Follow-up hooks on tray lifting mechanism of shuttling car

A lifting mechanism and tray technology, applied in the field of follow-up hooks, to avoid the effect of falling back

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

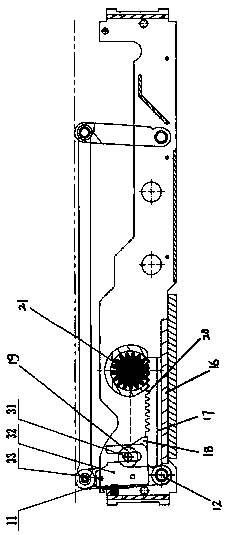

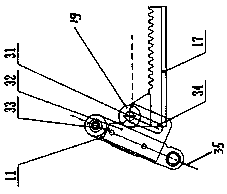

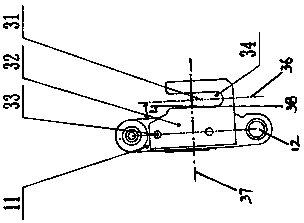

[0020] The present invention is described in detail below in conjunction with accompanying drawing:

[0021]A pallet lifting mechanism for a shuttle trolley, comprising a shelf support beam rear side guide rail 1 and a shelf support beam front side guide rail, a shuttle trolley is movable between the shelf support beam rear side guide rail 1 and the shelf support beam front side guide rail, the shuttle The frame of the trolley is composed of a rear trough frame 2, a front trough frame 5, a left frame 8 and a right frame. The front side traveling wheels 7 of the shuttle trolley are provided, and four pairs of traveling wheels are arranged symmetrically on the outside of the front trough frame 5 and the rear trough frame 2 of the vehicle frame of the shuttle trolley, one pair of which is the active traveling wheel pair, It is connected with the main drive gear 26. The two road wheels at the right end of the frame of the shuttle car are connected to each other through the long ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com