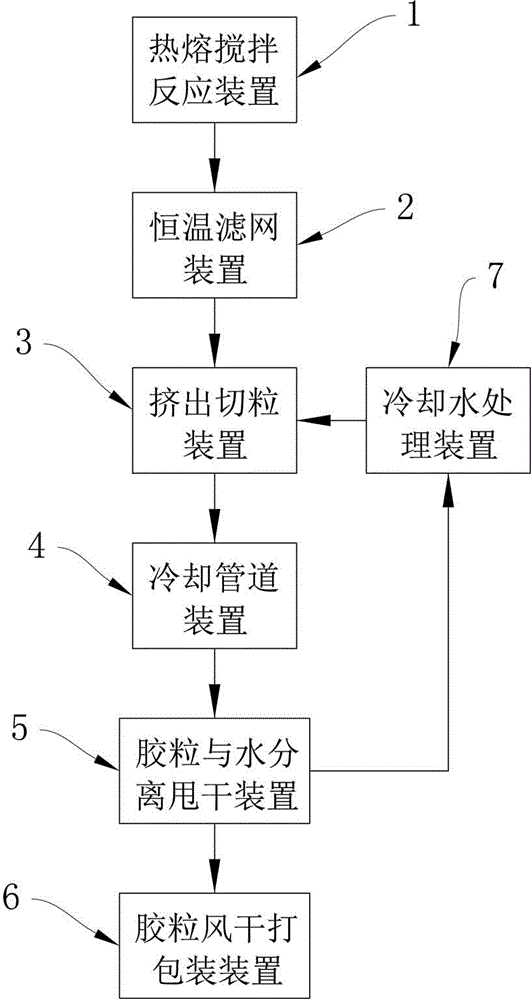

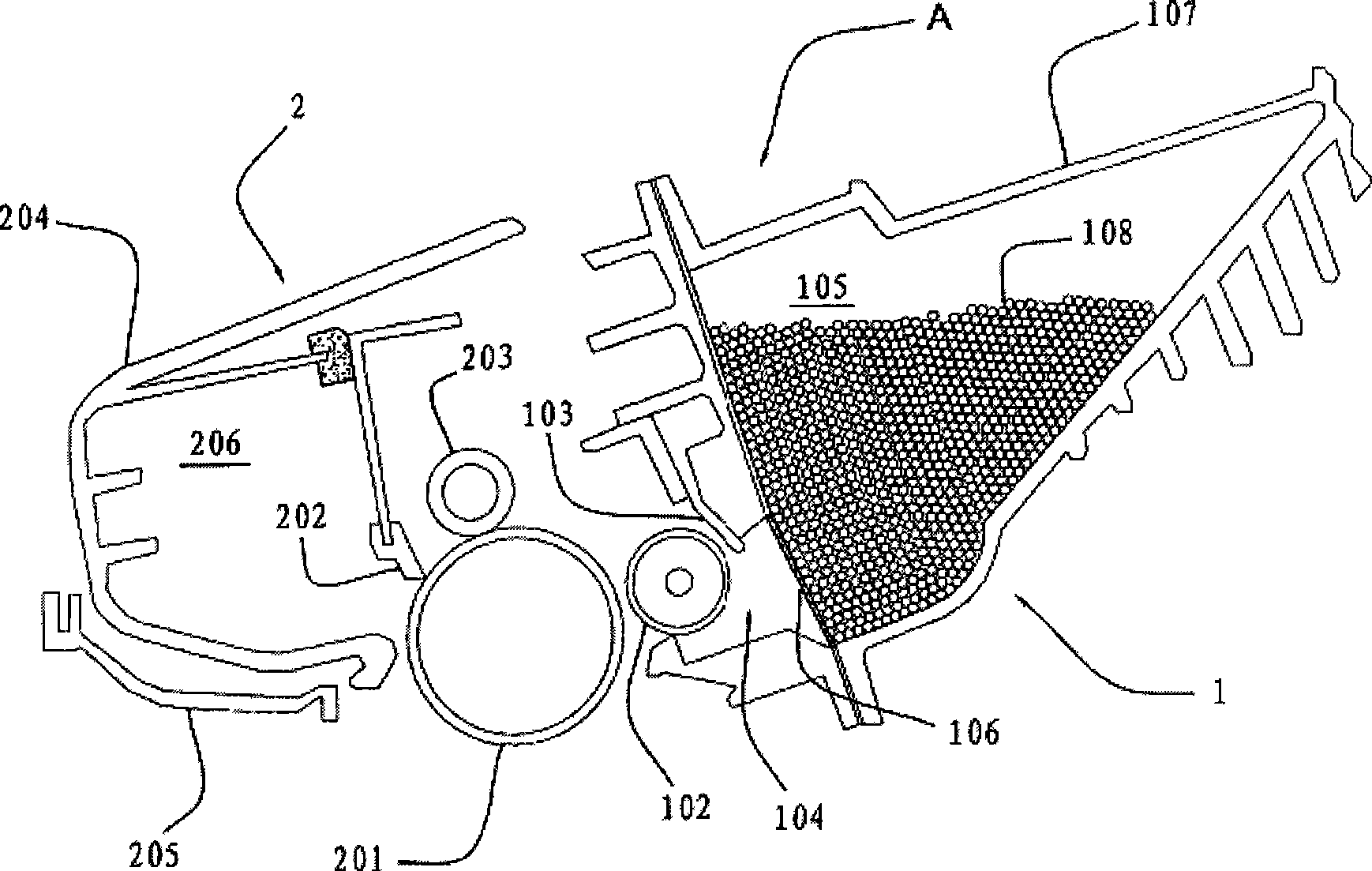

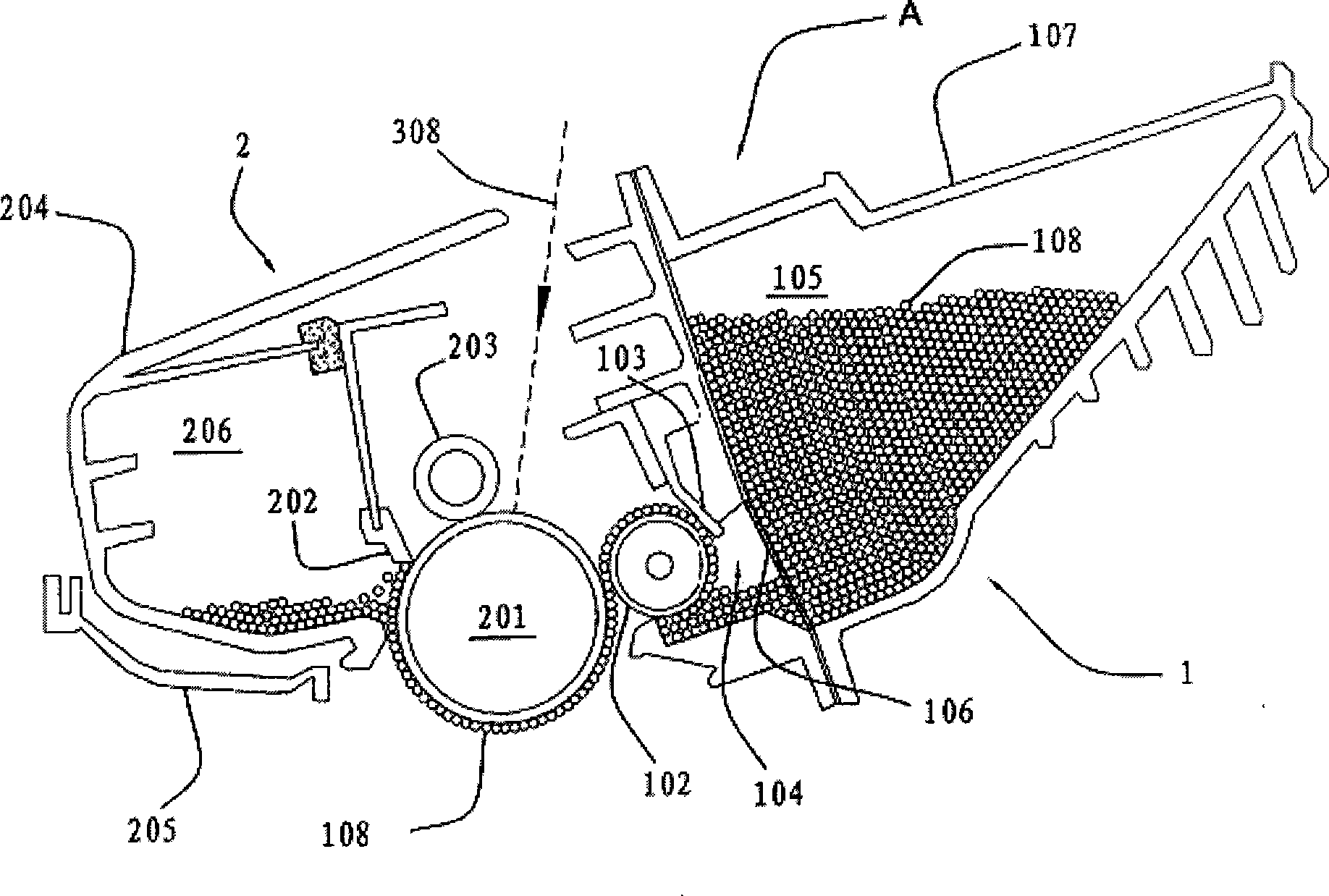

Flow line production system of hot melt adhesive particles

The invention relates to a flow line production system of hot melt adhesive particles. The flow line production system comprises a hot melt stirring reaction device, a constant-temperature filter screen device, an extrusion granulating device, a cooling pipeline device, a colloidal particle and water separation spin-drying device, a colloidal particle air-drying packaging device and a cooling water treatment device, wherein the constant-temperature filter screen device can realize alternate switching of two filter screens to improve the production efficiency; the extrusion granulating device consists of a hot melt adhesive material input end, a granulating cavity body, a granulating motor and a colloidal particle cutter and can realize extrusion, granulation and cooling at the same time. The cooling pipeline device consists of a support body, an input end pipe, a plurality of cooling cross tubes, an output end pipe and a plurality of U-shaped joints, can meet requirements for colloidal particle cooling, occupies a small space and is energy-saving and environment-friendly; the colloidal particle and water separation spin-drying device consists of a frame, an outer barrel shell, an inner filter vat, a dehydration screw, a dehydration motor and a front filtered water tank, can finish separation of cooling water and colloidal particles and colloidal particle spin-drying, and is high in treatment effect and ideal in dehydration effect.

Owner:FOSHAN XINTAO NEW MATERIAL TECH

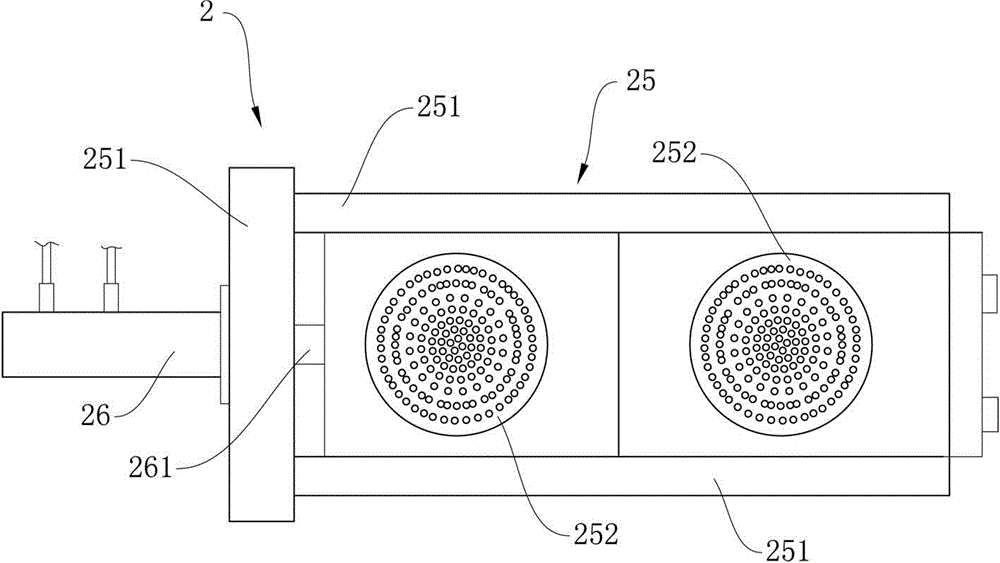

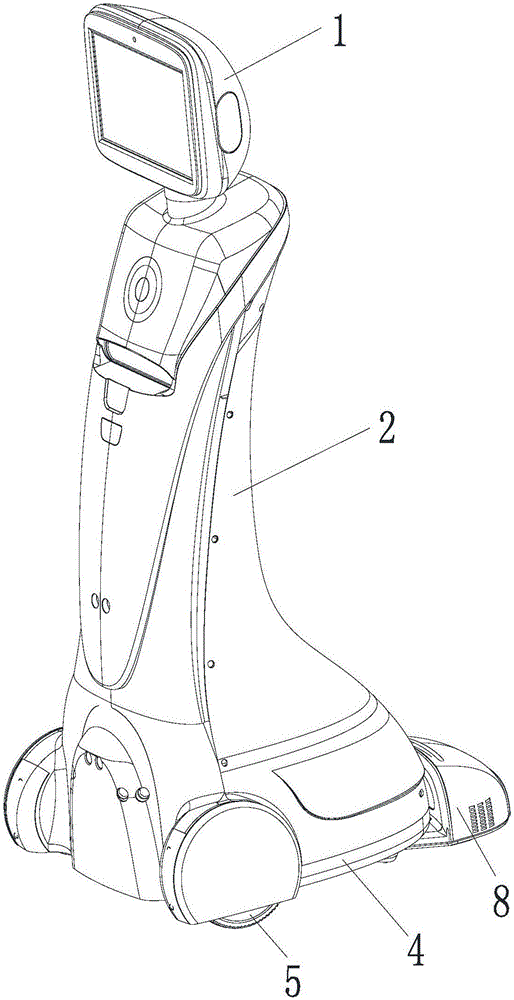

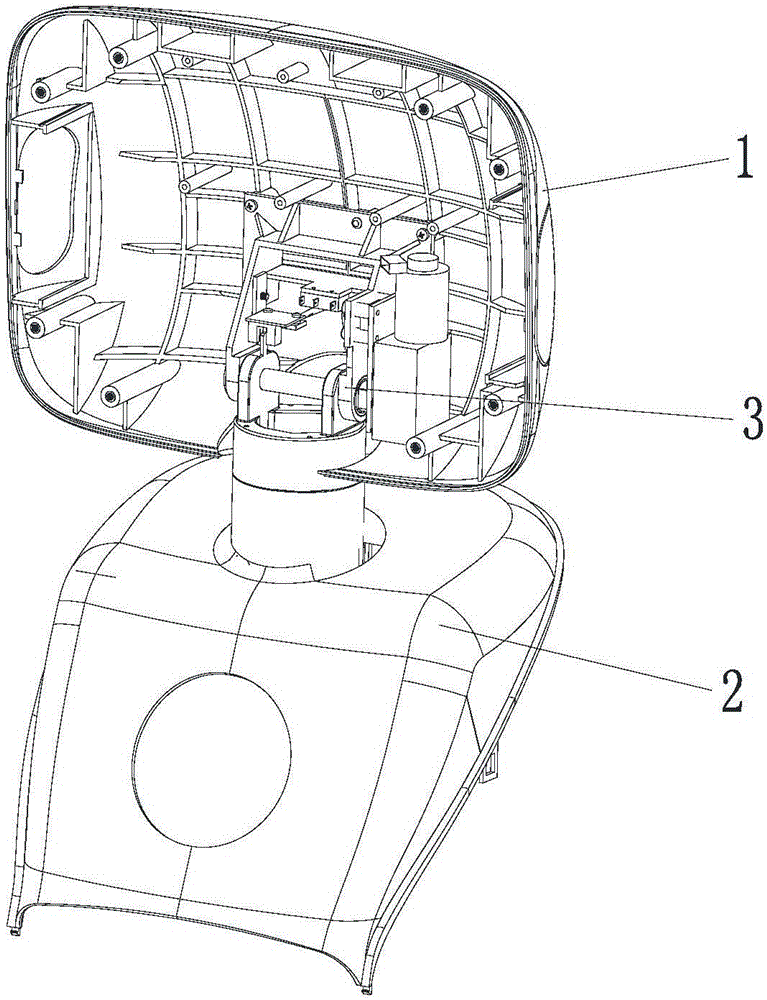

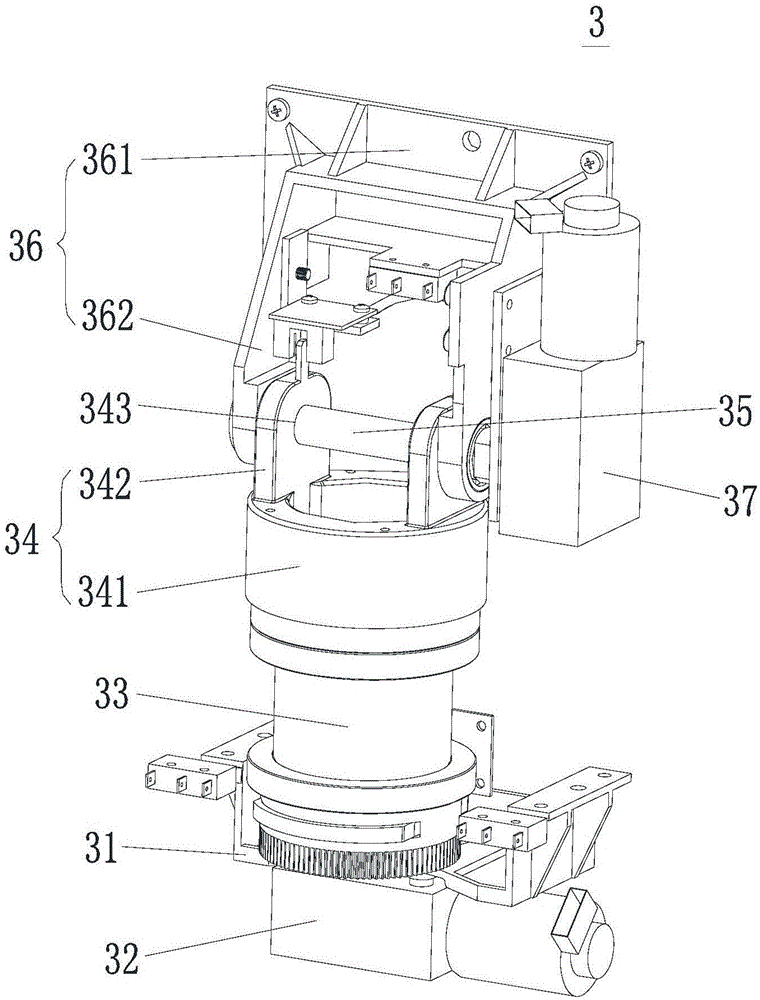

Service robot

InactiveCN105856255AImprove interactivityPrevent dumpingProgramme-controlled manipulatorEngineeringService robot

The invention provides a service robot. The service robot comprises a head, a body, a rotating mechanism and a base; the rotating mechanism connects the head with the body, and the rotating mechanism comprises a first installation seat, a first motor, a first rotating shaft, a rotating connecting part, a second rotating shaft, a second installation seat and a second motor; the first installation seat is connected with the body, the first rotating shaft is vertically installed on the first installation seat, the rotating connecting part is rotatably connected with the first rotating shaft in the radial direction of the first rotating shaft, the first motor controls the rotating connecting part to rotate, the second rotating shaft is transversely installed on the rotating connecting part, the second rotating shaft is rotatably connected with the rotating connecting part in the radial direction of the second rotating shaft, the second motor controls the second rotating shaft to rotate, the second installation seat is installed on the second rotating shaft, and the second installation seat is connected with the head. The service robot utilizes the first motor and the second motor to control the head to rotate left and right or rotate up and down relative to the body respectively, left-and-right rotation and up-and-down rotation are not mutually affected, and therefore the service robot is more flexible, and the interactivity with people is improved.

Owner:HANGZHOU AMY RONOTICS CO LTD

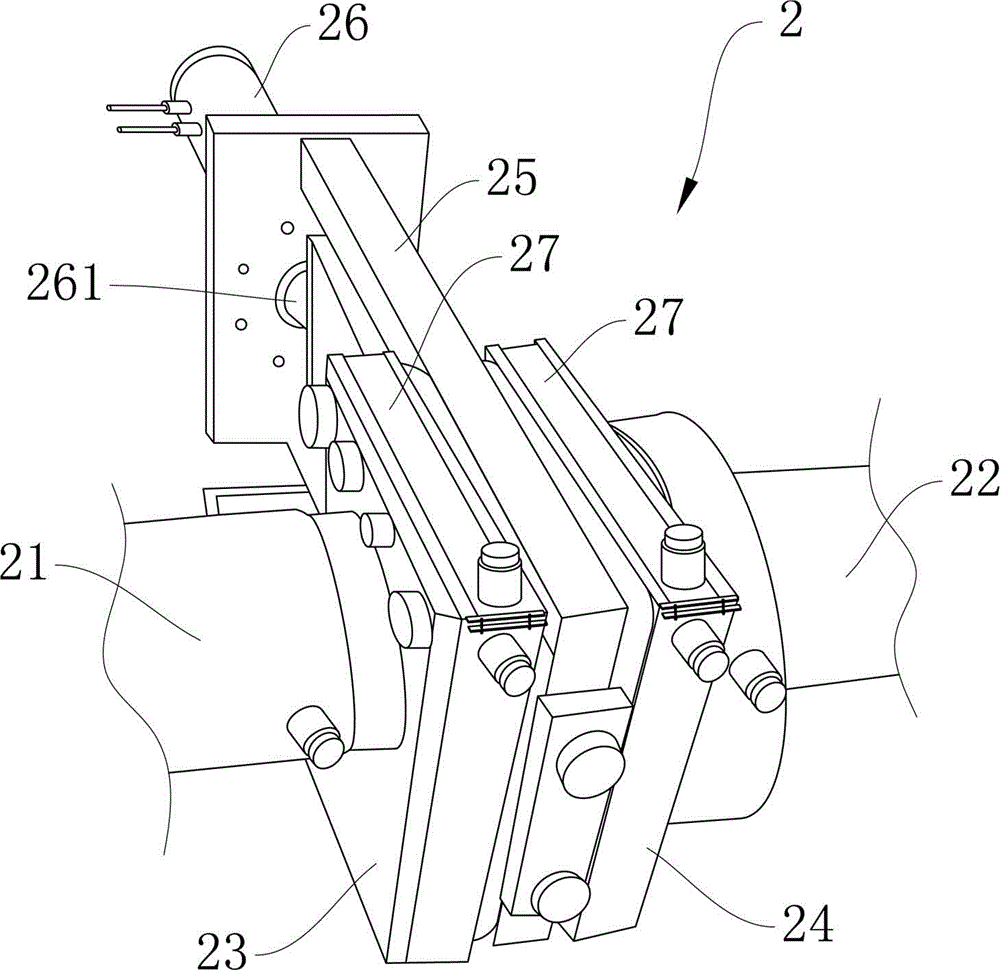

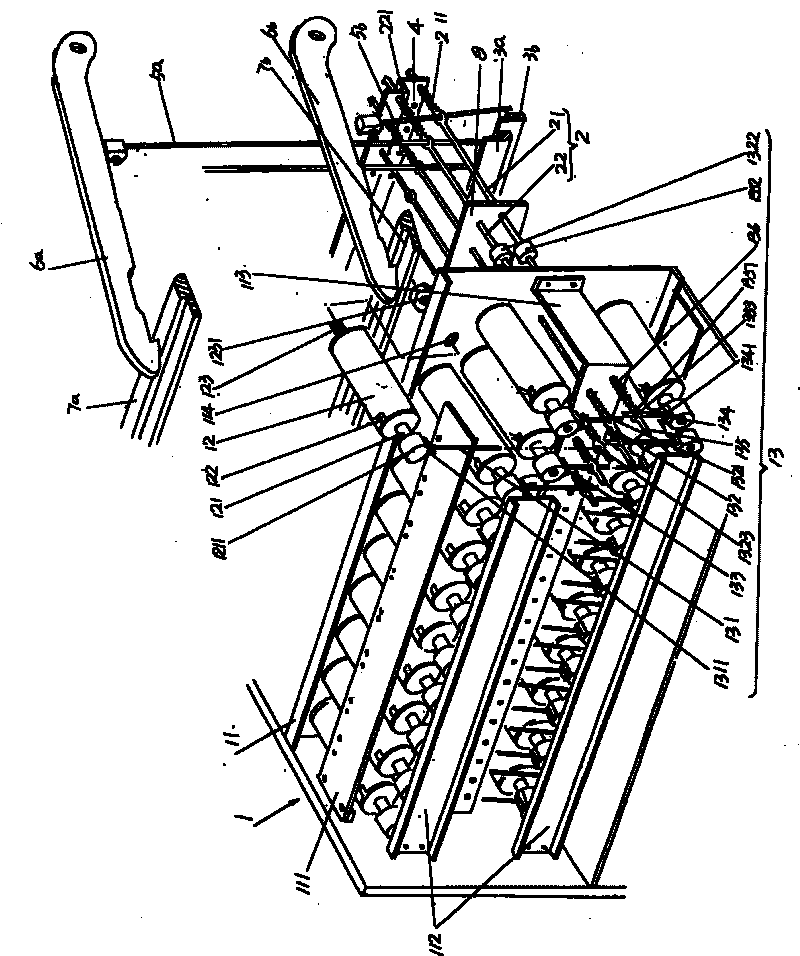

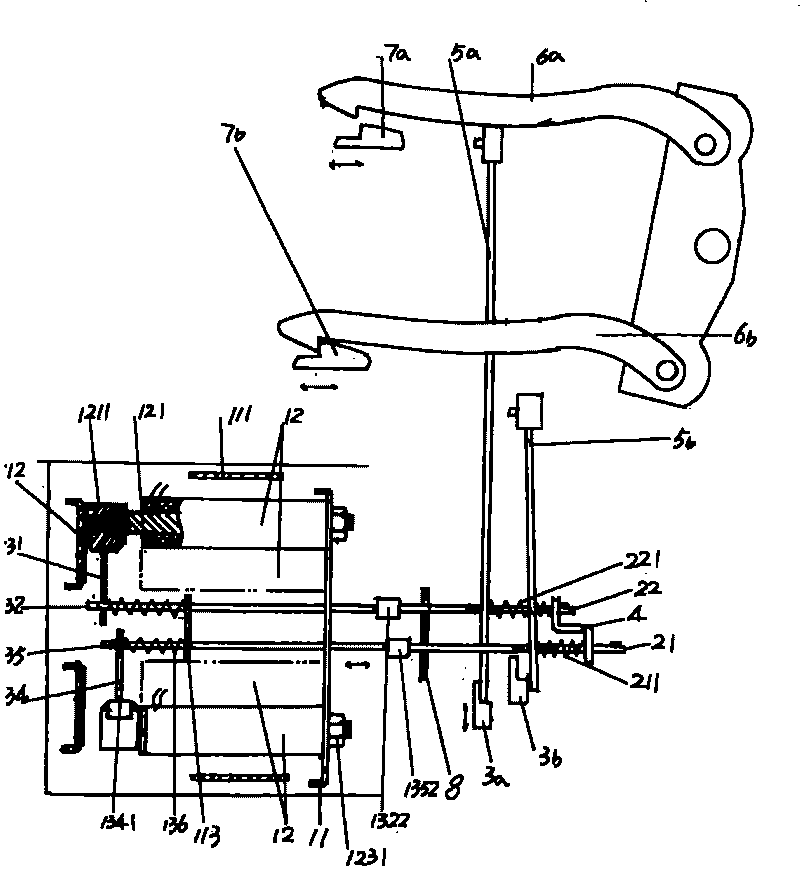

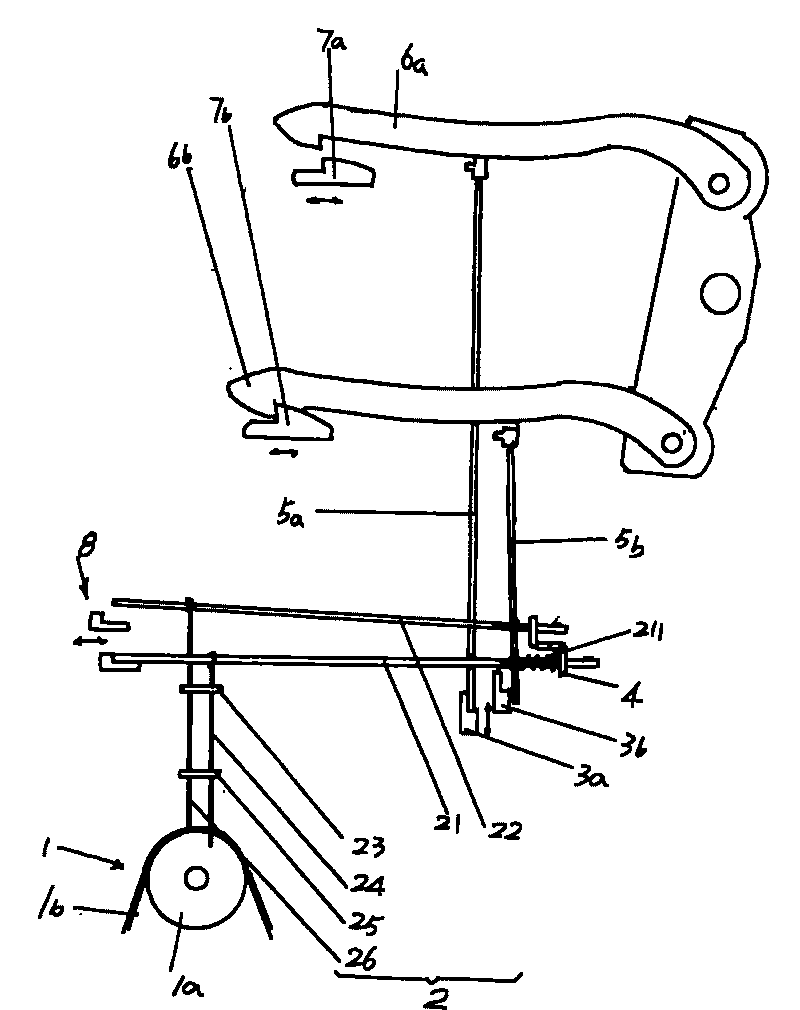

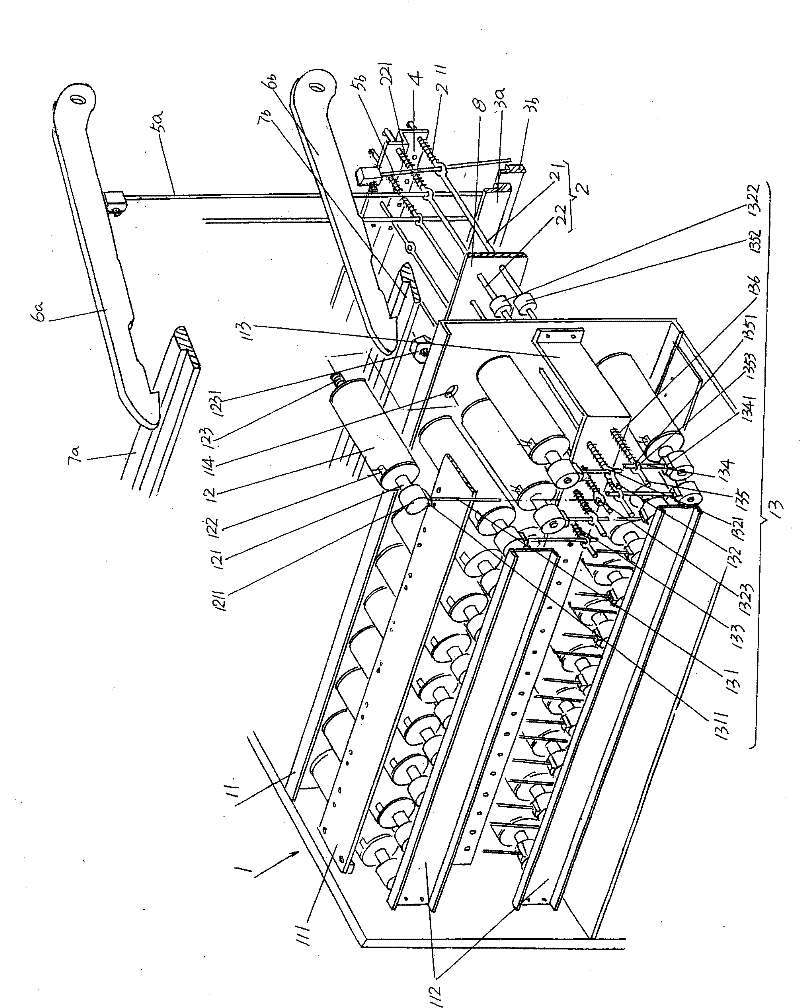

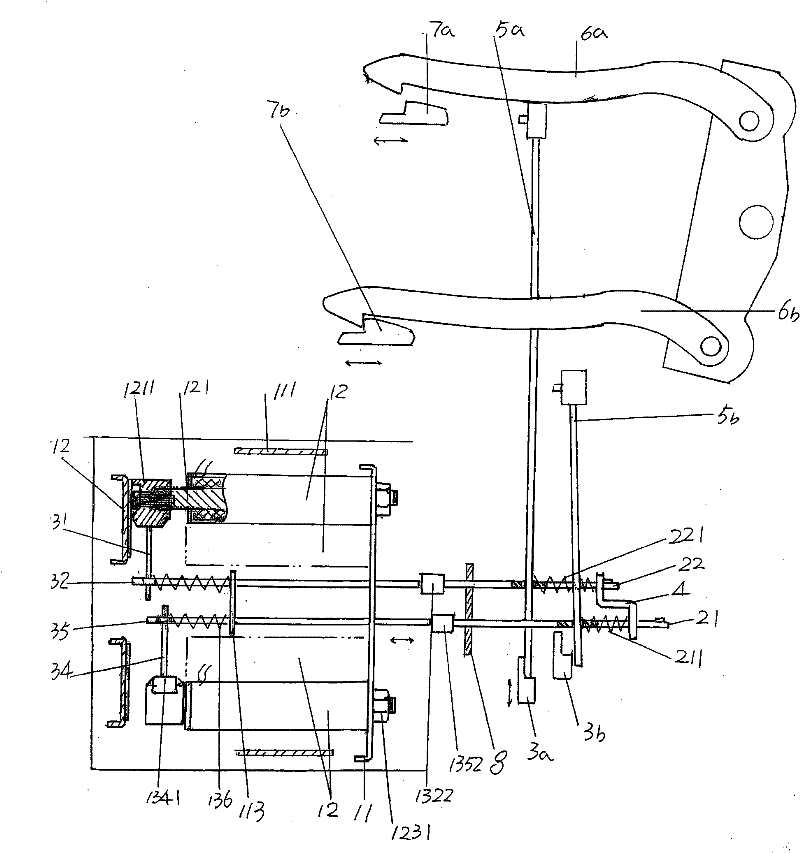

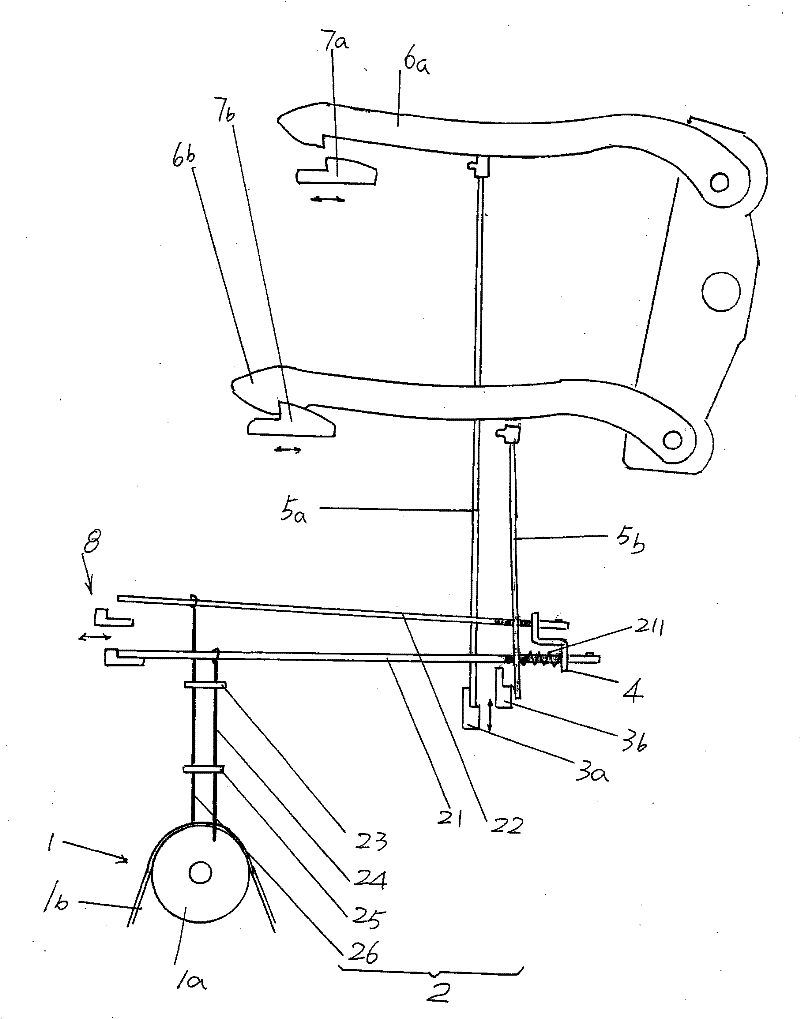

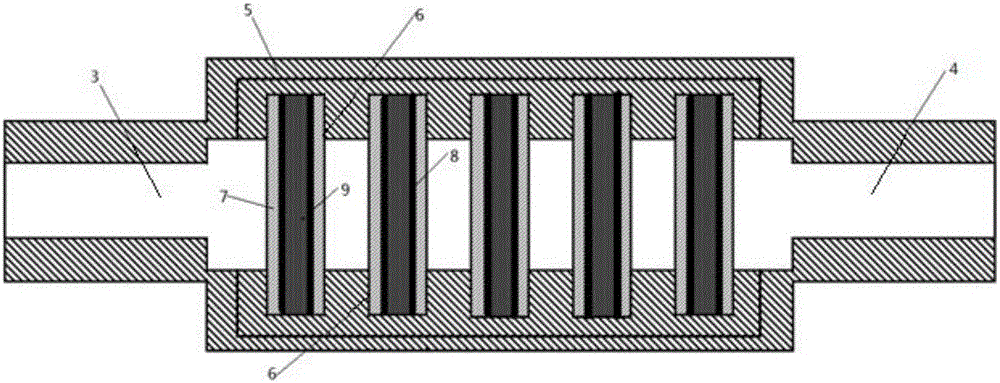

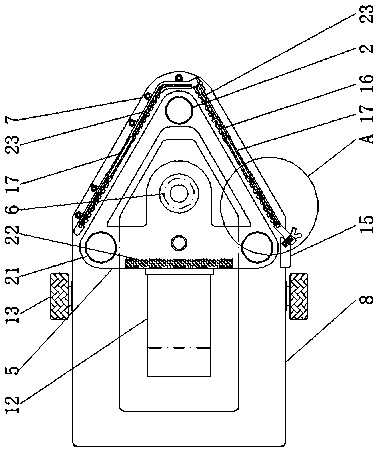

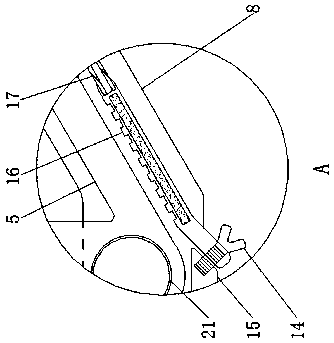

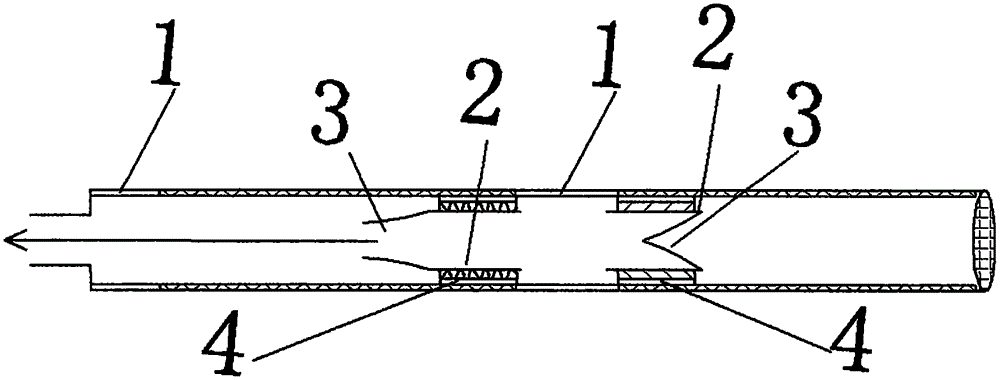

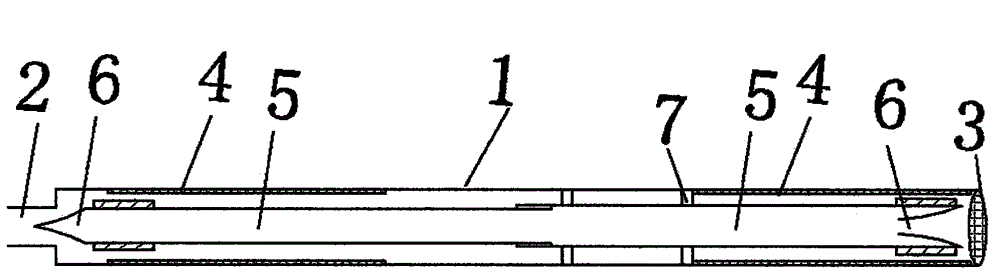

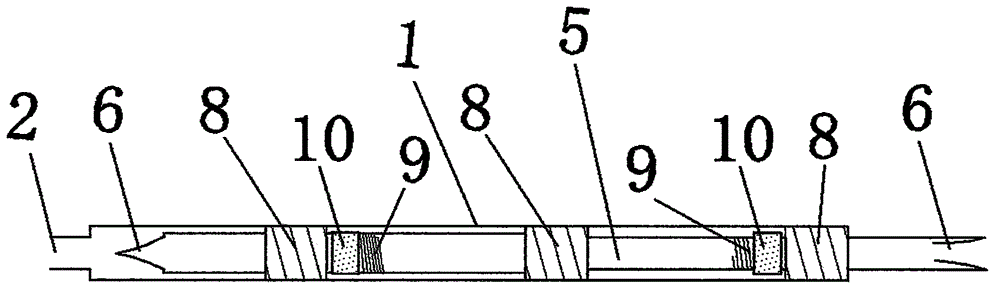

Electronic needle selecting mechanism of passive multi-arm device

ActiveCN101705556AExtended service lifeGuarantee work reliabilityDobbiesEngineeringBiomedical engineering

An electronic needle selecting mechanism of a passive multi-arm device belongs to the technical field of textile machine and comprises a signal supply device and an execution device that consists of a first transverse needle and a second transverse needle; the signal supply device comprises a bracket, a group of electromagnetic valves and a group of transverse needle actuating devices; the amount of the group of the electromagnetic valves is equal to the total amount of the first transverse needles and the second transverse needles; all electromagnetic valves are arranged in the length direction of the bracket and used for actuating the transverse needle actuating devices; the amount of the group of the transverse needle actuating devices is equal to the total amount of the first transverse needles and the second transverse needles; and all transverse needle actuating devices are arranged on the bracket, connected with the electromagnetic valves and matched with the first transverse needles and the second transverse needles, thus actuating the first transverse needles and the second transverse needles. The electronic needle selecting mechanism prolongs the service life of the signal supply device, can ensure working reliability, stability and adaptability of the signal supply device, is beneficial to reducing usage cost, and simplifies the whole structure.

Owner:常熟纺织机械厂有限公司

Integrated pipeline pump

PendingCN110397602AWill not affect work efficiency too muchAffect work efficiencyPump componentsCooling/ventillation arrangementImpellerWater flow

The invention relates to the technical field of submersible electric pumps, and provides an integrated pipeline pump. The integrated pipeline pump comprises a pump shell, an impeller shaft, a pump impeller, a motor stator and a motor rotor, wherein the impeller shaft is connected with the pump shell through a plurality of pump guide vanes; a stator groove is formed in the inner wall of the pump shell; the motor stator is arranged at the bottom of the stator groove; the motor rotor is arranged on the rim of the pump impeller; an air gap is arranged between the motor rotor and the motor stator;a first flow passage and a second flow passage are respectively arranged between the two sides of the pump impeller rim and the two groove walls of the stator groove; and the first flow passage and the second flow passage respectively communicate with two ends of the air gap. According to the integrated pipeline pump, a cooling channel formed by the first flow channel, the air gap and the second flow channel is arranged between the motor stator and the motor rotor, and water flow pumped to the cooling channel is utilized, therefore, the natural water cooling of the motor stator and the motor rotor of the pipeline pump in the working process is achieved, and the safe and stable operation of the pipeline pump is ensured.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

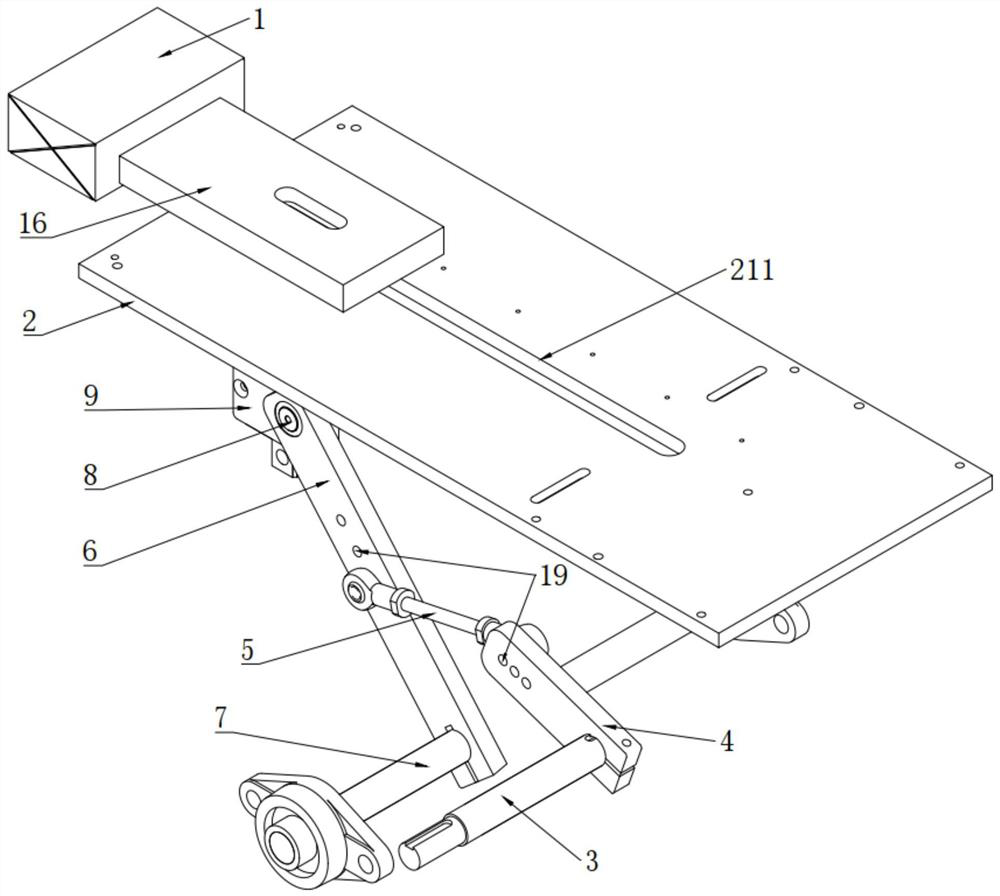

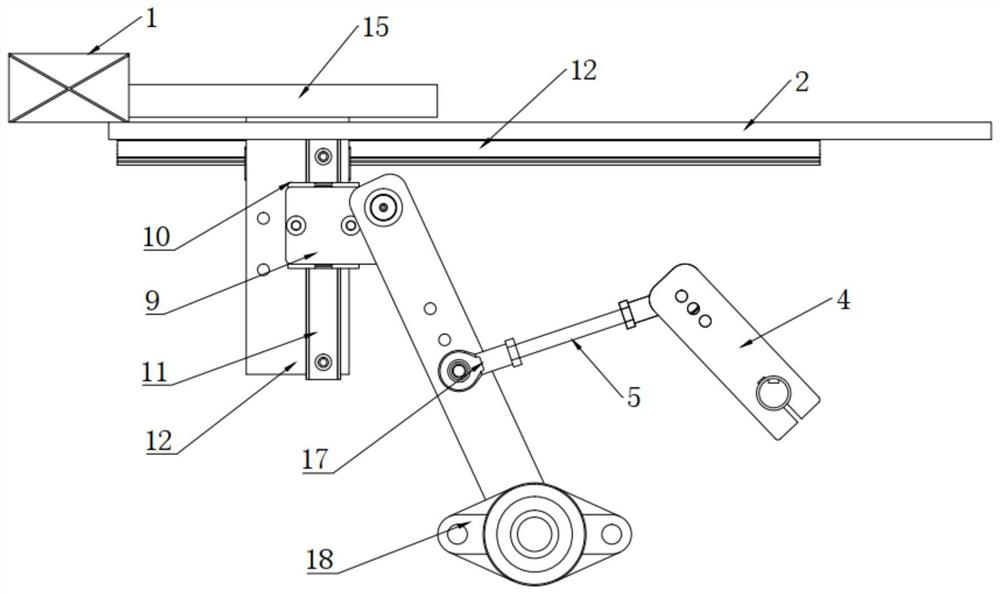

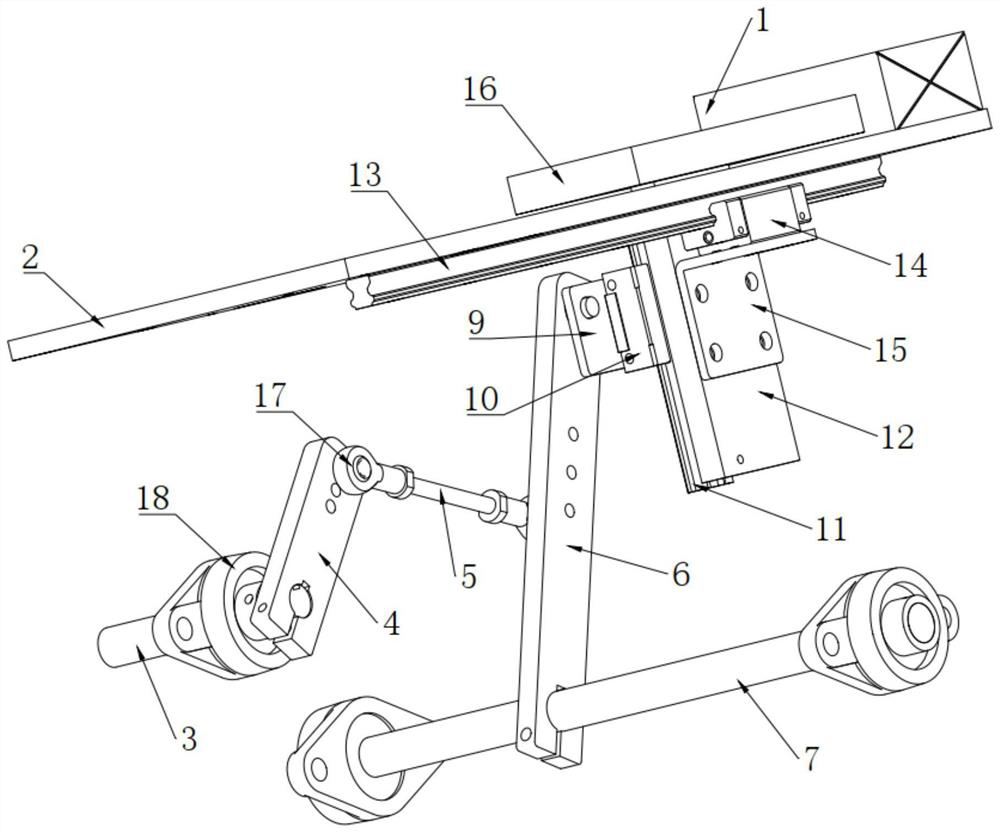

Automatic circulating and reciprocating type material pushing device

InactiveCN111717606ASimple controlSimple structureConveyorsGearingRotational axisReciprocating motion

The invention discloses an automatic circulating and reciprocating type material pushing device. The device comprises a platform used for containing products, a moving groove is formed in the platformin a penetrating mode, and a rotating shaft mechanism, a swing rod mechanism and a sliding block pushing block mechanism are arranged on the platform; and the second rotating shafts are used for being fixedly connected to the second swing rod; the swing rod mechanism comprises a first swing rod, a connecting rod and a second swing rod, and the end, away from the second rotating shaft, of the second swing rod is rotationally connected to an up-down sliding block connecting plate through a rotating bearing. The material pushing device can drive the swing rod and the connecting rod to circularlyrotate only by connecting a chain wheel or a synchronizing wheel from a driving position to provide rotating acting force for the first rotating shaft without a motor, the pushing block can be betterdriven to do non-stop reciprocating motion, the control mode is simple, the manufacturing cost is low, the structure is simple, the operation is convenient, and maintenance cost is lower.

Owner:BENGBU COLLEGE

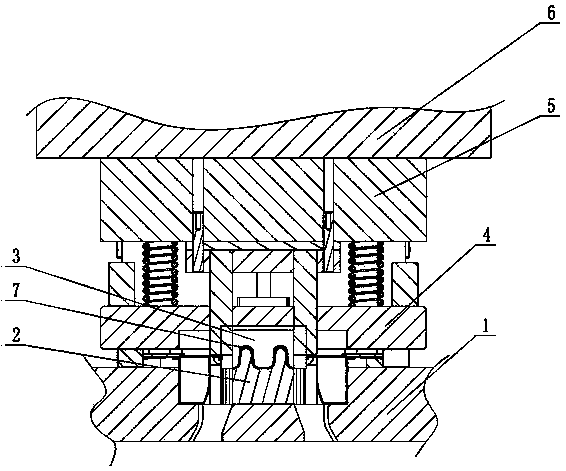

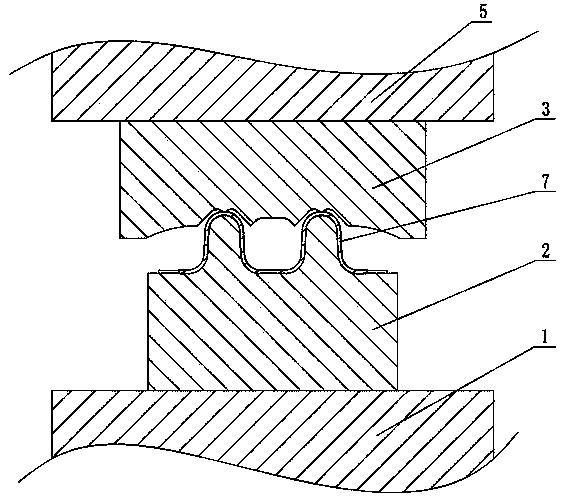

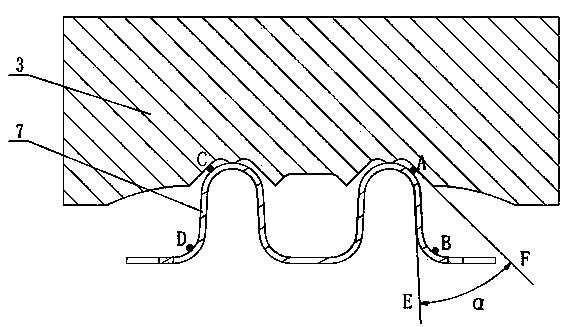

Stamping die and separation technology for separating hot-formed steel plate

A stamping die for separating a hot-formed steel plate comprises a lower die seat and a lower separation insert fixed on the lower die seat. A workpiece is positioned on the lower separation insert, an upper separation insert is arranged on an upper die seat, the upper die seat is fixedly connected on a press sliding block, a pressing block is elastically connected with the upper die seat, the sliding block is driven by a press to move up and down, the shape of the cutting edge surface of the lower separation insert is the same as the shape of the surface of the workpiece, the hardness of the upper separation insert is higher than or equals to the hardness of the lower separation insert, and the hardness of the upper separation insert and the lower separation insert is at least HRC 50 and tenacity is achieved. The invention also provides a corresponding separation technology, and a low speed separation technology and a cutting edge point contact separation technology are mainly used for the high-strength hot-formed steel plate. The stamping die for separating the hot-formed steel plate is suitable for the separation work of the hot-formed steel plate, separation efficiency is guaranteed, impact on the separation device is also reduced greatly during separation, abrasion to the separation device is reduced, the service life of the separation device is prolonged, and acting force needed during the separation can be reduced greatly.

Owner:无锡红弦汽车轻量化科技有限公司 +1

Residual powder cleaning equipment

InactiveCN101477324AQuick cleanThe cleaning part is cleaned quicklyElectrographic process apparatusLight sensingMetallurgy

The invention relates to a residual powder cleaning device for a carbon powder box, which comprises a driving part which supplies power for the powder box, a voltage supply part which supplies voltage for the powder box, an exposure part which drives a light-sensing drum on the powder box to expose, a part for cleaning carbon powder on the cleaning powder box, and a powder box supporting frame. The residual powder cleaning device not only can effectively clean the carbon powder in a developing bin but also can not waste a printing medium, and simultaneously reduces the manufacturing cost; and the work efficiency of the residual powder cleaning device can not be influenced by the operating speed of an electrophotographic imaging device, so that the developing bin is quicker and more complete to clean. Moreover, the residual powder cleaning device solves the technical problems of high cleaning cost and low efficiency of the prior residual powder.

Owner:ZHUHAI SEINE TECH CO LTD

Electronic needle selecting mechanism of passive multi-arm device

ActiveCN101705556BExtended service lifeGuarantee work reliabilityDobbiesEngineeringBiomedical engineering

An electronic needle selecting mechanism of a passive multi-arm device belongs to the technical field of textile machine and comprises a signal supply device and an execution device that consists of a first transverse needle and a second transverse needle; the signal supply device comprises a bracket, a group of electromagnetic valves and a group of transverse needle actuating devices; the amountof the group of the electromagnetic valves is equal to the total amount of the first transverse needles and the second transverse needles; all electromagnetic valves are arranged in the length direction of the bracket and used for actuating the transverse needle actuating devices; the amount of the group of the transverse needle actuating devices is equal to the total amount of the first transverse needles and the second transverse needles; and all transverse needle actuating devices are arranged on the bracket, connected with the electromagnetic valves and matched with the first transverse needles and the second transverse needles, thus actuating the first transverse needles and the second transverse needles. The electronic needle selecting mechanism prolongs the service life of the signal supply device, can ensure working reliability, stability and adaptability of the signal supply device, is beneficial to reducing usage cost, and simplifies the whole structure.

Owner:常熟纺织机械厂有限公司

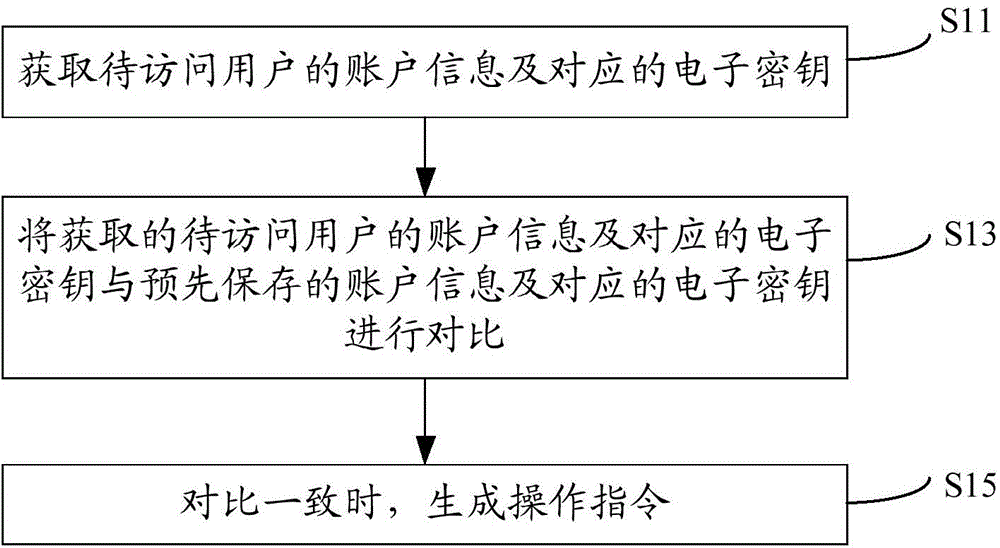

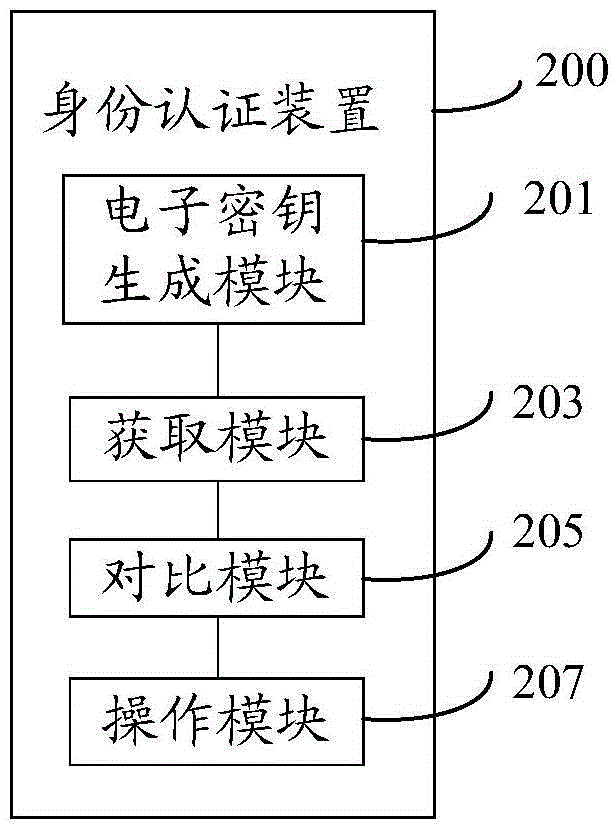

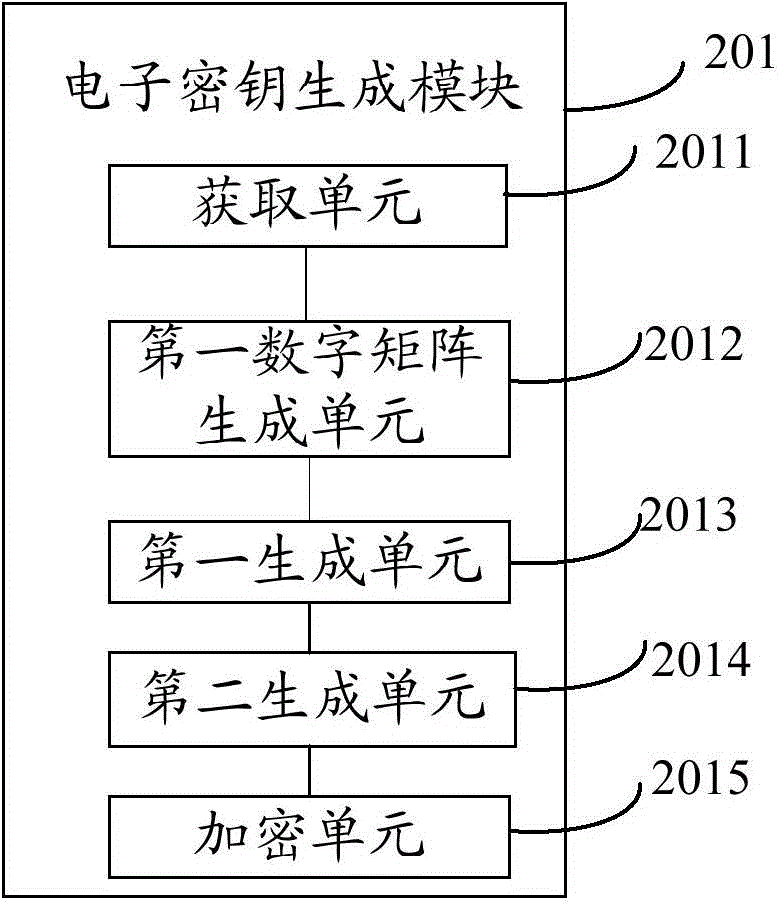

Identity authentication method, identity authentication device, and server

InactiveCN105827404AEnsure safetyWill not affect work efficiencyKey distribution for secure communicationUser identity/authority verificationUser authenticationMulti-user

The invention provides an identity authentication method, an identity authentication device, and a server. The method comprises the following steps: acquiring the account information of an account to be accessed and a corresponding electronic key; comparing the acquired account information of the account to be accessed and the acquired corresponding electronic key with pre-stored account information and a pre-stored corresponding electronic key respectively; and generating an operation instruction if the acquired account information of the account to be accessed and the acquired corresponding electronic key are consistent with the pre-stored account information and the pre-stored corresponding electronic key. According to the scheme of the invention, a method combining single-user authentication and multi-user authentication is adopted, joint authentication of multiple users is needed for the access and operation of only a few sensitive data, authentication of a single user is needed for generation operation, the efficiency of daily work is not affected, and the safety of sensitive data and operation is ensured.

Owner:中国移动通信集团陕西有限公司

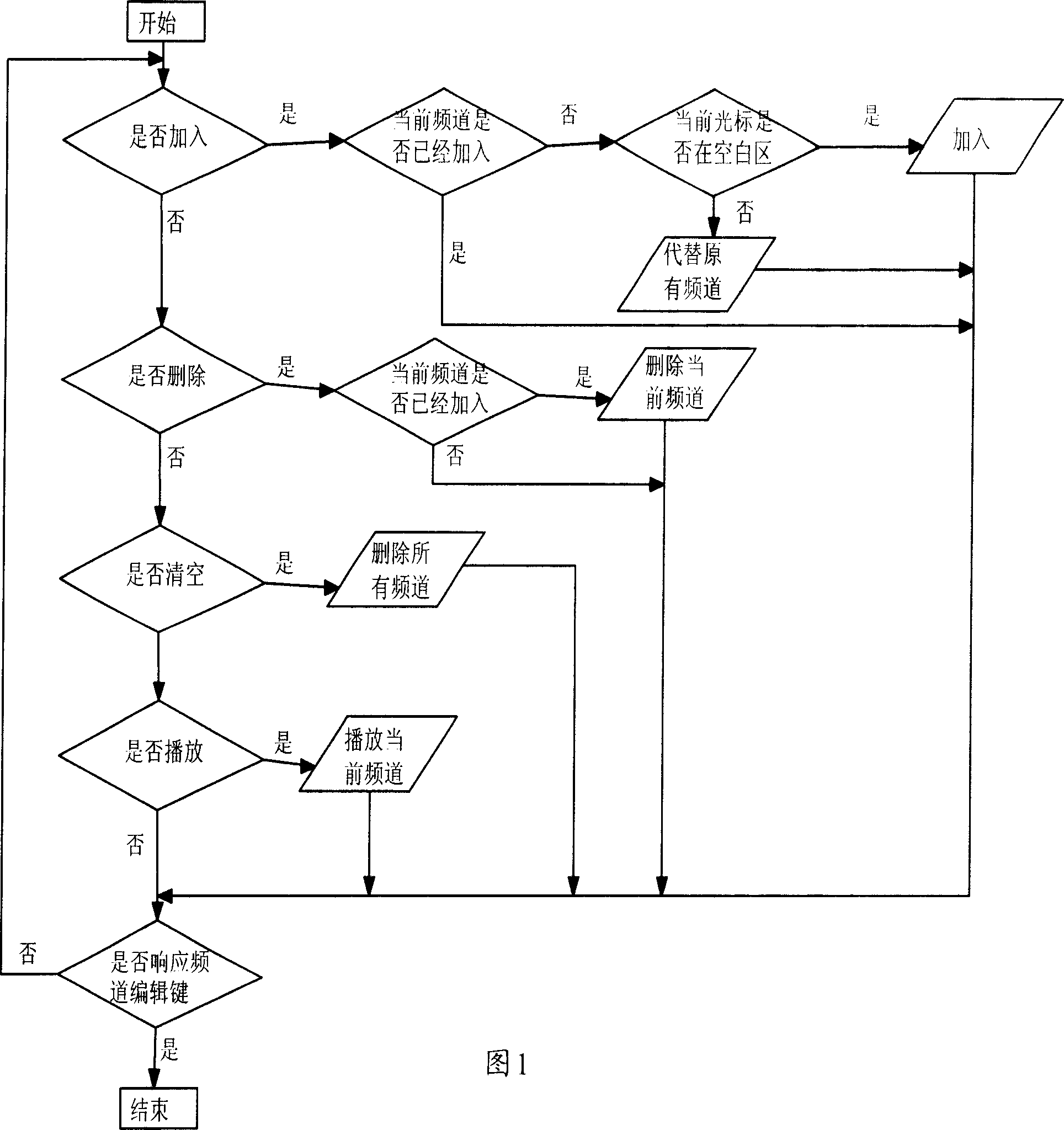

Method for setting of preference TV program

InactiveCN1929571ANovel functionWill not affect work efficiencyTelevision system detailsColor television detailsChannel dataControl set

This invention discloses one set method for preference television program into one device, which comprises the following steps: setting one channel edit key to control set process of programs; setting one reference channel list to store it into one memory device to store user channel data; receiving user play operation order and selecting preference relative channel; transferring the relative data into buffer and executing play process.

Owner:SHENZHEN SKYWORTH RGB ELECTRONICS CO LTD

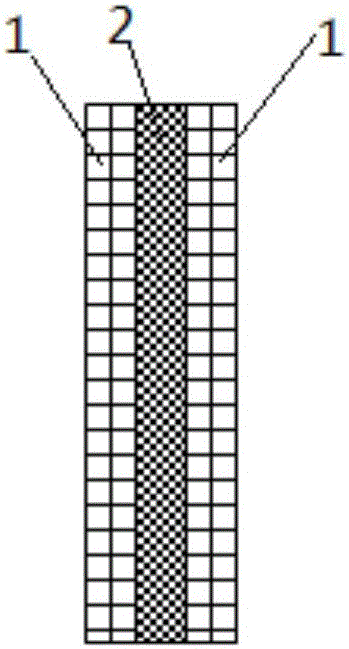

Carbon fiber automobile air conditioner filter

ActiveCN105854431AImprove mechanical propertiesSmall mechanical propertiesHuman health protectionDispersed particle filtrationActivated carbonCarbon fibers

The invention discloses a carbon fiber automobile air conditioner filter which comprises a filter cartridge, wherein the filter cartridge is provided with an air inlet and an air outlet, a plurality of slots are formed in the filter cartridge, and a filter frame is inserted into each slot. The carbon fiber automobile air conditioner filter is characterized in that magnetic attraction strips are arranged on the two inner sides of each filter frame respectively, wherein filter core materials are arranged between the magnetic attraction strips on the two sides; each filter core material comprises nonwoven fabric layers arranged on the surfaces of the two sides and blended from organic fiber filaments and activated carbon fiber filaments and a middle activated carbon fiber felt filtration and adsorption layer; the surface density of the blended nonwoven fabric layers is 30 to 200g / m<2>, and the surface density of the activated carbon fiber felt filtration and adsorption layers is 60 to 400g / m<2>. According to the carbon fiber automobile air conditioner filter, harmful substances in haze can be adsorbed and filtered in a targeted manner; with the adoption of a matched pluggable structure, a filter element can be flexibly replaced; moreover, a purification level can be freely regulated according to hazy weather, so that air quality in an automobile in different climatic environments can be effectively improved.

Owner:SHANDONG UNIV

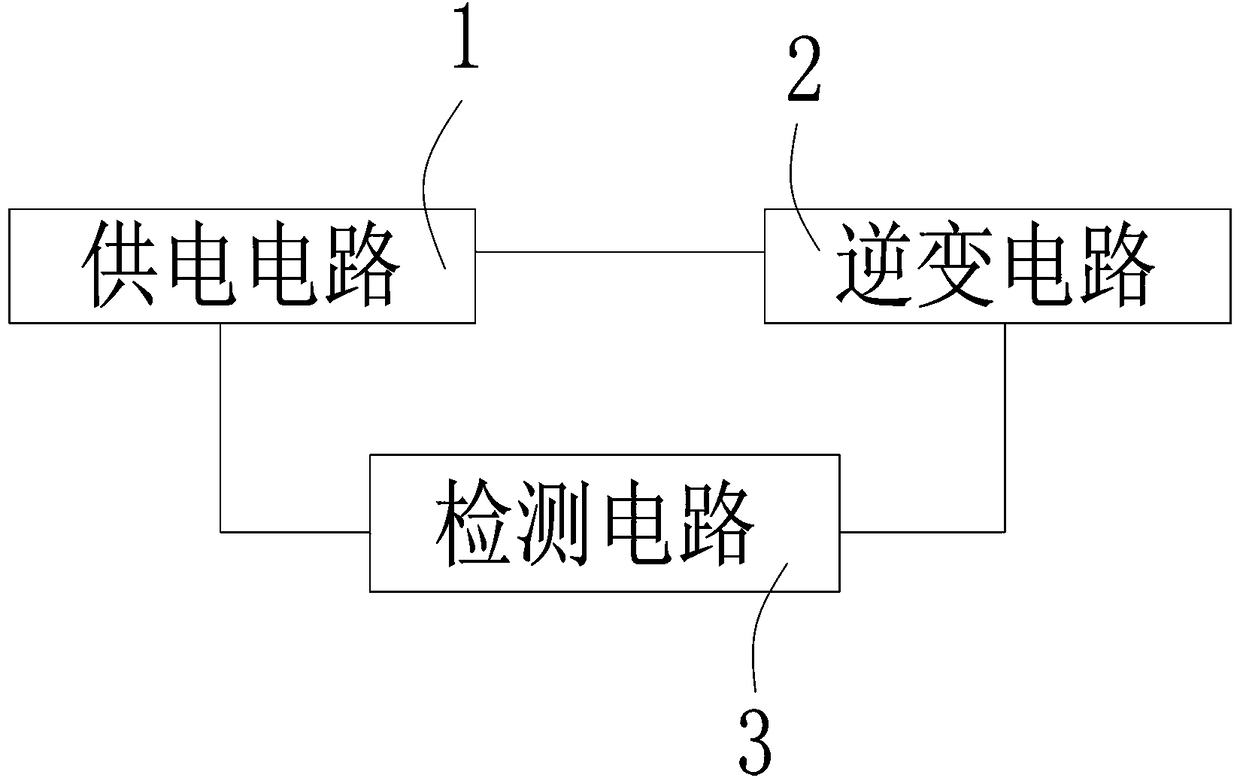

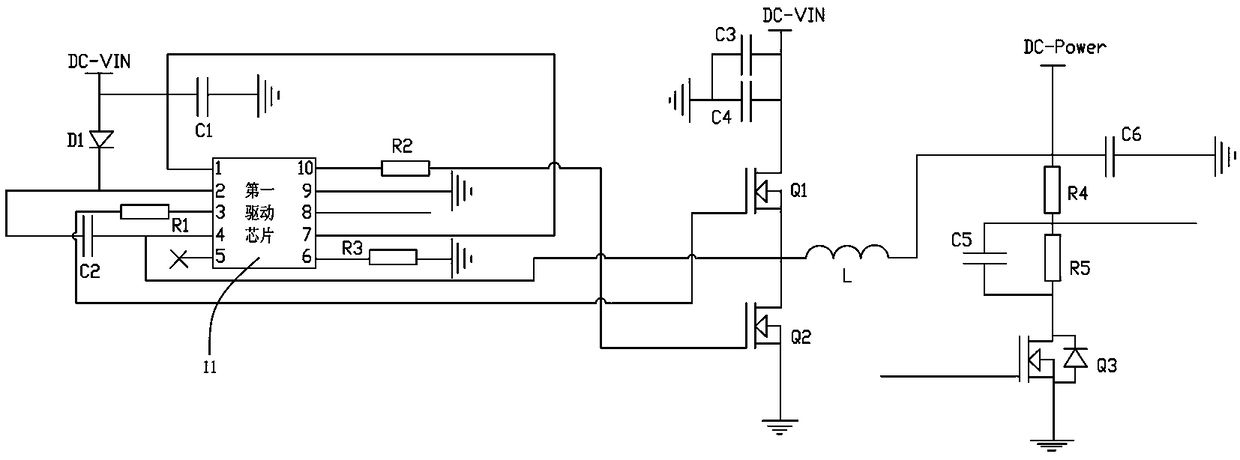

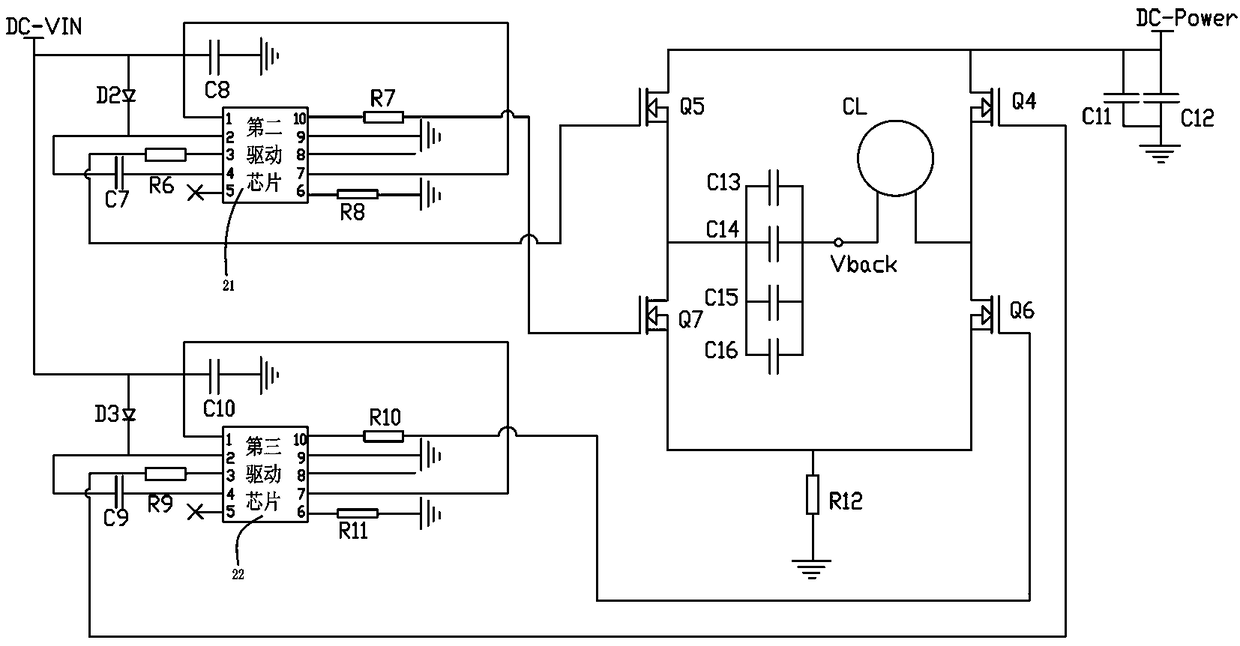

Method and circuit of determining wireless charging foreign matter based on Q value

PendingCN108173359ASimple structureWill not reduce efficiencyCircuit arrangementsStopped workForeign matter

The invention relates to a method and circuit of determining wireless charging foreign matter based on a Q value. The circuit of determining wireless charging foreign matter based on a Q value includes a wireless transmitting circuit and a detection circuit, wherein the detection circuit is electrically connected with the wireless transmitting circuit; the wireless transmitting circuit emits electromagnetic wave which continuously changes the frequency and enables the wireless transmitting circuit to stop working; and during the process of transmitting the electromagnetic wave from the wireless transmitting circuit, the detection circuit detects the Q value of the wireless transmitting circuit, and according to the detected Q value, determines whether foreign matter exists in the electromagnetic wave transmission range of the wireless transmitting circuit. In the circuit of determining wireless charging foreign matter based on a Q value, the wireless transmitting circuit and the detection circuit are employed; the wireless transmitting circuit emits the electromagnetic wave which continuously changes the frequency and enables the wireless transmitting circuit to stop working; and during the process of transmitting the electromagnetic wave from the wireless transmitting circuit, the detection circuit detects the Q value of the wireless transmitting circuit, and according to thedetected Q value, determines whether foreign matter exists in the electromagnetic wave transmission range of the wireless transmitting circuit. The circuit of determining wireless charging foreign matter based on a Q value has the advantages of being simple in the circuit structure, being low in cost and having no influence on the working efficiency of the system.

Owner:SHENZHEN CHIPSVISION MICRO CO LTD

Fatigue state recognition method, device and equipment

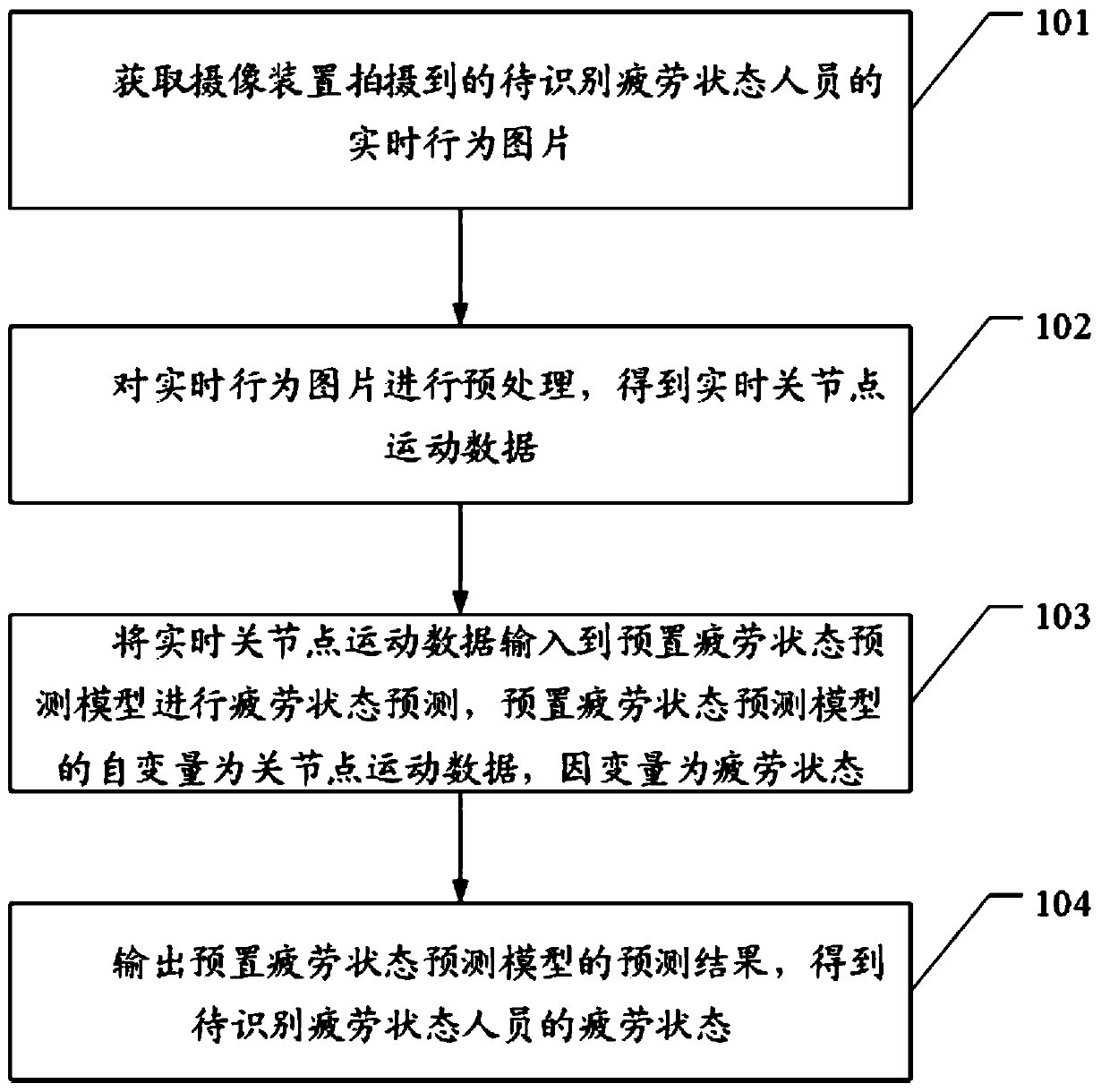

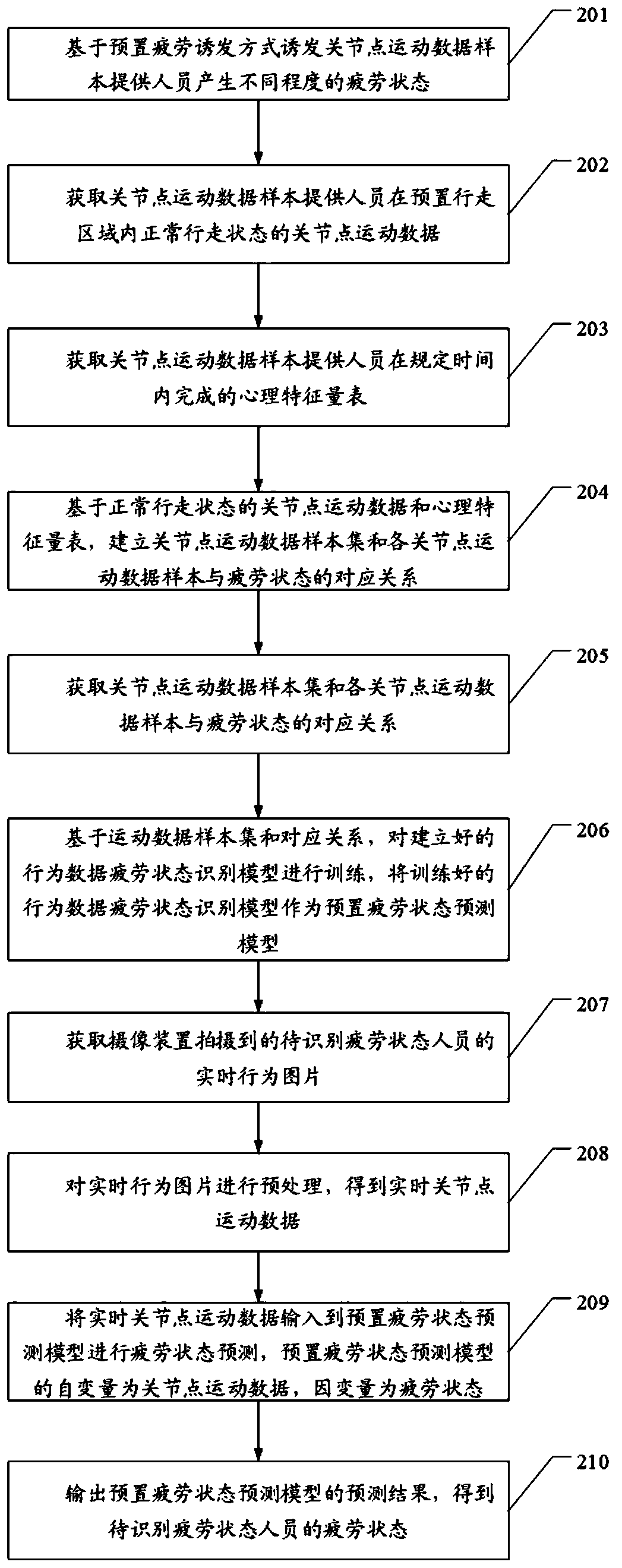

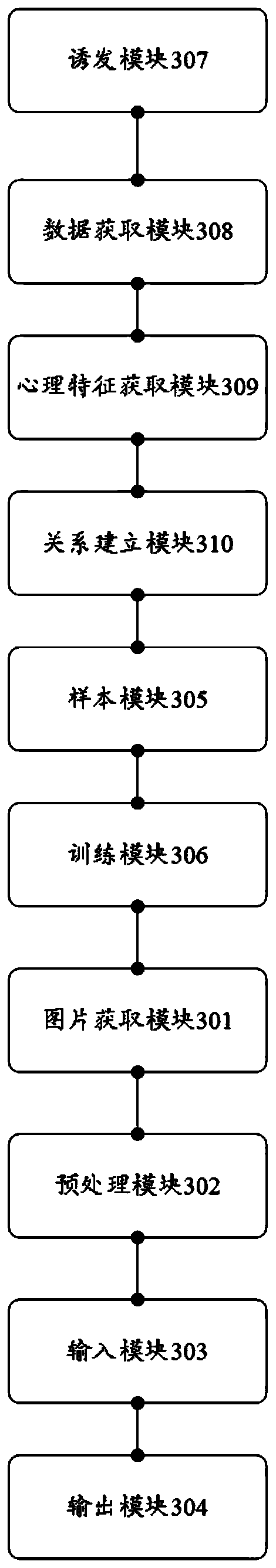

InactiveCN110717461AWill not affect work efficiencyIt will not affect the normal operation of electric power operationForecastingCharacter and pattern recognitionSimulationPower grid

The invention discloses a fatigue state c method, device and equipment. The method comprises: shooting the motion condition of the person in the fatigue state to be identified during power grid operation in real time; acquiring a real-time behavior picture of the person in the fatigue state to be identified; preprocessing the real-time behavior picture to obtain real-time articulation point motiondata; inputting the real-time joint point motion data into a preset fatigue state prediction model; wherein the preset fatigue state prediction model takes joint point motion data as independent variables; the fatigue state being used as a dependent variable; and outputting a fatigue state prediction result corresponding to the input articulation point motion data; obtaining the fatigue state ofthe person in the to-be-identified fatigue state. The real-time performance is realized on the fatigue state identification of the to-be-identified fatigue state personnel. Moreover, the method does not affect the work efficiency of the to-be-recognized fatigue state person, does not affect the normal operation of the power operation of the to-be-recognized fatigue state person, and solves technical problems that a conventional fatigue state recognition mode for a power grid worker is poor in timeliness and is low in reliability.

Owner:GUANGDONG POWER GRID CO LTD +1

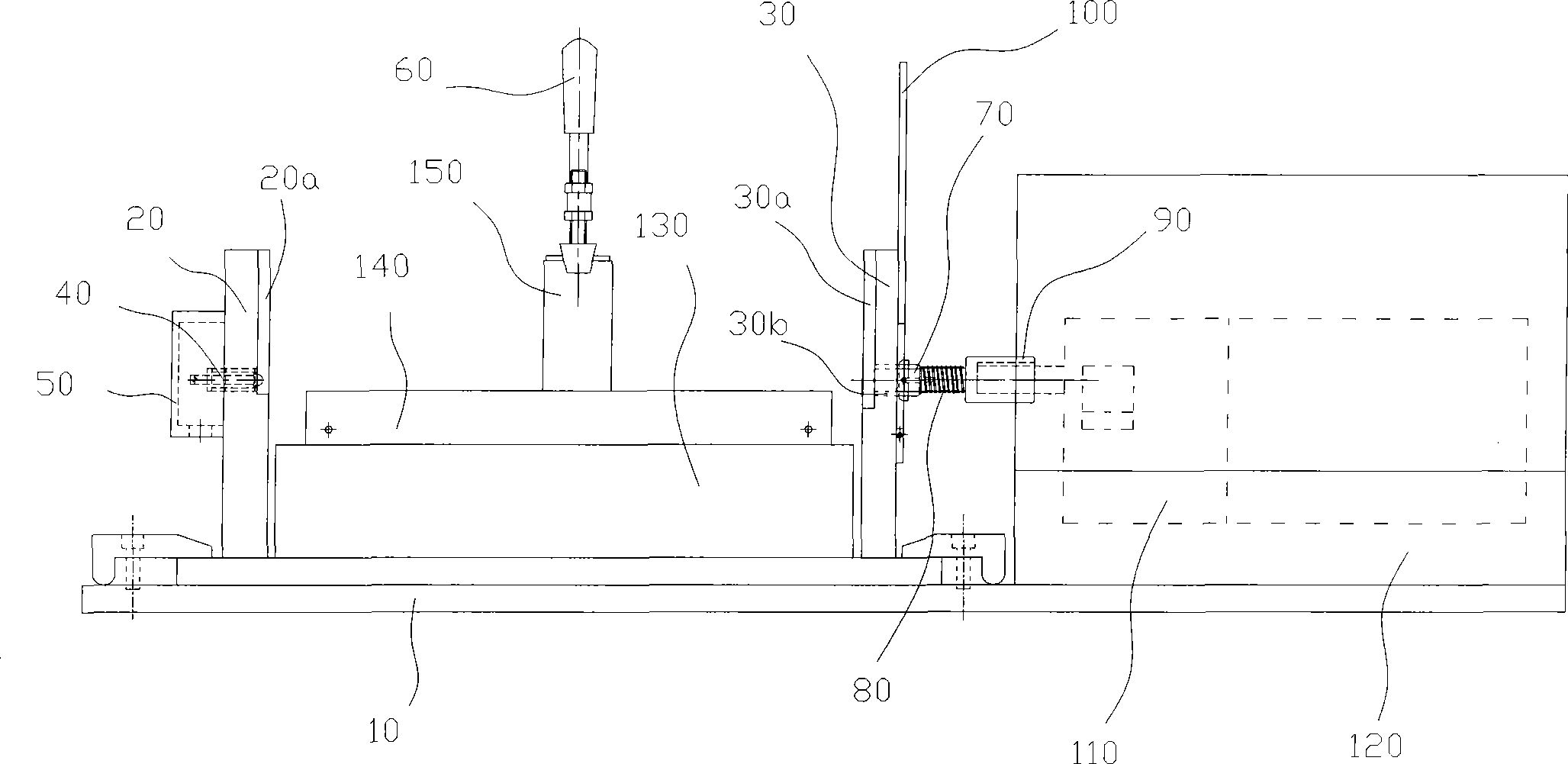

Drilling coring machine for highway pavement detection

PendingCN108798576AEasy to turn to openWill not affect work efficiencyCore removalDrilling machines and methodsFixed frameRoad surface

The invention relates to a drilling coring machine for highway pavement detection. The drilling coring machine comprises a movable frame and a base; a bracket, a handle and vertical columns are connected and fixed to the top of the base from left to right; and the movable frame and the vertical columns constitute an up-down sliding structure through a fixed frame and a screw rod fixedly connectedto the bottom of a rotating handle. The drilling coring machine for highway pavement detection has the beneficial effects that by adopting the structures of a first side plate, a second side plate anda rubber baffle, a barrier can be formed on the outer circle of a drilling tube, noise generated when the drilling tube works is blocked, and thus the effect of lowering the noise hazard is achieved;the second side plate can be conveniently rotated to be opened, and thus the working efficiency of constructors is not affected; and through the design of a visual window, a worker can observe the drilling tube outside the first side plate and the second side plate, so that the more convenient effect is achieved.

Owner:广东鸿翔工程检测咨询有限公司

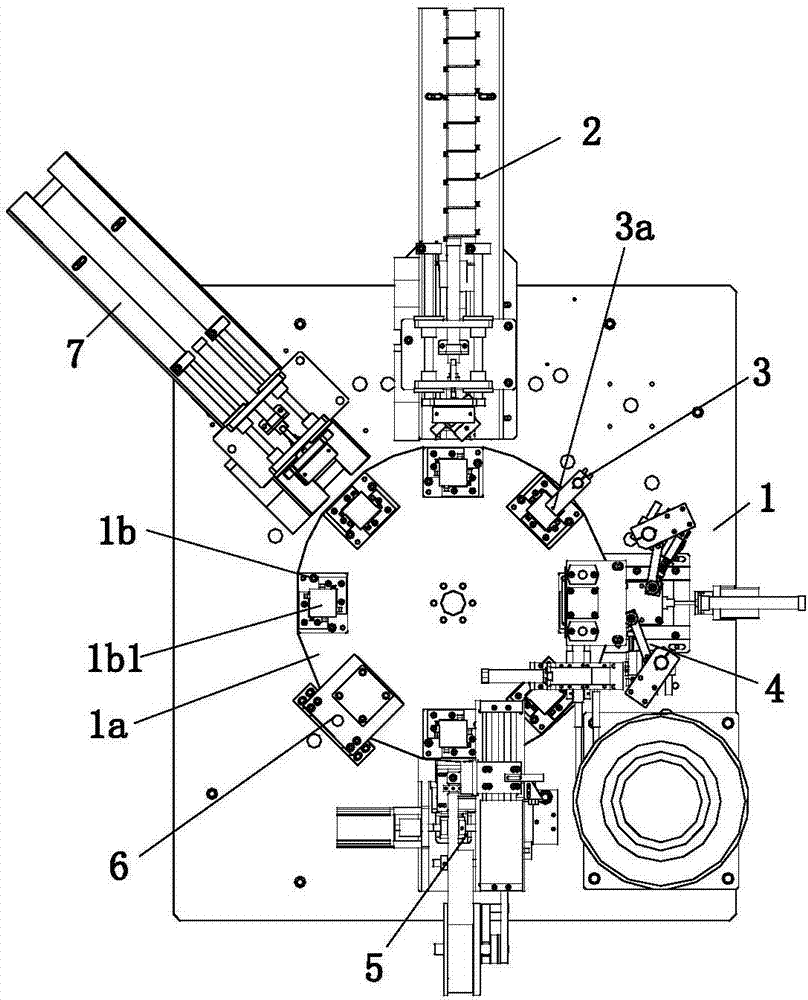

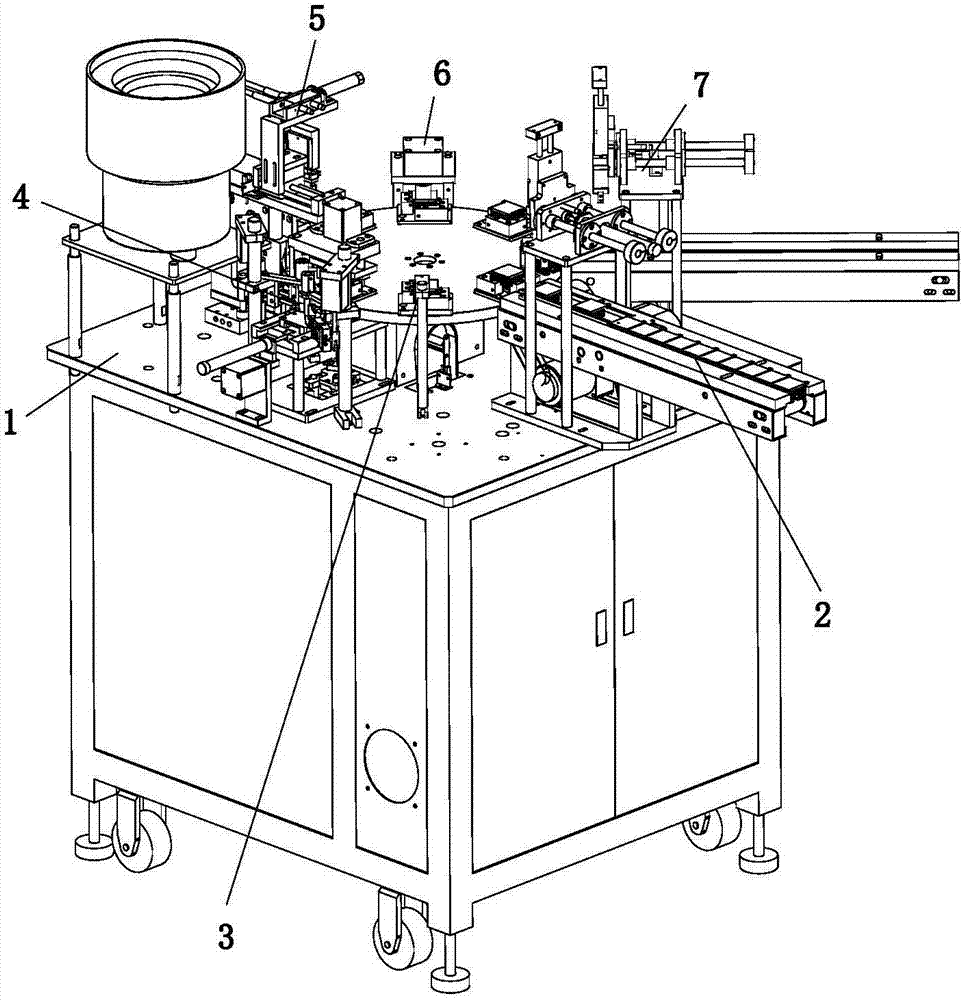

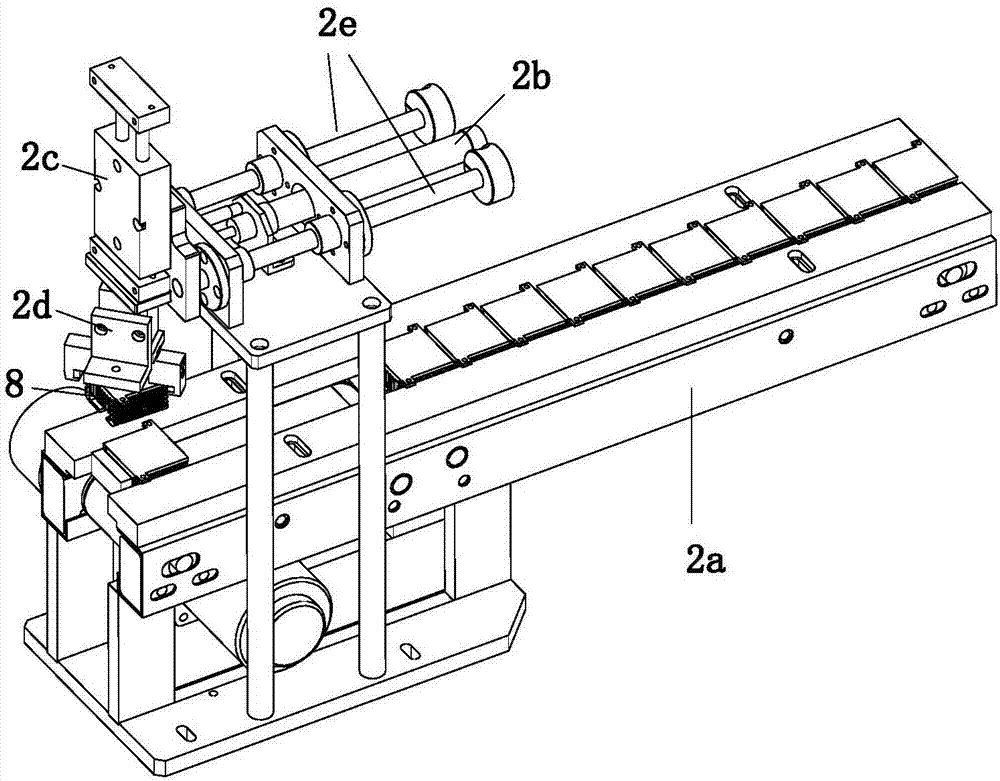

Nail blanking assembly for cooling fin glue nail installation and labeling machine

InactiveCN107284981AWill not affect work efficiencyPrecisely control the amount of blankingConveyorsConveyor partsEngineeringAutomation

The invention relates to the field of automation equipment, in particular to a nail blanking assembly for a cooling fin glue nail installation and labeling machine. The nail blanking assembly comprises a supporting frame, an installation block, a second air cylinder, a rotating wheel, an insertion needle, a blanking plate and a nail blanking pipe. The second air cylinder is installed below the top of the supporting frame in an inverted mode. The installation block is fixedly connected with the supporting frame and located below the second air cylinder. The rotating wheel is pivoted to the installation block through a bearing. The second air cylinder is connected with the eccentric position of the back of the rotating wheel. The insertion needle and the blanking plate are in transmission connection with the eccentric position of the front portion of the rotating wheel, the connection position of the insertion needle and the eccentric position of the front portion of the rotating wheel is away from the connection position of the blanking plate and the eccentric position of the front portion of the rotating wheel, and a connection line of the insertion needle and the eccentric position of the front portion of the rotating wheel and a connection line of the blanking plate and the eccentric position of the front portion of the rotating wheel penetrate through the circle center of the rotating wheel. The nail blanking pipe is of a hollow structure. The blanking plate can move at the bottom of the nail blanking pipe through driving of the rotating wheel so that opening and closing of the bottom of the nail blanking pipe can be controlled. The insertion needle can be inserted into the middle section of the nail blanking pipe through driving of the rotating wheel. According to the nail blanking assembly for the cooling fin glue nail installation and labeling machine, the blanking amount can be precisely controlled, the effect that the blanking amount is one each time is ensured, and thus the working efficiency of other mechanisms cannot be affected.

Owner:WUHU TAIQING ELECTRONICS TECH CO LTD

Anti-blocking device for coal drop pipe

InactiveCN112079136AAvoid cloggingWill not affect work efficiencyConveyorsLarge containersMechanical engineeringPetroleum engineering

The invention discloses an anti-blocking device for a coal drop pipe, relates to the technical field of coal drop pipes, and provides the following scheme aiming at the problems that an existing coaldrop pipe is blocked, needs to be manually dredged by workers, is low in manual dredging efficiency and can influence the working efficiency of the device: the anti-blocking device comprises a first pipe; the bottom of the first pipe is fixedly connected with a second pipe; a fixed base is fixedly connected to the outer wall of the left side of the second pipe; a first stirring mechanism is movably arranged in the first pipe in a sleeved manner; a second stirring mechanism is movably arranged in the second pipe in a sleeved manner; a driving vibration mechanism is fixedly connected to the leftside of the first pipe; and a transmission mechanism is arranged between the bottom of the driving vibration mechanism and the first stirring mechanism. The anti-blocking device not only facilitatesstirring in a pipe, but also can drive the pipe to vibrate, so that the anti-blocking effect of the pipe can be improved, manual cleaning is not needed, labor is saved, efficiency is high, the workingefficiency of the device is not affected, and the anti-blocking device is multipurpose and high in practicability.

Owner:安徽独库机械设备有限公司

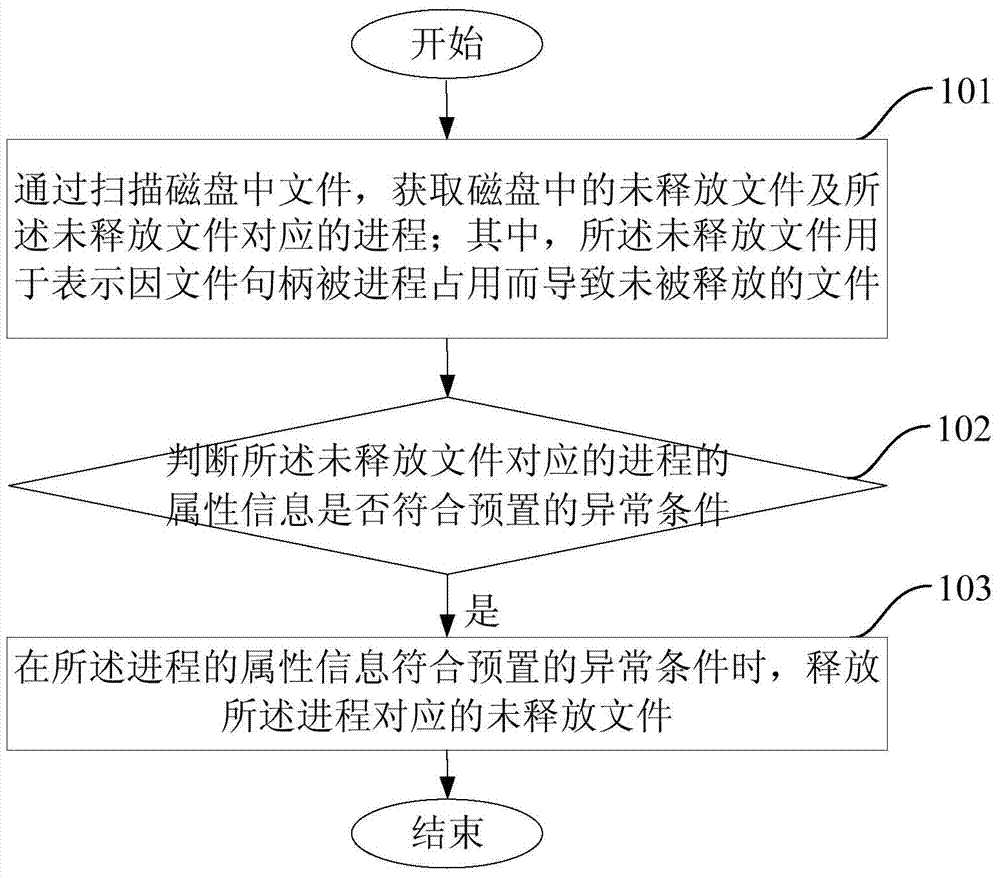

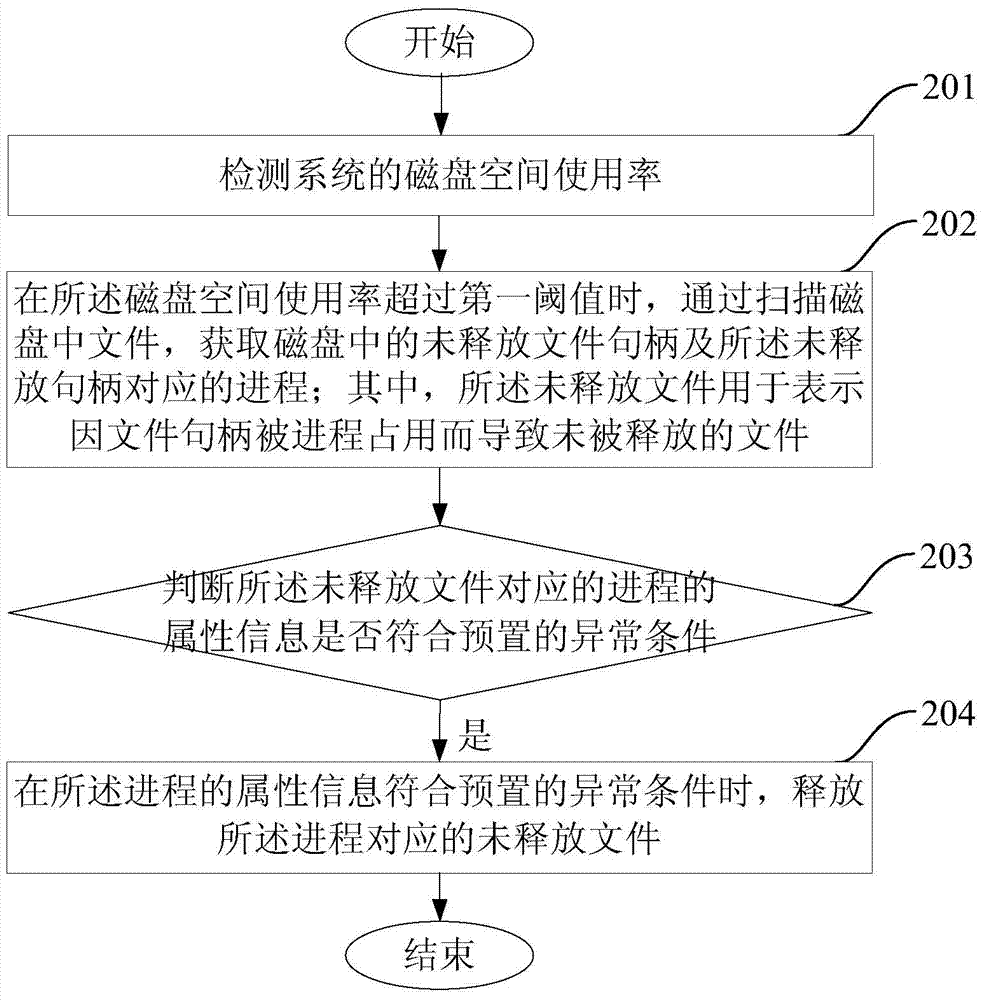

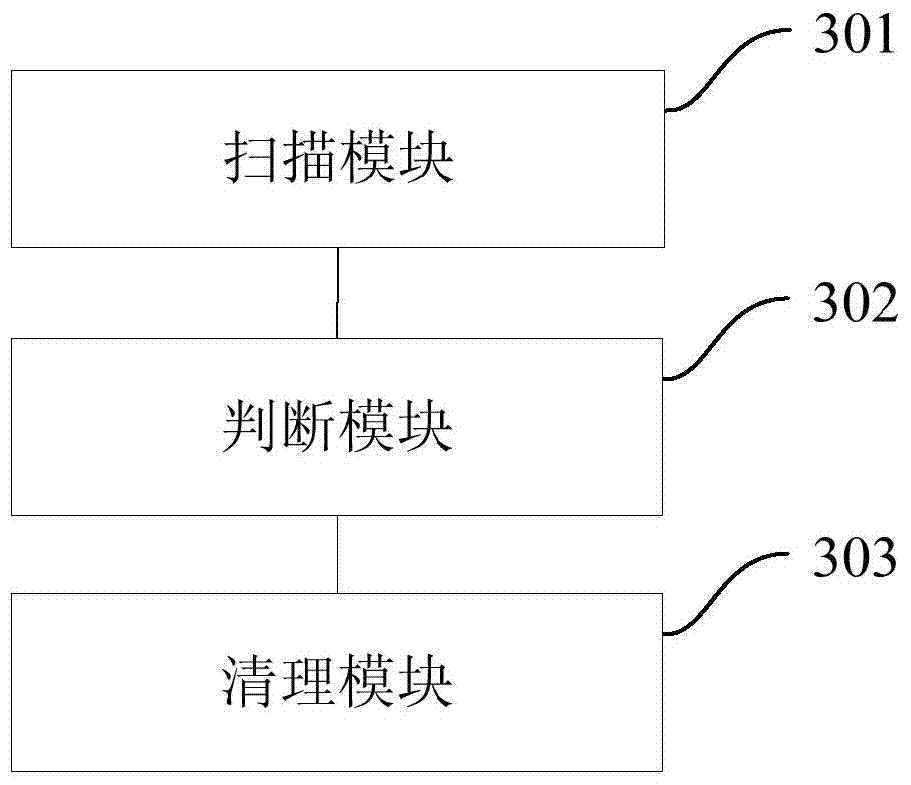

Cleaning method and device for disk space

ActiveCN104503704AIncrease disk spaceReduce the rate of manslaughterInput/output to record carriersOperating systemDisk space

The embodiment of the invention provides a cleaning method and device for a disk space. The method specifically comprises the following steps: scanning files in a disk to obtain unreleased files in the disk and procedures corresponding to the unreleased files, wherein the unreleased files are used for representing files which are not released caused by the fact that file handles are occupied by the procedures; judging whether attribute information of the procedures corresponding to the unreleased files meets pre-set abnormal conditions or not; and when the attribute information of the procedures meets the pre-set abnormal conditions, releasing the unreleased files corresponding to the procedures. By the aid of the cleaning method and device for the disk space, the disk space can be effectively improved under the condition that the working efficiency is not influenced.

Owner:BEIJING QIHOO TECH CO LTD

Double-plug series connection application method of reciprocating pump and high-efficiency liquid pump applying method

InactiveCN106678086AReduce vibrationSimple structurePressure pumpsMachines/enginesComposite applicationEngineering

The invention relates to a double-plug series connection application method of a reciprocating pump, and a high-efficiency liquid pump applying the method, and solves the problems that a conventional reciprocating pump influences the continuity of a liquid flow, and is complex in structure, high in manufacturing cost, a, and heavy. According to the double-plug series connection application method, two sets of hollow plungers or pistons, each of which is provided with a one-way valve, are assembled in a pump cylinder in a series connection manner, and are respectively in reciprocating movement in opposite directions to perform one-way pushing on the liquid flow in turns; and the liquid flow adopts a smooth, continuous and even flowing manner in a pump body. The high-efficiency liquid pump disclosed by the invention is simple in structure and high in efficiency; and a plurality of pumps are in composite application: a liquid inlet of the last pump body is integrally connected with a liquid outlet of the next pump body, the pumps are in series connection for application, and any sets in the pumps can be opened and closed according to the pressure requirement, so that the high-efficiency liquid pump is suitable for a deep oil well pump, a high-lift high-pressure pump and the like.

Owner:吴新保

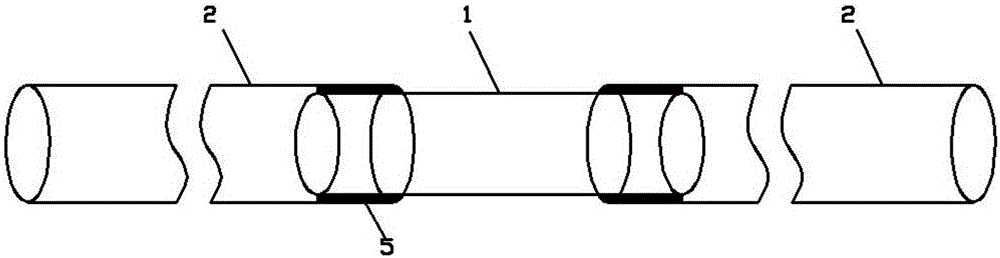

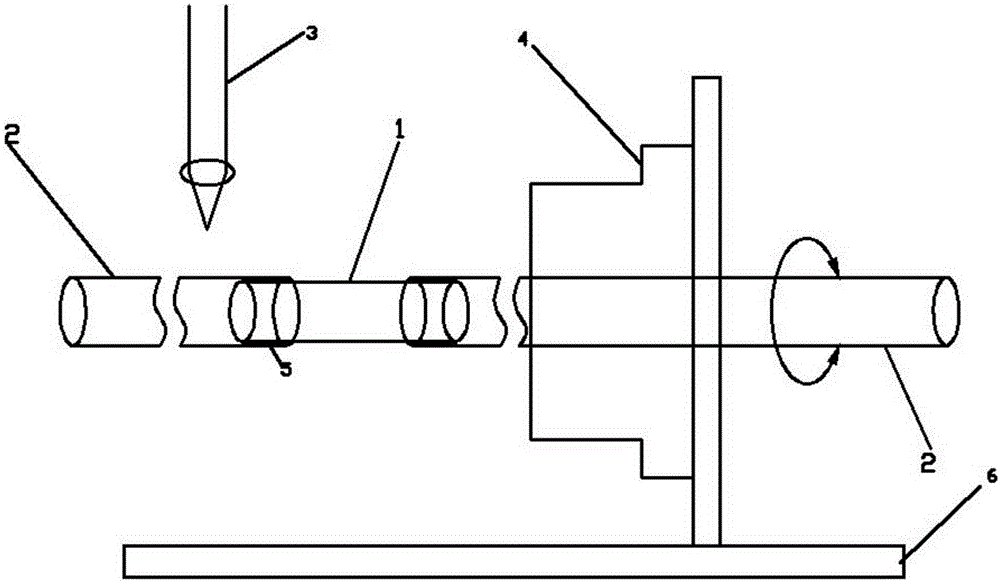

Cutting method capable of saving cardiovascular stent pipe tailings

ActiveCN105234564AIncrease profitReduce usageMetal working apparatusLaser beam welding apparatusCardiovascular stentEngineering

The invention discloses a cutting method capable of saving cardiovascular stent pipe tailings. The cutting method is characterized in that used pipes are divided into small-aperture pipes and large-aperture pipes. The cutting method comprises the following steps: firstly, selecting the small-aperture pipes with length of about 30mm, uniformly coating a layer of strong glue on the outer surfaces at the two ends of each small-aperture pipe by use of a cotton swab, bonding the two ends of each small-aperture pipe with large-aperture pipes under the action of strong glue to form bonding parts, thereby realizing seamless bonding between the small-aperture pipes and the large- aperture pipes; then, putting the bonded pipes into a clamp on a working platform to carry out cutting, wherein a small-aperture pipe section with length of about 30mm is bonded between two large-aperture pipe sections, so that large-aperture pipe tailings are reduced to an extreme; after the large-aperture pipes are cut, heating the bonding parts of the pipes, thereby realizing separation of the two pipes. The cutting method is simple to operate, and more economical; utilization rate of the pipes is increased by 5%-10%, and use of raw materials is effectively saved.

Owner:JW MEDICAL SYSTEMS LTD

Water pumping method of water pushing pipes and efficient liquid pump using method

The invention discloses a water pumping method of water pushing pipes and a liquid pump using the method. The problem of extra power consumption and the problem that a piston pump affects the continuity of liquid flow due to the fact that the direction and the speed of the liquid flow pumped by a centrifugal liquid pump are changed multiple times are solved. According to the method, two pipelines, i.e., the water pushing pipes with one-way valves are used for making reciprocating motion in opposite directions, so that one-way pushing is conducted on the liquid flow; the liquid flow flows in a pump body smoothly, continuously and evenly; the structure is simple; and efficiency is high. A plurality of combinations are applied in a composite mode, a liquid inlet of the previous combination and a liquid outlet of the next combination are connected together, the combinations are connected in series for application, and the method is suitable for a deep oil well pump, a high lift pump, a high pressure pump and the like.

Owner:吴新保

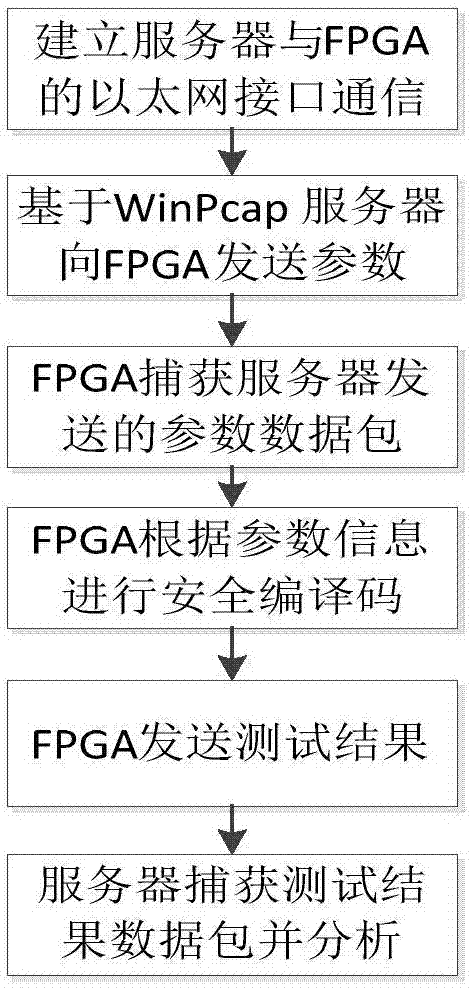

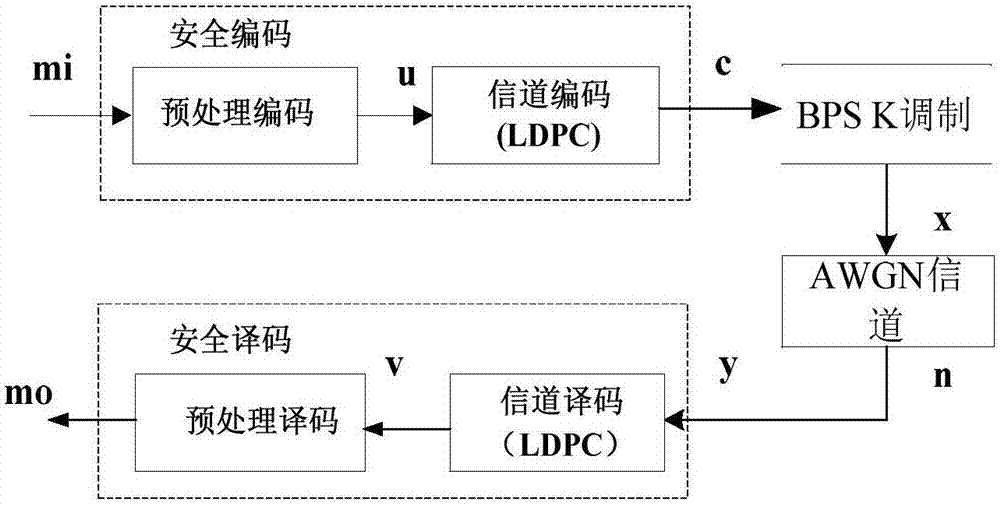

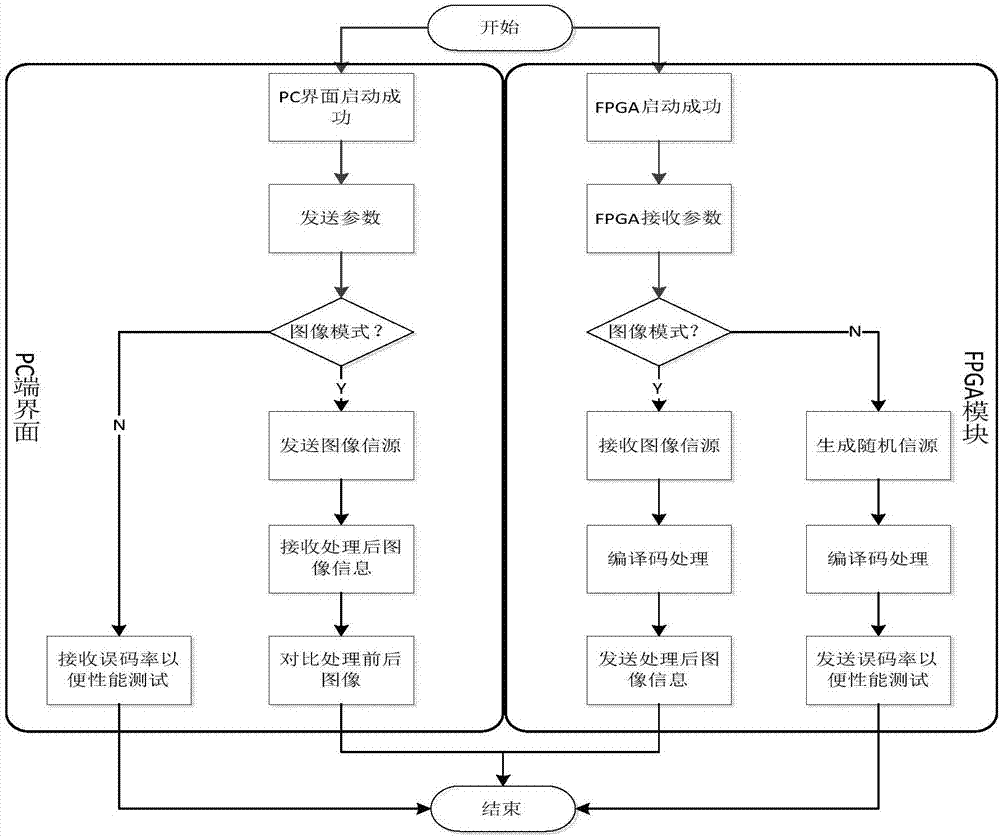

Physical layer secure coding system based on Ethernet communication

ActiveCN107342847AEasy to testGood secure coding performanceChannel coding adaptationPHYSecure coding

The invention relates to a physical layer secure coding system based on Ethernet communication. The system includes a server, an FPGA module and an Ethernet communication auxiliary platform. The FPGA module includes a physical layer PHY chip, an MAC controller and an FIFO memory. The FPGA module achieves the function of secure coding and decoding. According to the physical layer secure coding system based on Ethernet communication, communication is realized through the Ethernet communication auxiliary platform. High efficiency, high speed and high performance are obvious advantages of the Ethernet. With the Ethernet as a communication platform, the data transmission rate of the whole system will not affect the work efficiency of the system. Better coordination between hardware and software is realized. The function of physical layer secure coding is completed.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

Multi-function closed cylinder type hydraulic piling hammer

InactiveCN101748730BIncreased fall accelerationWill not affect work efficiencyBulkheads/pilesSuction forceGas chamber

The invention relates to a multi-function closed cylinder type hydraulic piling hammer. The technical scheme is as follows: the multi-function closed cylinder type hydraulic piling hammer is mainly formed by connecting an upper hammer body, a middle hammer body, a lower hammer body and a bottom hammer body, wherein, each of the upper hammer body, the middle hammer body and the lower hammer body respectively forms a closed structure; the lower hammer body mainly consists of a hammer cylinder barrel, an upper hammer core, an upper hammer core sealing device and a gas chamber, the hammer cylinder barrel and the upper hammer core form the gas chamber which is positioned at the upper part of the upper hammer core, when the upper hammer core moves downward, the pressure of the gas chamber provides the downward thrust for the hammer core, the hammer cylinder barrel is provided with a lower hammer core, a lower hammer core sealing device and a vacuum chamber therein, and the suction force of the vacuum chamber provides a downward drawing force for the hammer core. The multi-function closed cylinder type hydraulic piling hammer has the benefits that the action force in the same direction of the downward motion is increased at the upper part and the lower part of the upper hammer core, thereby improving the falling acceleration of the hammer core, improving the hitting energy under the premise of not increasing the weight of the hammer body; meanwhile, due to the adoption of the closed cylinder type structure, the working efficiency can not be affected during underwater operation.

Owner:高天宝 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com