Nail blanking assembly for cooling fin glue nail installation and labeling machine

A labeling machine and nail dropping technology, which is applied to conveyor objects, conveyors, transportation and packaging, etc., can solve the problems of forehearth stuck, the pneumatic control board cannot be reset, and accurate quantitative blanking cannot be realized.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

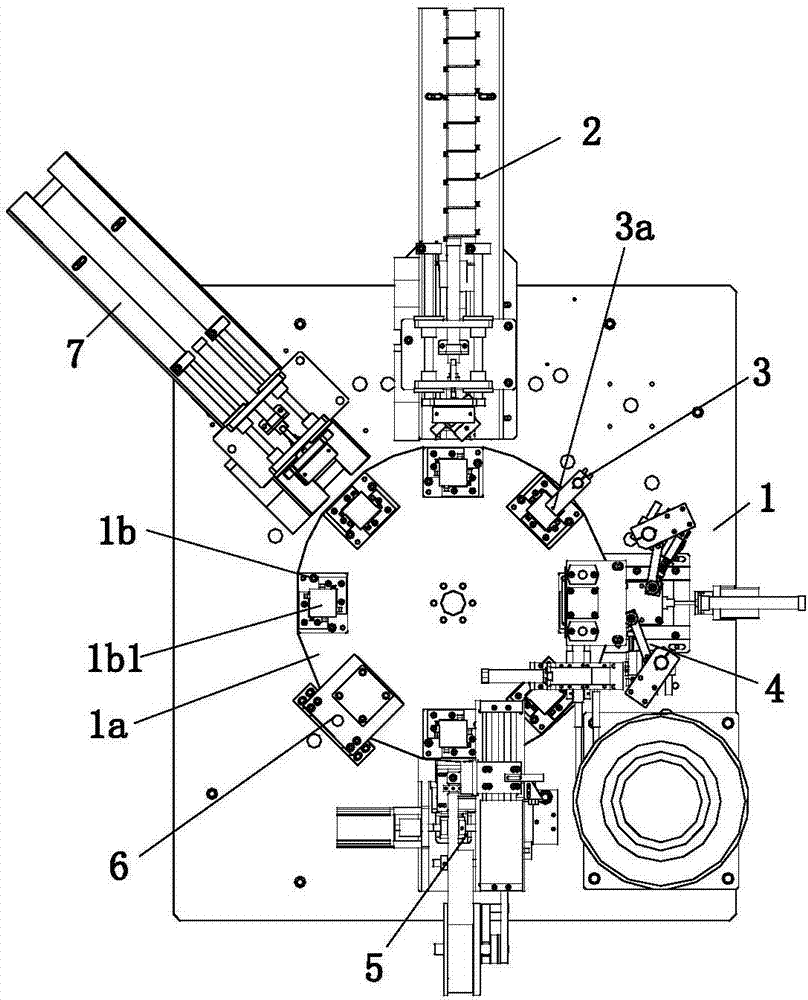

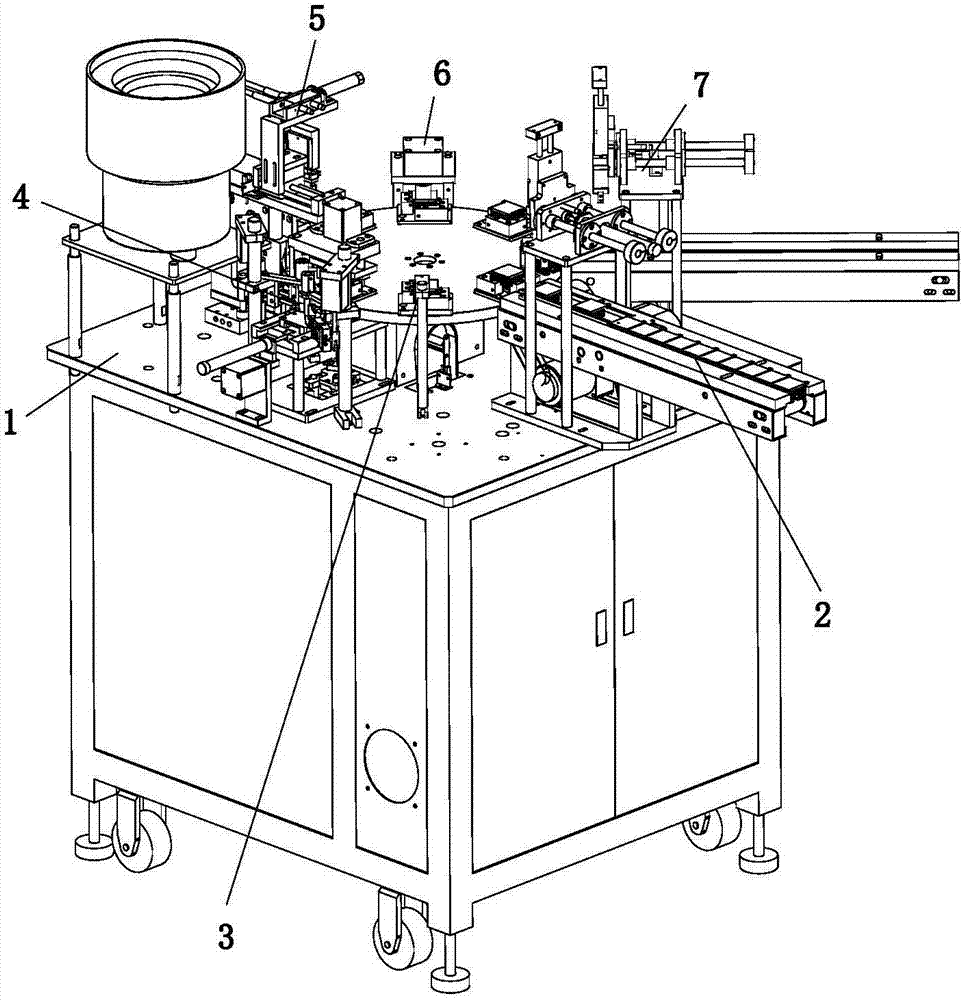

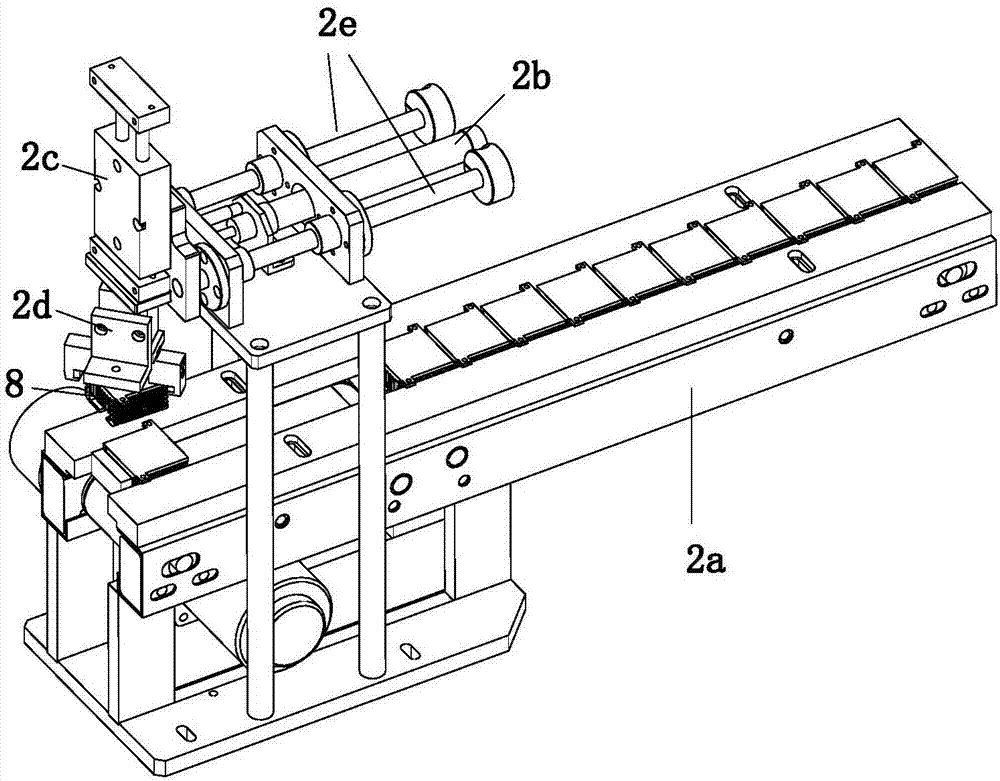

[0027] refer to figure 1 with figure 2 As shown, a labeling machine with rubber nails for heat sinks includes a workbench 1, which is provided with a turntable 1a, and the turntable 1a is pivotally connected to a certain shaft above the workbench 1 through a bearing mechanism. The workbench 1 The stepper motor that drives the turntable 1a to move stepwise around the fixed axis is located below the turntable 1a. The turntable 1a is provided with a number of positioning fixtures 1b that are evenly distributed along the circumference. The direction of rotation is provided with heat sink feeding device 2, heat sink in-position detection device 3, rubber nail installation device 4, heat sink labeling device 5, label pressing device 6 and heat sink unloading device 7.

[0028] The positioning fixture 1b includes an emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com