Patents

Literature

68results about How to "Achieve disengagement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

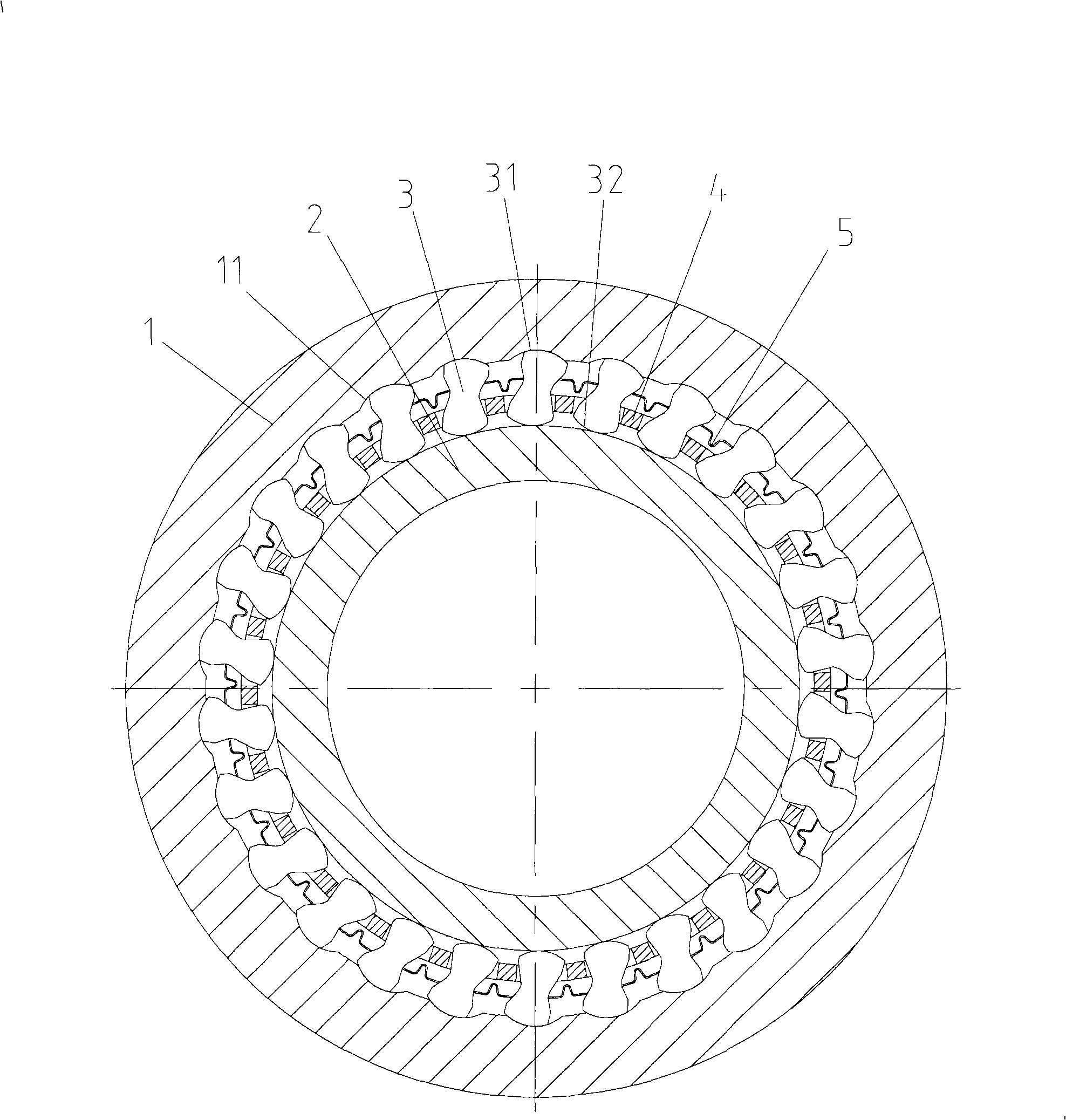

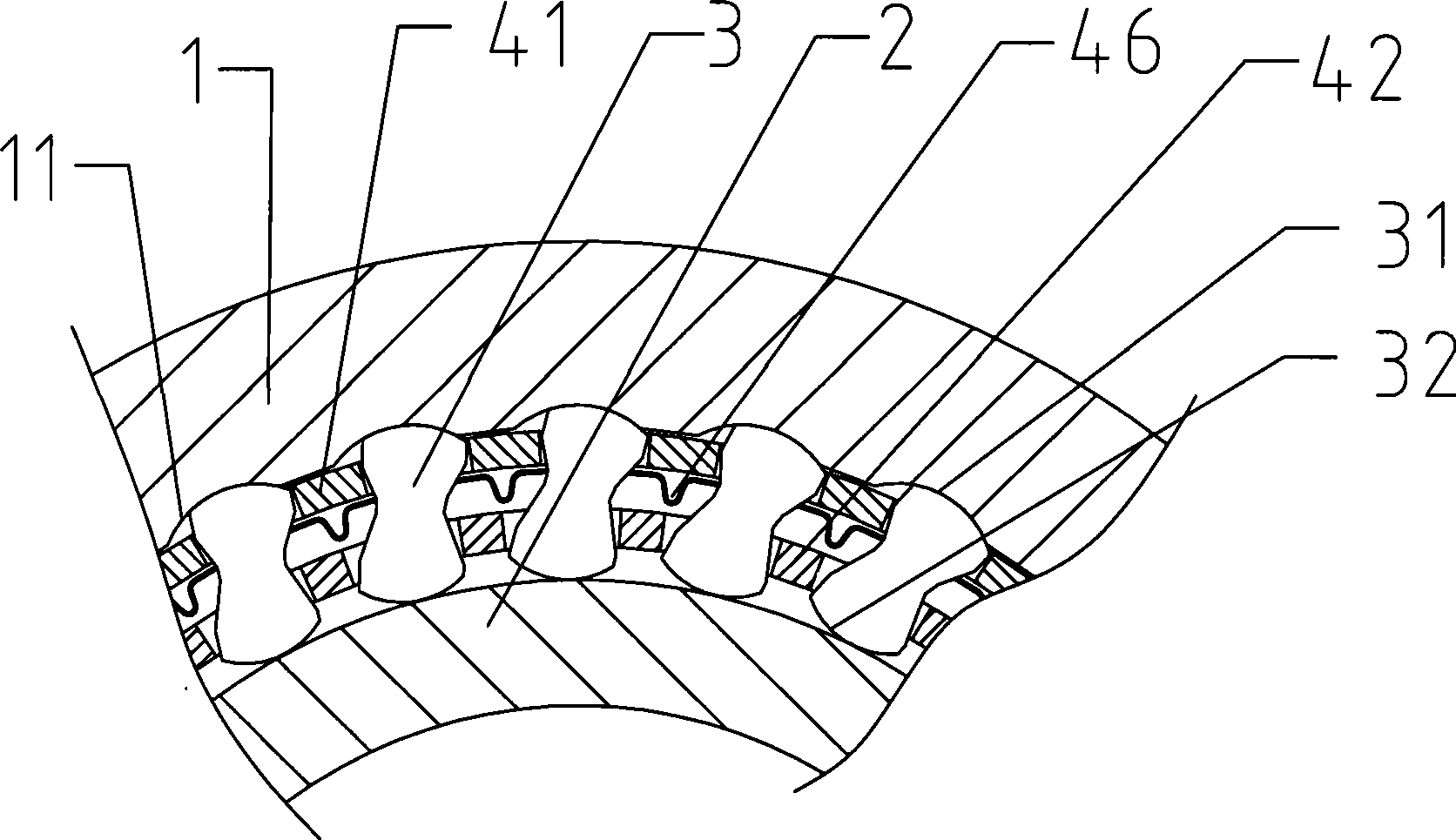

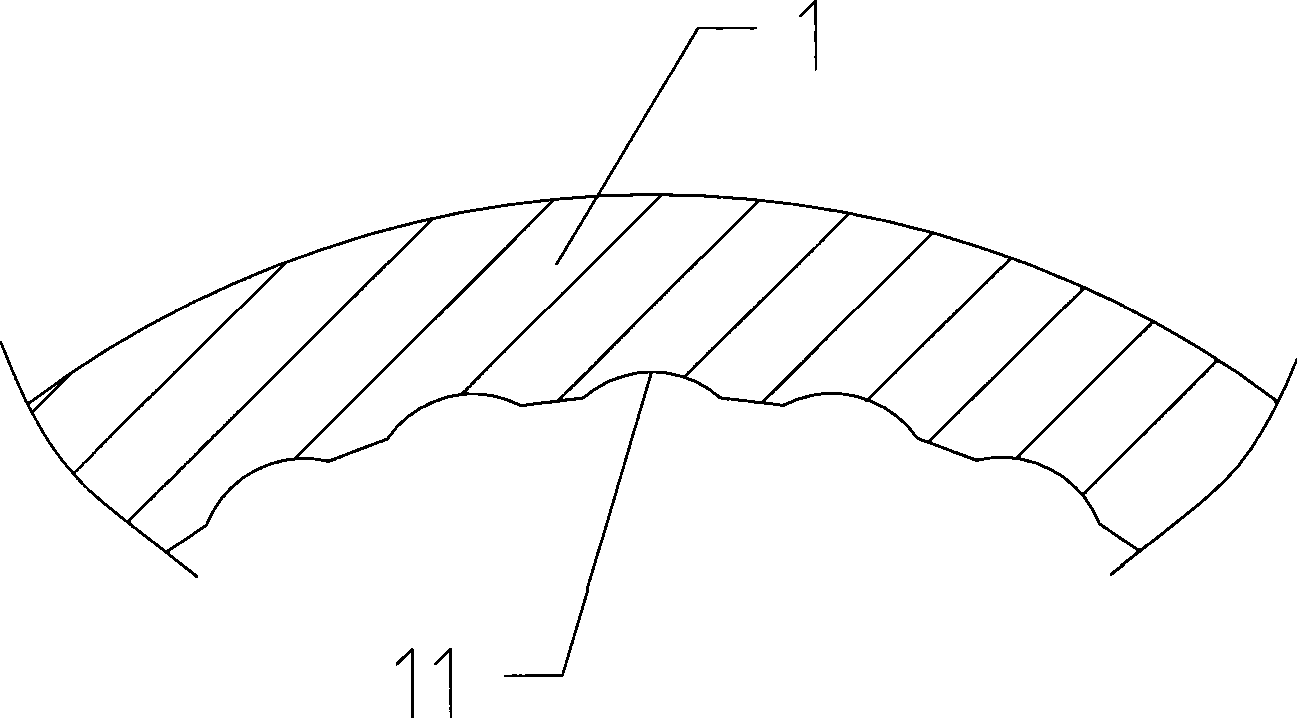

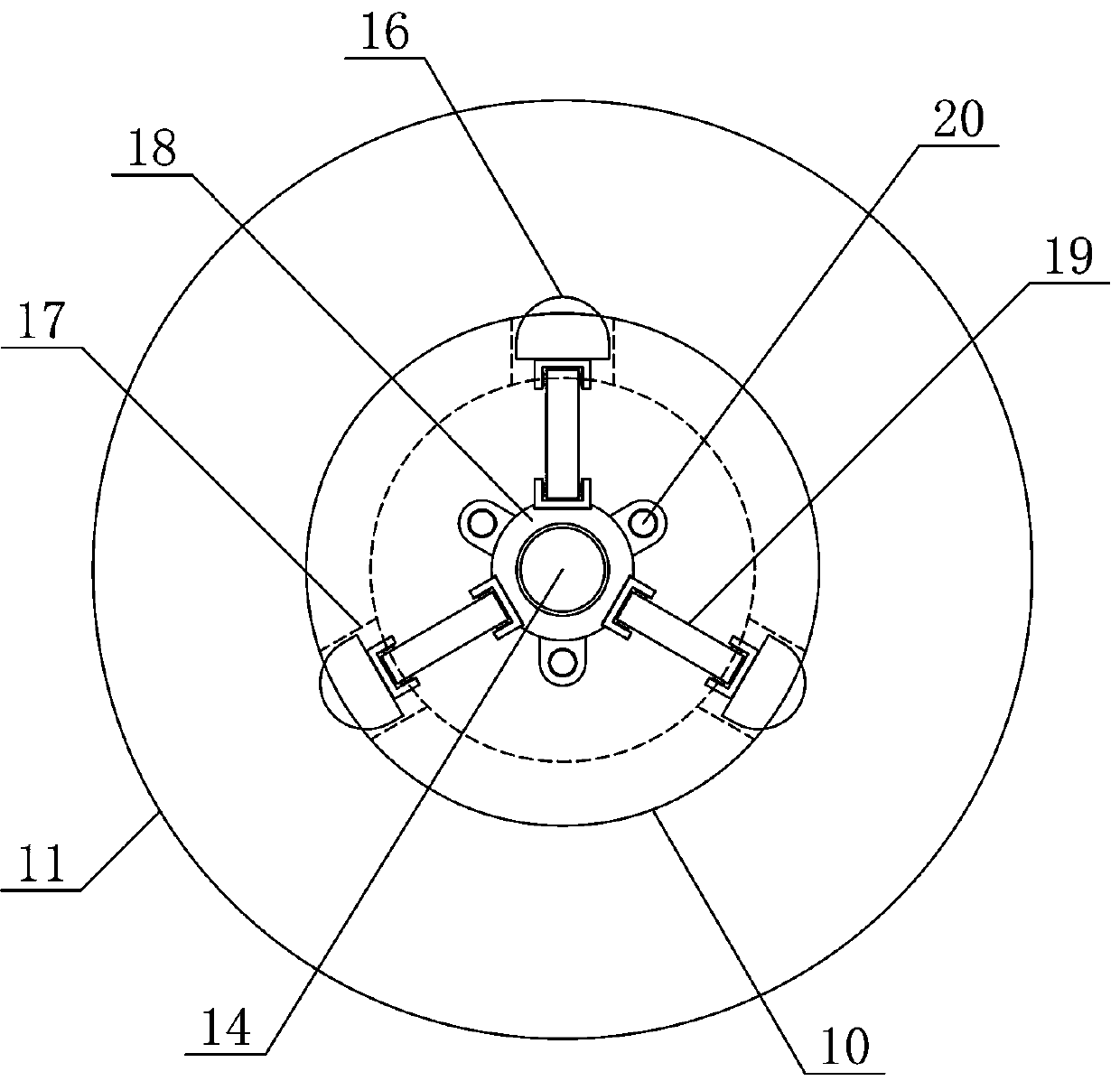

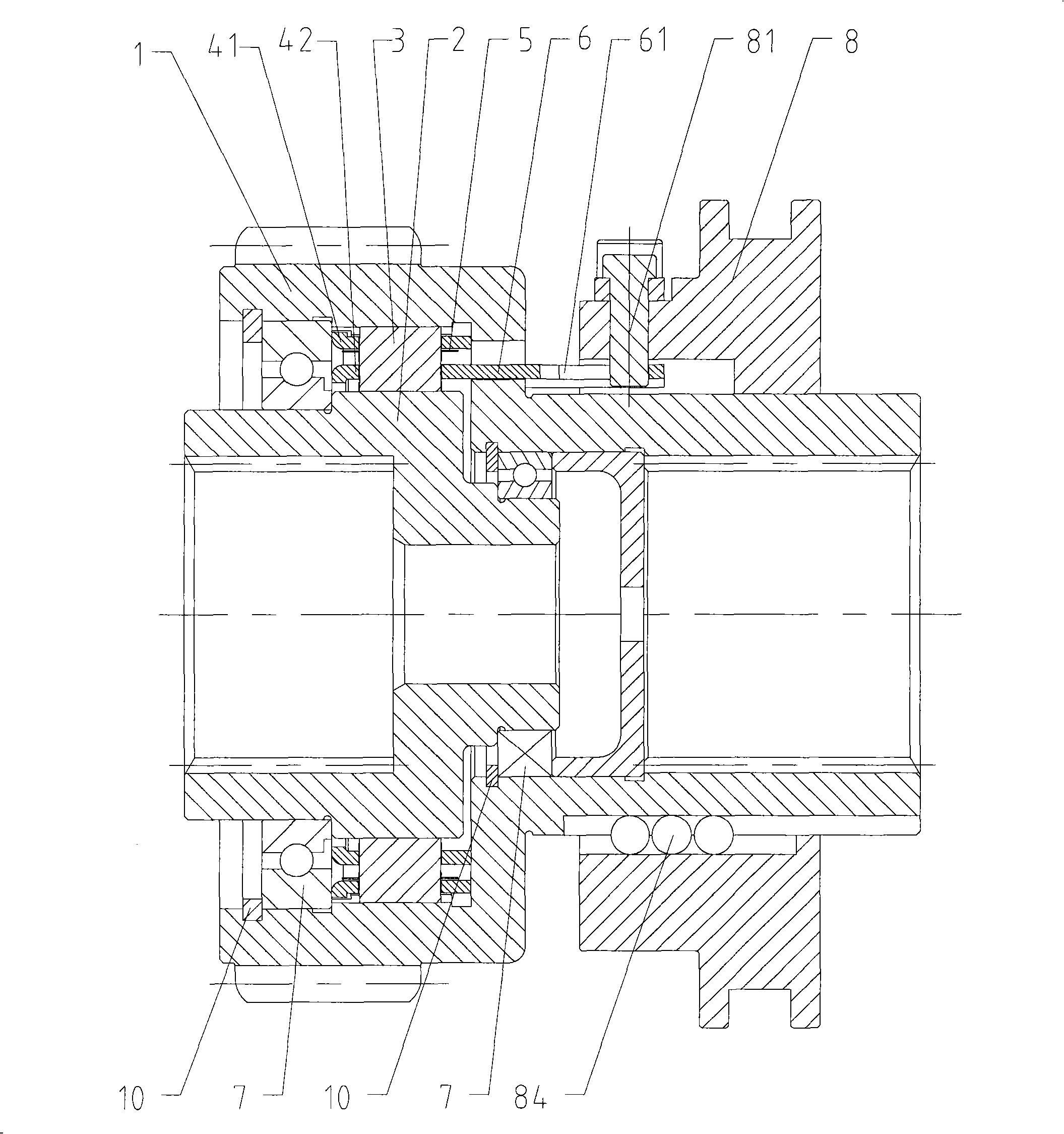

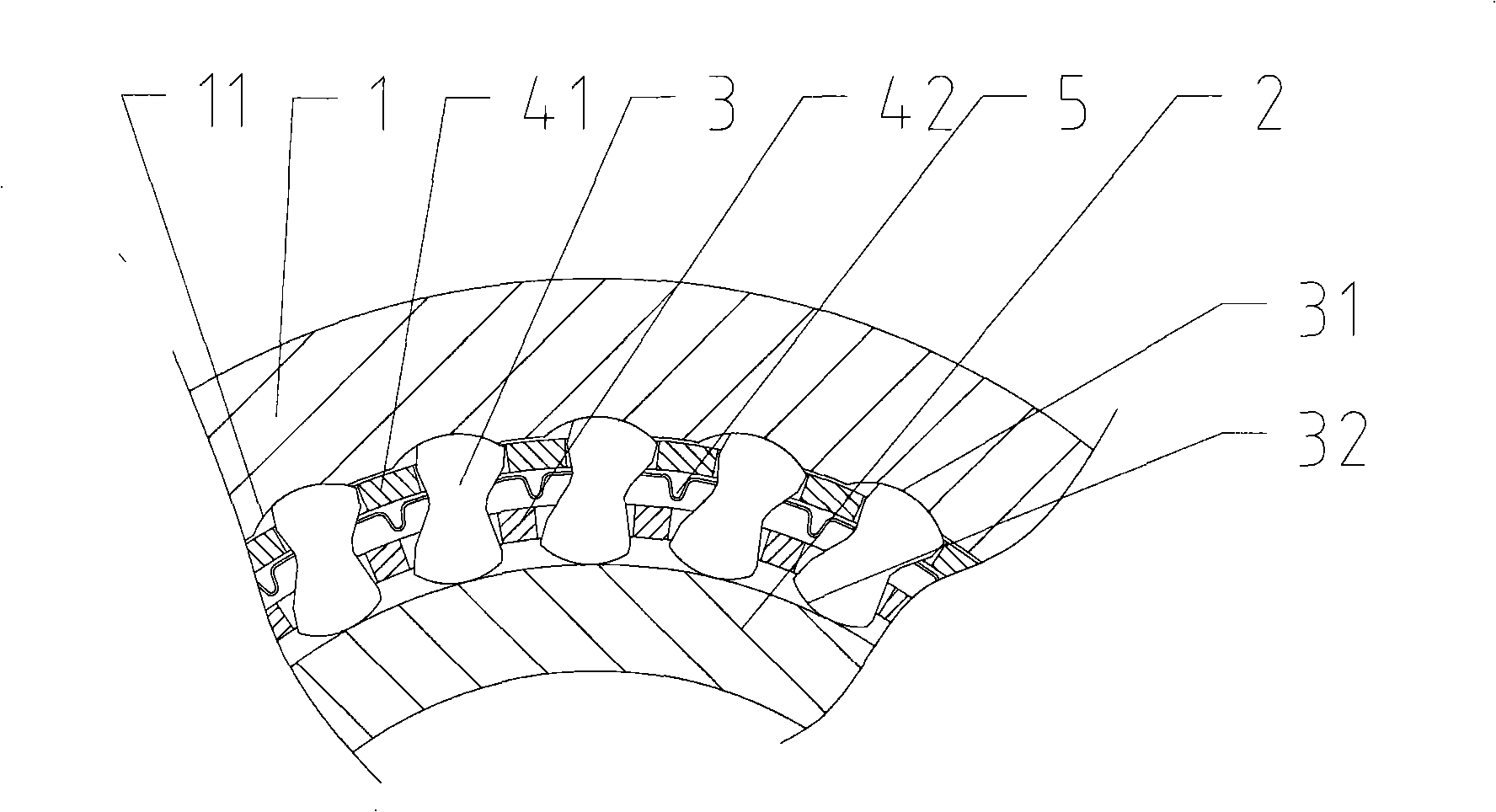

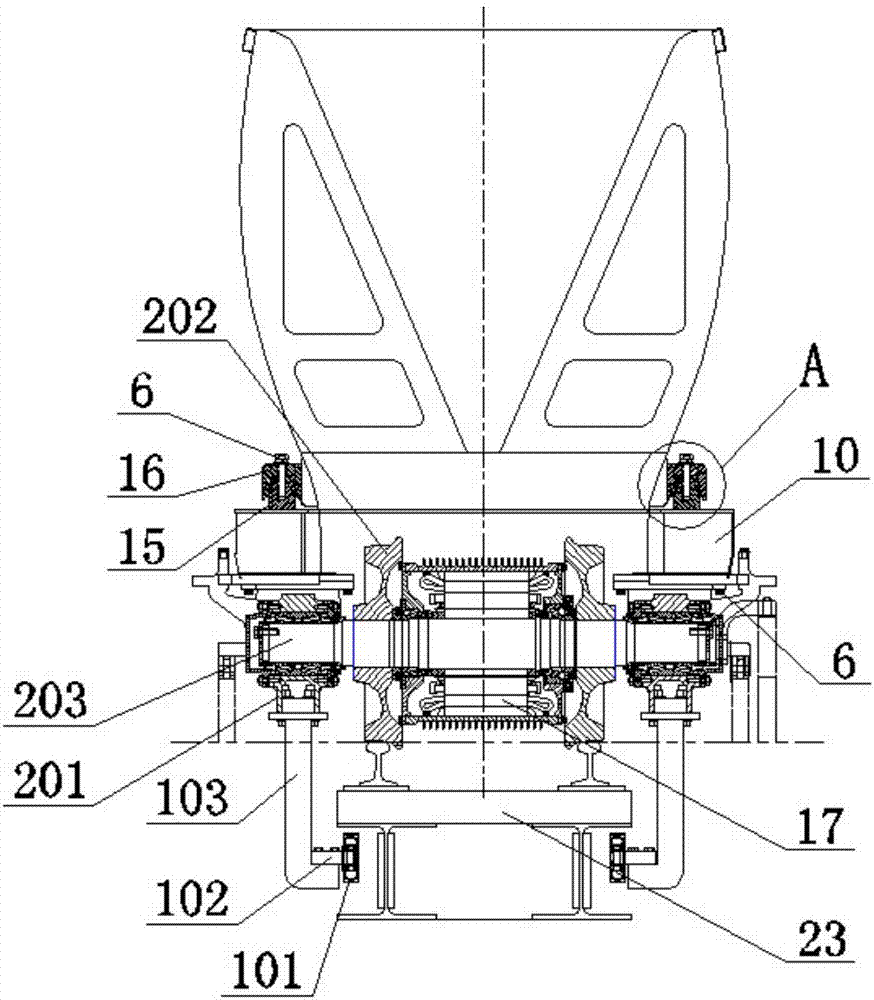

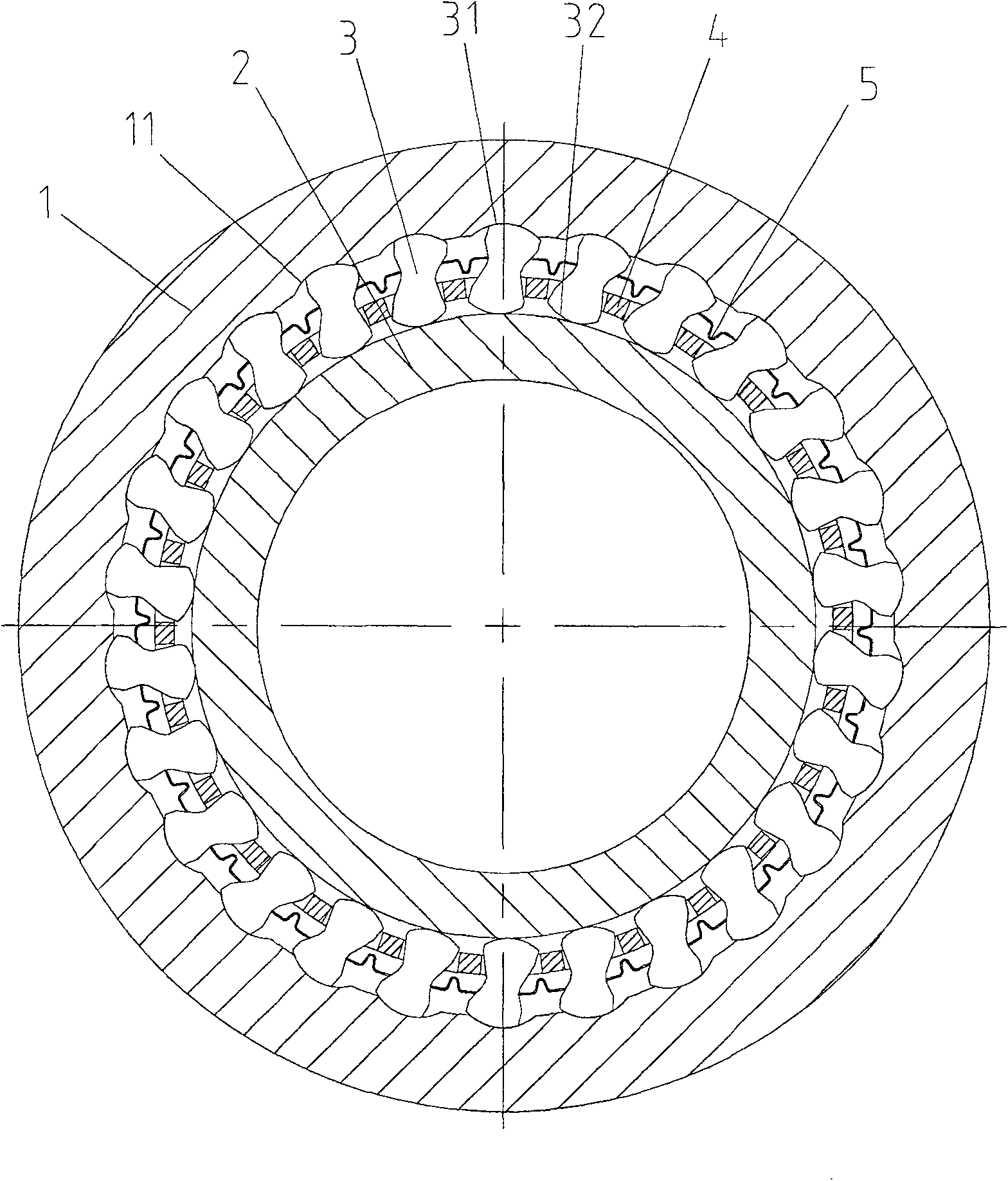

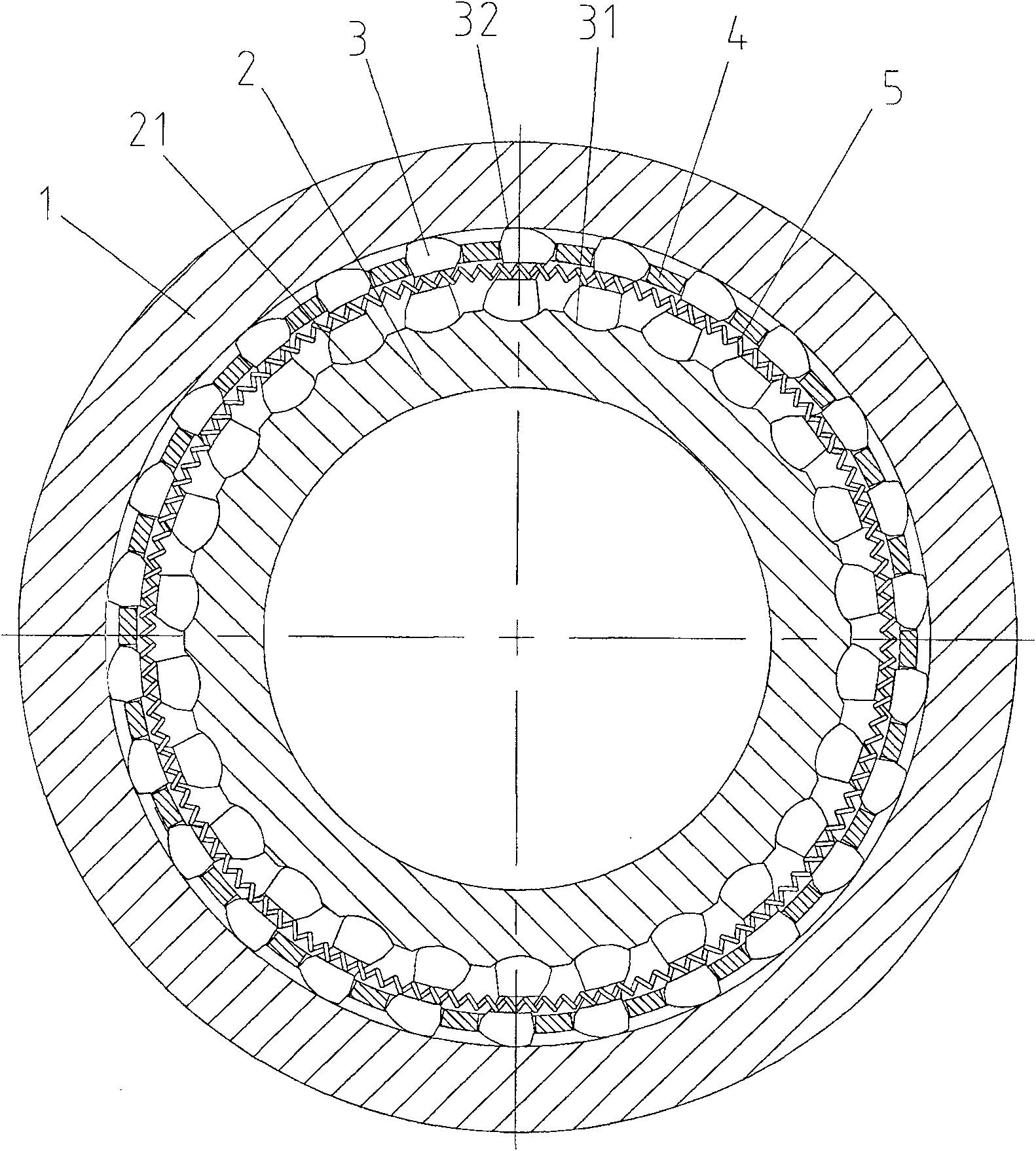

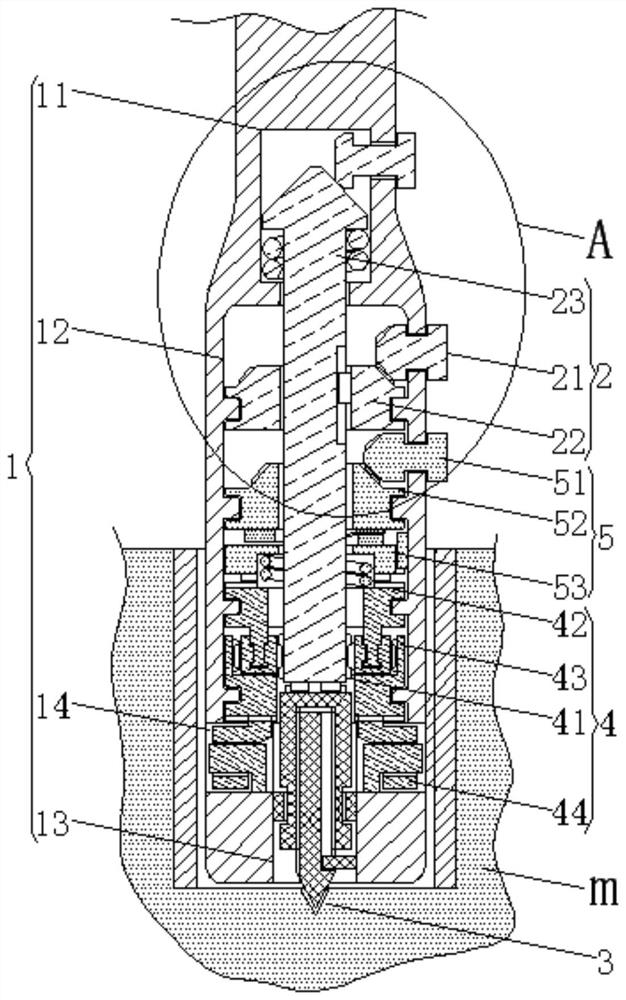

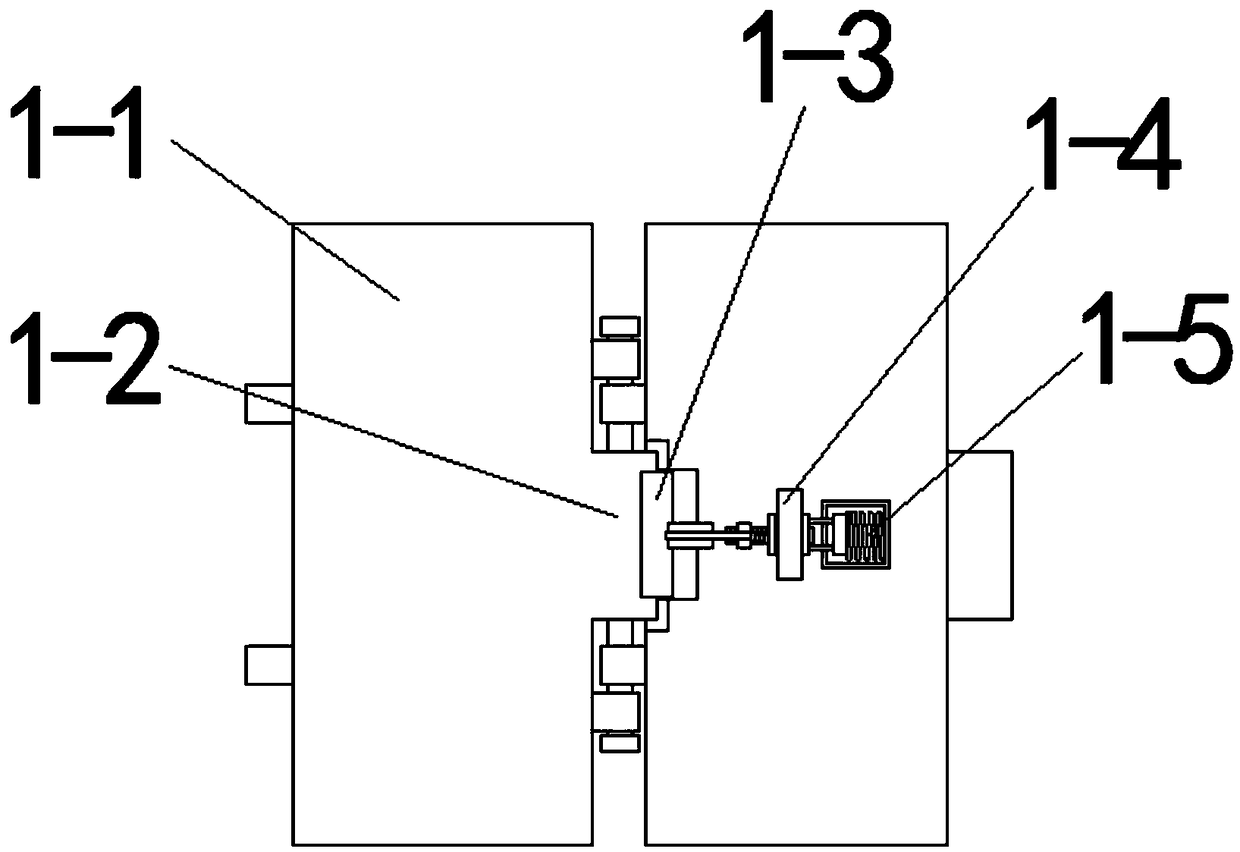

Tri-state overrunning clutch

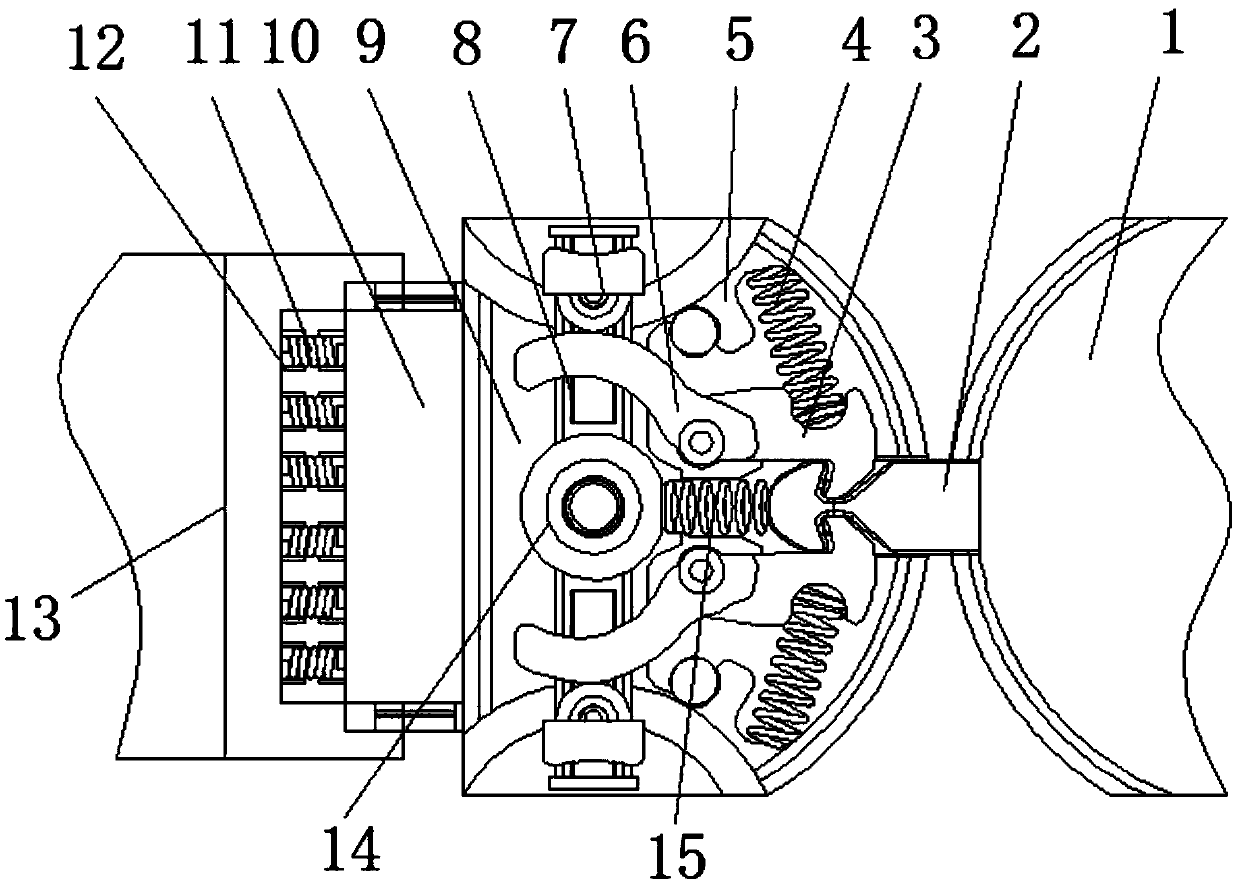

The invention relates to a tristate superior clutch comprising an outer ring, an inner ring, a plurality of wedgy blocks positioned between the outer ring and the inner ring and a retaining frame which is positioned between the outer ring and inner ring and used for retaining the wedgy blocks; a first working face of the wedgy blocks permanently contacts one of the working faces of the outer ring and the inner ring and can make a second working face of the wedgy blocks contact or leave the other working face of the working faces of the outer ring and the inner ring through rotation. Through controlling the wedgy blocks to fully leave the other working face, the outer ring and the inner ring can freely rotate in a positive direction and a negative direction, thereby obtaining a bidirectional separation working state of the tristate superior clutch; through controlling the wedgy blocks to restore a common superior wedging working position, an unidirectional superior working state or a unidirectional wedging working state of the tristate superior clutch is obtained.

Owner:BYD CO LTD

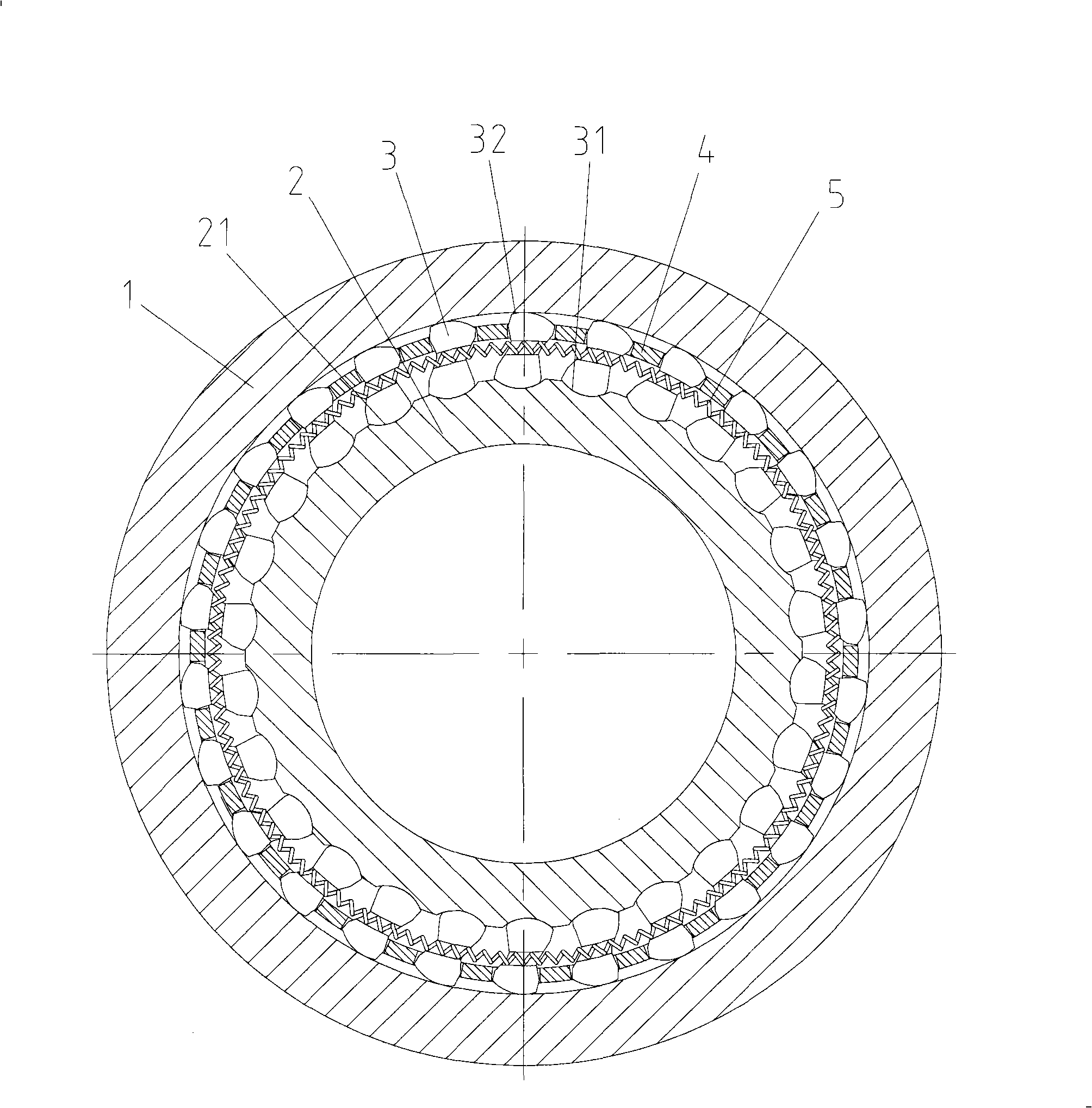

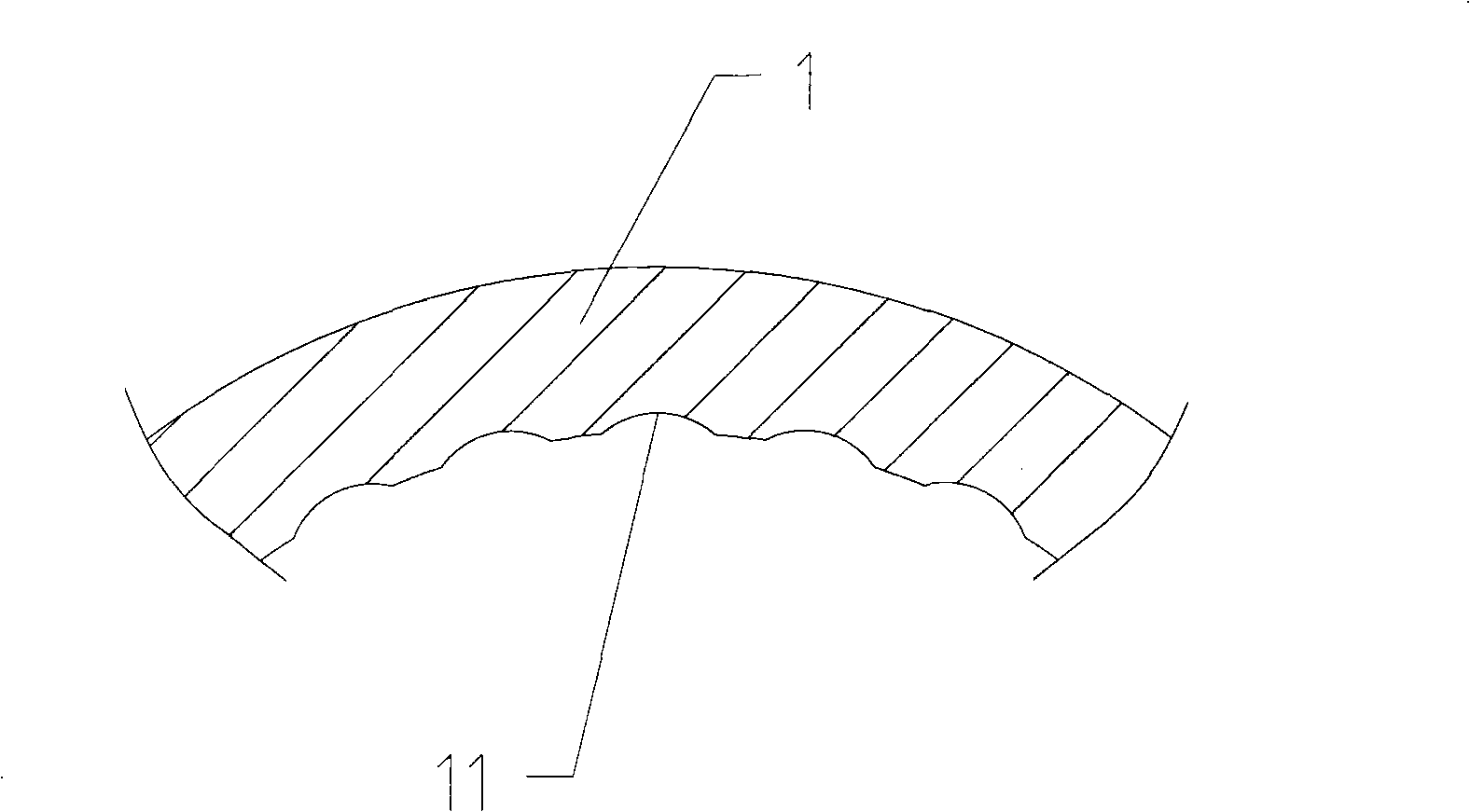

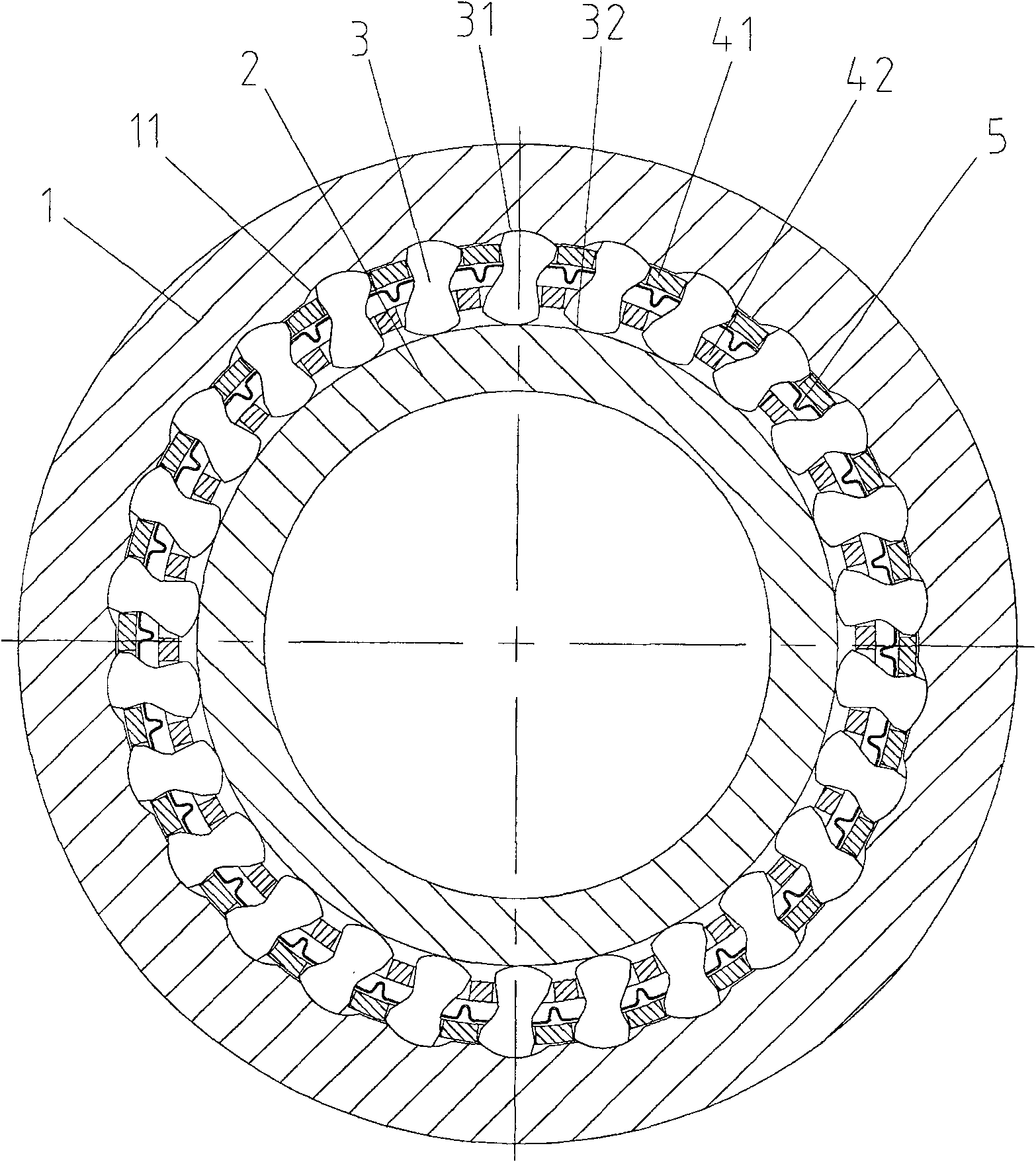

Tri-state overrunning clutch

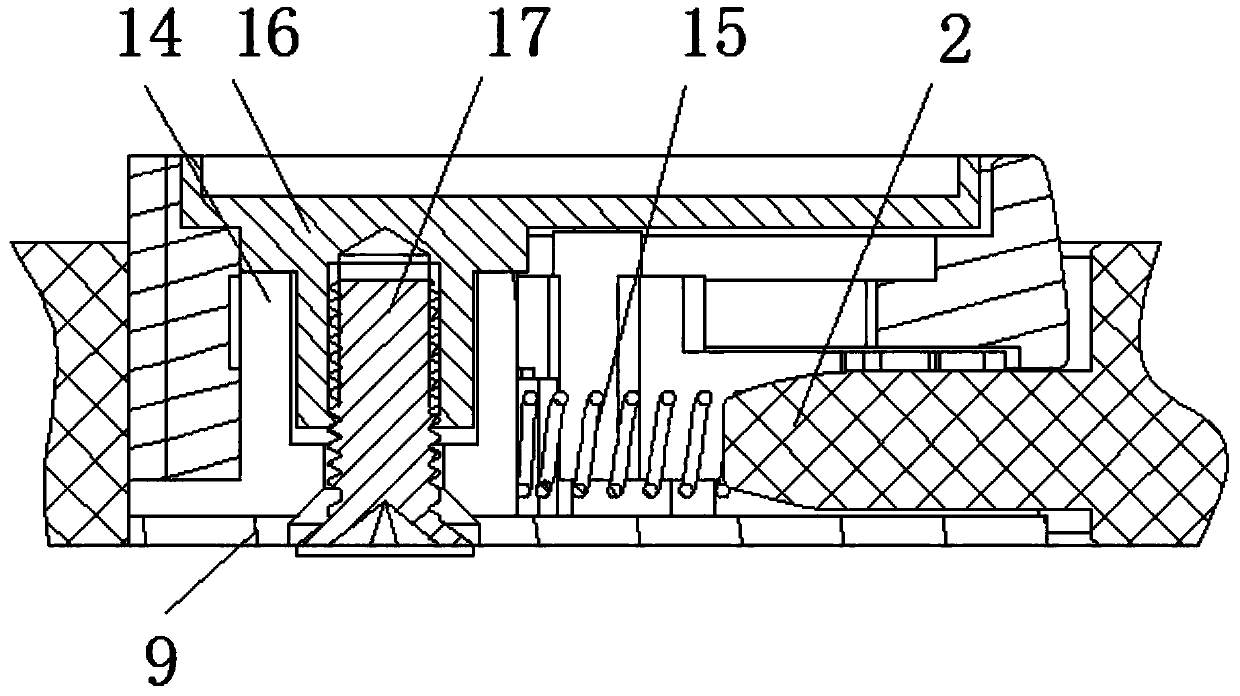

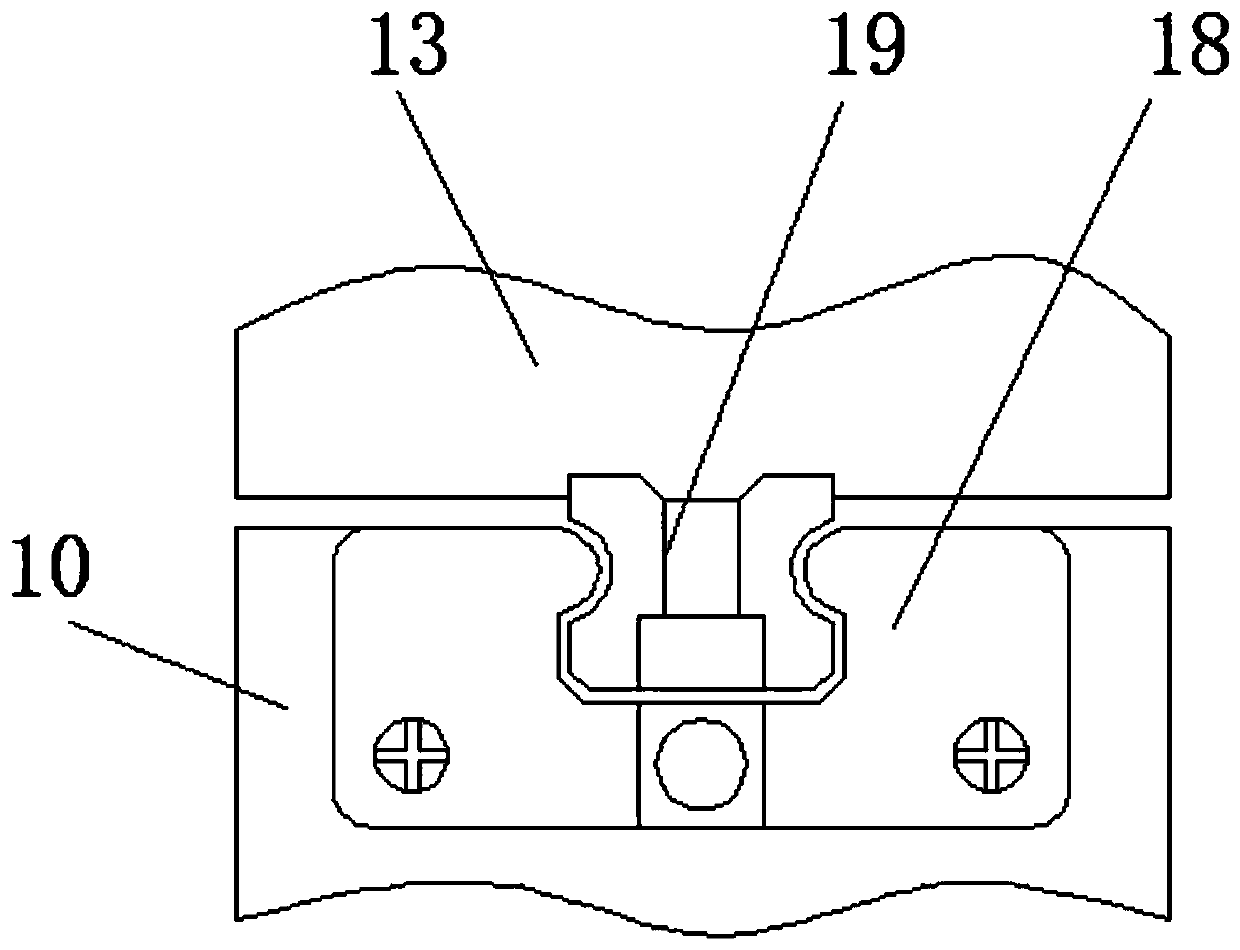

The invention provides a three-state overrunning clutch which comprises an outer circle, an inner circle, a plurality of wedge blocks positioned between the outer circle and the inner circle, and an outer holding rack and an inner holding rack positioned between the outer circle and the inner circle and holding the plurality of wedge blocks. A plurality of arc grooves are formed on the working face of the outer circle and each arc groove is matched with a working face of the corresponding wedge block and holds the working face inside the arc groove; the inner holding rack is provided with a plurality of protruding plates axially extending outwards, and each protruding plate is provided with oblique holes inclined relative to the axial direction. An axial sliding poke tray is arranged on the outer circumference of the outer circle, wherein a plurality of poke rods, which are respectively inserted into the corresponding oblique holes, are fixed on the poke tray. Through the electromagnetic driving mechanism, the poke tray slides axially on the outer circumference of the outer circle. By removing the poke tray, the wedge blocks are controlled to completely move off the working face of the inner circle, so that the outer circle and the inner circle can rotate freely in both the positive and the negative directions, thus achieving the two-way separating working state of the three-state overrunning clutch.

Owner:BYD CO LTD

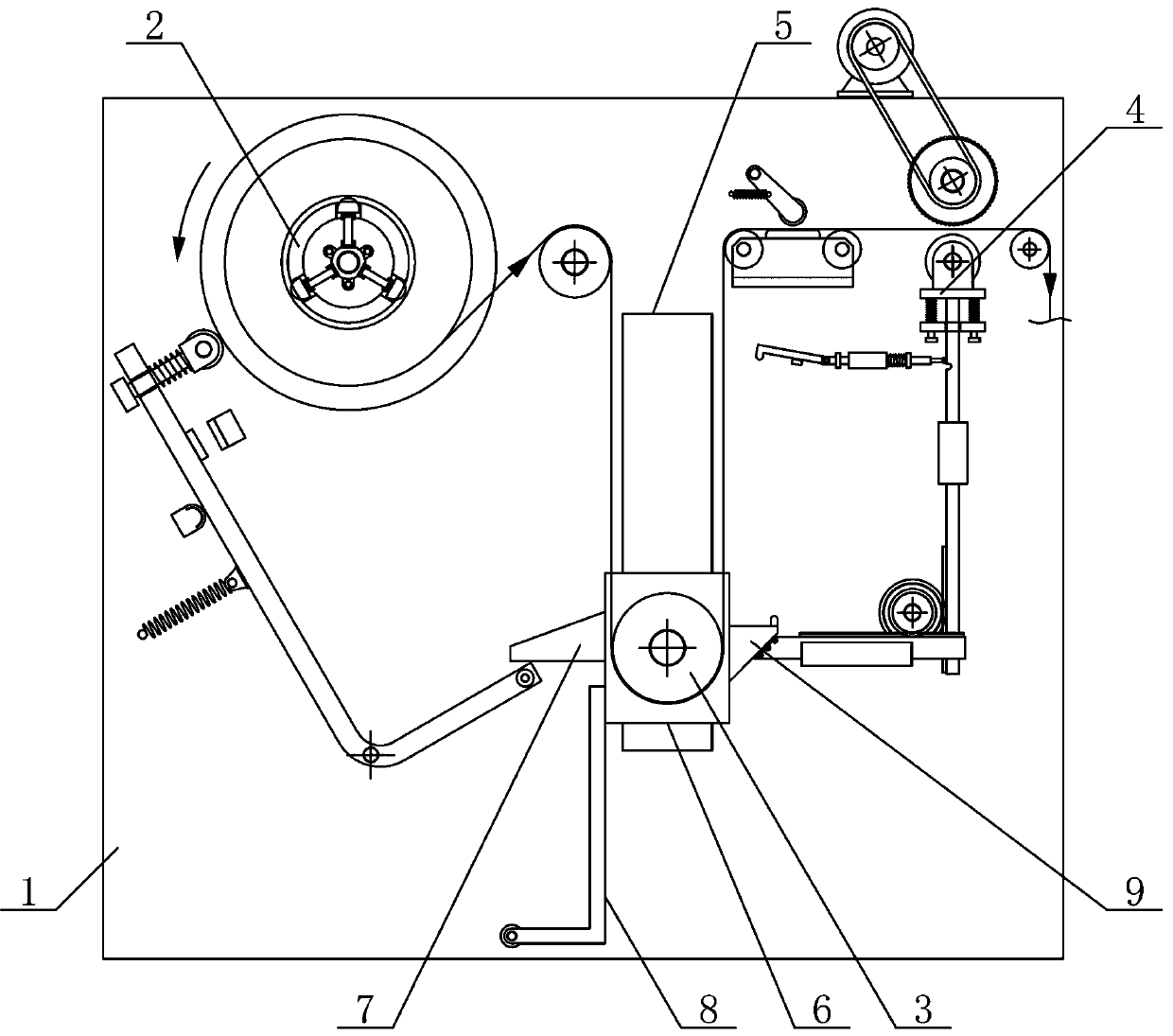

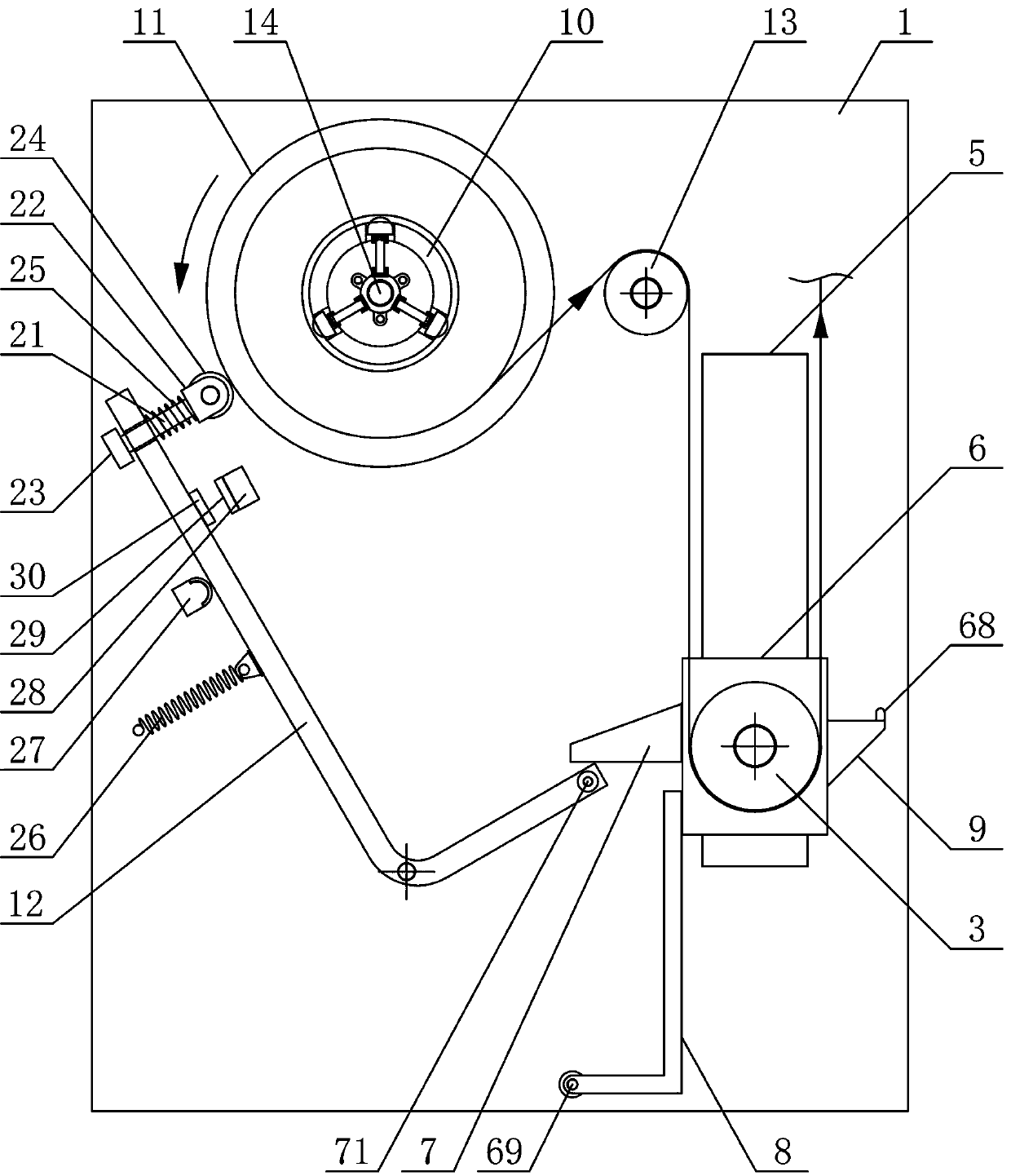

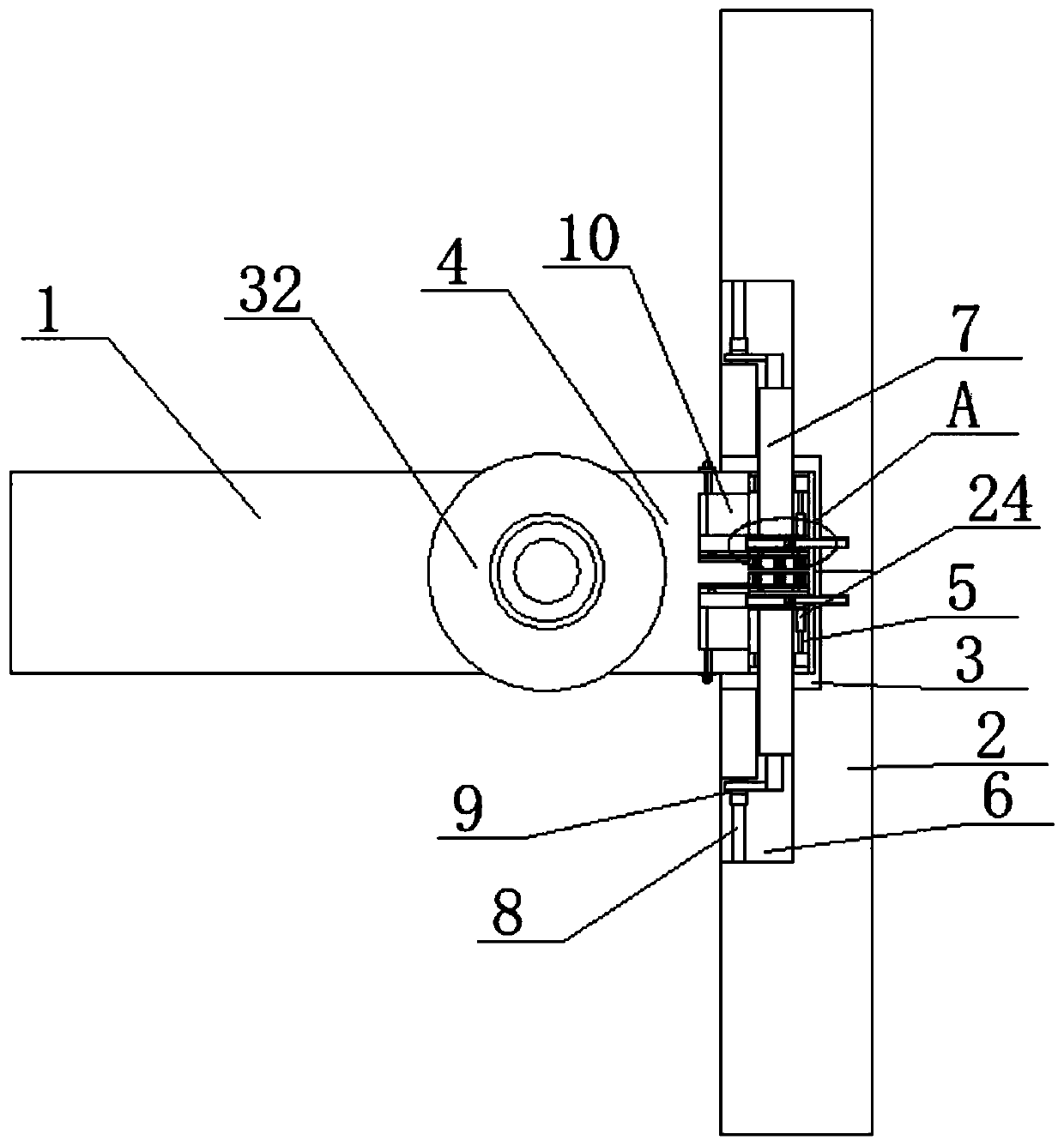

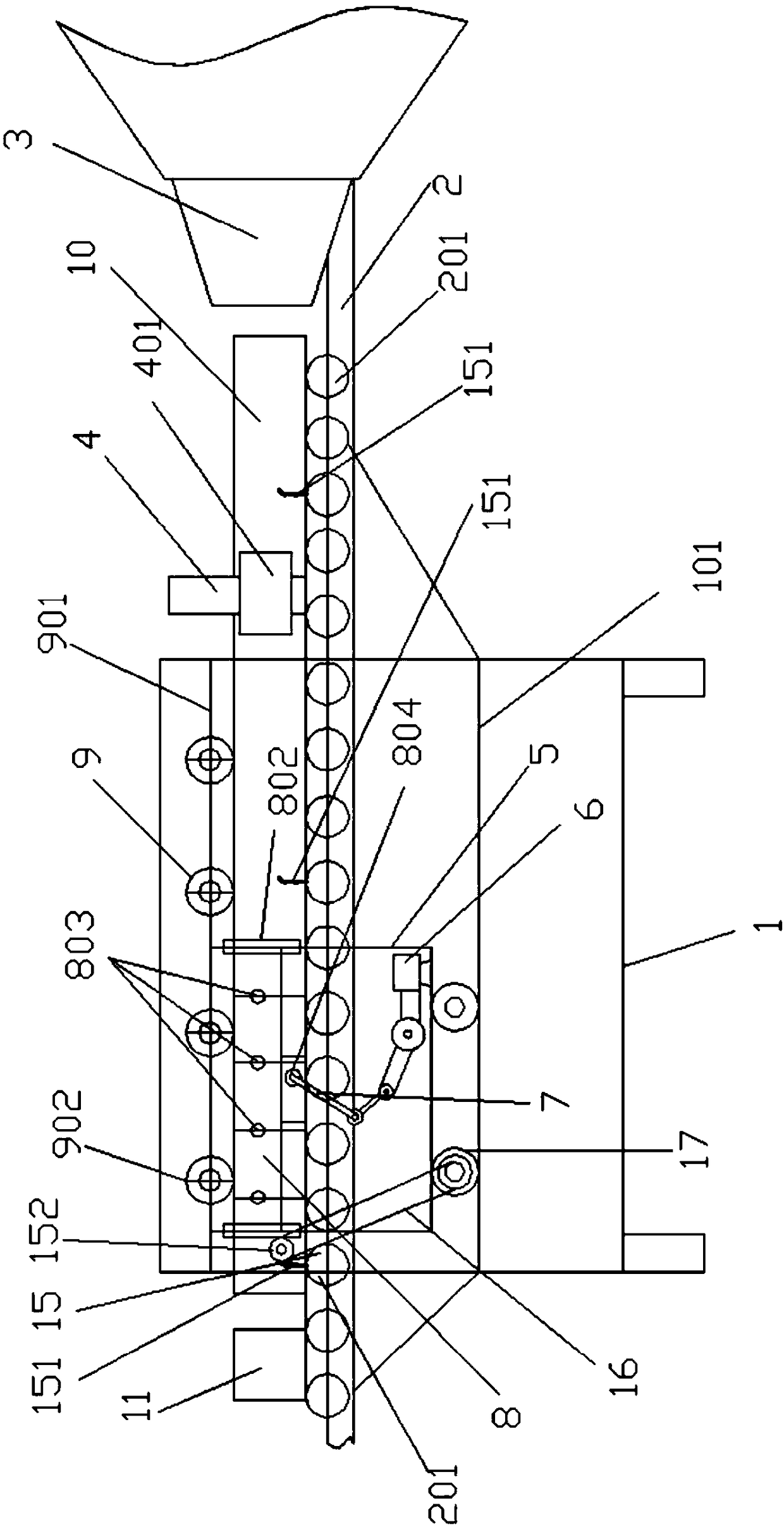

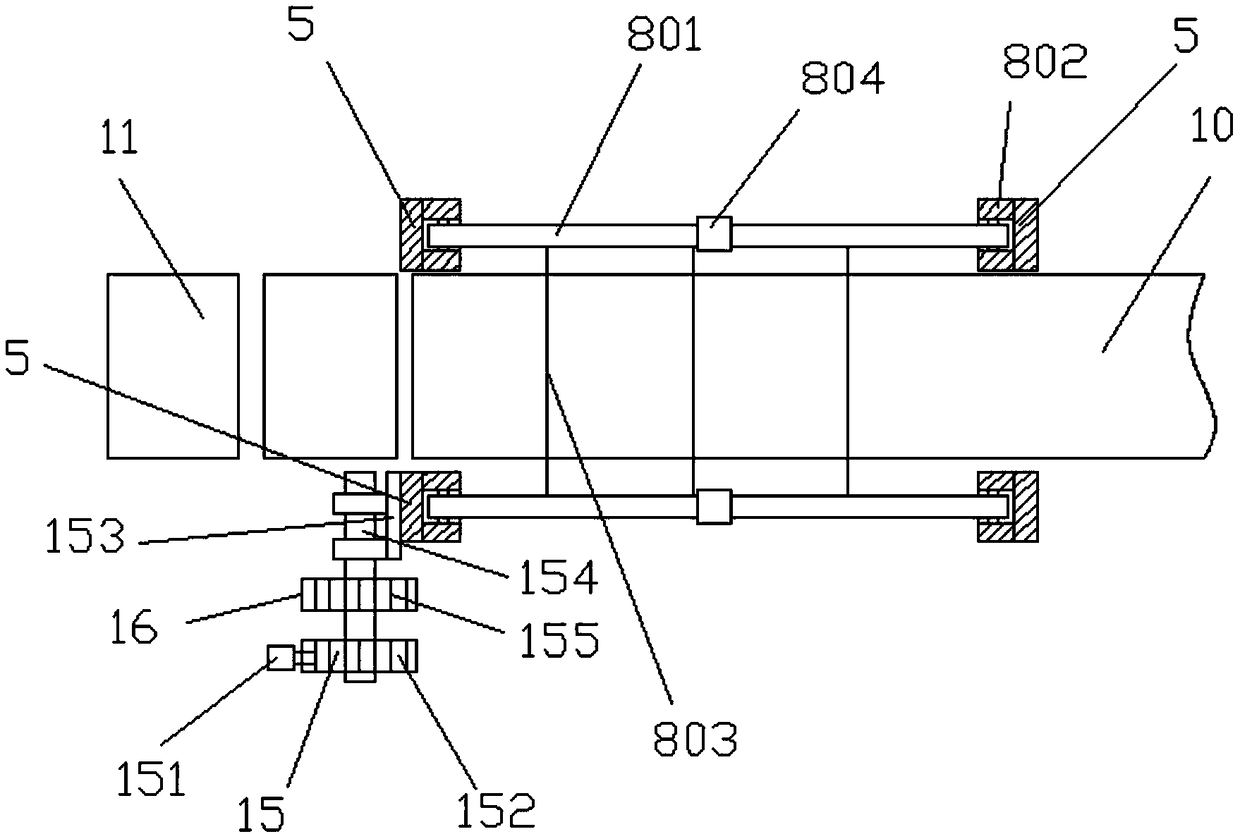

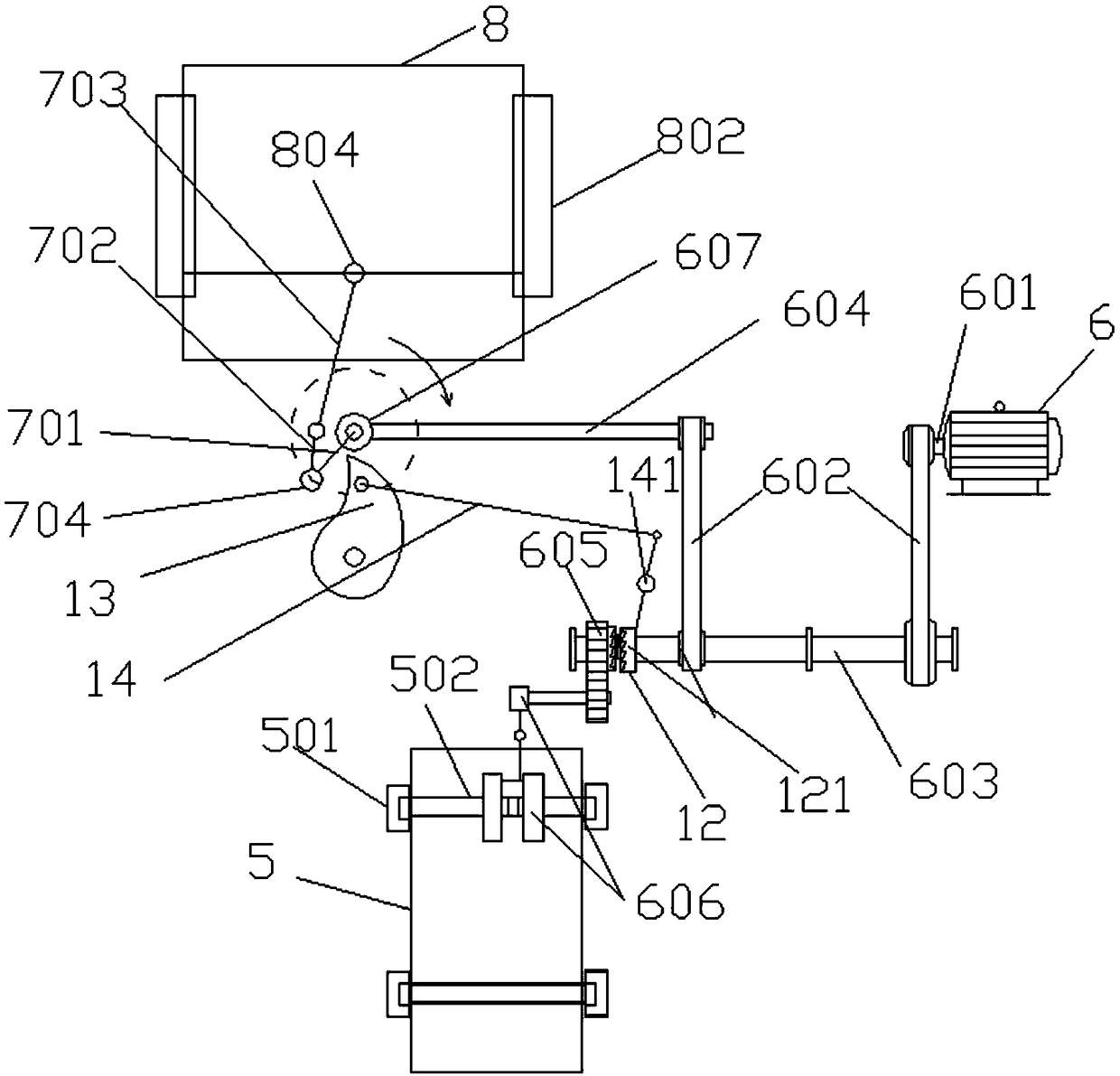

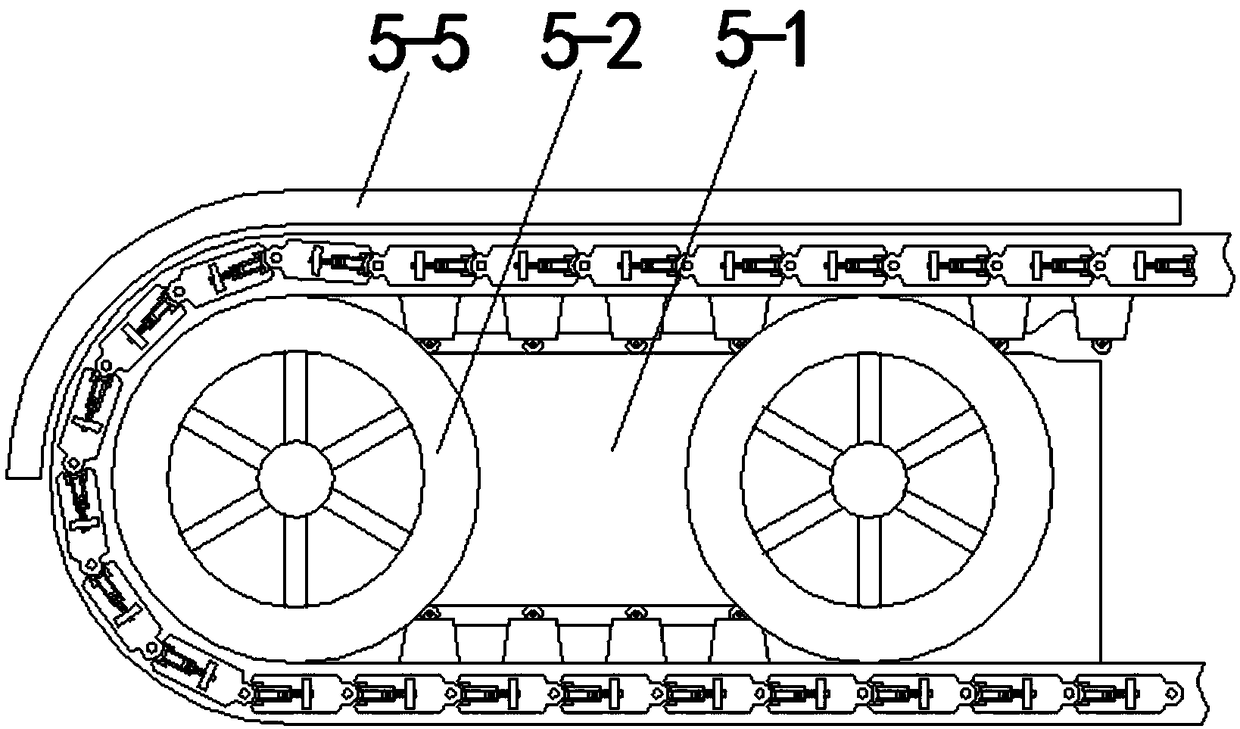

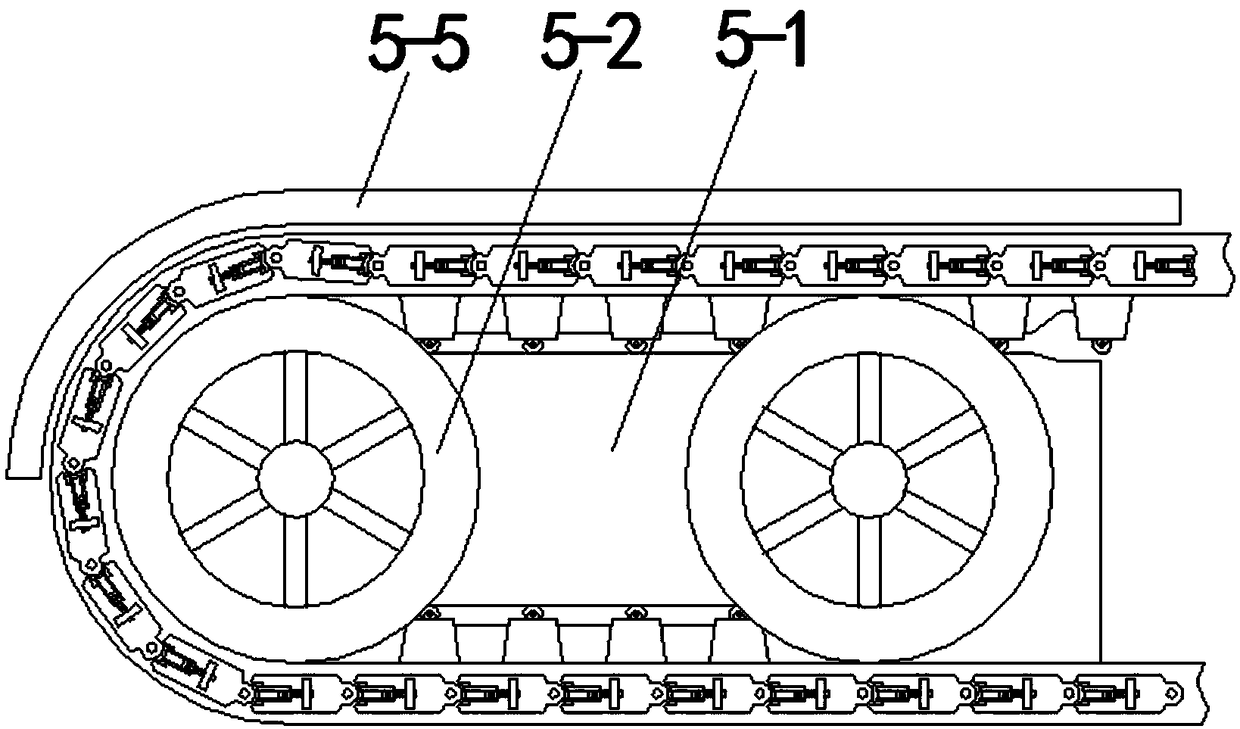

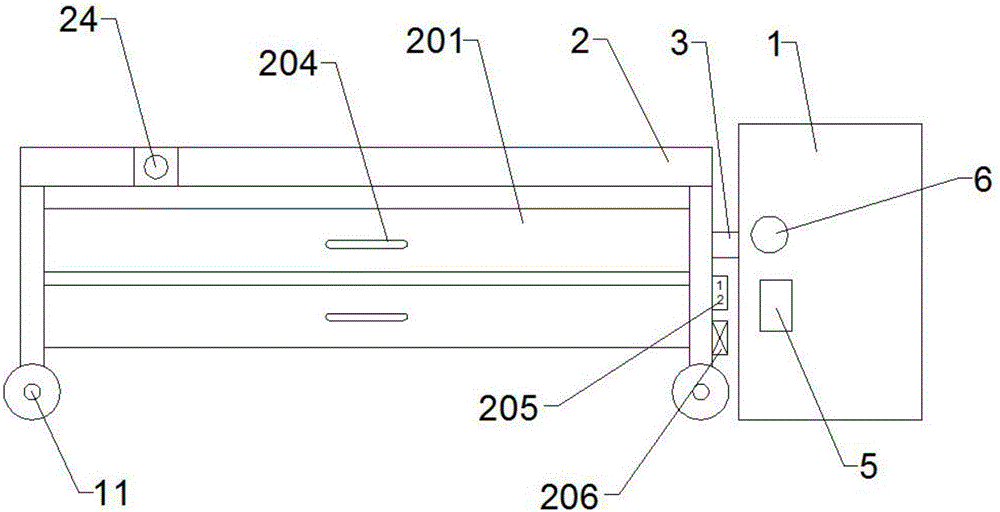

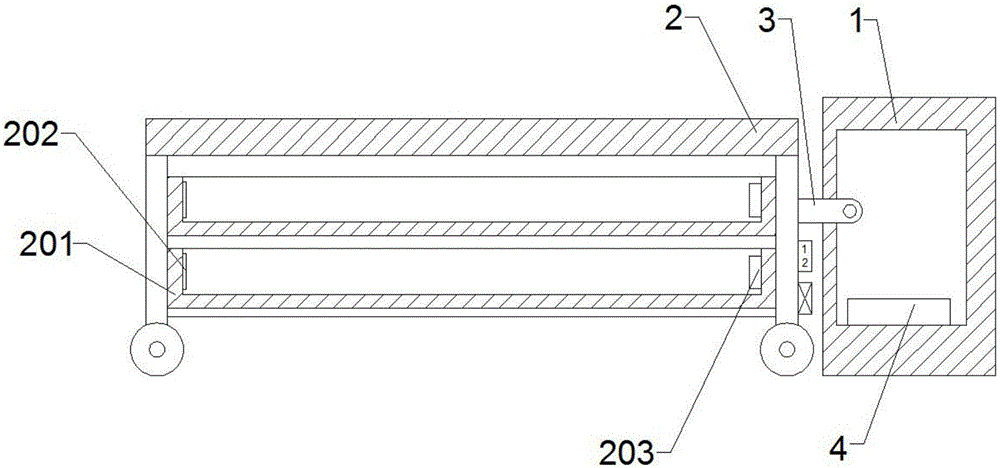

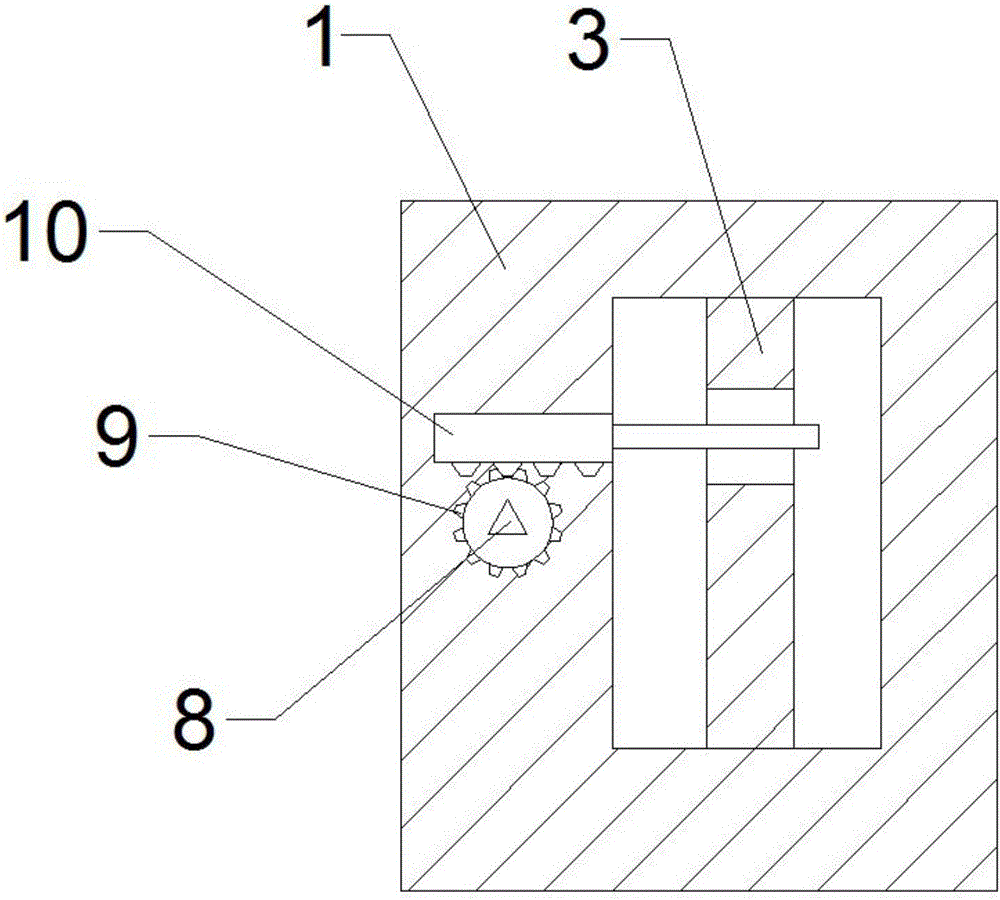

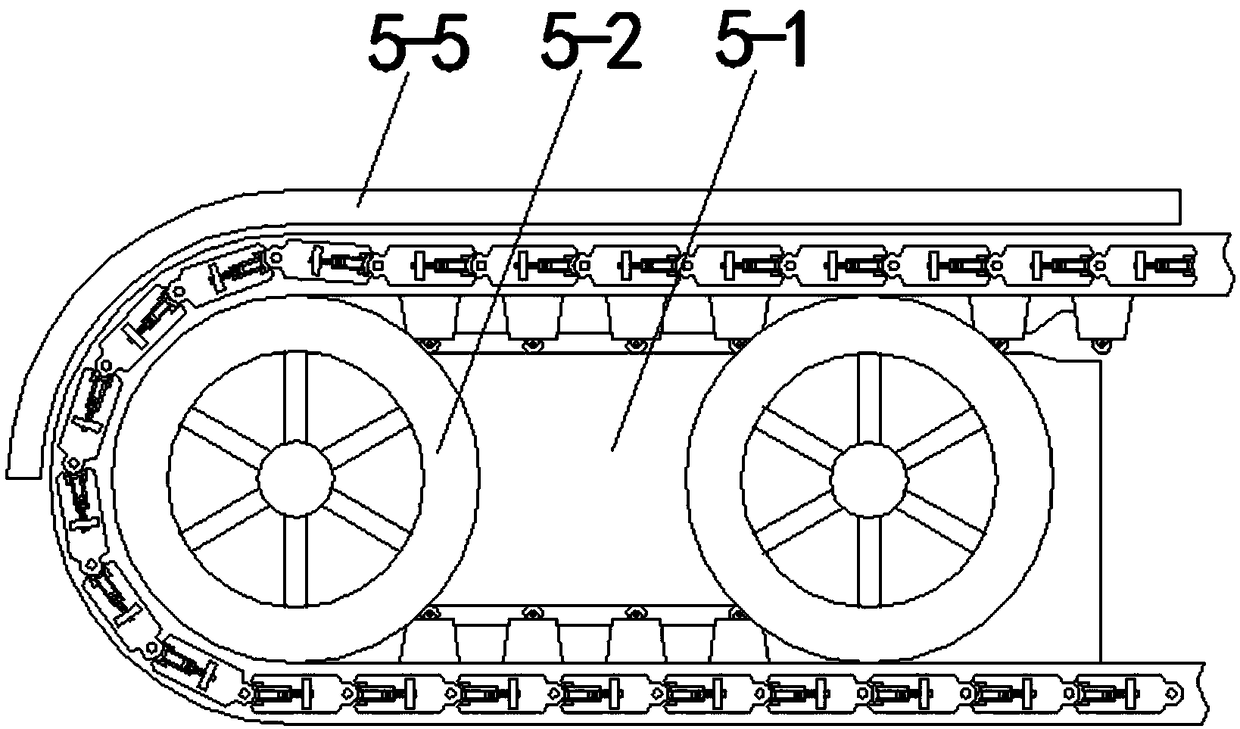

Textile fabric conveying device

ActiveCN111532827ASmooth and orderly unwinding transmissionEfficient and smooth unwinding transmissionWebs handlingMechanical equipmentIndustrial engineering

The invention discloses a textile fabric conveying device, and belongs to the field of textile processing mechanical equipment. According to the textile fabric conveying device, a fabric unwinding mechanism and a fabric conveying mechanism are arranged on the two sides of a fabric conveying support correspondingly, a lifting fabric guide roller is horizontally arranged on the fabric conveying support between the fabric unwinding mechanism and the fabric conveying mechanism, the lifting fabric guide roller is horizontally and rotationally connected to a reciprocating lifting guide block, a fabric unwinding roller is horizontally, coaxially and fixedly arranged in the middle of a fabric unwinding rotary plate, a pressing plate damping swing rod is arranged on a fabric conveying support on the lower side of the fabric unwinding rotary plate, the two sides of a fabric non-return support are horizontally and rotationally connected with a front material guiding rotary roller and a rear material guiding rotary roller correspondingly, and a lifting material pressing rotary roller is arranged on the lower side of a fabric conveying rotary roller. The textile fabric conveying device is reasonable in structural design, textile fabrics can be efficiently, smoothly, sequentially and intermittently conveyed, stable, accurate and continuous sectional conveying of textile fabrics is achieved,the automation degree of textile fabric conveying and processing is improved, and the requirements of production and use are met.

Owner:山东新天合包装制品有限公司

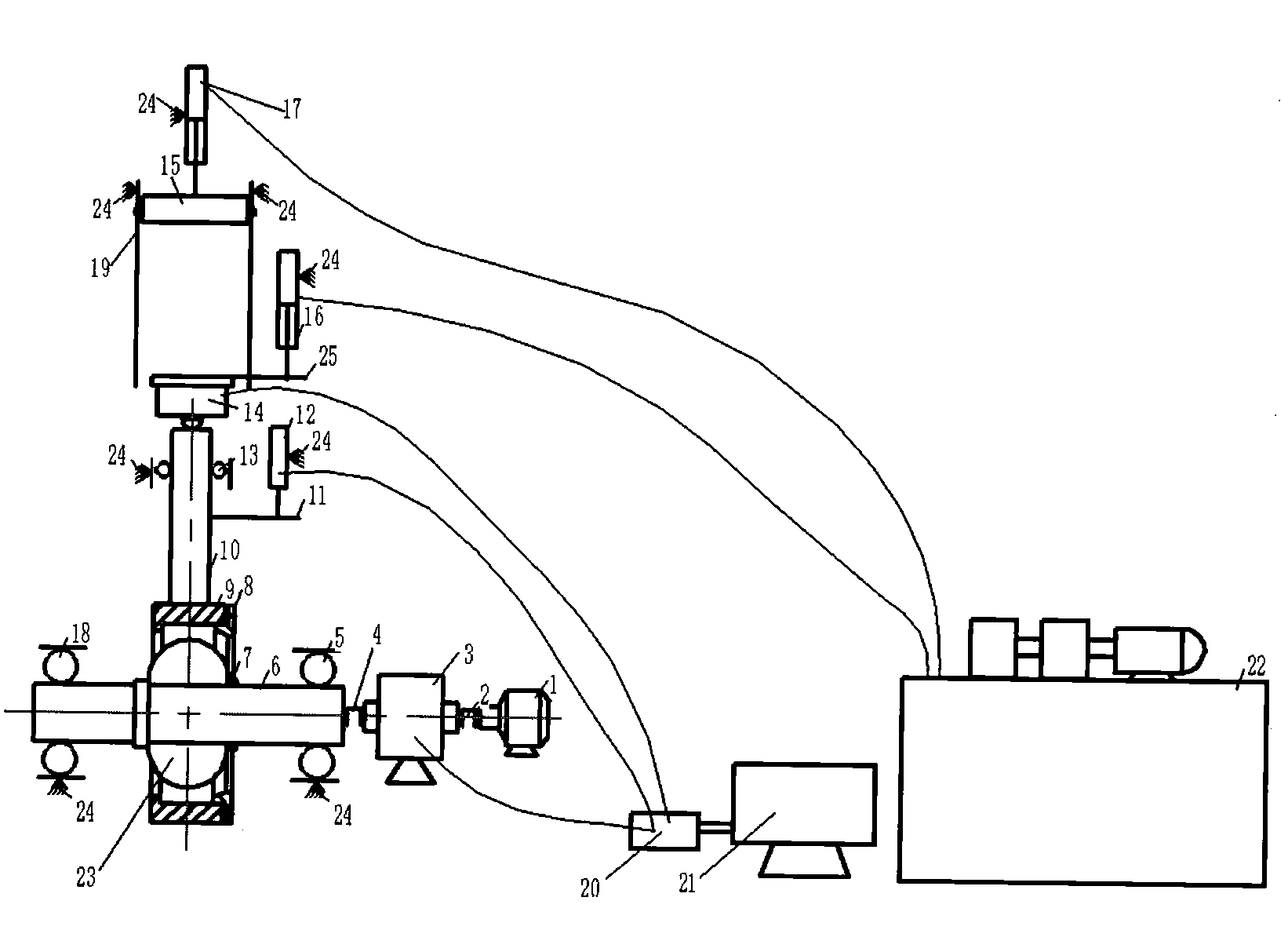

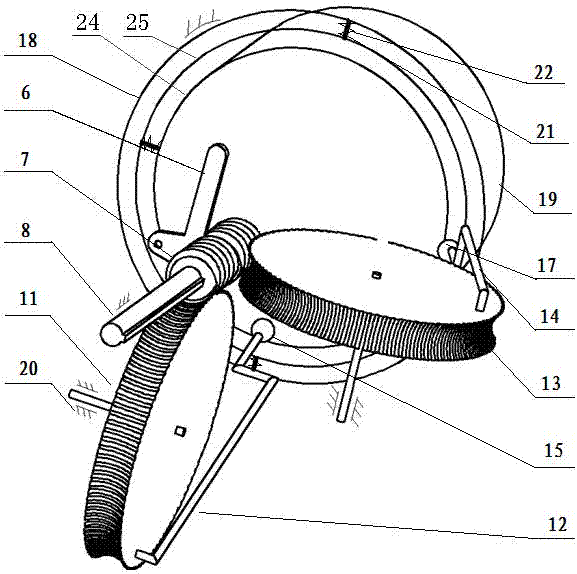

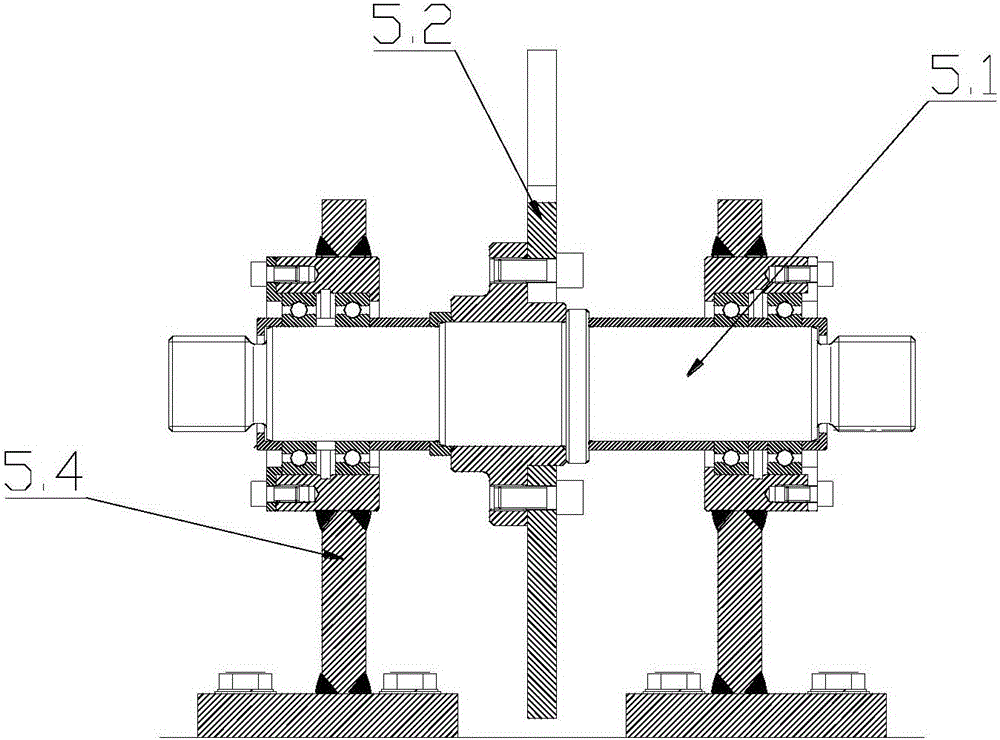

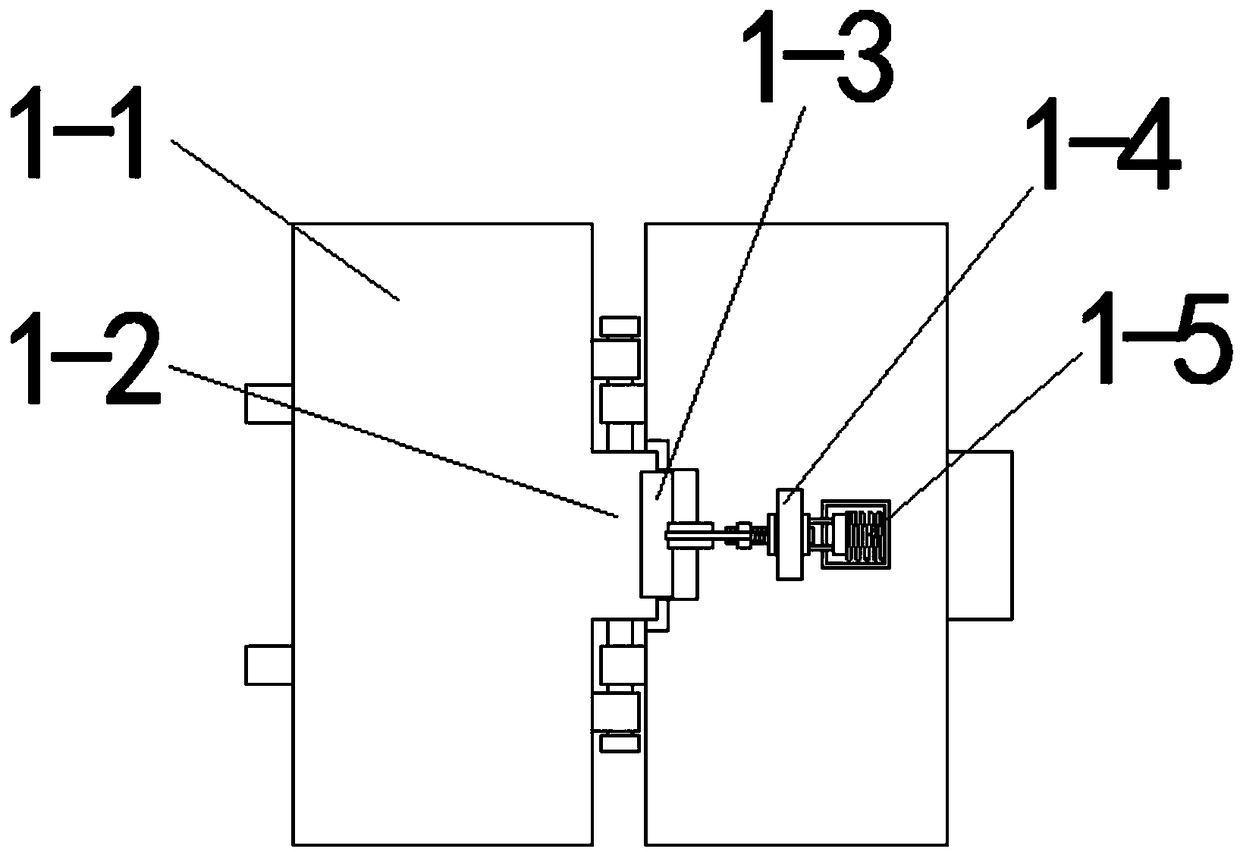

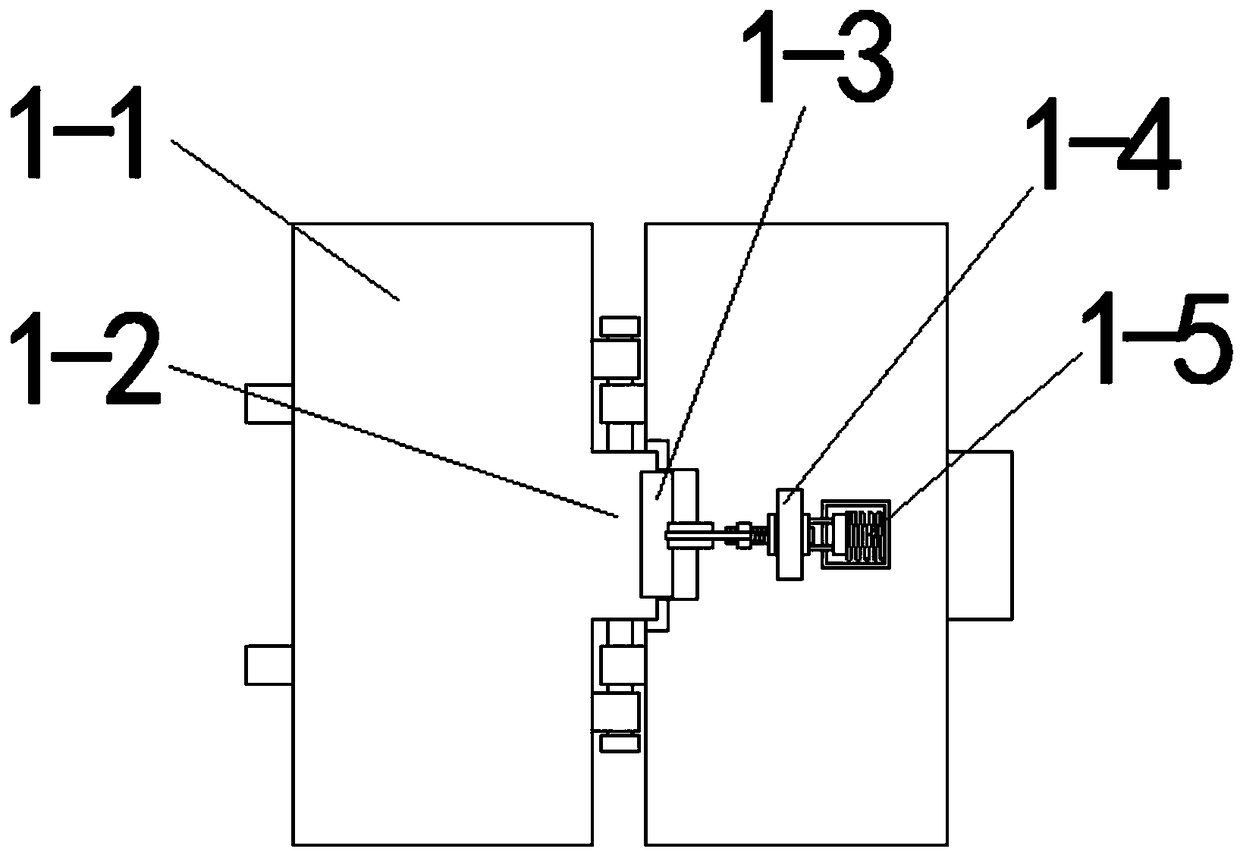

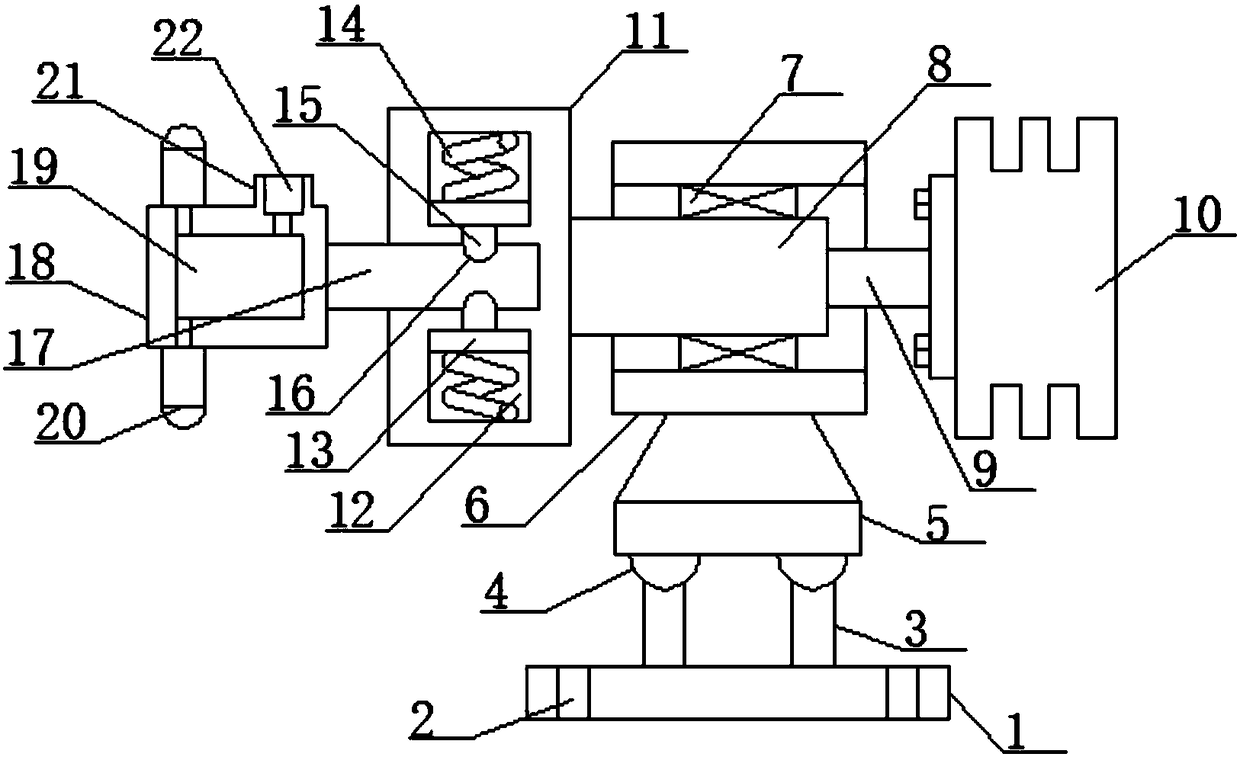

Experimental machine for evaluating impact-loading type tribological performance of joint bearing

InactiveCN103076178ARealize tribological performance testingAchieve disengagementMachine bearings testingShock testingFriction torqueCoupling

The invention relates to an experimental machine for testing the tribological performance of a joint bearing under the action of an impact load. The experimental machine comprises a transmission device, a loading device and a detecting device. A servo motor is connected with a torque meter through a first coupling and is connected with a supporting shaft through a friction-torque clutch. The upper end surface of an impact weight is fixedly connected with an impact-weight lifting cylinder, a load sensor is positioned below the impact weight, a load-sensor measuring head is contacted with the upper end surface of a force-transferring rod, a steady-load loading cylinder is connected with a loading rod, the loading rod is fixedly connected with the load sensor, the steady-load loading cylinder and the impact-weight lifting cylinder are connected with a hydraulic station through oil pipes, the lower end surface of the force-transferring rod is contacted with a bearing seat, a joint-bearing sample is installed on the supporting shaft, and an outer ring of the joint-bearing sample is fixedly arranged in the bearing seat through an end cover. By adopting the invention, the detection for the tribological performance of the joint bearing can be realized under the conditions of different impact inertias and different rotating speeds.

Owner:YANSHAN UNIV

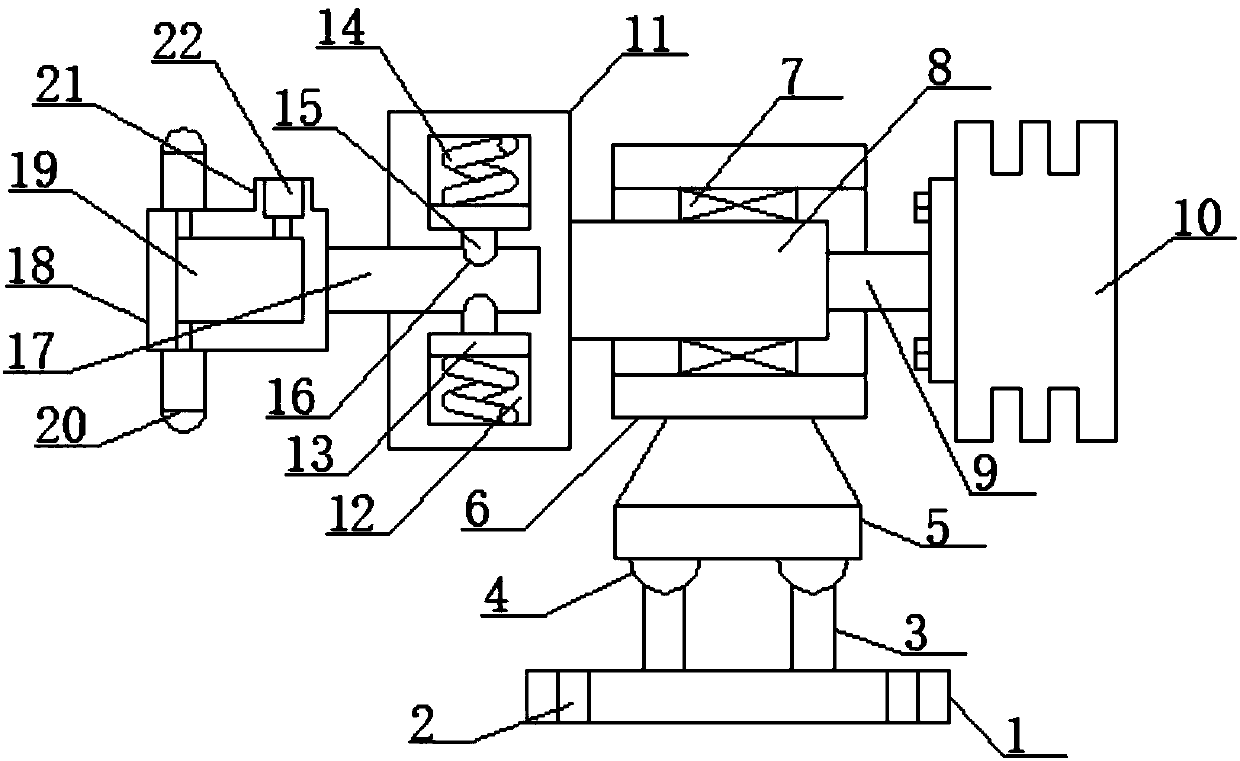

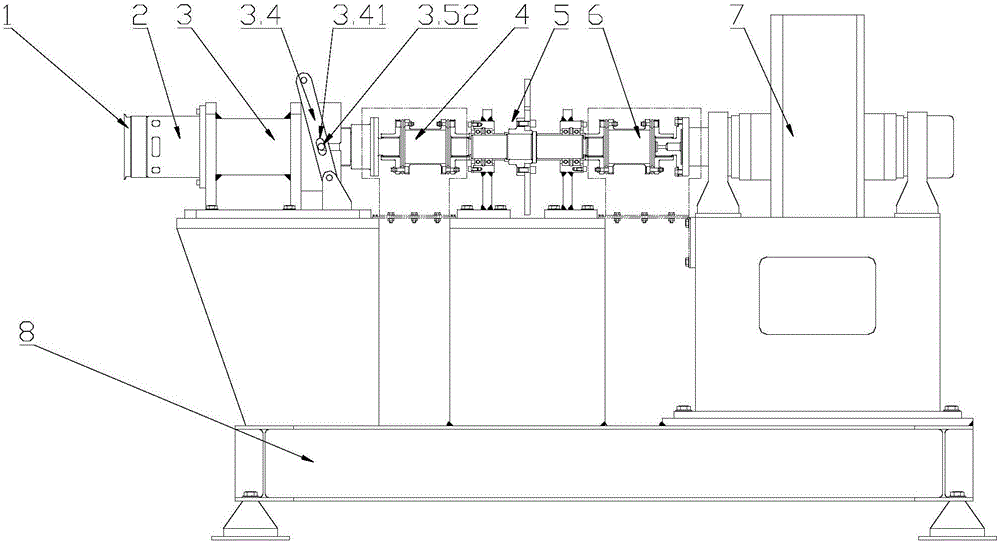

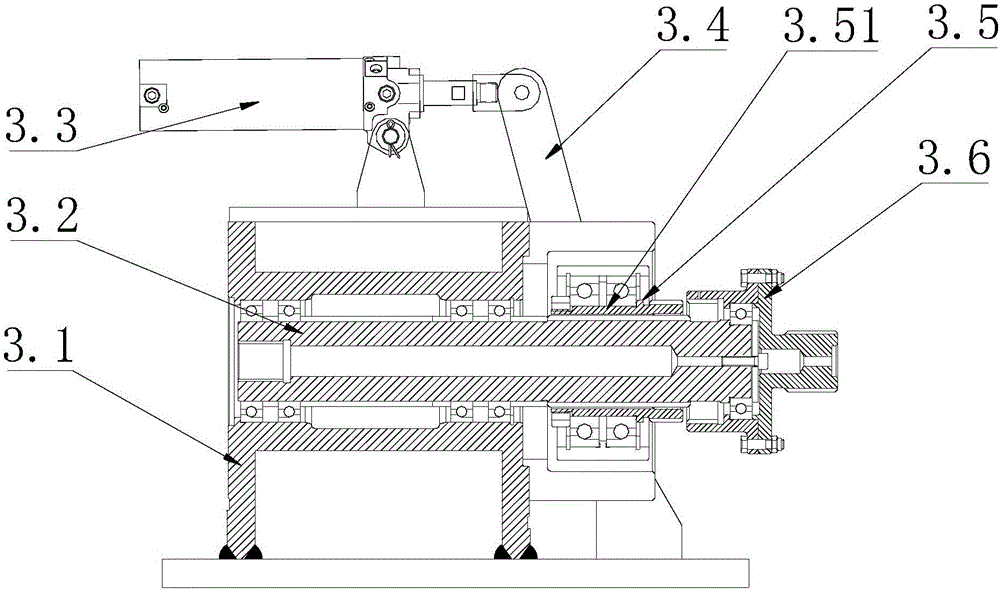

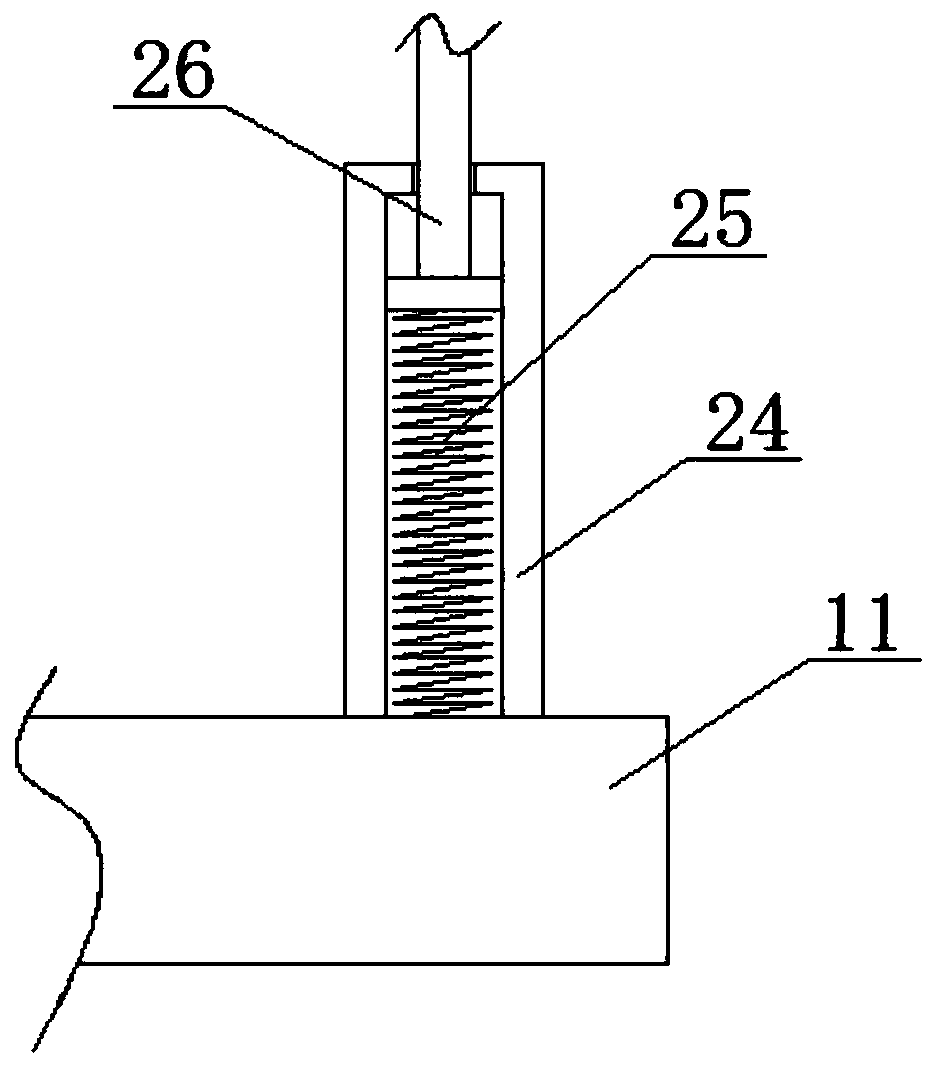

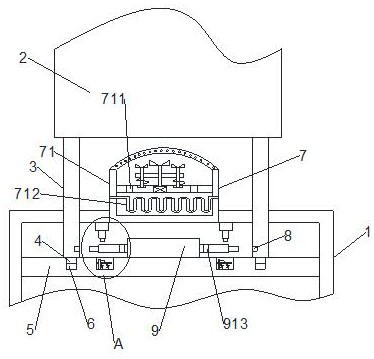

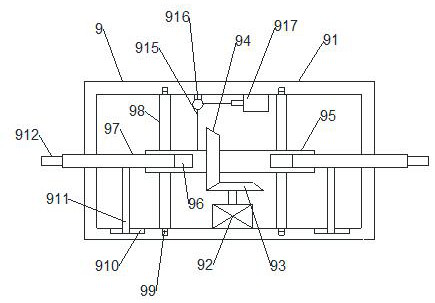

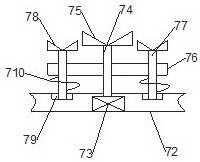

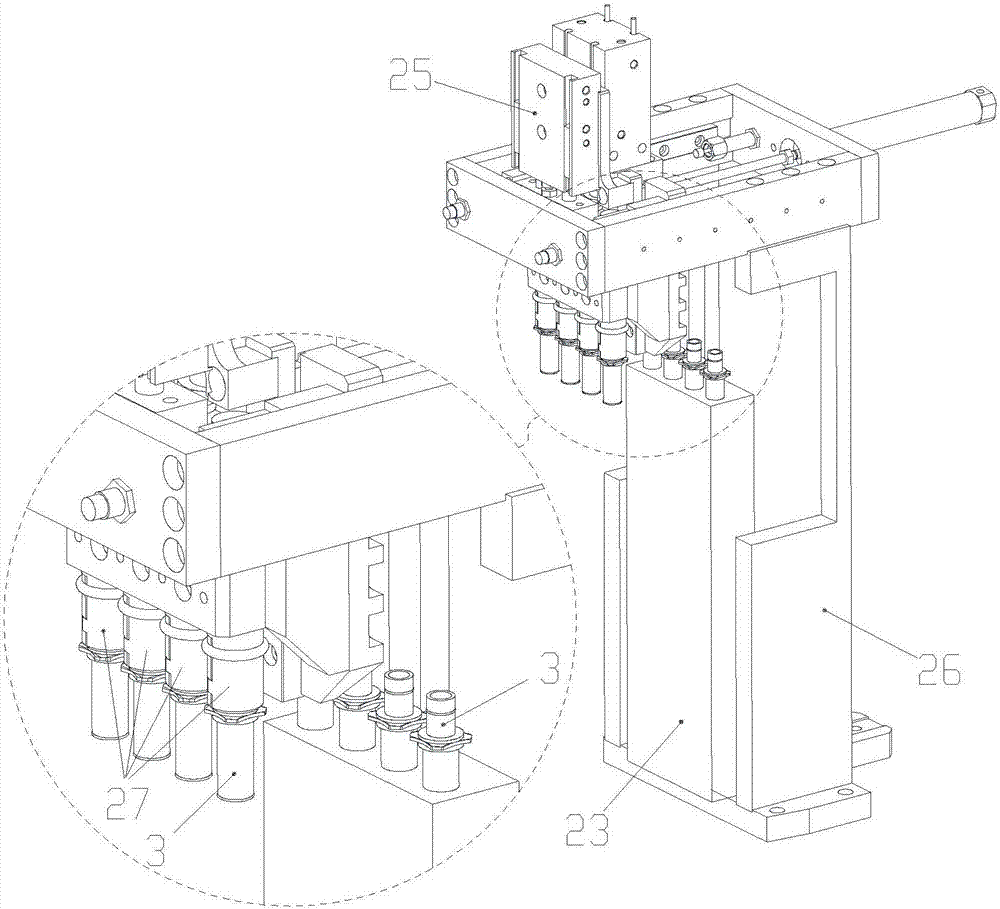

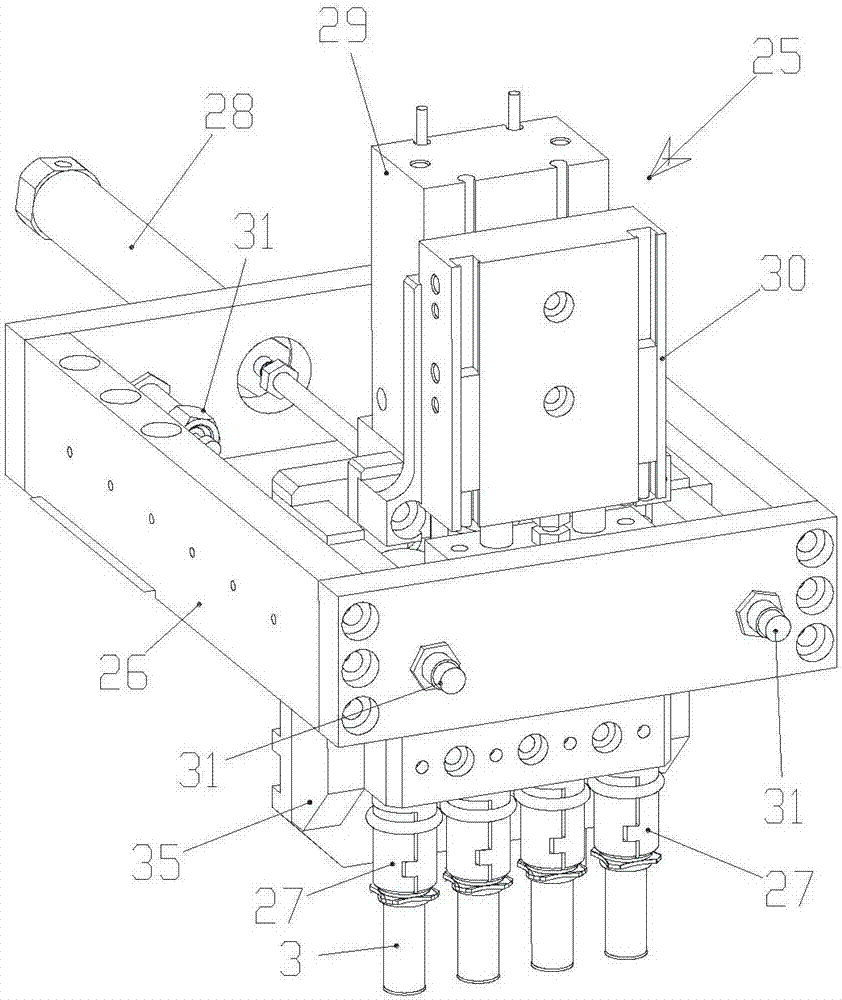

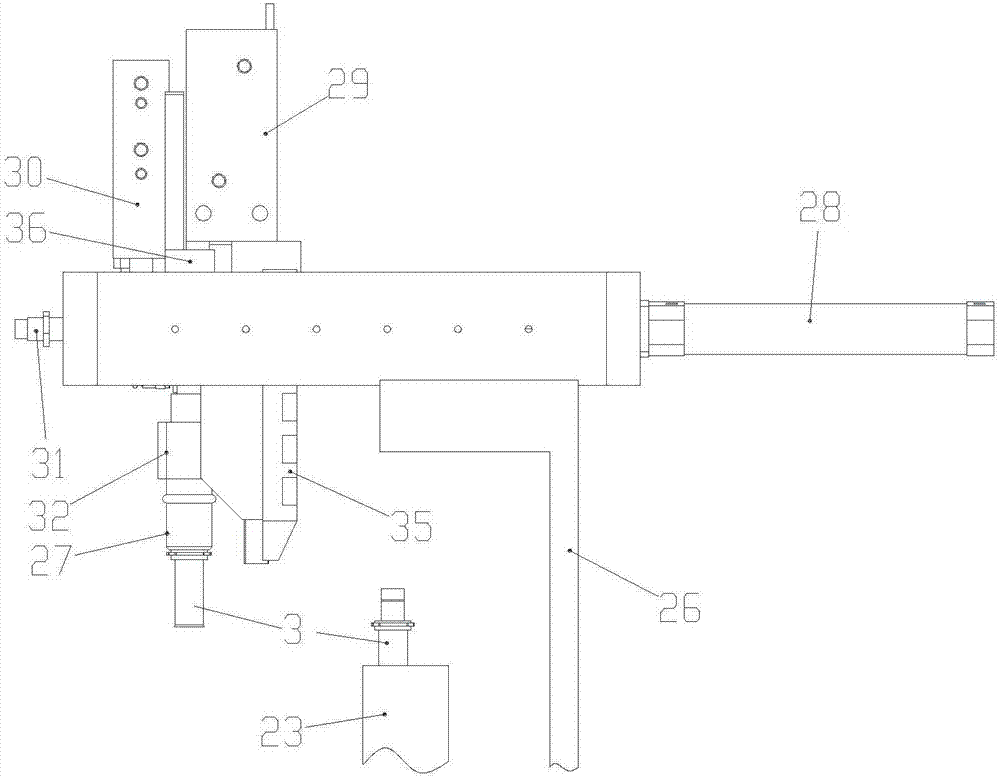

Driving device for cement pipeline making and middle connecting mechanism of cement pipeline

InactiveCN108015891AIncrease effective spin rateAvoid damageCeramic shaping apparatusMechanical energy handlingPower flowContact type

The invention discloses a driving device for cement pipeline making and a middle connecting mechanism of a cement pipeline. The driving device and the middle connecting mechanism comprise a bottom fixing base plate, and multiple bolt holes used for being connected are formed in the bottom fixing base plate; three threaded adjusting mechanisms which are arranged in an annular array mode are installed on the upper surface of the bottom fixing base plate, and the top parts of the multiple threaded adjusting mechanisms are installed at the bottom part of a bottom supporting base block through hinges; and the top part of the bottom supporting base block is provided with an outer shaft sleeve. According to the driving device and the middle connecting mechanism, an internal contact type method isused for carrying out the connection function of rotary parts so that the synchronous rotation effect can be realized, and the effective rotation rate of a motor is improved; in addition, the devicecan achieve disengagement under an emergency condition, so that the phenomenon that the motor is damaged due to too large driving force or lower current of the motor is effectively prevented; and thedevice is provided with an air power telescopic mechanism, so that the abutting effect with a telescopic function is realized by utilizing air power, and the practicability is high.

Owner:庄清梅

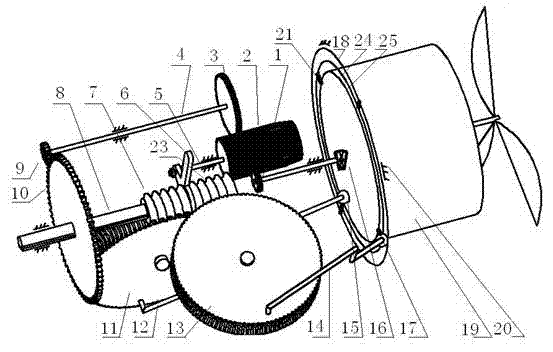

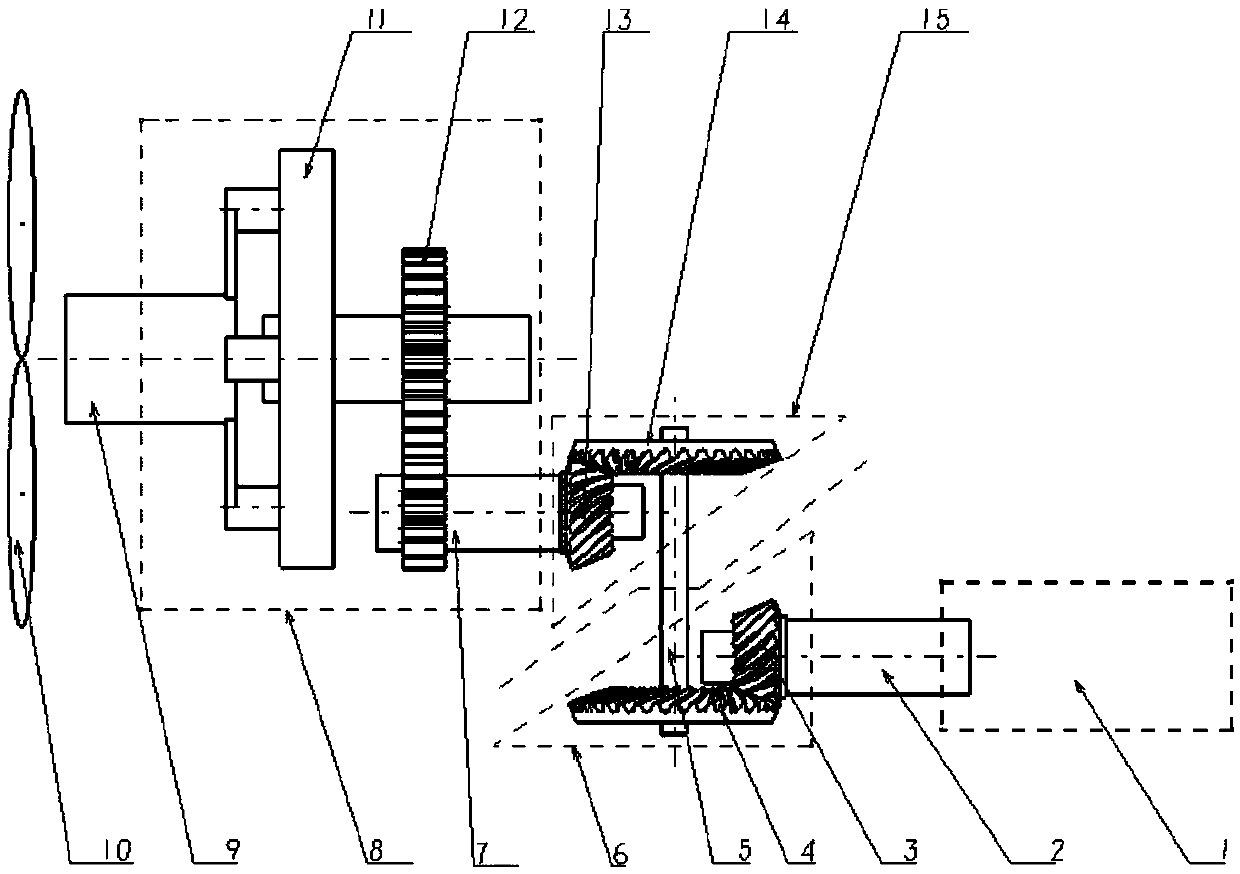

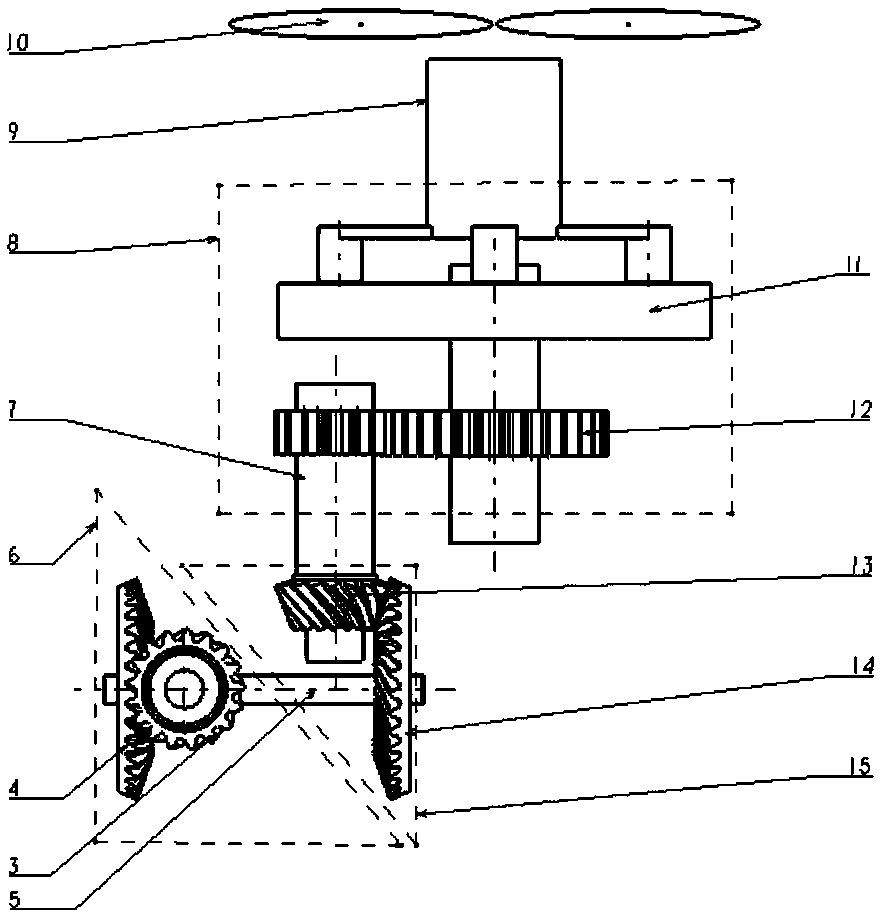

Spatial fan oscillating mechanism

ActiveCN103244444AGood flexibilitySimple structurePump installationsNon-positive displacement fluid enginesTwo degrees of freedomWork space

The invention discloses a spatial fan oscillating mechanism which comprises a gear speed reduction mechanism, a gear adjusting mechanism, a spatial steering mechanism, a motor and a frame. The gear speed reduction mechanism is provided with power by an input gear mounted on a motor spindle. The spatial oscillating mechanism is used for adjusting spatial oscillating directions. The gear adjusting mechanism comprises two worm gears, a worm set and a gear adjusting switch, wherein the worm gears are arranged on different degrees of freedom, and state of meshing of worm threads on the worm set and teeth of the worm gears can be adjusted by shifting the gear adjusting switch. The spatial fan oscillating mechanism is good in flexibility as an operation space of two degrees of freedom in left and right and pitching can be realized, and is simple in structure, capable of realizing multi-level work modes and easy to control. Without additional motor, a gearbox can disengage meshing while the oscillating mechanism is still, and energy is sufficiently saved.

Owner:江阴智产汇知识产权运营有限公司

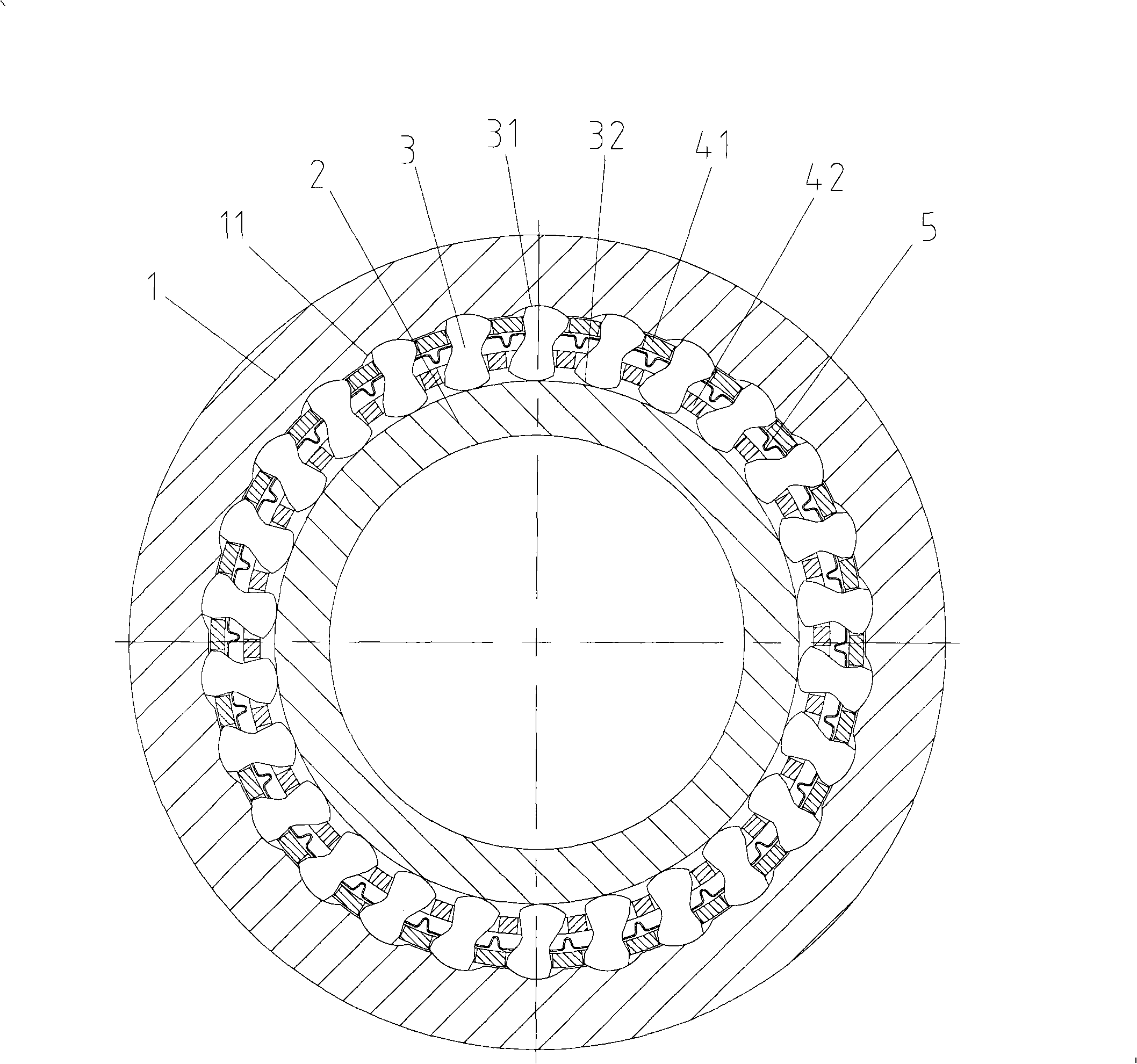

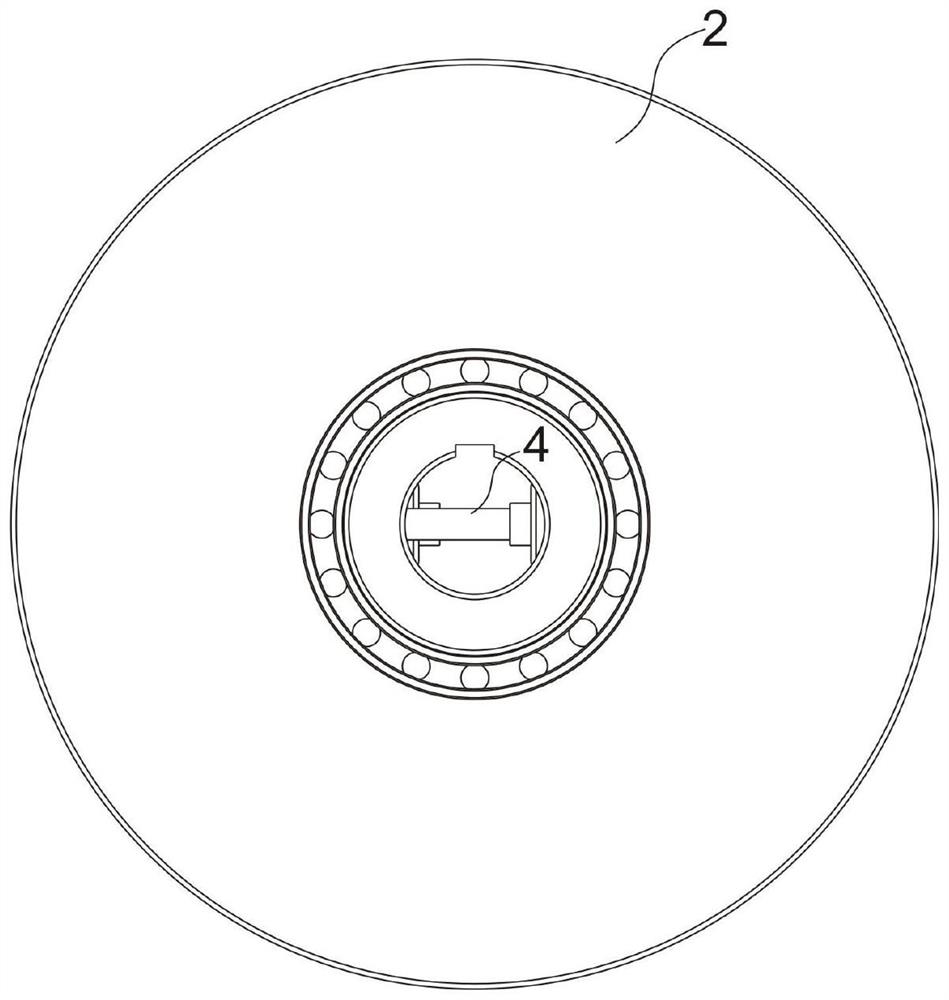

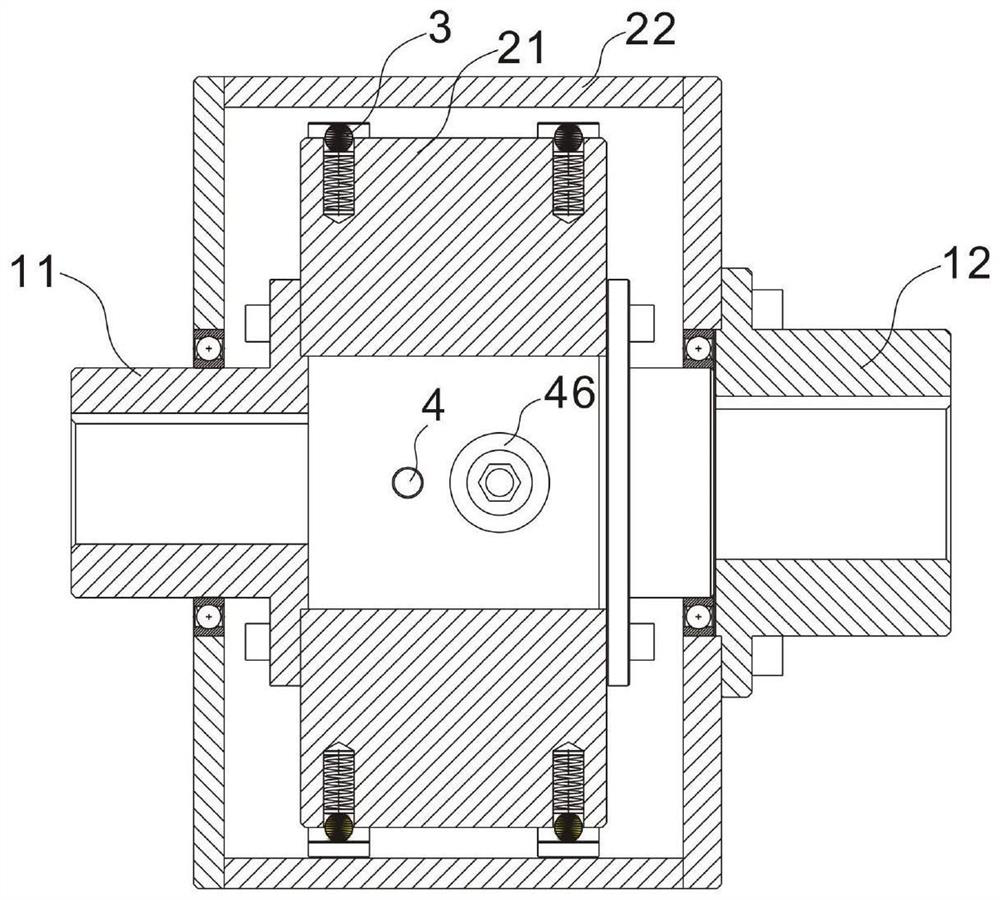

Tri-state overrunning clutch

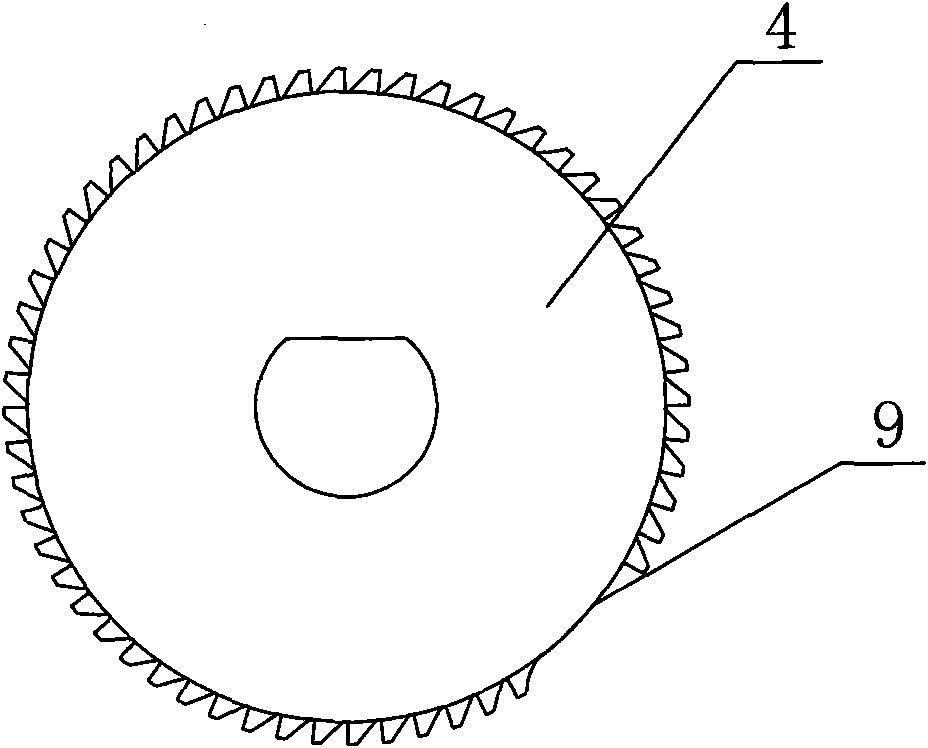

ActiveCN101328938AAchieve disengagementExtended service lifeFreewheel clutchesEngineeringMechanical engineering

The invention provides a tristate superior clutch, which comprises an outer ring, an inner ring, a plurality of wedgy blocks positioned between the outer ring and the inner ring and an outer retaining frame and an inner retaining frame which are positioned between the outer ring and inner ring and used for retaining the blocks. A plurality of circular arc grooves are arranged on a working face of the outer ring; each circular arc groove is matched with a working face of the corresponding wedgy block and retains the working face in the circular arc groove. The inner retaining frame is provided with a plurality of convex plates which extend outwards along the axial direction; each convex plate is provided with an oblique hole which is oblique corresponding to the axial direction. A poking disc which can slide in the axial direction is arranged on the peripheral surface of the outer ring; a plurality of poke rods which are respectively inserted into the corresponding oblique hole are fixed on the poking disc. Through moving the poke rods of the poking disc to control the wedgy blocks to fully leave a working face of the inner ring, the outer ring and the inner ring can freely rotate in a positive direction and a negative direction, thereby obtaining a bidirectional separation working state of the tristate superior clutch.

Owner:BYD CO LTD

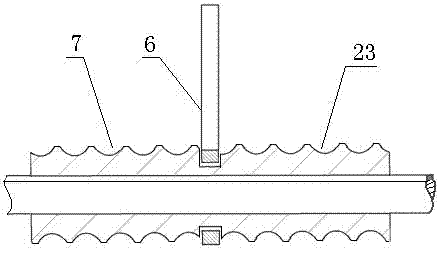

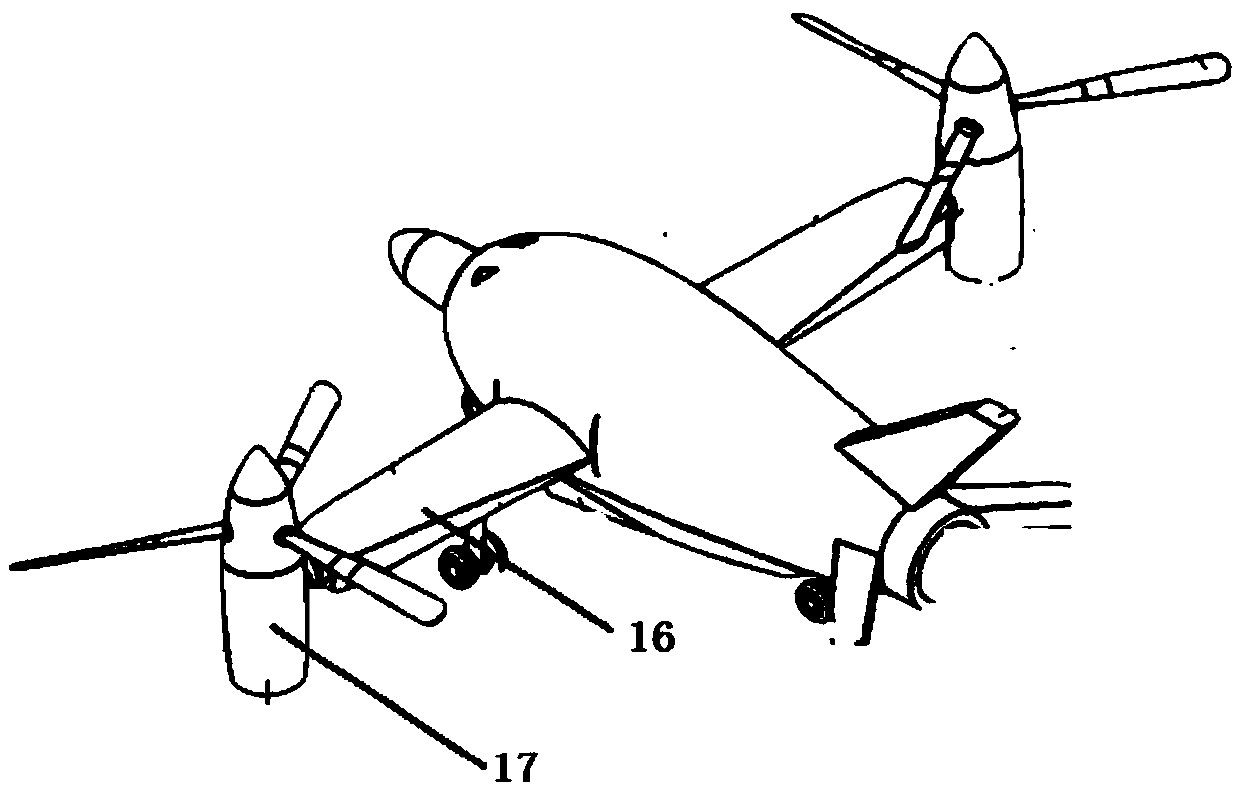

Tilting transmission device for fixing engine

InactiveCN109533312AReduce development difficultySolve the problem of large space occupied by vertical placementPower plant arrangements/mountingAircraft power transmissionGear wheelPropeller

The invention provides a tilting transmission device for fixing an engine, and belongs to the technical field of design of a rotor wing system of a helicopter. The tilting transmission device comprises a fixed end and a tilting end, the fixed end comprises the engine and a second bevel gear meshed with a first bevel gear on the end portion of a first output shaft of the engine, the tilting end comprises a third bevel gear coaxial with the second bevel gear and a fourth bevel gear meshed with the third bevel gear, and a third output shaft connected with the fourth bevel gear drives a propellerto rotate. A control mechanism controls the tilting end to rotate, so that the third output shaft can be converted into a second state from a first state, in the first state, the axis of the third output shaft is parallel to the direction of a longitudinal shaft of the helicopter to achieve forward light, and in the second state, the axis of the third output shaft is parallel to the direction of aperpendicular shaft of the helicopter to achieve lifting. According to the tilting transmission device, tilting of a rotor wing of the propeller is away from the engine so that the engine can be fixed relatively, and difficulty of design and evidence taking of the engine is greatly reduced.

Owner:CHINA HELICOPTER RES & DEV INST

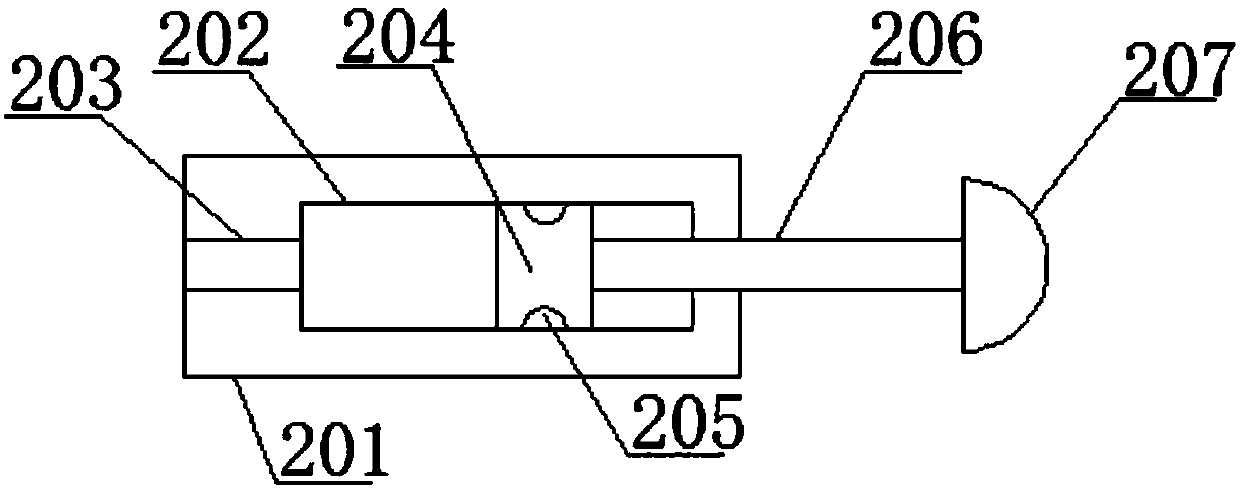

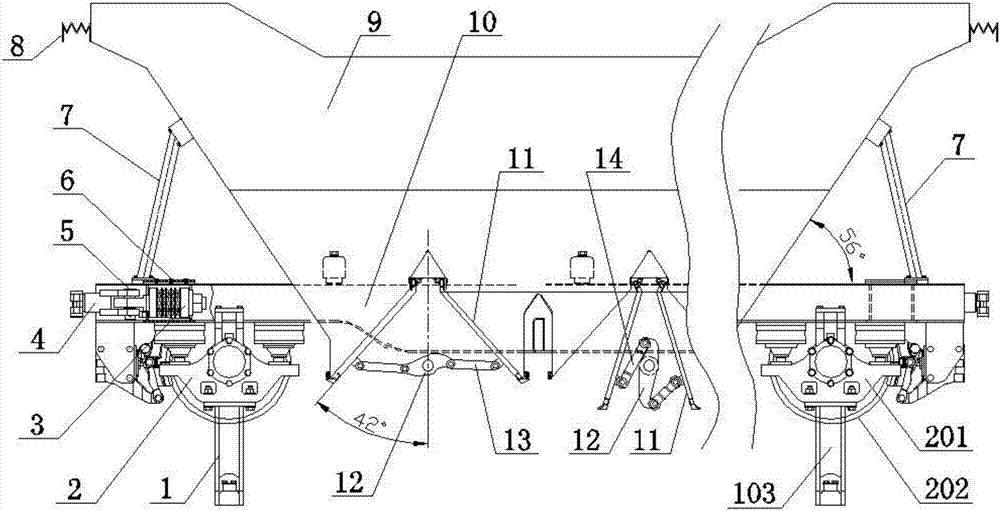

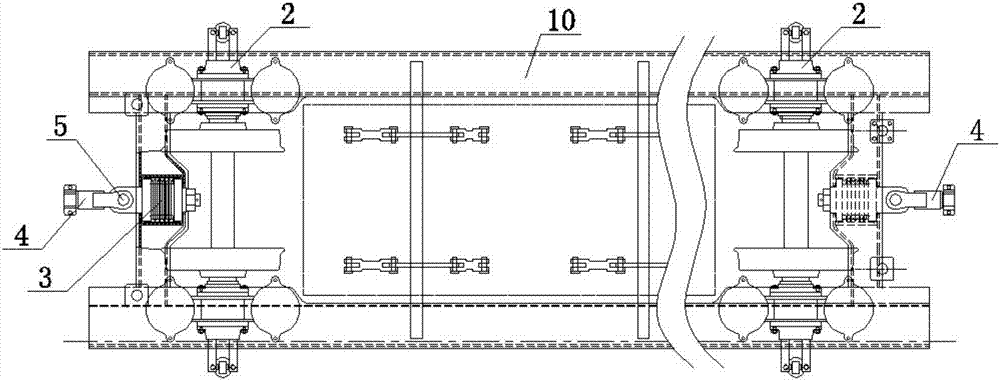

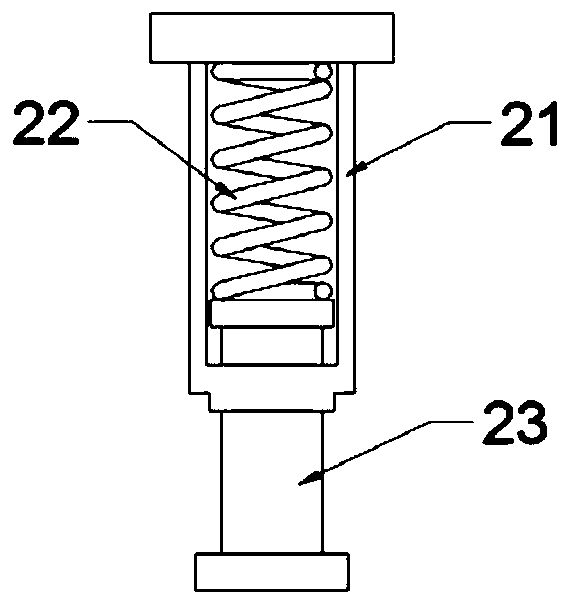

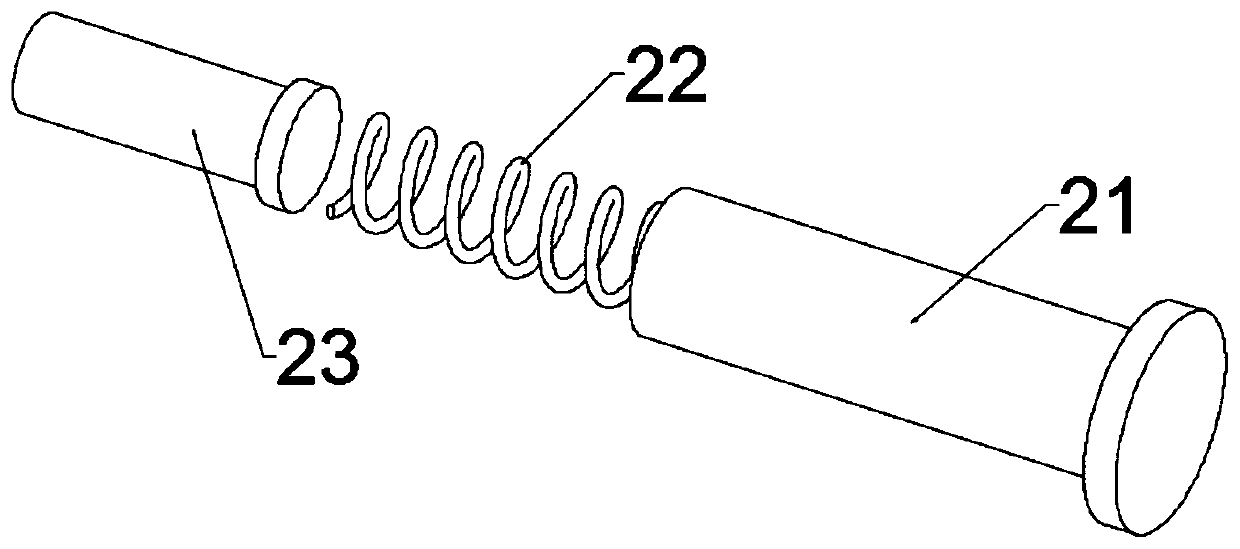

Manual coupling buffer structure

PendingCN107117185AReduce longitudinal impactSimple structureDraw-gearRailway couplingsCouplingWhole body

The invention provides a manual coupling buffer structure. The manual coupling buffer structure comprises buffers (3), two clamp rings (21) and two traction rods (40). Notch grooves are formed in the clamp rings (21), and connecting necks (42) are formed in one ends of the traction rods (40); and the clamp rings (21) are mutually connected with the connecting necks (42) on the inter-adjacent traction rods (40) in a clamped mode through flange parts located on the two sides of the notch grooves, every two clamp rings (21) are connected in series through connecting bolts (6) and fixedly connected with the traction rods (40) to form a whole body, and the buffers (3) are connected at the free ends of the traction rods (40). By utilizing the manual coupling buffer structure, the longitudinal impact between vehicles can be alleviated, when the mutual coupling state between the vehicles needs to be removed, an operating worker only needs to disassemble the connecting bolts with the help of a simple auxiliary tool, and then disconnection between every two adjacent vehicles can be achieved; and the manual coupling buffer structure has the outstanding advantages that the structure is simple, operation is convenient, the coupling reliability is high and the implementation cost is low.

Owner:CRRC ZIYANG CO LTD

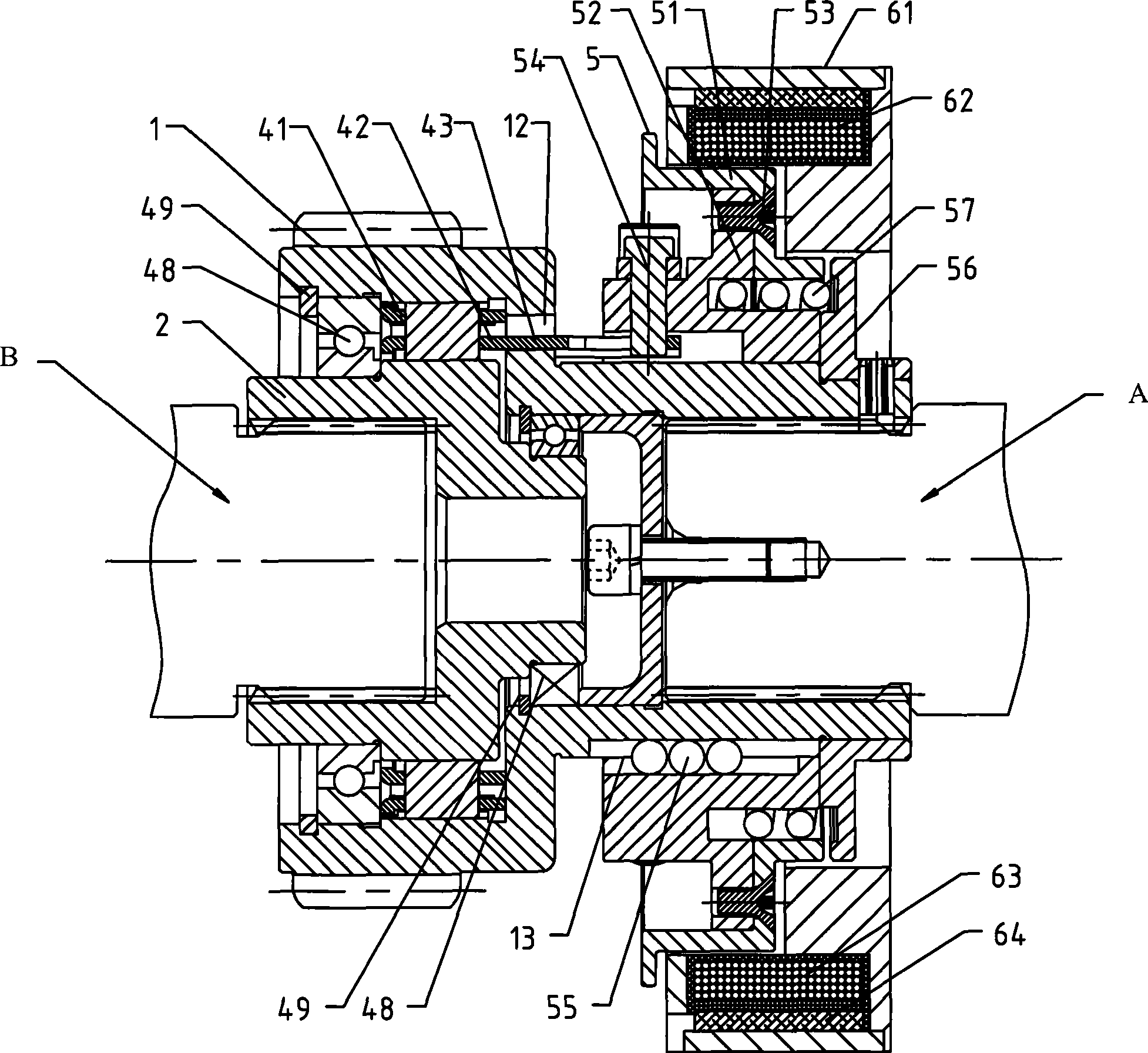

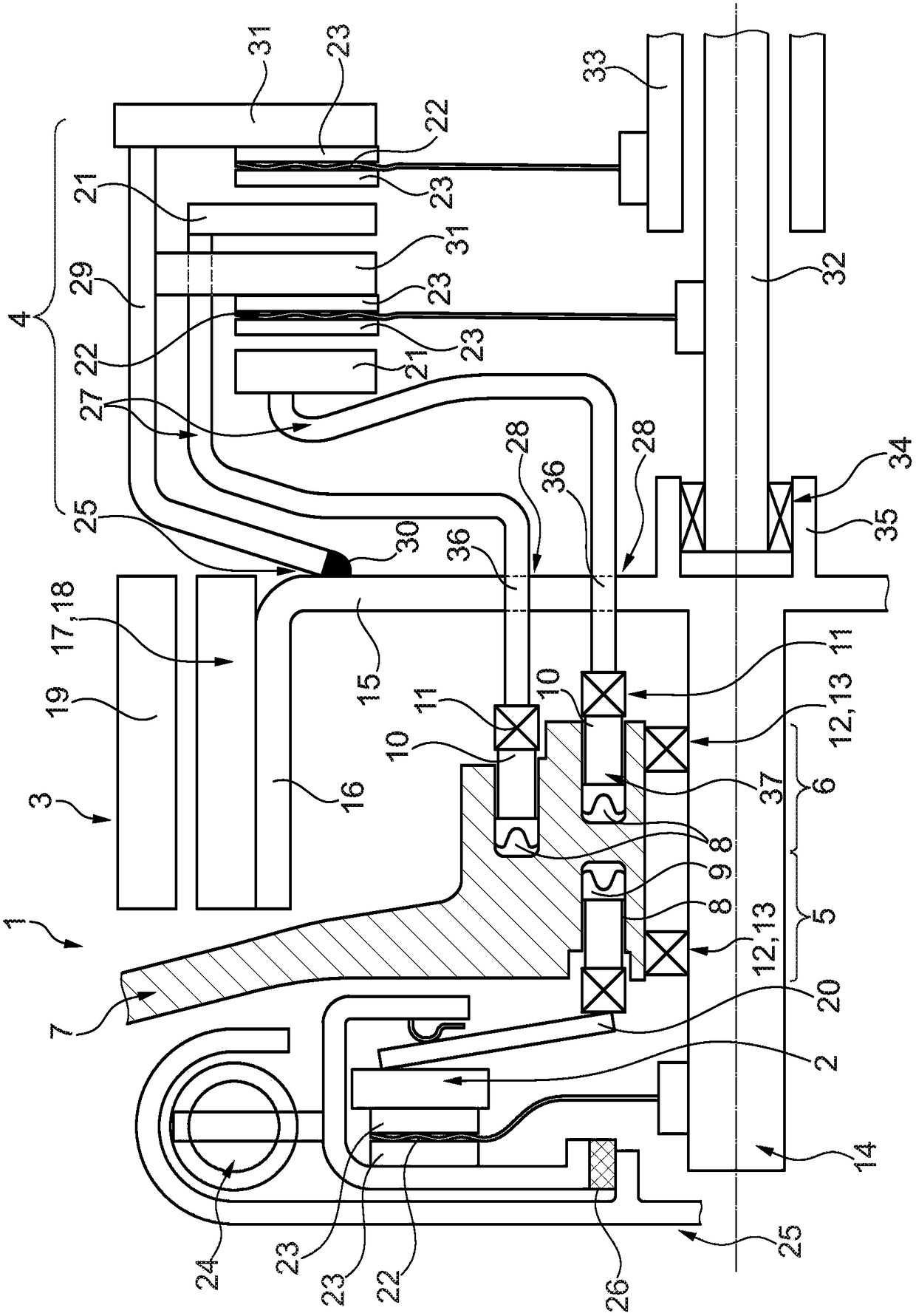

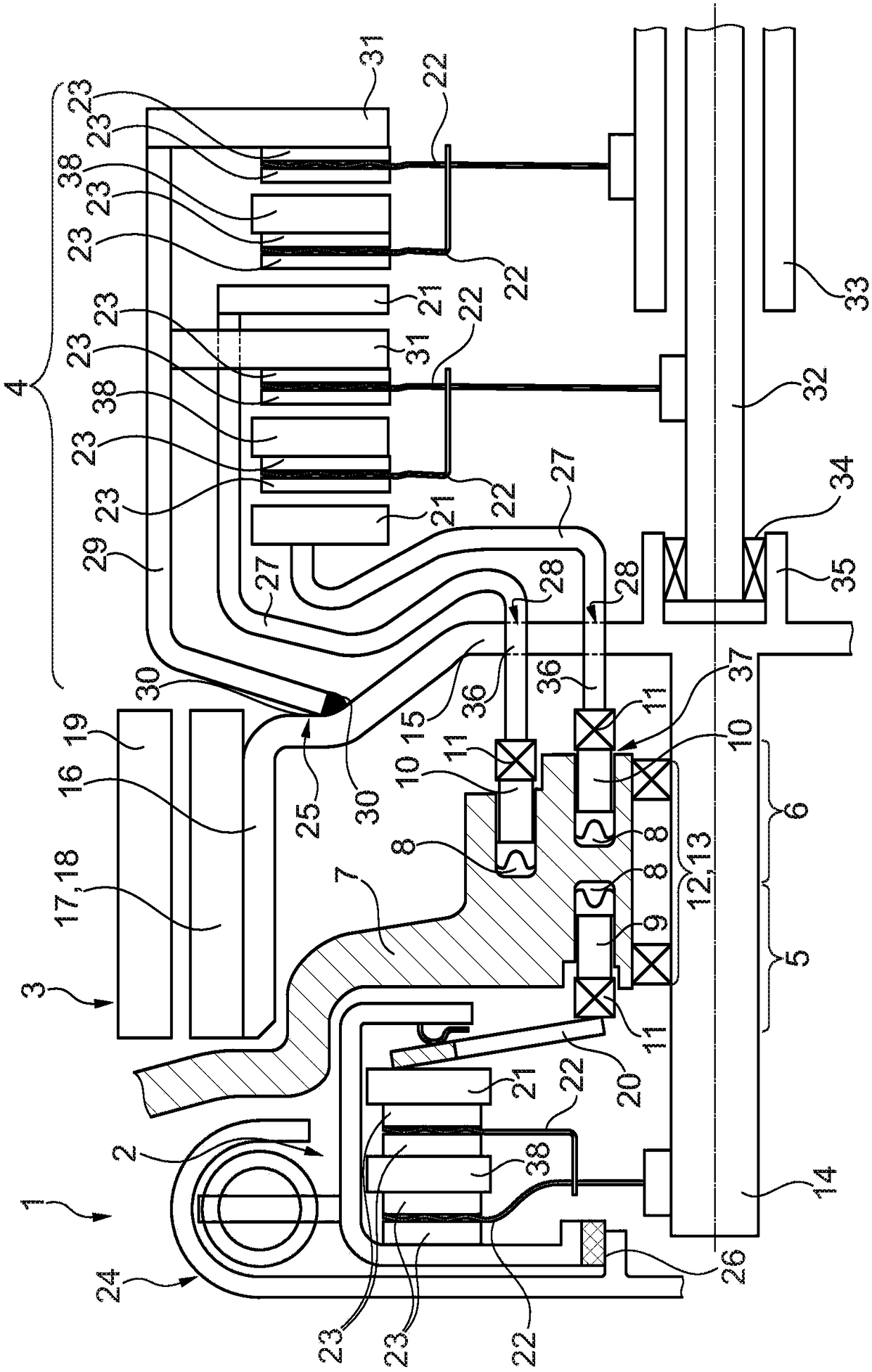

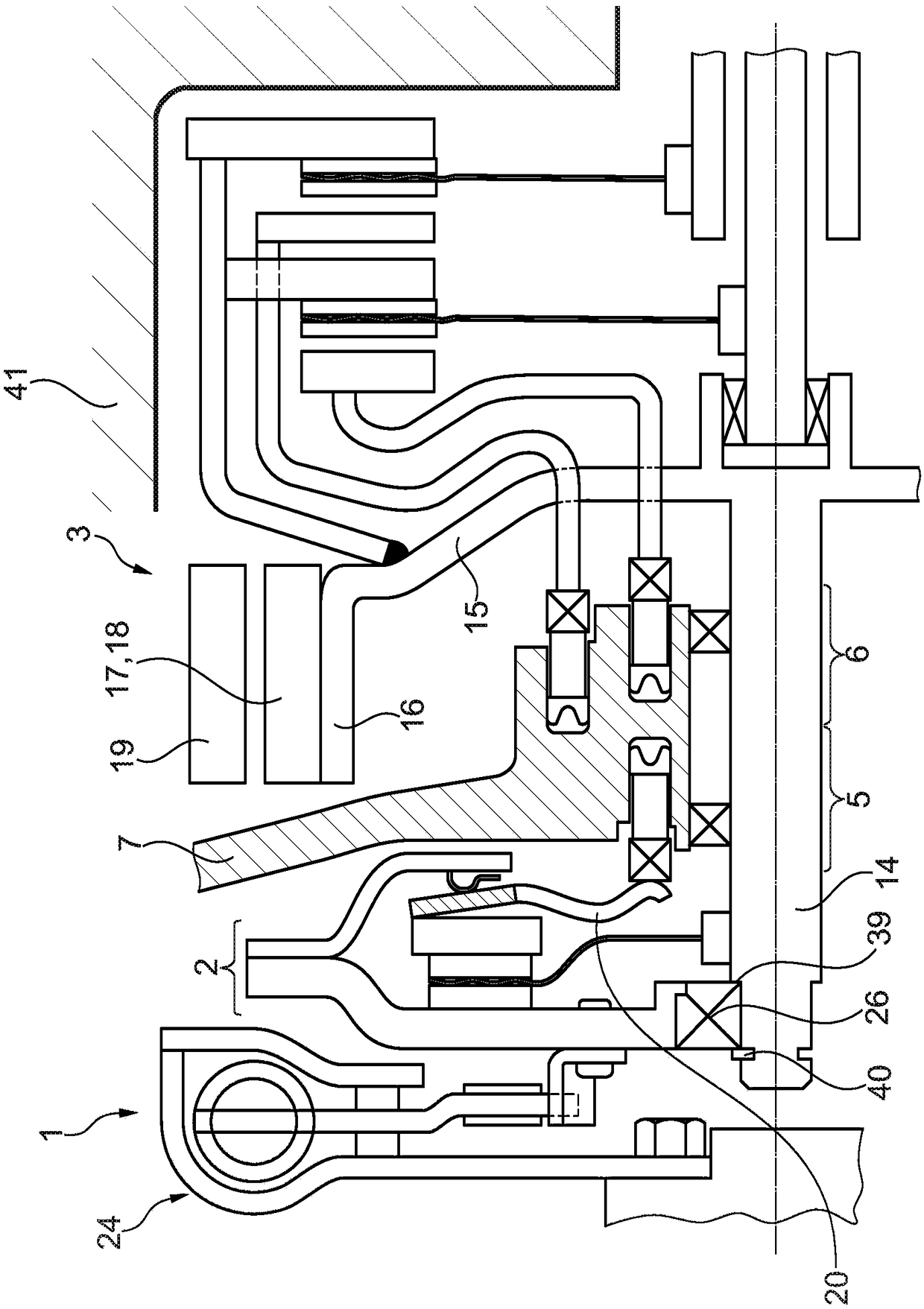

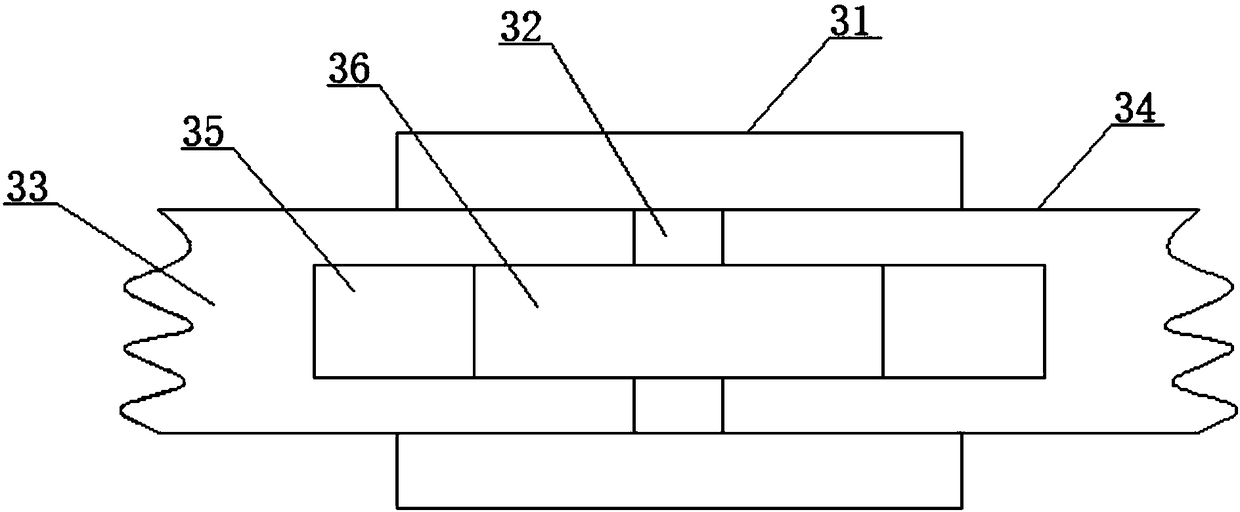

Hybrid module comprising a disconnect clutch and a main clutch and actuating system arranged therebetween

ActiveCN108349368AEnables torque transmissionReduce in quantityHybrid vehiclesFluid actuated clutchesTorque transmissionEngineering

The invention relates to a hybrid module (1) for a motor vehicle, for coupling to an internal combustion engine, comprising a disconnect clutch (2) by which means the internal combustion engine can beseparated from a drive train of the motor vehicle and by which means torque can be supplied from the internal combustion engine to the drive train, and an electric motor (3) that can be connected tothe drive train by means of a main clutch (4), for torque transmission, a disconnect clutch actuating system (5) being used to actuate the disconnect clutch (2) and a main clutch actuating system (6)being used to actuate the main clutch (4), both actuating systems (5, 6) being arranged between the disconnect clutch (2) and the main clutch (4). The invention also relates to a drive arrangement fora motor vehicle comprising an internal combustion engine, which is connected or connectable to a transmission comprising at least one transmission input shaft (32, 33) by means of a hybrid module (1)according to the invention.

Owner:SCHAEFFLER TECH AG & CO KG

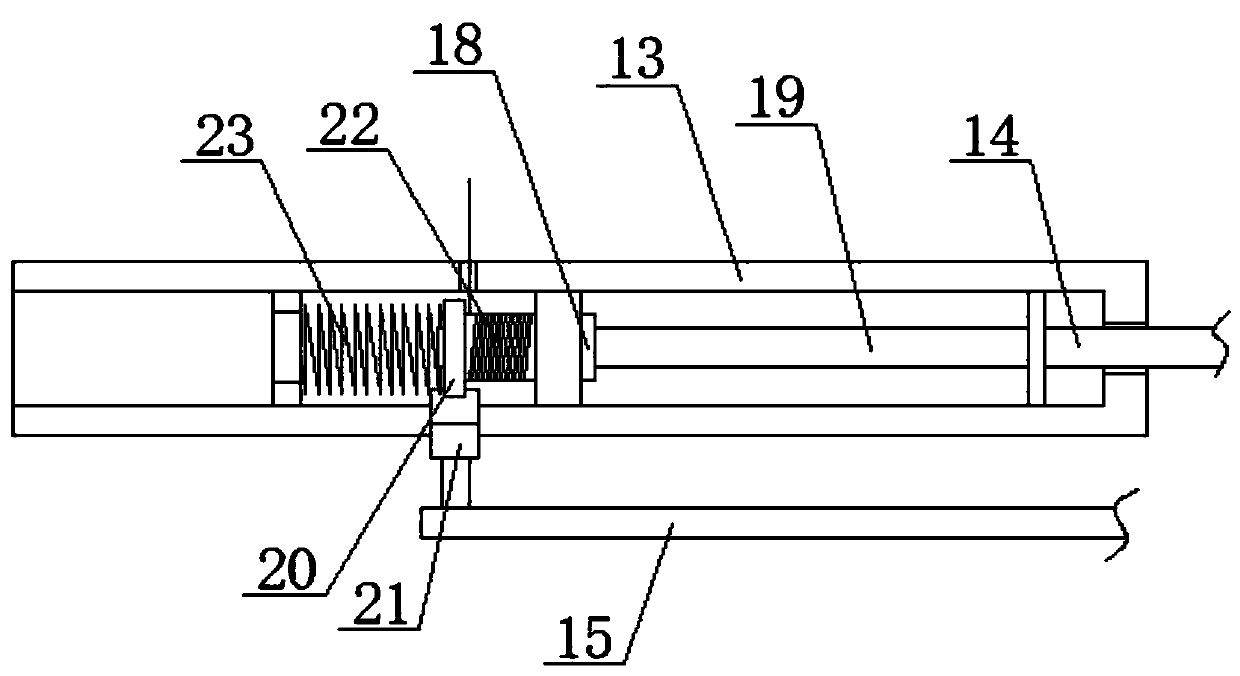

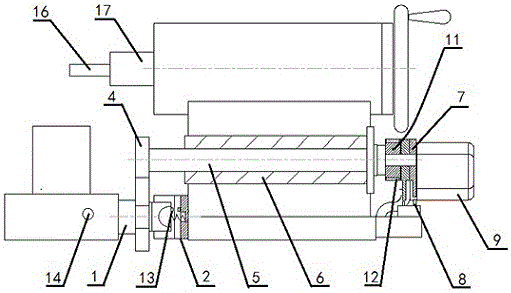

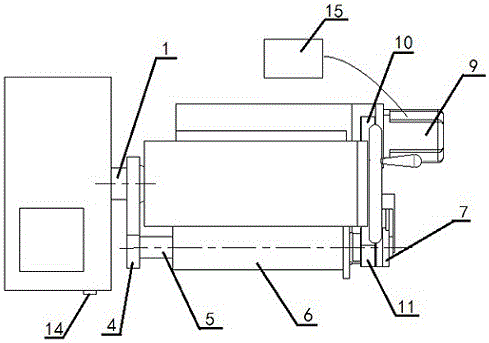

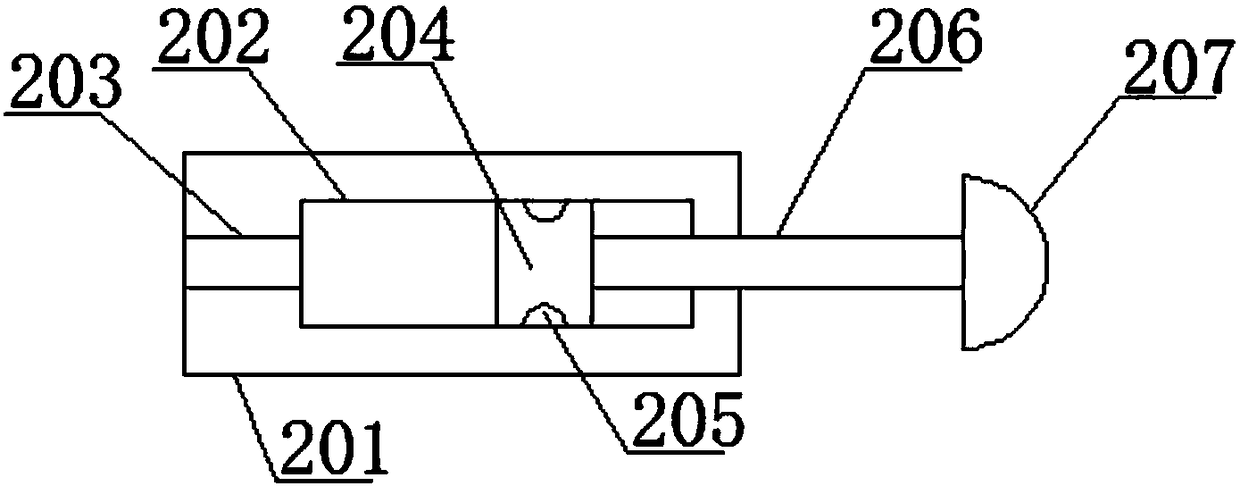

Air turbine starter property testing device

ActiveCN106198035AAchieve associativityAchieve disengagementGas-turbine engine testingJet-propulsion engine testingDrive shaftEngineering

The invention discloses an air turbine starter property testing device. The device includes a transmission mechanism which includes a pedestal, a transmission shaft, a drive cylinder, a connecting guide rod, a connecting assembly and an output flange. The transmission shaft is arranged on the pedestal in a first direction. One end of the transmission shaft is in transmission connection to an output shaft of a torquemeter, and the other end of the transmission shaft is coaxially connected to the output flange. A cylinder body of the drive cylinder is fixed to the pedestal. A telescopic end of the drive cylinder is movably connected to one end of the connecting guide rod. The middle part of the connecting guide rod is provided with waist-shaped holes in the length direction of the connecting guide rod. The connecting assembly is slidingly arranged at the waist-shaped holes of the connecting guide rod. The connecting assembly is intended for detachably connecting the transmission shaft and the output flange. The other end of the connecting guide rod extends in a second direction. The other end of the connecting guide rod is movably connected to the pedestal. The first direction and the second direction are in non-parallel arrangement. The output flange and a brake mechanism are in transmission connection. According to the invention, the device is easy to operate, is safe and reliable, and has high automation.

Owner:WUHAN HANGDA AERO SCI & TECH DEV

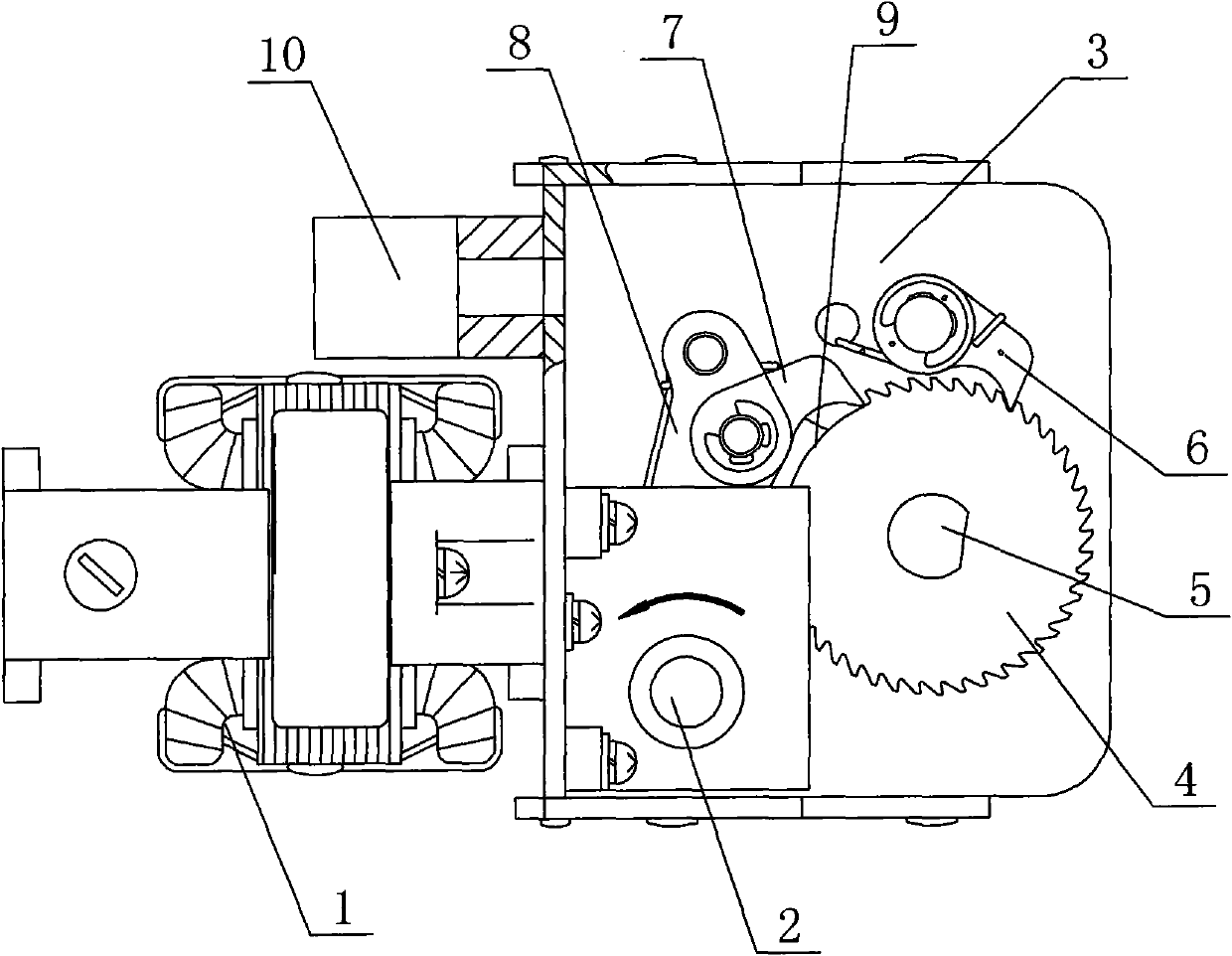

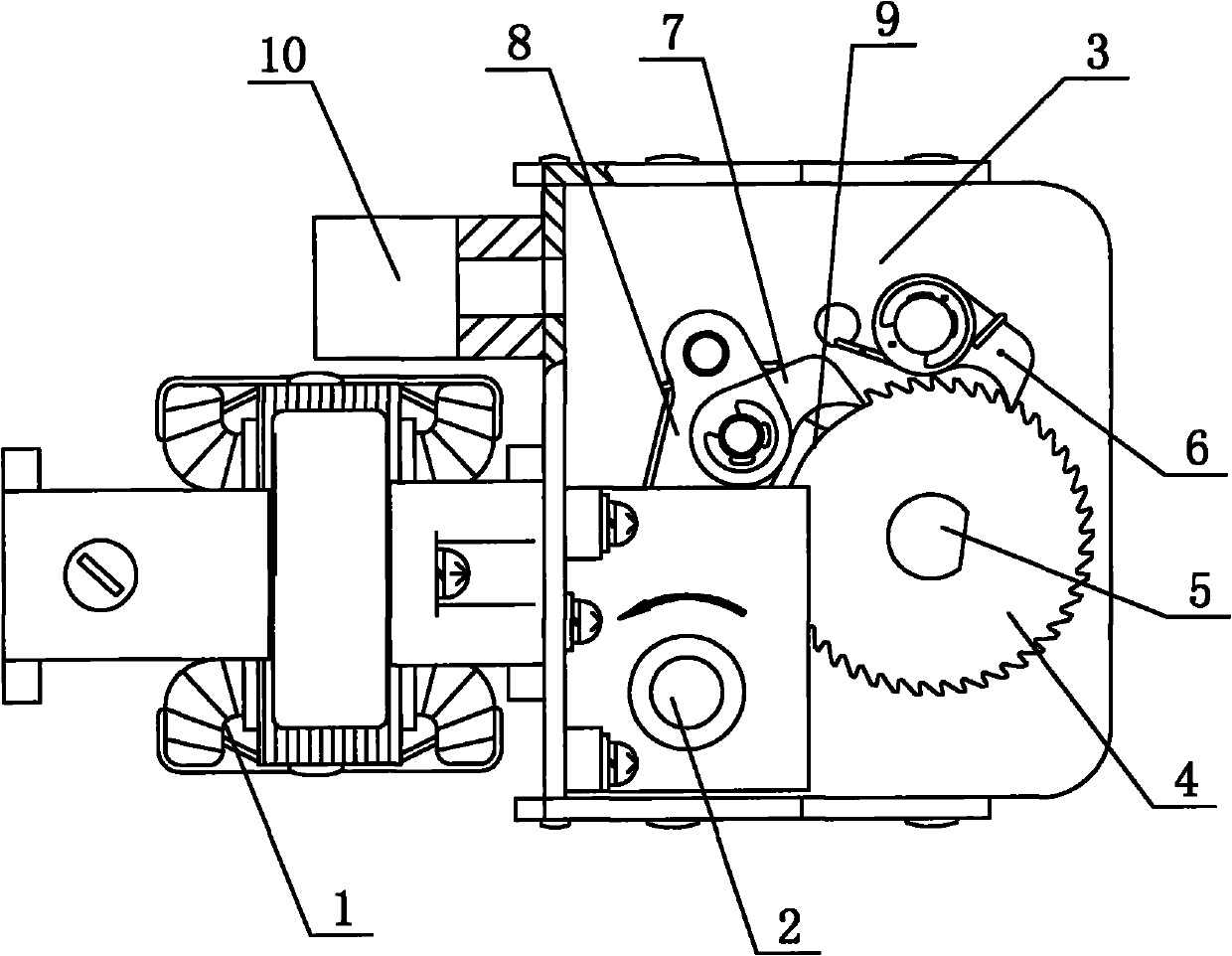

Intelligent universal type motor-operating mechanism of breaker

InactiveCN102169764AAchieve disengagementEnsure one-way operationContact driving mechanismsRocker armPower unit

The invention discloses an intelligent universal type motor-operating mechanism of a breaker, comprising a bent plate and a ratchet wheel which are arranged on a main shaft, wherein a support tightly matched with the ratchet wheel is arranged corresponding to the ratchet wheel; the support is hinged with one end of a rocker arm; the other end of the rocker arm is hinged with a connecting plate; the connecting plate is connected with a power unit; a neutral gear part lower than the ratchet wheel is arranged on the ratchet wheel; the neutral gear part is a no-toothed structure with a smooth curved surface; and the support is inserted into the neutral gear part when the ratchet wheel is rotated to a set angle. The neutral gear part is arranged on the ratchet wheel of the intelligent universal type motor-operating mechanism of the breaker disclosed by the invention, the accumulation of energy for the breaker is ended, and the support is inserted into the neutral gear part when the ratchet wheel is rotated to the set angle, so that the support is released from the ratchet wheel without providing a special component for pushing the support away; the intelligent universal type motor-operating mechanism of the breaker not only has a simple structure, convenience and rapidness in installation and saved cost, but also has good performance and capability of ensuring one-way operation of the main shaft of the breaker.

Owner:无锡市惠源机电制造有限公司

Connecting component of assembled concrete frame beam column

PendingCN110145026AAchieve disengagementSimplify the assembly processProtective buildings/sheltersShock proofingEngineeringMechanical engineering

The invention belongs to the field of buildings, in particular to a connecting component of an assembled concrete frame beam column. For solving the problems that an existing assembled joint fixing mode is troublesome, an operation process is complicated, and thus, installation is troublesome, the following scheme is proposed: the connecting component of the assembled concrete frame beam column comprises a first connecting plate and two second connecting plates, the two second connecting plates are positioned on one side of the first connecting plate, clamping openings are separately formed inthe sides, which are close to each other, of the two second connecting plates, one side of the first connecting plate is rotatably connected with a mounting plate, one side of the mounting plate extends into the two clamping openings, a clamping column is driven to move by rotating a threaded ring, then a movable cover further can be driven to move, finally, a fixing rod is clamped into the clamping openings, thus, the two second connecting plates are both connected with the first connecting plate, an assembling process is simple, assembling can be implemented by only needing to rotate the threaded ring, thus, during splicing, rapid assembling can be implemented, and certain simplicity and convenience are achieved.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

Propagation device based on digital technology application

PendingCN112253907ARealize threaded connectionRealize heat dissipationMachine framesStands/trestlesElectric machineryEngineering

The invention discloses a propagation device based on digital technology application. The device comprises a propagation body and a display screen, wherein fixing installation columns are symmetrically arranged on the side bottom wall of the display screen, fixing clamping blocks are arranged at the bottom ends of the fixing installation columns, a fixing transverse plate is arranged inside the propagation body, and fixing clamping grooves are formed in the fixing transverse plate. According to the propagation device, the fixing clamping blocks and the fixing clamping grooves are clamped and connected to preliminarily fix the fixing installation columns, and preliminary fixing installation of the propagation body and the display screen is achieved; and a positive and negative rotation motor is started, a driving bevel gear rotates, the driving bevel gear meshes with a driven bevel gear, the driven bevel gear rotates, an adjusting shaft rotates, then the threaded connection of threadedopenings and threaded movable rods is achieved, then clamping movable rods and reinforcing openings are limited and fixed, and limiting and fixing of the fixing installation columns are accomplished.

Owner:南京希亘数字技术有限公司

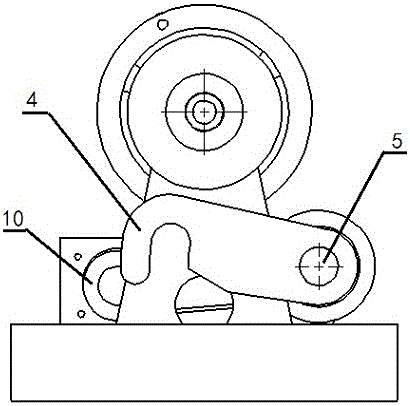

Collision type connecting and disconnecting mechanism for mine car

The invention discloses a collision type connecting and disconnecting mechanism for a mine car, comprising a first fixed plate, hooks and a second fixed plate, wherein a first fixture block is fixed at the left end of the first fixed plate, second fixture blocks are connected to the upper end and the lower end of the first fixture block, the hooks are arranged at the left end of the second fixtureblock, slide beads are connected to the outsides of the hooks, and the second fixed plate is arranged at the left end of a damping spring. According to the collision type connecting and disconnectingmechanism for a mine car, two second fixture blocks are arranged on a bottom plate, the two fixture blocks are arranged in up-down symmetry, a clearance is formed between the two fixture blocks, while the first fixture block is arranged on the first fixed plate, the bottom plate and the first fixed plate are fixed on two different mine cars, and when opposite collision occurs to the two mine cars, the first fixture block is clamped between the two second fixture blocks to complete fixing; and compared with conventional chain hooking, the collision type connecting and disconnecting mechanism is simple in operation, relatively low in labor intensity, and favorable for alleviating the load of workers.

Owner:宋文伟

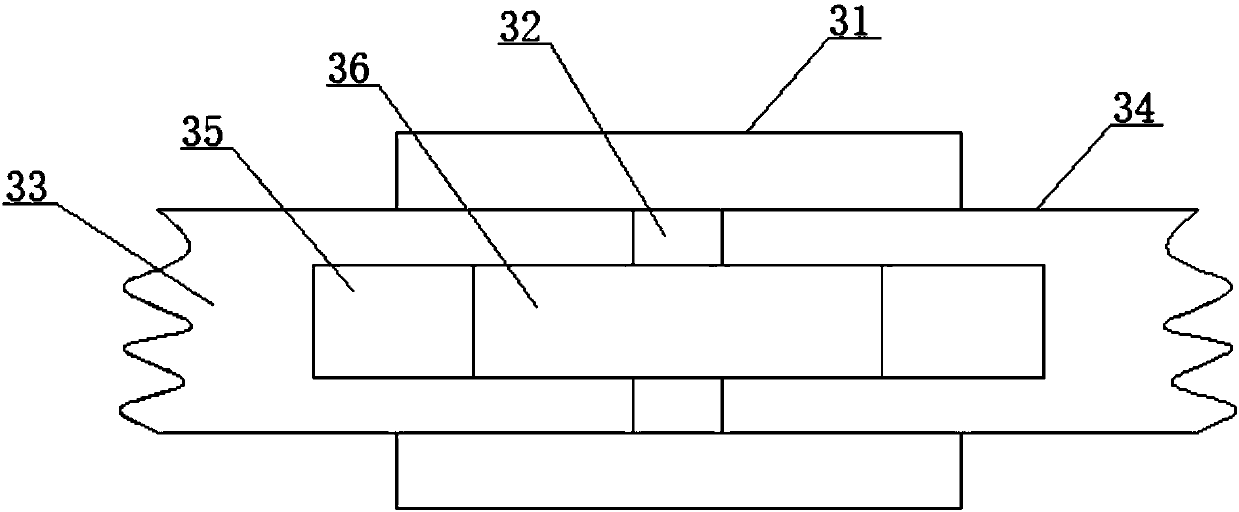

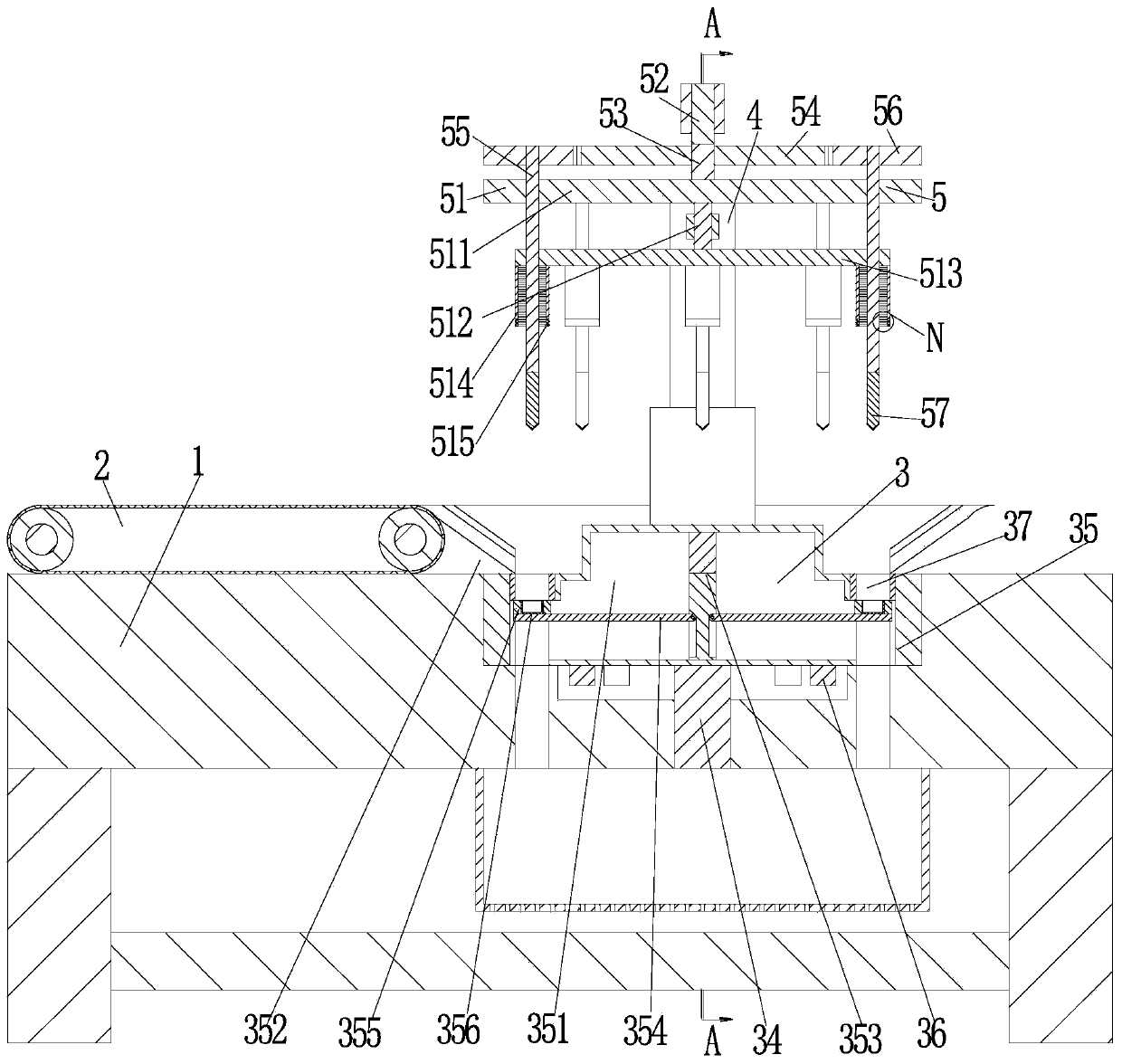

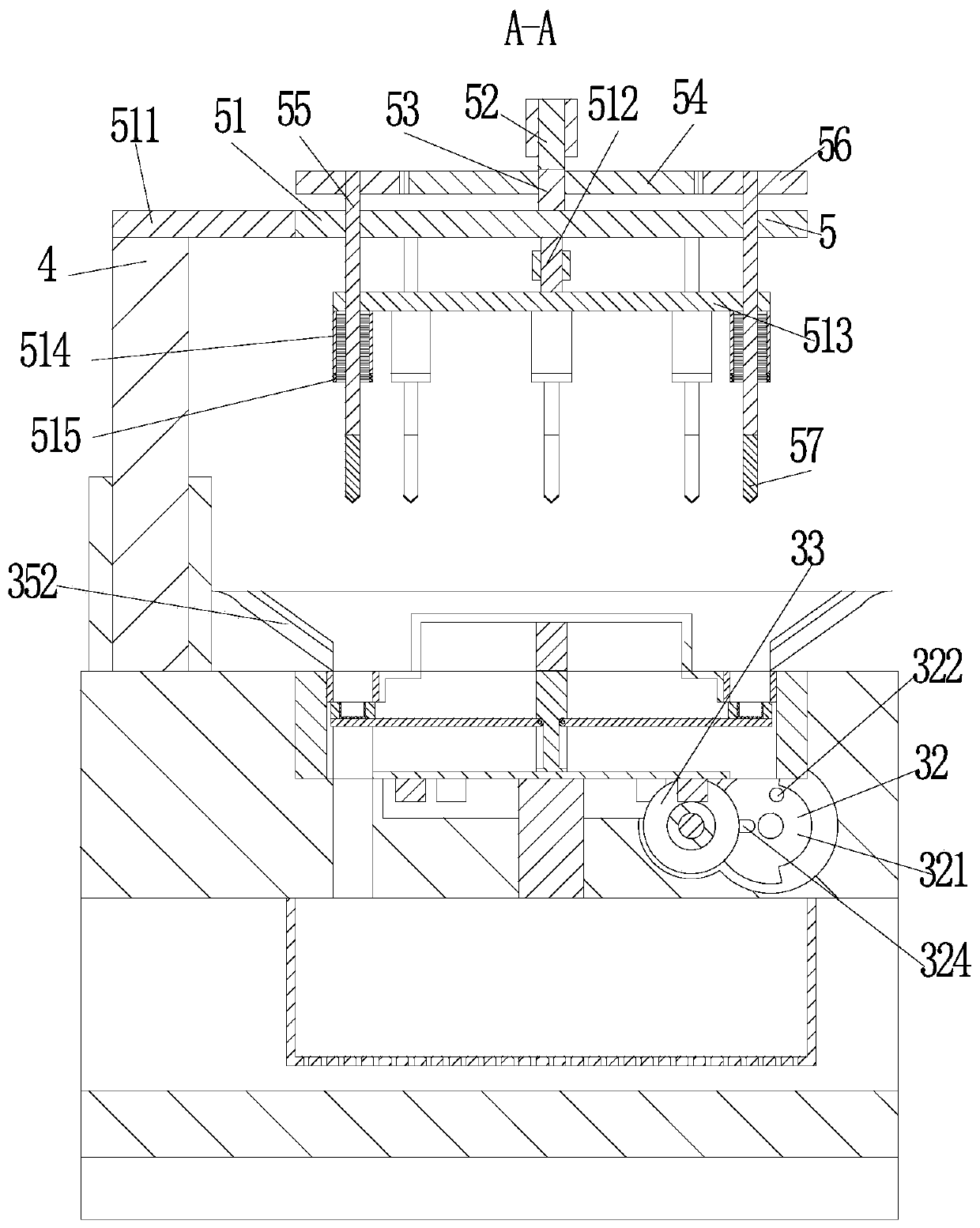

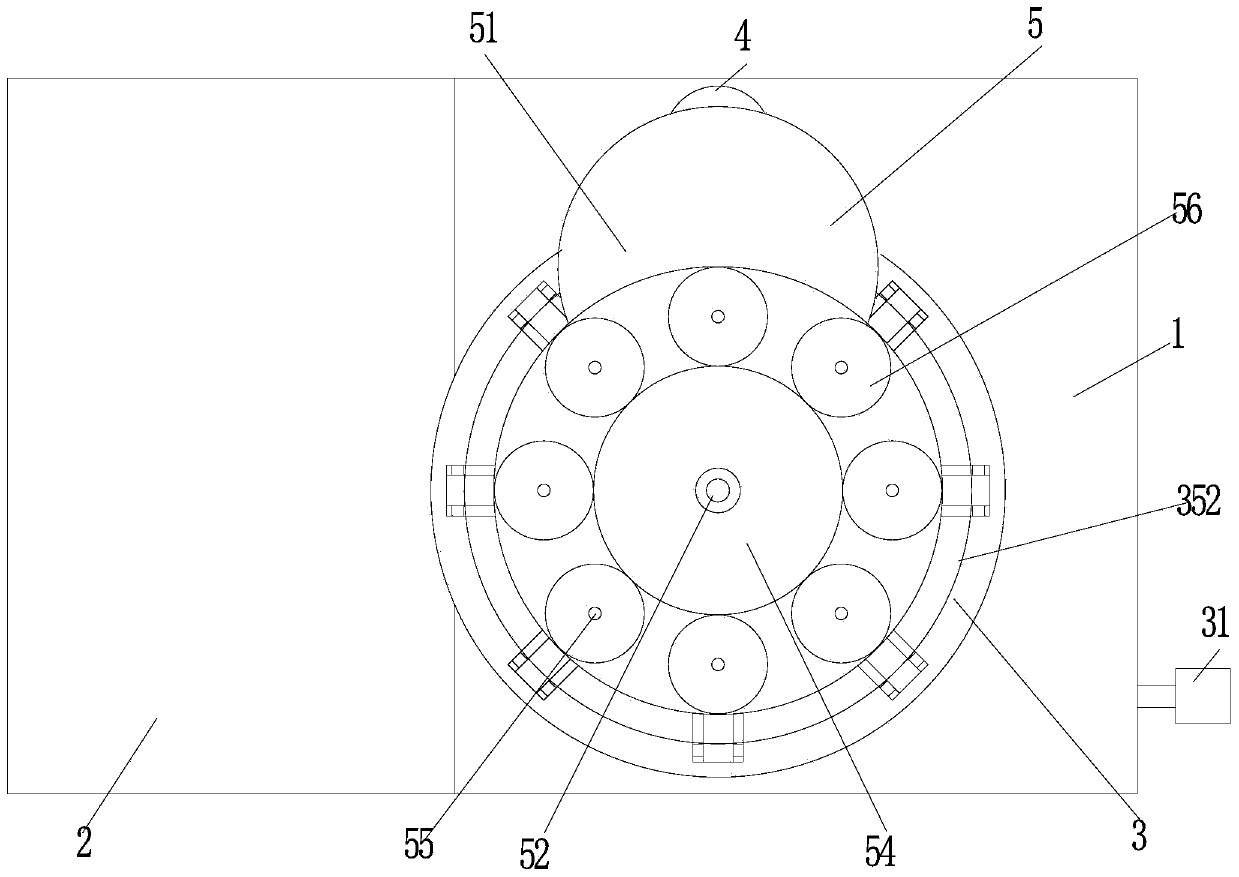

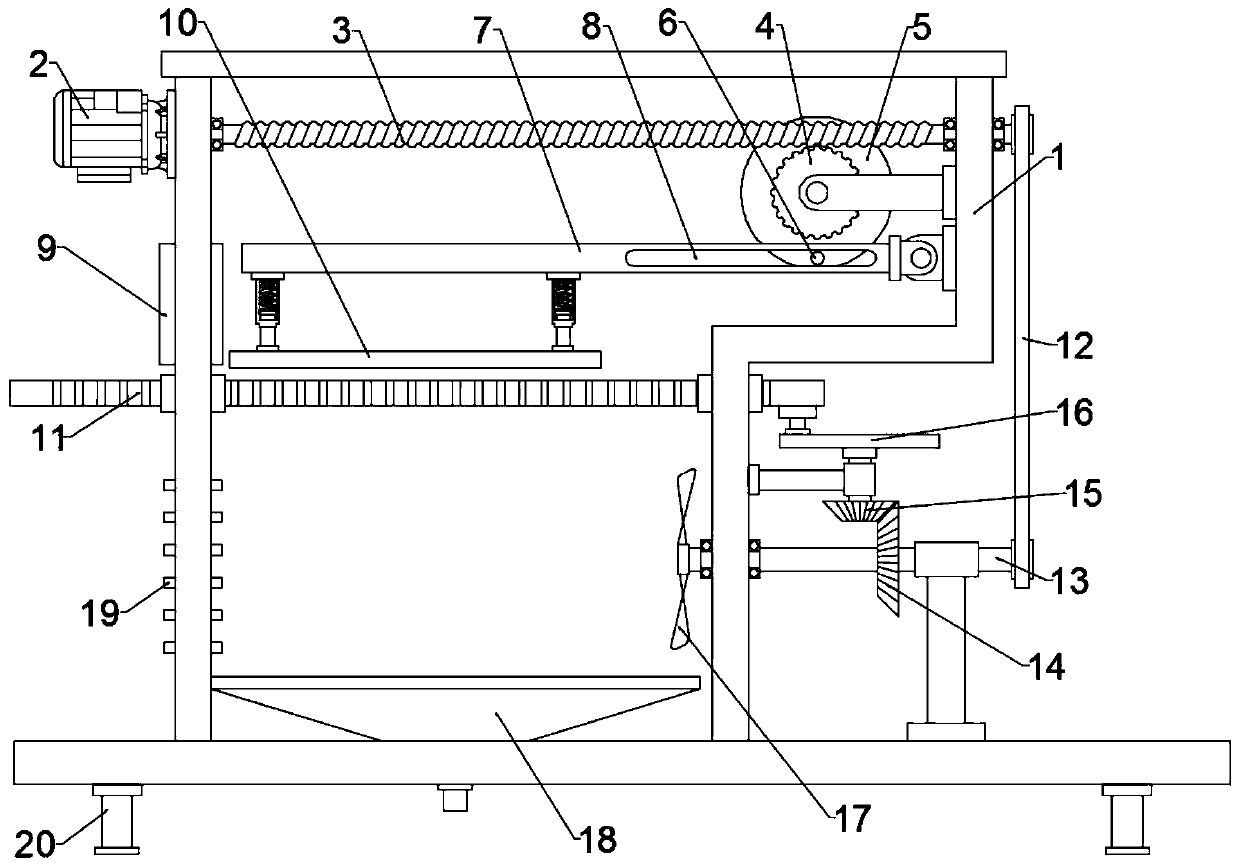

Automatic tapping machine for manufacturing and machining of metal pipe fitting movable joints

InactiveCN111421194ATo achieve the purpose of clamping and positioningControl motion cycleThread cutting feeding devicesThread cutting machinesPipe fittingElectric machinery

The invention relates to an automatic tapping machine for manufacturing and machining of metal pipe fitting movable joints. The automatic tapping machine comprises a workbench, a belt conveyor, a positioning device, a telescopic support and a tapping device, wherein the belt conveyor is installed at the upper end of the left side of the workbench, the positioning device is installed at the right end of the belt conveyor, the telescopic support is fixedly installed at the upper end face of the front side of the workbench, and the tapping device is fixedly installed at the upper end of the telescopic support. The belt conveyor and the positioning device are matched, and a first motor drives a control frame to move, so that the rotation period of a rotating plate is controlled, the contact period of clamping blocks and the movable joints is controlled, and the purpose of clamping and positioning the multiple movable joints is achieved. The movable joints are positioned, fixed and internally tapped through the matching of the telescopic support and the tapping device, and meanwhile the machined movable joints are separated from the positioning device, so that the machined movable joints are collected.

Owner:刘志文

Automatic feeding control method used for numerical control lathe tailstock and capable of controlling drilling depth

ActiveCN106180765ARealize synchronized movementRealize finishingTailstocks/centresAttachable boring/drilling devicesNumerical controlDrive motor

The invention provides an automatic feeding control method used for a numerical control lathe tailstock and capable of controlling the drilling depth. A connecting device for automatic connection and separation of a saddle and the tailstock of a numerical control lathe is adopted. The connecting device comprises a centering assembly, a rotating arm assembly, a driving assembly and a drill bit assembly. The drill bit assembly is mounted in a barrel sleeve of the numerical control lathe tailstock. The centering assembly comprises a centering shaft and a V-shaped block. The rotating arm assembly comprises a rotating arm, a rotating shaft, a shaft sleeve and two limiting press blocks. The driving assembly comprises a pair of belt drive parts, a drive motor, a reset switch and a controller, wherein the controller is mounted in a distribution box of the lathe, the reset switch is mounted in front of the saddle of the numerical control lathe, and the drive motor is fixedly connected with the numerical control lathe tailstock and electrically connected with the controller.

Owner:盐城市力真佳机电有限公司

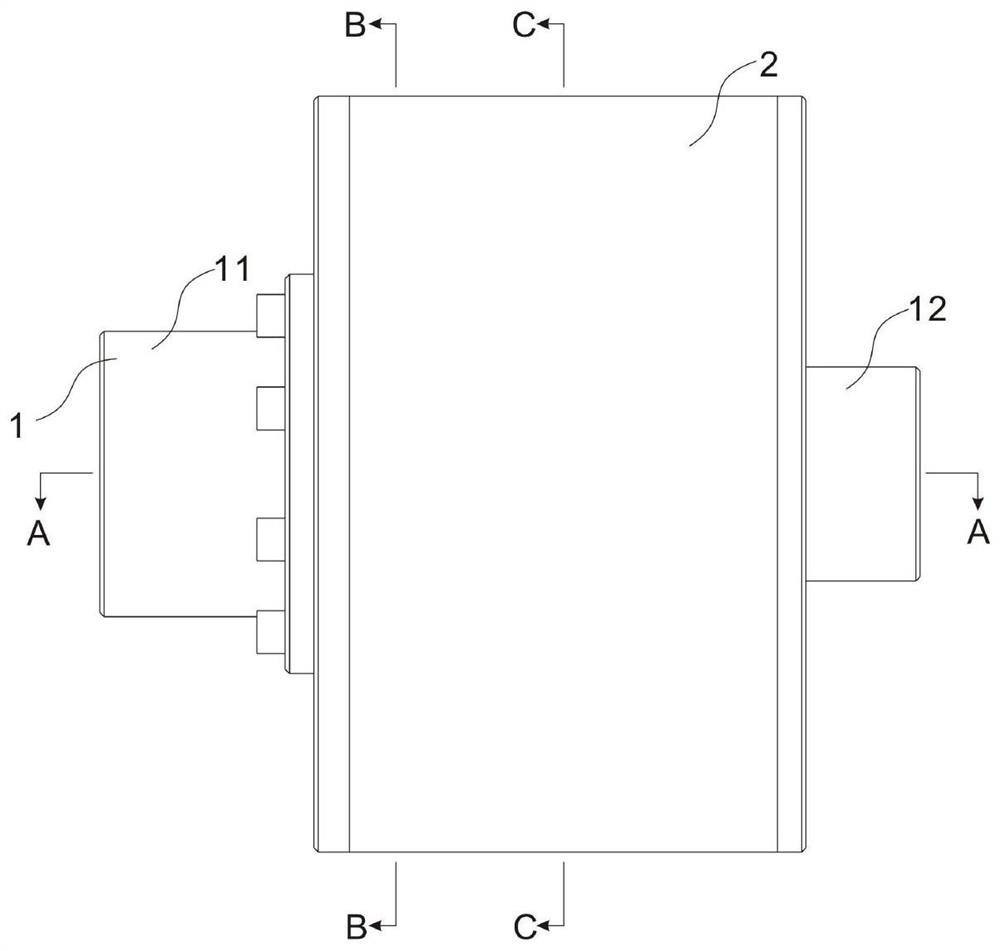

Torque limiting coupler with soft start function

ActiveCN112360892AWith soft start functionSatisfy the protective effectCouplings with disconnecting safety membersMechanical energy handlingCouplingElectric machinery

The invention discloses a torque limiting coupler with a soft start function. The torque limiting coupler comprises a rotor, wherein an inner rotor is arranged at a driving end in a sleeving manner; an outer ring is connected with a load end; a plurality of first transmission devices and a plurality of second transmission devices are arranged on the inner rotor; the first transmission devices areuniformly distributed along the outer circumference of the inner rotor; first thrust rods are arranged on the inner side, opposite to the first transmission devices, of the outer ring; each second transmission device comprises a thrust end and a counterweight end; the thrust ends are positioned on the outer circumference of the inner rotor; the thrust ends are uniformly distributed along the outercircumference of the inner rotor and are crossed with the first transmission devices; and second thrust rods are arranged on the inner side, opposite to the end parts of the second transmission devices, of the outer ring. According to the torque limiting coupler, the torque of the driving end is transmitted to the load end through the transmission devices arranged on the inner rotor; when a rotating shaft of a motor rotates, the torque of the load end can be smoothly increased, and rigid impact is avoided; and after the load end conducts normal operation, enough large torque can be transmitted, and equipment and mechanisms of a transmission chain can be protected.

Owner:嘉兴美茵钛传动科技有限公司

Energy-saving type mud-head-free automatic green brick cutting device

PendingCN108789793AEnable connectivityNo energy consumptionCeramic shaping apparatusBrickReciprocating motion

The invention provides an energy-saving type mud-head-free automatic green brick cutting device. A green brick cutting frame right faces an opening of an extruding machine and is fixedly arranged in the mud strip conveying direction of a mud strip conveyor, a mud strip positioning wheel is arranged in front of the green brick cutting frame, a tackle is arranged on the lower portion of the interior, a self pressing type rolling press roller is arranged on the upper portion of the interior, the tackle is provided with a cutting device, the cutting device is connected with a speed reduction motorthrough a crank connecting rod mechanism and is continuously driven by the speed reduction motor to periodically reciprocate up and down to cut green bricks, the speed reduction motor intermittentlydrives the tackle to retreat and reset through a clutch, the tackle and the mud strip conveyor are in automatic intermittent disconnection or connection through a ratchet-pawl mechanism, the crank connecting rod mechanism achieves engaging and disengaging switching of the clutch through the cam mechanism and a shifting fork, the self pressing type rolling press roller is attached to the mud stripand the upper end faces of the green bricks all the time and is matched with all devices to cut the green bricks. The device is compact in structure, small in occupied area, energy-saving, and capableof reducing consumption and emissions. In the green brick cutting process, no mud head exists, no remaining materials are generated, the cost is low, maintaining is easy, and the device is easy to popularize.

Owner:陕西新兴建材机械制造有限公司

Tri-state overrunning clutch

ActiveCN100595448CAchieve disengagementExtended service lifeFreewheel clutchesClutchPositive direction

The invention relates to a tristate superior clutch comprising an outer ring, an inner ring, a plurality of wedgy blocks positioned between the outer ring and the inner ring and a retaining frame which is positioned between the outer ring and inner ring and used for retaining the wedgy blocks; a first working face of the wedgy blocks permanently contacts one of the working faces of the outer ringand the inner ring and can make a second working face of the wedgy blocks contact or leave the other working face of the working faces of the outer ring and the inner ring through rotation. Through controlling the wedgy blocks to fully leave the other working face, the outer ring and the inner ring can freely rotate in a positive direction and a negative direction, thereby obtaining a bidirectional separation working state of the tristate superior clutch; through controlling the wedgy blocks to restore a common superior wedging working position, an unidirectional superior working state or a unidirectional wedging working state of the tristate superior clutch is obtained.

Owner:BYD CO LTD

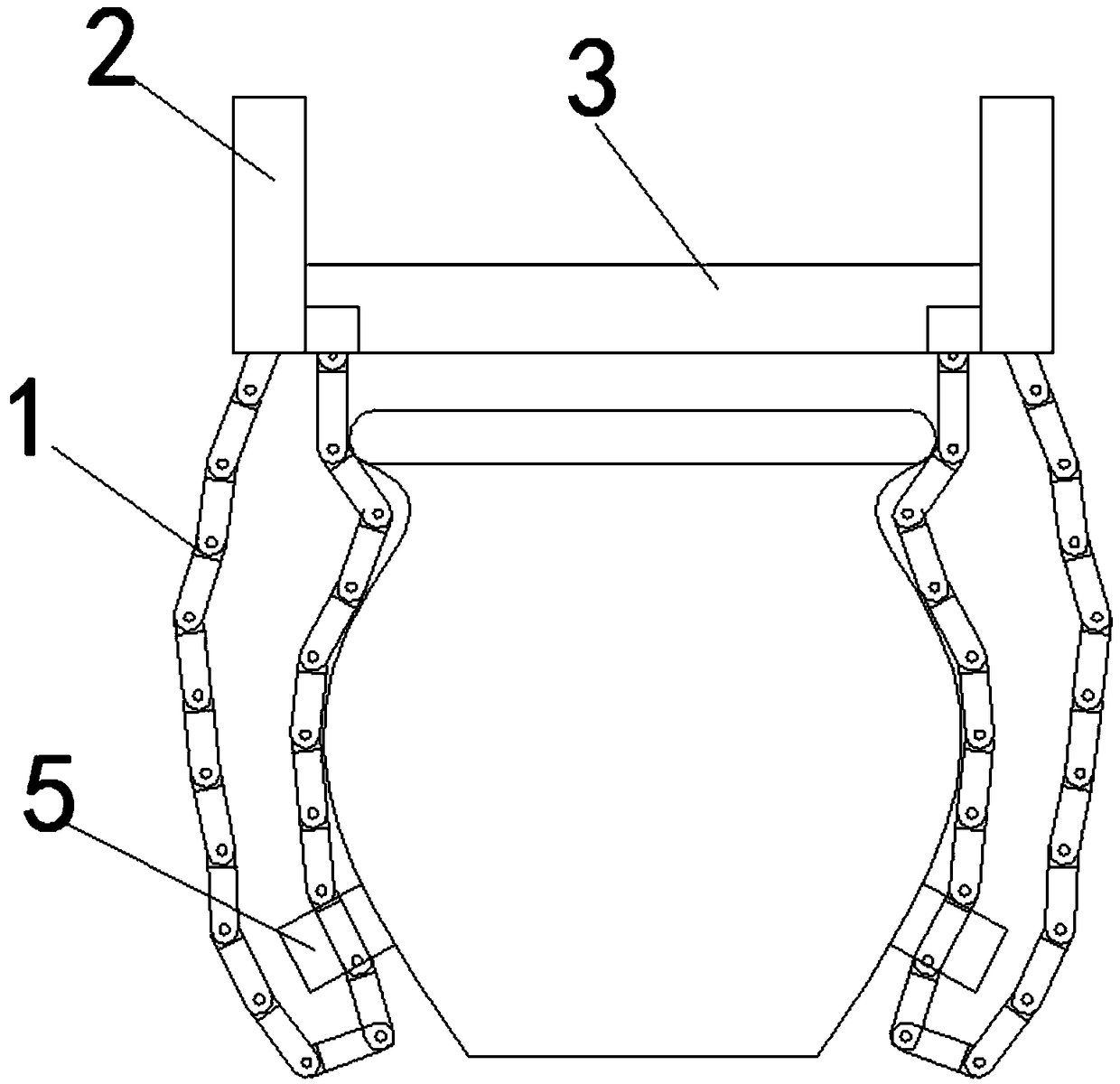

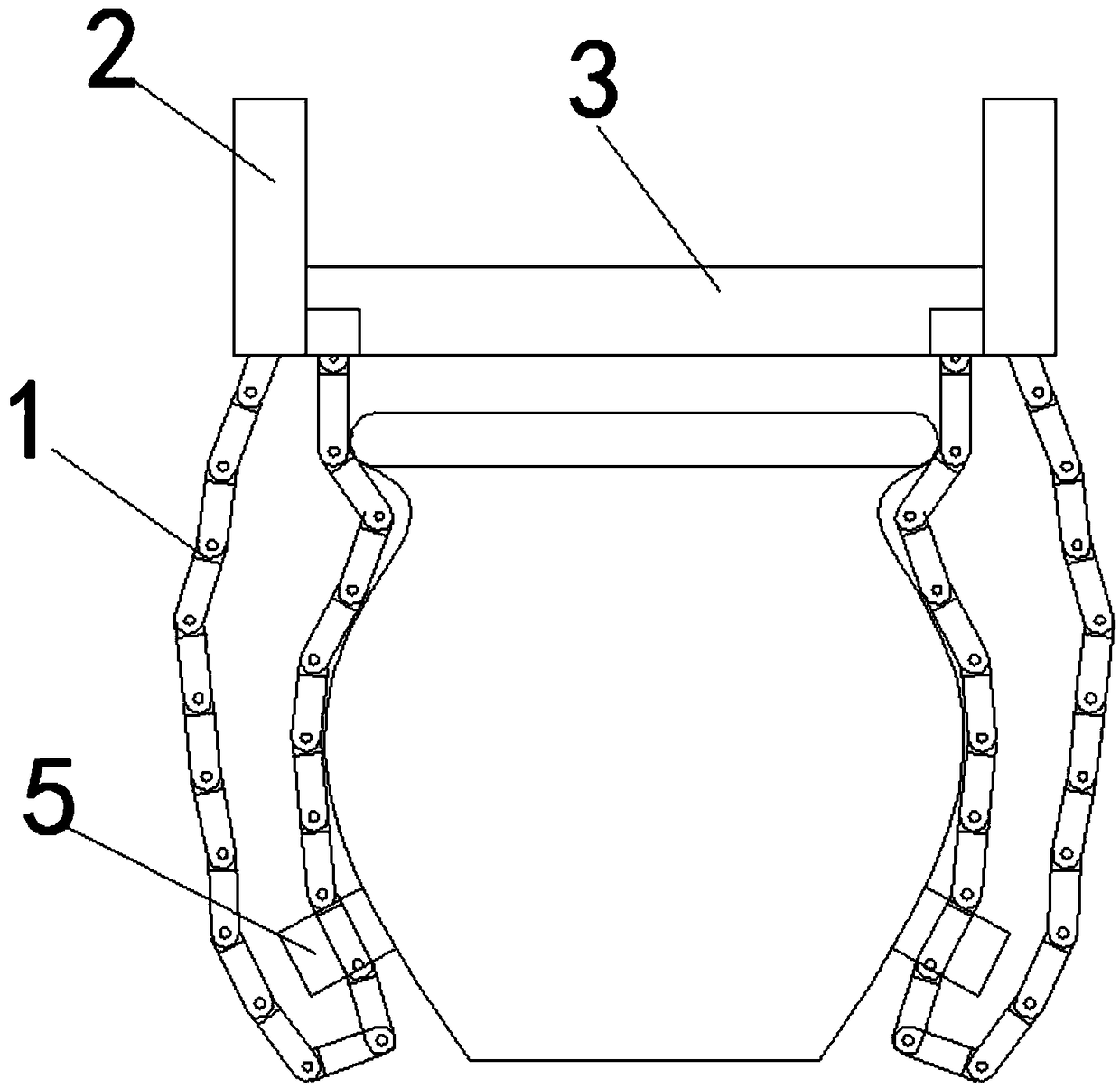

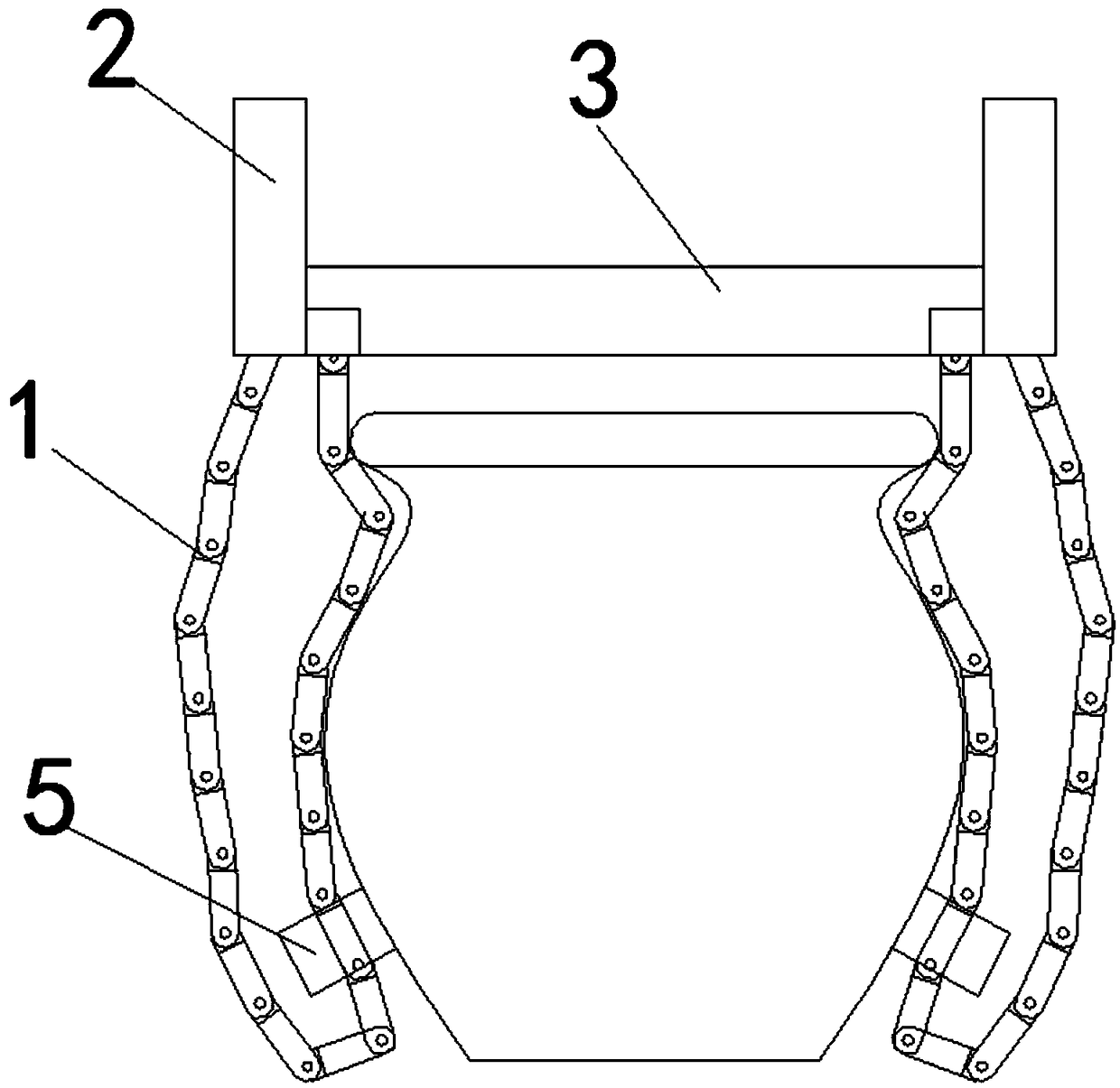

Self-adapting intelligent grabbing mechanical arm

ActiveCN109048968AAutomatic deformation adaptationSolve the problem of automatic deformation adaptationGripping headsEngineeringUltimate tensile strength

The invention belongs to the technical field of mechanical arms, and particularly relates to a self-adapting intelligent grabbing mechanical arm. A plurality of mechanical arm joints are connected ina hinging mode to form a joint chain. The joint chain is provided with a tracking vehicle. Locking shafts and locking pieces are arranged on the mechanical arm joints. Locking piece driving pieces arearranged on the locking pieces and are rotatably driven by a magnetic wheel. A second magnetic wheel is arranged in the tracking vehicle and is arranged corresponding to the magnetic wheel. The two sides of a vehicle body are respectively provided with a bonding fan. The tracing vehicle slides from top to bottom along the side wall of a ceramic jar, so that a curve which is attached to the outerside wall of the ceramic jar is formed by the joint chain to automatically adapt to the surface curve of the ceramic jar, extra pressure on the ceramic jar is avoided after a grabbing structure with the lower end bunched is formed, and the shape of the joint chain is locked, so that the ceramic jar is grabbed. Meanwhile, due to the combination of the adaptability of a flexible mechanical arm and the strength of a rigid mechanical arm, grabbing of the ceramic jar is realized.

Owner:德源自动化科技(义乌)有限公司

Manipulator joint

ActiveCN109048967ASolve the problem of automatic deformation adaptationAchieve disengagementJointsGripping headsEngineeringSacroiliac joint

The invention belongs to the technical field of manipulators, in particular to a manipulator joint. A plurality of manipulator joints are hingedly connected to form a joint chain; a tracking vehicle is arranged on the joint chain; a locking shaft and a locking piece are arranged on the manipulator joint; the locking piece is provided with a locking piece driving member; the locking piece driving member is rotationally driven by a magnetic wheel; a second magnetic wheel is disposed inside the tracking vehicle; the second magnetic wheel is disposed corresponding to the magnetic wheel; a fittingfan is arranged on each side of the vehicle body; the tracking vehicle slides from the top to the bottom along a side wall of a clay pot, so that the joint chains form a curve which fits the outer wall of the clay pot and automatically adapts to the curve of the surface of the clay pot; and a gripping structure with a tightening lower end is formed to avoid additional pressure on the clay pot andto lock the shape of the joint chain, thereby gripping the clay pot. The manipulator joint has the flexibility of a flexible manipulator and the strength of a rigid manipulator to achieve the grip ofthe clay pot.

Owner:常州今研精密机械有限公司

High speed carrying manipulator used for valve body assembly

InactiveCN107053150AAchieve clampingReduce precisionProgramme-controlled manipulatorGripping headsEngineeringSlide plate

Owner:TANGSHAN ZHENGYUAN PIPE IND CO LTD

Installation foundation of detection alarm device for preventing overhead cable from being scratched

PendingCN114277833APrevent retractionQuick plug installationFoundation engineeringTowersGear wheelBevel gear

The invention discloses an installation foundation of a detection alarm device for preventing an overhead cable from being scraped off, the installation foundation is used for being inserted into a prefabricated jack in the ground, and the prefabricated jack at least comprises a hard hole wall and a soil hole bottom and comprises an insertion part fixed underground and an overground part arranged above the insertion part; the inserting part comprises an inserting column body and a shaft inserting assembly; the input device comprises an input bevel gear set, a driven ring assembly and a driven rod assembly. The shaft insertion assembly comprises a sun gear, a planet wheel set and an outer gear set.

Owner:国网山东省电力公司平邑县供电公司 +1

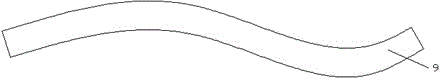

Cable with thermal insulation shield cover provided with guide slope portions and sliding groove sliders

InactiveCN104992766AAvoid displacementAchieve disengagementInsulated cablesInsulated conductorsThermal insulationCooling fluid

The invention relates a cable with a thermal insulation shield cover provided with guide slope portions and sliding groove sliders. The cable includes a cylindrical cable body (9) arranged in the thermal insulation shield cover and the thermal insulation shield cover including an upper thermal insulation shield cover (8) and a lower thermal insulation shield cover (7); the cover walls of the upper thermal insulation shield cover (8) and the lower thermal insulation shield cover (7) include respective bottom walls (80 and 70) and side walls at two sides of a corresponding bottom wall (80 or 70); the inner sides of the bottom walls (80 and 70) are provided with a plurality of slide grooves (85 and 75); a left limiting slider (86) and a right limiting slider (76) are respectively arranged in each slide groove (85 and 75) in a movable manner; the bottom walls (80 and 70) contact with dome portions of the cable body (9) which are opposite to each other on the diameter of the cable body (9); the left limiting sliders (86) and the right limiting sliders (76) contact with the shell of the cable body (9), so that the left limiting sliders (86) and the right limiting sliders (76) can slide according to the arrangement position of the cable body (9), and therefore, the cable body (9) can be fixed and supported, and the displacement of the cable body (9) can be prevented; and cooling fluid channels (81 and 71) which extend long the cover walls are arranged in the cover walls.

Owner:杭州乔日家纺贸易商行

Soybean plant threshing device for soybean collection and storage

ActiveCN110063511AEasy to storeAchieve disengagementSievingGas current separationGear driveDrive shaft

The invention particularly discloses a soybean plant threshing device for soybean collection and storage. Rotation of a worm is utilized for driving a driven shaft and a worm gear to rotate at the same time, the worm gear drives an embossment arranged on the periphery of a rotary wheel to rotate circumferentially, and a swing plate is driven to reciprocatingly swing so as to beat dried soybean plants; the device effectively solves the problems that existing soybean plants need to be separated, sorted and cleaned separately after large-batch drying in the sun, the processes are complex, and theconsumed time is long. The device comprises a shell body, an electromotor installed on the outer portion of the shell body, the worm connected to the output end of the electromotor and connected to the upper portion of the shell body through a bearing, a threshing assembly and a vibration assembly, the threshing assembly comprises the worm gear meshed with the worm and rotatably arranged on the inner wall of the shell body, the rotary wheel fixed to the back portion of the worm gear, and the swing plate connected with the rotary wheel and hinged to the inner wall of the shell body, wherein afixed column is fixed to the periphery of the side wall of the rotary wheel and embedded in an embedding groove formed in the swing plate, and the vibration assembly is further arranged in the middleof the shell body.

Owner:赣州轩义科技有限公司

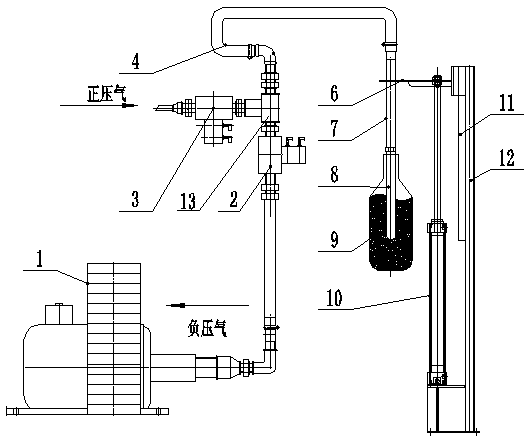

Device for compactly filling packaging bag with flour materials and compact-filling method

The invention provides a device for compactly filling a packaging bag with flour materials and a compact-filling method. The volume of flour in the packaging bag becomes small through vibration or up-down compacting, however, much time is consumed, so that the whole packaging speed is influenced. The device comprises a guide rail support (12), wherein a linear guide rail (11) is arranged on the guide rail support, and a slide carriage (6) is arranged on the linear guide rail; and the slide carriage is connected with an air cylinder (10), and a steel pipe (7), one end of the steel pipe is connected with a hose (4), the other end of the steel pipe is connected with a titanium filter rod (8), the titanium filter rod is inserted into the flour packaging bag (9), positive pressure gas enters the air cylinder (10), and a stop valve I is connected with a vacuum fan (1). The device and the method are used for compactly filling the packaging bag with the flour materials.

Owner:哈尔滨联科包装机械有限公司

Safe first-aid bed with automatic identification function

InactiveCN106038151AAchieve disengagementAvoid random placementLocks for portable objectsOperating tablesEngineeringFirst aid

The invention discloses a safe first-aid bed with an automatic identification function. The safe first-aid bed comprises a fixing base, a first-aid bed body, a lock plate, an electronic recognizer, a first electromagnetic card, a baffle plate, first electromagnets, a rotary knob, a gear, a lock rod, sliding wheels, a fixing board, a second electromagnet, a first spring, a brake block, a third electromagnet, a connecting pin, a second spring, a positioning pin, a fourth electromagnet, a guide groove, a positioning hole, a fifth electromagnet and a second electromagnetic card. The safe first-aid bed with the automatic identification function is simple in structure and powerful in function, through the fixed-point management with special people, the problem that the first-aid bed is placed at will is effectively prevented, therefore, if needed, the first-aid bed can be taken at the highest speed, and thus the rescue time of a patient can not be delayed.

Owner:YANGTZE UNIVERSITY

Manipulator adaptive grabbing method

InactiveCN109333577AAutomatic deformation adaptationSolve the problem of automatic deformation adaptationGripping headsEngineeringManipulator

The invention belongs to the technical field of manipulators, and particularly relates to a manipulator adaptive grabbing method. A plurality of manipulator joints are connected in a hinged mode to form a joint chain, and a tracking vehicle is arranged on the joint chain; the manipulator joints are provided with locking shafts and locking pieces, and locking piece driving parts are arranged on thelocking pieces and driven through rotating of a magnetic wheel; a second magnetic wheel is arranged in the tracking vehicle, the second magnetic wheel and the magnetic wheel are arranged correspondingly, and two attaching fans are arranged on the two sides of a vehicle body correspondingly; the tracking vehicle slides along the side wall of a terrine from top to bottom, thus the joint chain formsa curve attached to the outer side wall of the terrine to automatically adapt to a surface curve of the terrine, after a grabbing structure with the lower end collected is formed, extra pressure forthe terrine is avoided, the shape of the joint chain is locked, and thus the terrine is grabbed; and meanwhile, the joint chain has adaptation of a flexible manipulator and the strength of a rigid manipulator, and thus the terrine is grabbed.

Owner:赵静

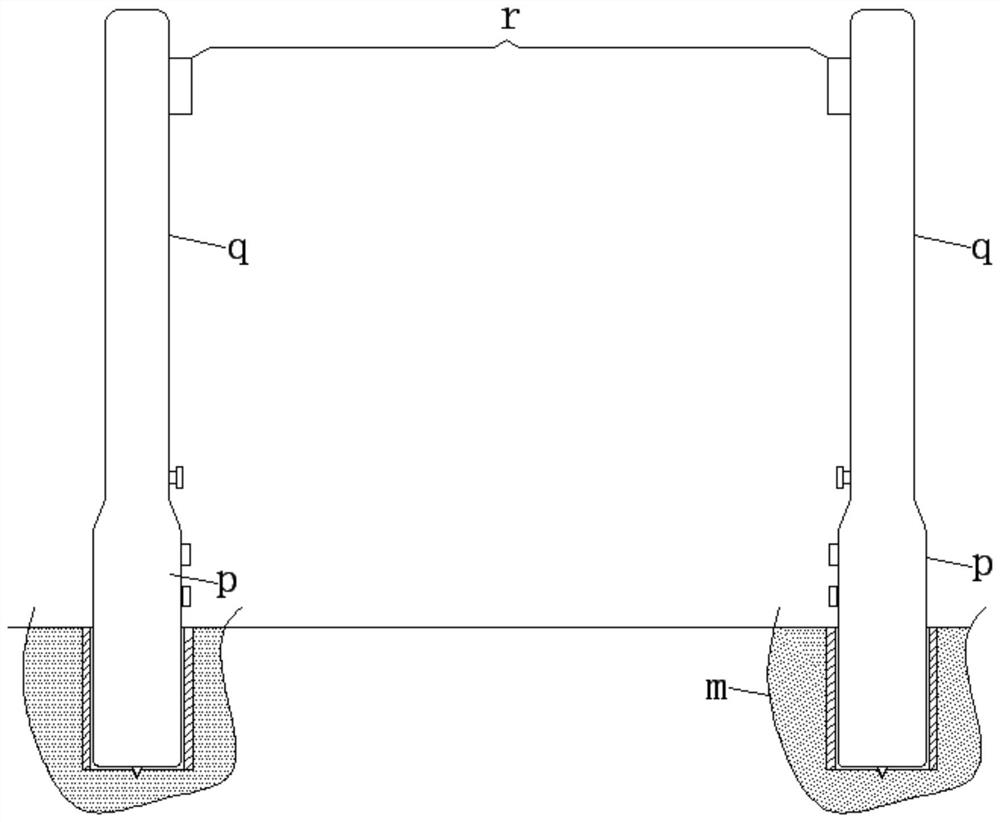

Drive device and cement pipeline middle connection mechanism for cement pipe manufacturing

InactiveCN108372583AIncrease effective spin ratePrevent excessive driving forceAuxillary shaping apparatusElectric machinerySTI Outpatient

The invention discloses a drive device and cement pipeline middle connection mechanism for cement pipe manufacturing. The drive device and cement pipeline middle connection mechanism for cement pipe manufacturing comprises a bottom fixing substrate; the bottom fixing substrate is internally provided with multiple bolt holes used for connection; three threaded regulation mechanisms arranged in an annular array are installed on the upper surface of the bottom fixing substrate; the tops of the multiple threaded regulation mechanisms are installed at the bottom of a bottom supporting base block; and an external shaft sleeve is installed on the top of the bottom supporting base block. According to the drive device and cement pipeline middle connection mechanism for cement pipe manufacturing, byutilizing an interior abutting method to perform the connection effect of a rotation part, the effect of synchronous rotation can be realized, and the effective rotation ratio of a motor is increased; in addition, under the emergency condition, the device can realize the separation effect, so that the motor is effectively prevented from damage caused by overlarge drive force or relatively low current; and in addition, the device has an air power telescopic mechanism, realizes the abutting effect with a telescopic function by utilizing air power and is strong in practicability.

Owner:刘晓丹

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com