Pre-assembly workbench for motor tricycle

A technology of three-wheeled motorcycles and workbenches, which is applied in the field of machinery, can solve the problems of not improving the working efficiency of three-wheeled motorcycles, and achieve the effects of reducing labor intensity, improving work efficiency, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

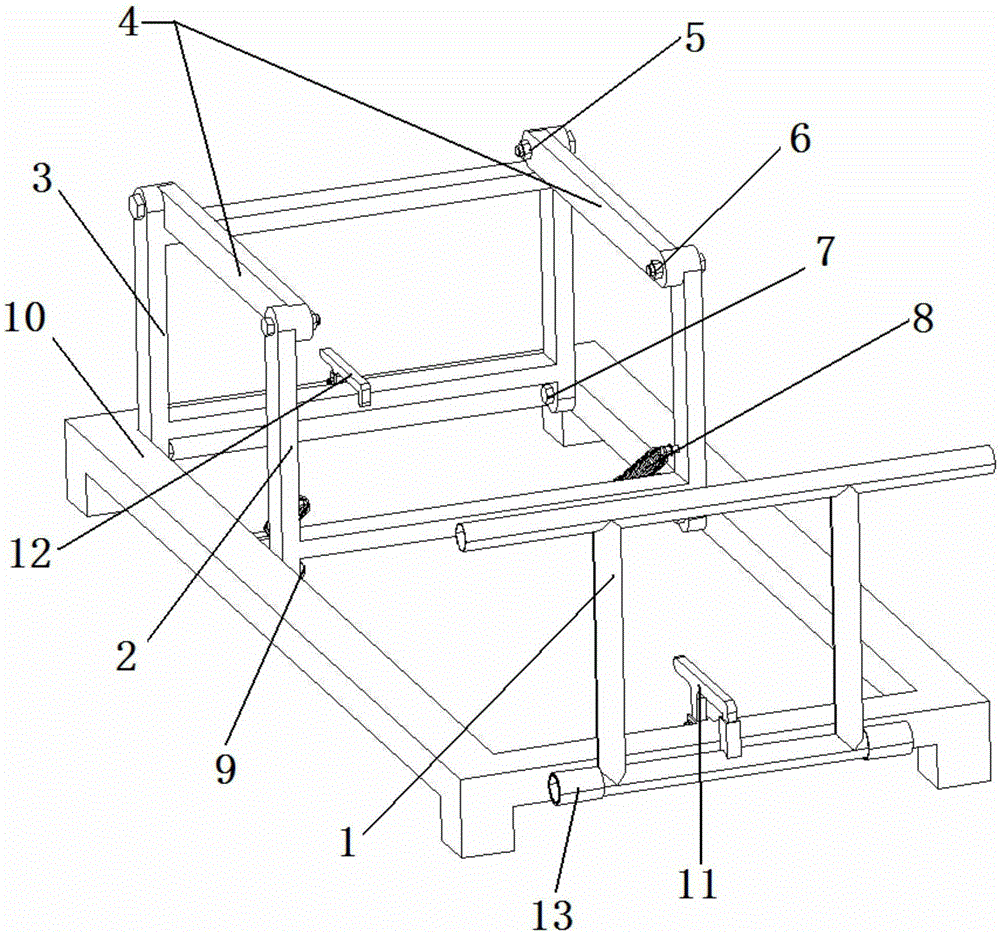

[0014] Three-wheel motorcycle pre-installation workbench, including base 10, first bracket 1, second bracket 2, third bracket 3, load-bearing link 4, first locking mechanism 11 and second locking mechanism 12, first bracket 1. The lower end is connected to the front end of the base 10 through the first rotating pair 13, the lower end of the second bracket 2 is connected to the middle of the base 10 through the second rotating pair 9, and the lower end of the third bracket 3 is connected to the bottom of the base 10 through the third rotating pair 7. At the rear end, one end of the load-bearing link 4 is connected to the upper end of the second bracket 2 through the fourth rotating pair 6, and the other end is connected to the upper end of the third bracket 3 through the fifth rotating pair 5, and the first locking mechanism 11 is installed on the base 10 and the second bracket. On a bracket 1 , the second locking mechanism 12 is installed on the base and the third bracket 3 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com