Multi-function closed cylinder type hydraulic piling hammer

A hydraulic piling hammer, multi-action technology, applied in the direction of sheet pile wall, building, foundation structure engineering, etc., can solve the problems affecting the efficiency of the hammer, and achieve the effect of increasing the striking energy and increasing the falling acceleration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: (designed with gas chamber and vacuum chamber)

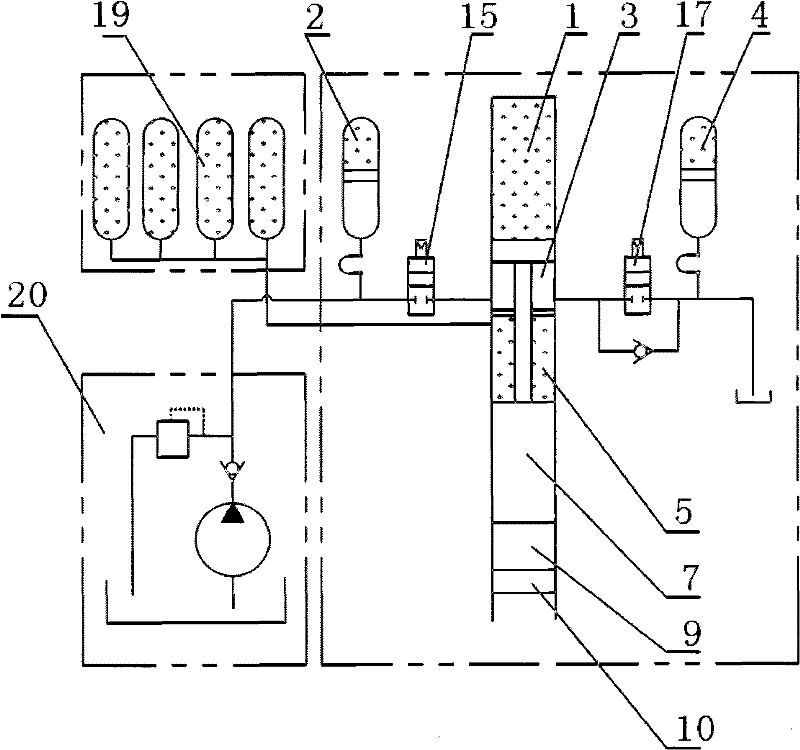

[0025] Refer to attached figure 1 with 2 , The hydraulic piling hammer system used in the present invention includes: a hydraulic power unit HPU, a hydraulic hose winch (optional), a hydraulic piling hammer PHD, and a control unit CSU.

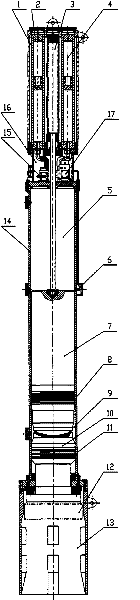

[0026] The hydraulic piling hammer of the present invention consists of a high-pressure nitrogen chamber 1, a high-pressure accumulator 2, a single-acting oil cylinder 3, a low-pressure accumulator 4, a gas chamber 5, a sensor 6, an upper hammer core 7, and an upper hammer core sealing device 8. Vacuum chamber 9, lower hammer core 10, lower hammer core sealing device 11, replacement block 12, pile sleeve 13, hammer cylinder 14, oil inlet valve 15, oil distribution chamber 16, oil return valve 17. For working conditions with pile frame conditions, the pile sleeve can be omitted. Among them, the upper hammer body, the middle hammer body, the lower hammer body and the bottom...

Embodiment 2

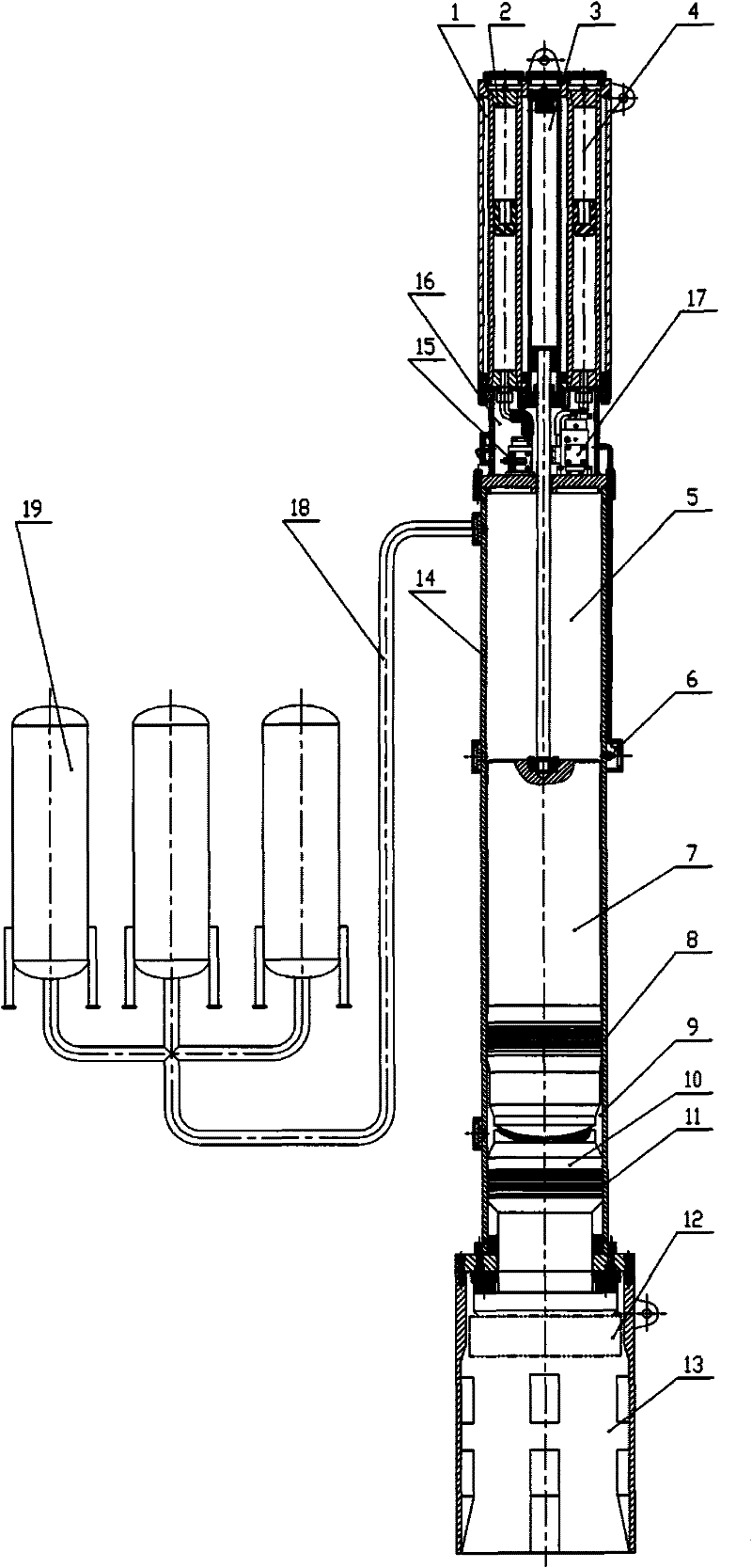

[0031] Refer to attached image 3 , another form of structure of the present invention (increasing the gas storage tank): other structures are the same as embodiment 1, and the difference is that when the piling work needs a higher sum and a fixed acceleration, the gas storage tank 19 can be increased, and the rubber hose 18 will The gas storage tank 19 is connected with the low-pressure gas chamber 5 to form a gas chamber with a larger volume, and a certain pressure is pre-applied. When the upper hammer core 7 reciprocates, the space formed by the gas storage tank and the gas chamber is much larger than the hammer cylinder. Therefore, when the upper hammer core 7 reciprocates, the relative volume change is small, so the pressure in the low-pressure air chamber 5 will not change greatly due to the reciprocating movement of the upper hammer core 7, thereby ensuring the effect on the The active force on the upper hammer core 7 remains constant.

Embodiment 3

[0033] Refer to attached Figure 4 , a structural form of the multi-action airtight cylinder type hydraulic piling hammer hammer body structure of the present invention (designed with a vacuum chamber), in the structure of this embodiment, there is no gas chamber 5, and when the upper hammer core 7 moves downward, There are three forces with the same direction of motion, which are respectively the gravity of the upper hammer core 7, the thrust formed by the pressure of the gas on the top of the single-acting cylinder 3 pistons, and the pulling force formed by the vacuum suction of the upper hammer core 7 lower vacuum chamber 9.

[0034] For other structures of the present invention, refer to Embodiment 1. The difference is that the upper part of the upper hammer core is an open structure with more than one opening. The hammer cylinder 14 is provided with a lower hammer core 10, a lower hammer core sealing device 11 and Vacuum chamber 9, vacuum chamber 9 is made of hammer cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com