Novel laser welding machine for automobile part machining

A laser welding machine, auto parts technology, applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of increased labor costs, slow welding speed, inconvenient welding, etc., to achieve reduced labor costs, fast welding speed , The effect of convenient welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

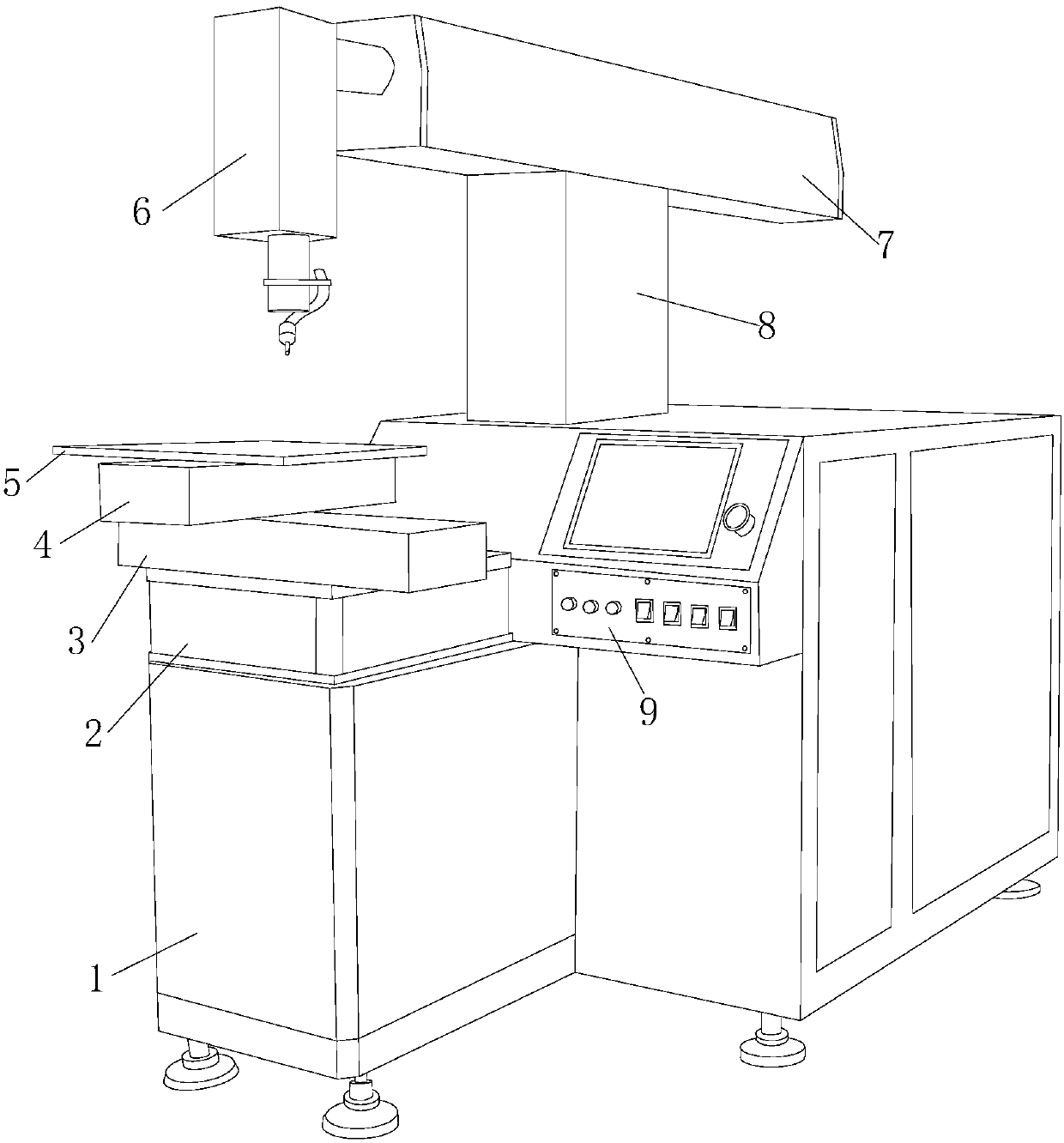

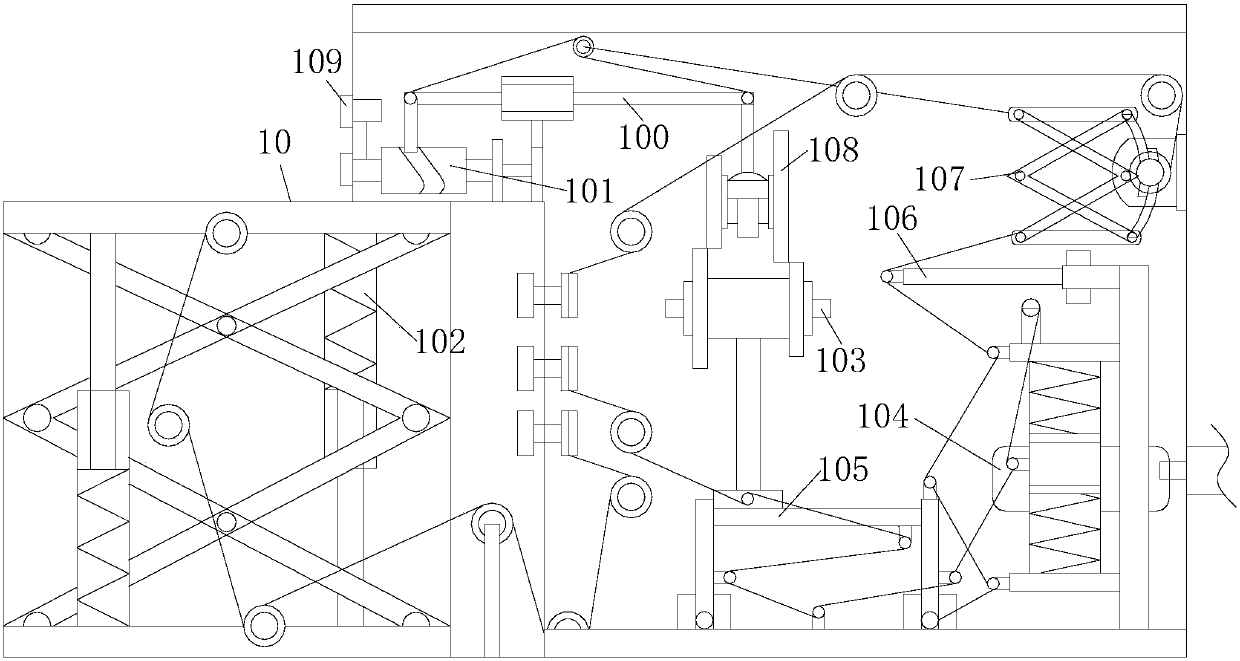

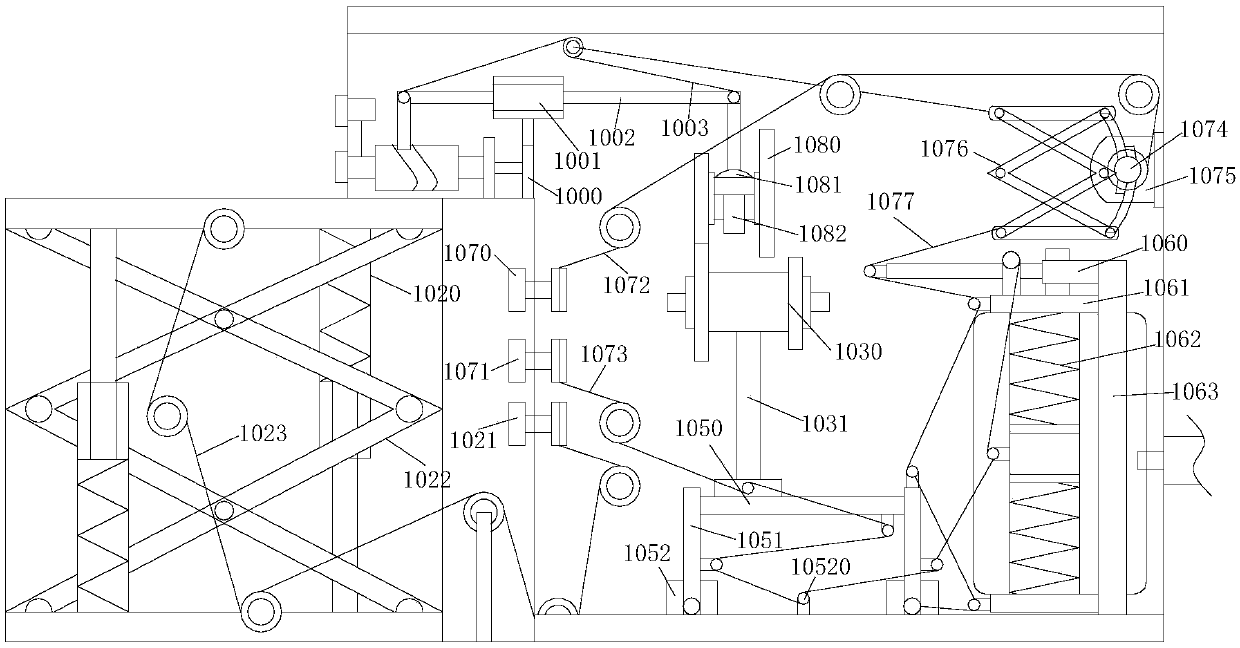

[0027] see Figure 1-Figure 3 , the present invention provides a new type of laser welding machine for auto parts processing: its structure includes a welding machine body 1, a lifting machine 2, a front and rear moving machine 3, a left and right moving machine 4, a positioning plate 5, a welding machine head 6, a machine Head moving frame 7, machine head elevating frame 8, data console 9, welding processing mechanism 10, described lifting and moving machine 2 is installed on welding machine body 1 and is positioned at the top of data console 9 side, is characterized in that:

[0028]The lifting and moving machine 2, the front and rear moving machine 3, the left and right moving machine 4, and the positioning plate 5 are arranged from top to bottom. The main body 1 is close to the side of the lifting and shifting machine 2. The head moving frame 7 and the head lifting frame 8 are in a vertical structure. The head lifting frame 8 is vertically installed on the welding machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com