Bending fixture

A bending and jig technology, applied in the field of flexible OLED screen bending process, can solve the problems of uneven coating, affecting the bending quality and yield rate of flexible OLED screens, and insufficient restrictions on flexible OLED screens, etc., to achieve improved Bending quality and yield, and the effect of ensuring the consistency of pasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only part of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

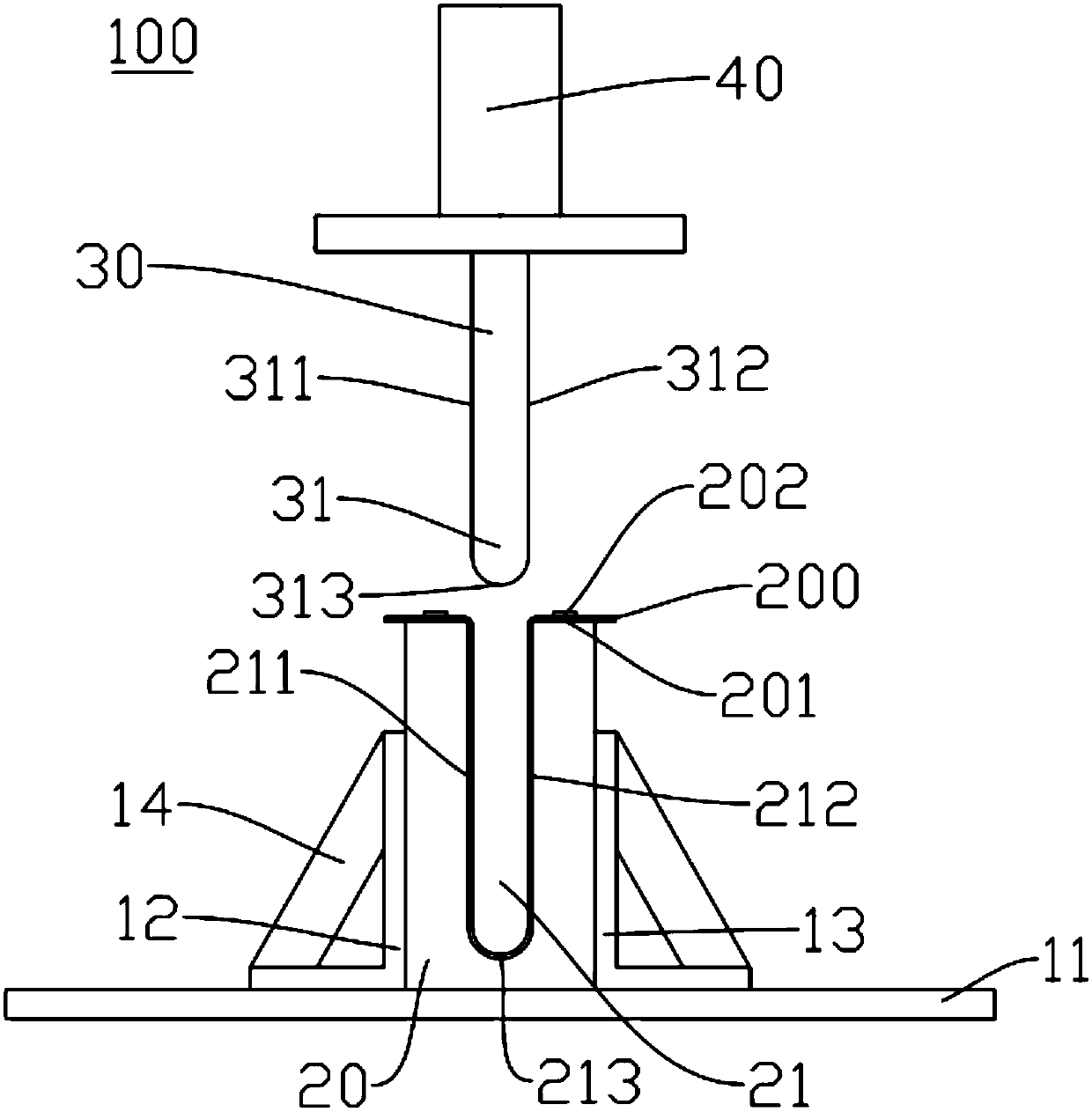

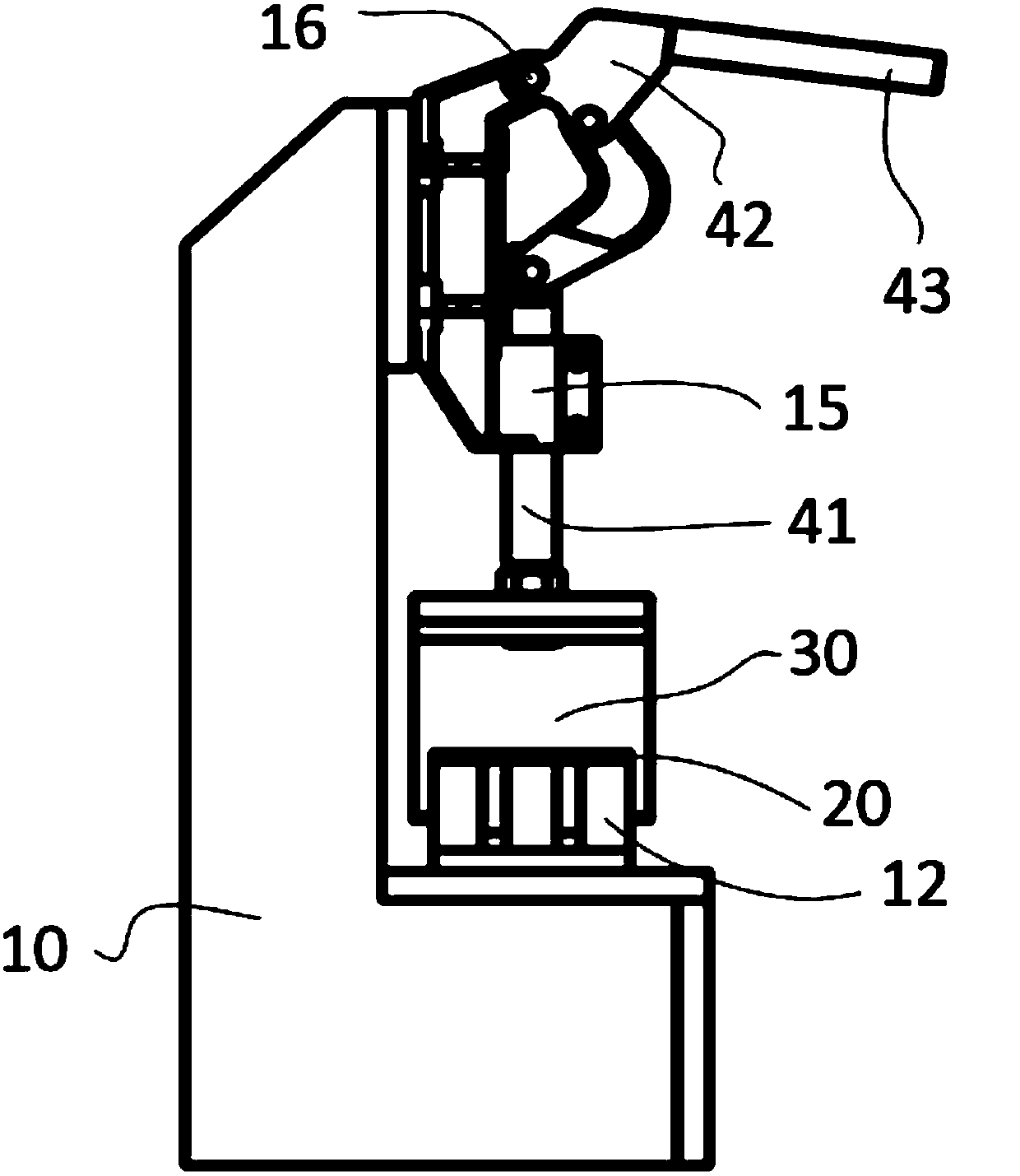

[0019] see figure 1 The bending jig 100 includes a bracket 10, a die 20, a punch 30 and a pressure handle 40, the bracket 10 cooperates with the die 20, the punch 30 cooperates with the pressure handle 40, and the flexible OLED The screen 200 is bent and shaped through the cooperation and pressing of the concave mold 20 and the convex mold 30 . Wherein, the bracket 10 includes a base 11, a left side plate 12 and a right side plate 13, and the ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com