Cutting method capable of saving cardiovascular stent pipe tailings

A cutting method and stent tube technology, which are applied to tubular articles, applications, laser welding equipment, etc., can solve the problems of waste of raw material resources, unusable rate, high price, etc., and achieve the effects of improving utilization rate, saving use and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment one: choose the 316L stainless steel tubing (small-caliber tubing) with a caliber of 1.4mm and the 316L stainless steel tubing (large-caliber tubing) with a caliber of 1.6mm:

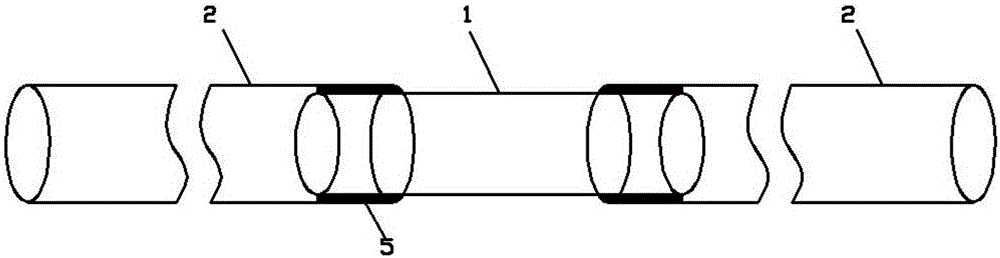

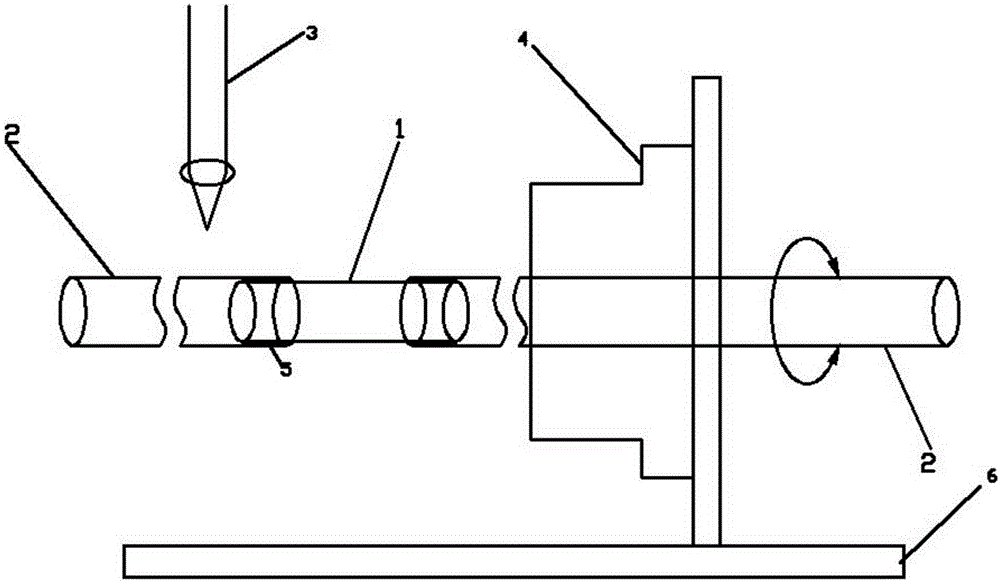

[0016] First, select a 1.4mm 316L stainless steel pipe with a length of about 30mm, and evenly apply a layer of Loctite 416 glue on the outer surface of both ends of the 1.4mm 316L stainless steel pipe with a cotton swab (other strong glue is also available), and the length of the application is 10mm ( See the bonding part 5) in the figure, and then insert a section of 1.6mm 316L stainless steel pipe at both ends of the 1.4mm 316L stainless steel pipe. mm 316L stainless steel pipes are bonded together to form the bonding part 5, thereby realizing seamless bonding between 1.4mm 316L stainless steel pipes and 1.6mm 316L stainless steel pipes; then place the bonded pipes on the working platform In the fixture 4 on 6, the 1.6mm 316L stainless steel pipe is cut by the laser beam 3 of the la...

Embodiment 2

[0017] Embodiment two: the cobalt-chromium pipe (small-diameter pipe) and the cobalt-chromium pipe (large-diameter pipe) with a diameter of 2.0mm are selected as caliber 1.6mm:

[0018] First, select a 1.6mm cobalt-chromium pipe with a length of about 30mm, and apply a layer of Loctite 416 glue evenly on the outer surface of both ends of the 1.6mm cobalt-chromium pipe with a cotton swab (other superglue is also available), and the length of the application is 10mm ( See the bonding part 5) in the figure, and then insert a section of large-diameter pipe 2 at both ends of the 1.6mm cobalt-chromium pipe, and under the action of superglue, the two ends of the 1.6mm cobalt-chromium pipe and the 2.0mm The cobalt-chromium pipes are bonded together to form the bonding portion 5, thereby realizing the seamless bonding between the 1.6mm cobalt-chrome pipes and the 2.0mm cobalt-chromium pipes; then the bonded pipes are placed on the working platform 6 In the fixture 4, the laser beam 3 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com