Automatic double-sided printing device

A double-sided printing, automatic technology, applied in printing, printing machines, general parts of printing machinery, etc., can solve problems such as increased equipment failure rate, easy occurrence of paper jams, increased labor costs for maintenance personnel, etc., to reduce the failure rate, The effect of reducing labor costs and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

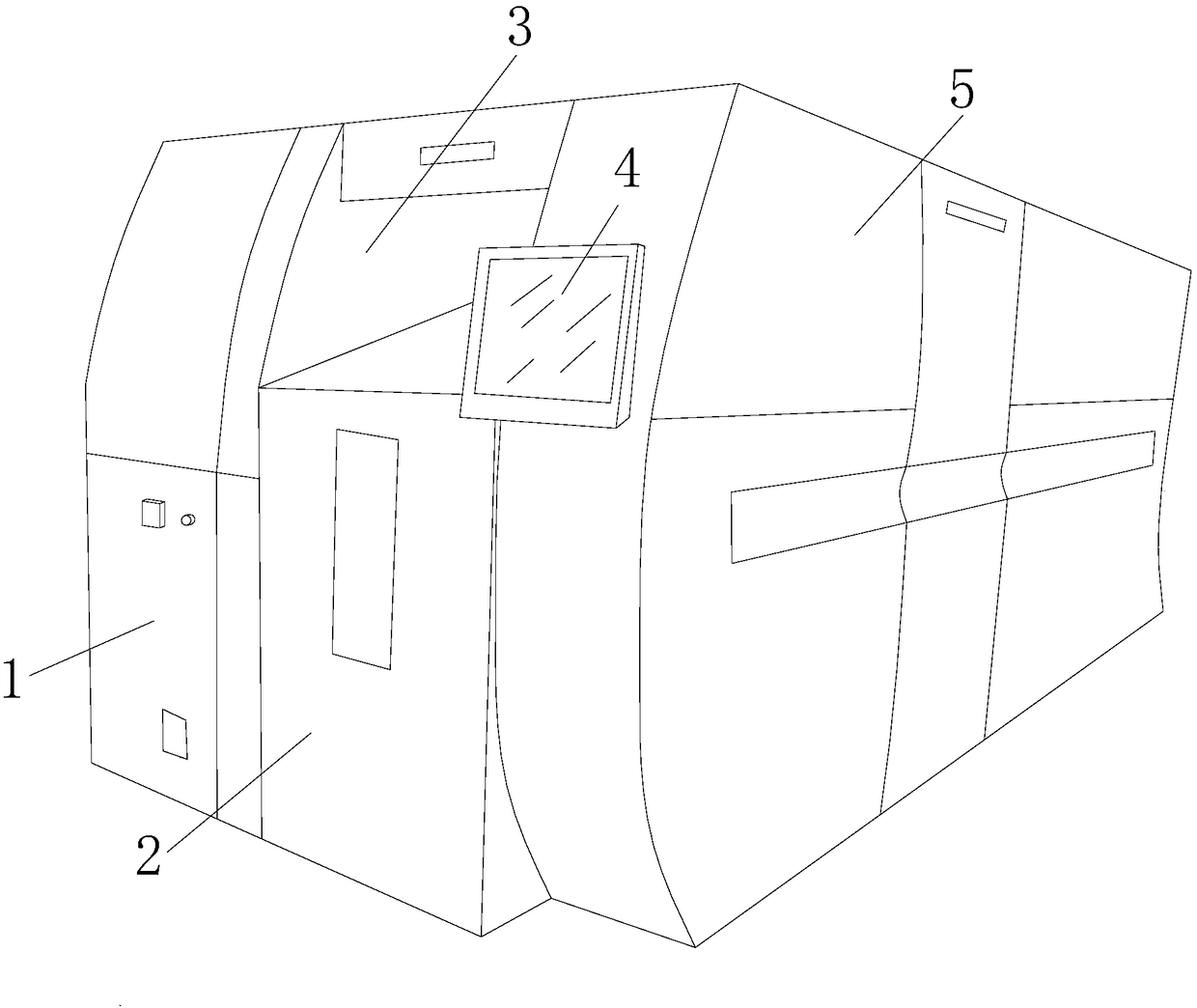

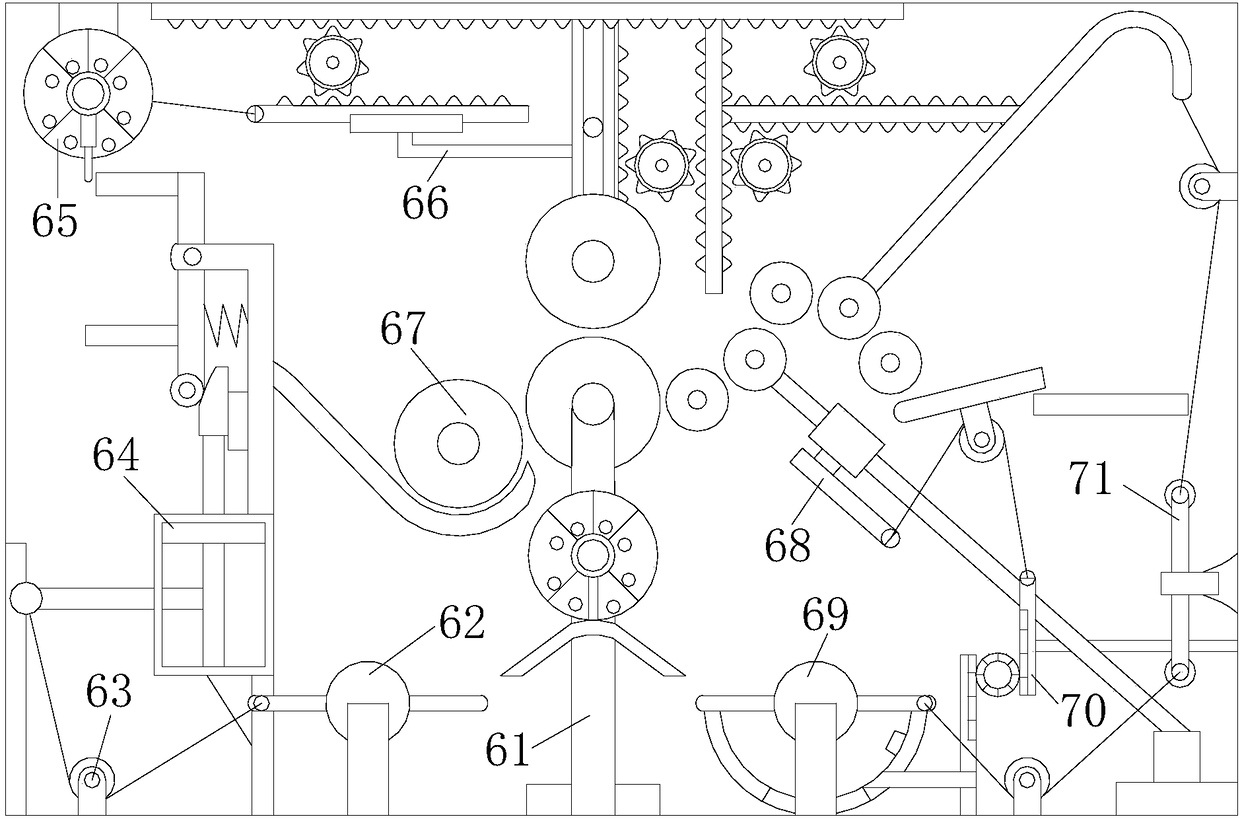

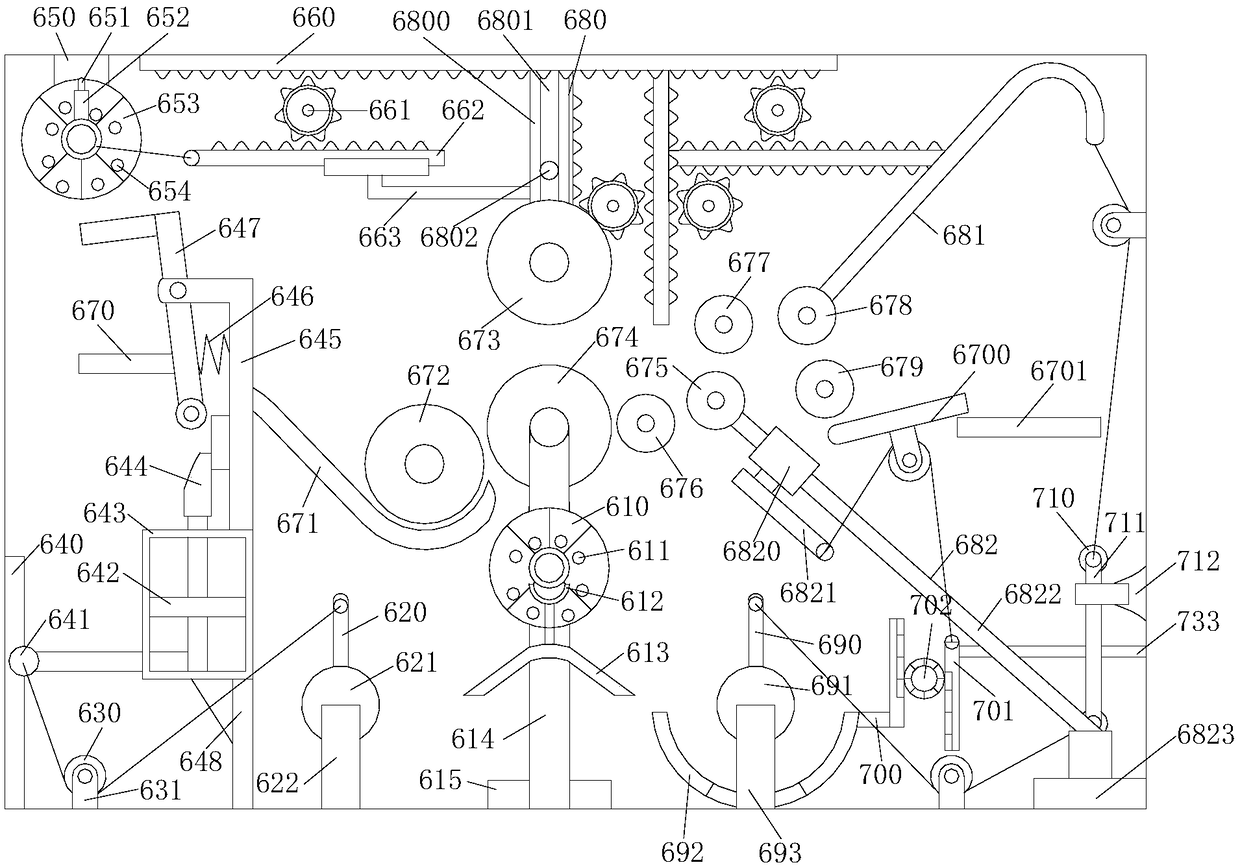

[0025] see Figure 1-Figure 3 , the present invention provides an automatic double-sided printing equipment: its structure includes an internal inspection chamber 2, a paper outlet 3, an intelligent control panel 4, a printing machine 5, and an internal paper jam automatic repair device 6. The inspection chamber 1 and the internal inspection chamber The bin 2 is adjacent, the paper outlet 3 is located above the inner inspection bin 2, the inner inspection bin 2 and the paper outlet 3 form an integrated structure, and the intelligent control board 4 is installed on the printing machine 5 to set a paper outlet The side of the mouth 3, the paper outlet 3 is adjacent to the intelligent control board 4, the internal jamming automatic repairing device 6 is installed inside the printing machine 5, and the internal jamming automatic repairing device 6 is composed of a drop bead structure 61 , a turning structure 62, a wire wheel structure 63, a pushing mechanism 64, a rolling structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com