Soybean plant threshing device for soybean collection and storage

A threshing device, soybean technology, applied in applications, using airflow to separate solids from solids, solid separation, etc., can solve the problems of time-consuming and complicated procedures, and achieve the effect of easy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

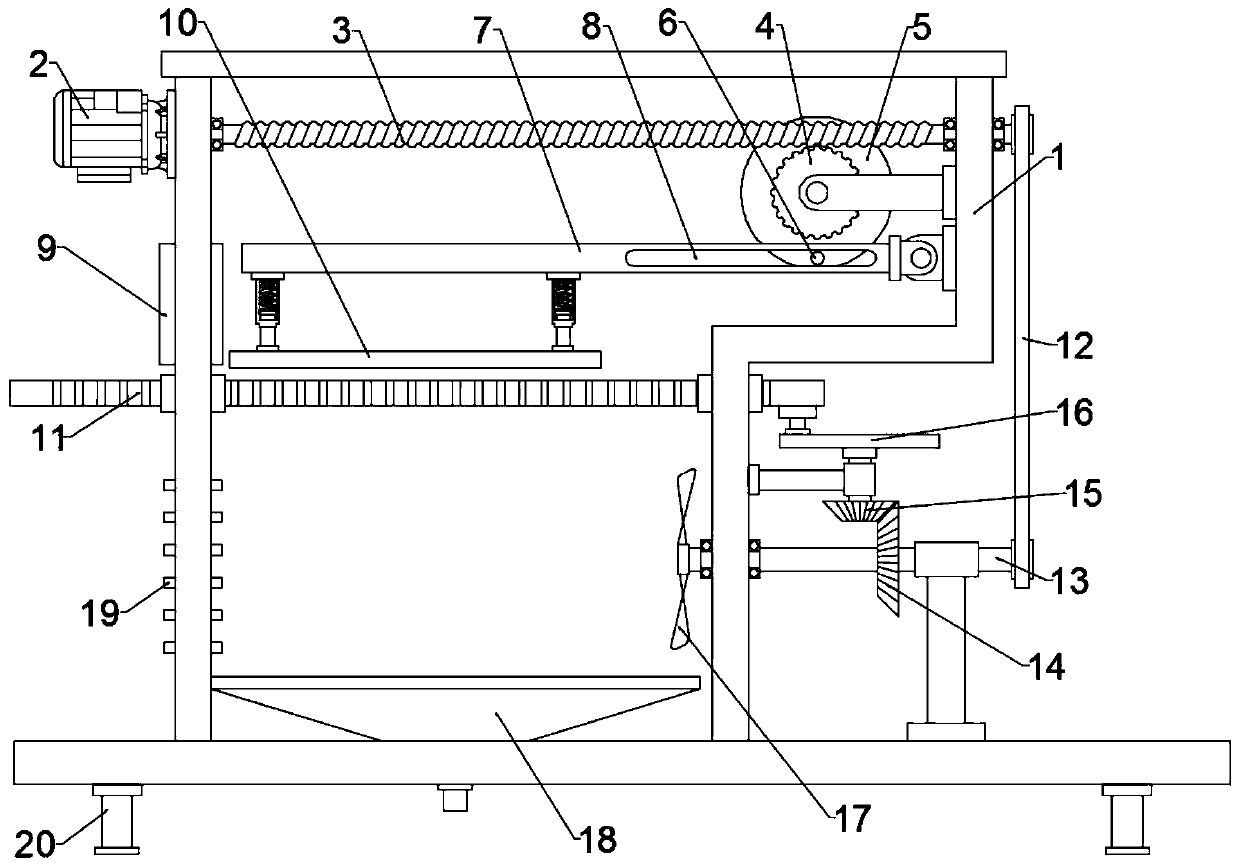

[0022] see Figure 1~3 , in an embodiment of the present invention, a bean strain threshing device for soybean collection and storage, comprising a housing 1, a motor 2 installed on the outside of the housing 1, a worm connected to the output end of the motor 2 and bearings connected to the upper part of the housing 1 3. The threshing component and the vibrating component that separates the threshed beans from the dregs;

[0023] Specifically, the threshing assembly includes a worm wheel 4 meshed with the worm 3 and rotated on the inner wall of the housing 1, a runner 5 fixed at the rear of the worm wheel 4, and connected to the runner 5 and hinged to the housing 1. The wobble plate 7 on the inner wall, wherein, the outer edge of the side wall of the runner 5 is fixed with a fixed column 6, and the fixed column 6 is embedded in the fitting groove 8 opened on the wobble plate 7, and drives the worm 3 when the motor 2 is energized. Rotate, thereby driving the worm wheel 4 and t...

Embodiment 2

[0026] In order to further clean the separated soybeans, in another embodiment of the present invention, a bean plant threshing device for soybean collection and storage also includes a dust removal mechanism, which is a fan fixed at the end of the driven shaft 13 17. Among them, a plurality of ash discharge pipes 19 are fixed on the inner wall of the housing 1 on the side opposite to the fan 17, and a connecting bucket 18 is fixed on the bottom of the housing 1, and the bottom of the connecting bucket 18 communicates with the bottom of the housing 1. Through the pipe, the four corners below the housing 1 are fixed with legs 20 for supporting the whole device. The rotating driven shaft 13 drives the fan 17 to rotate and blow air, and the fine dust mixed in the falling beans is discharged from the ash discharge pipe 19. Larger bean grains fall in the receiving bucket 18, and finally discharge from the through pipe.

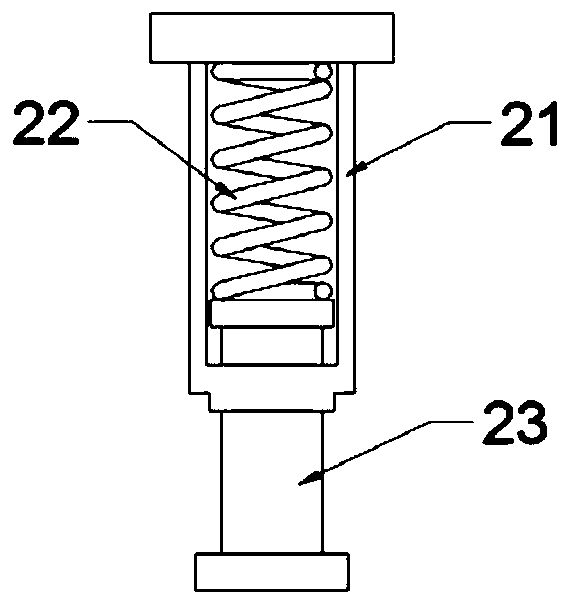

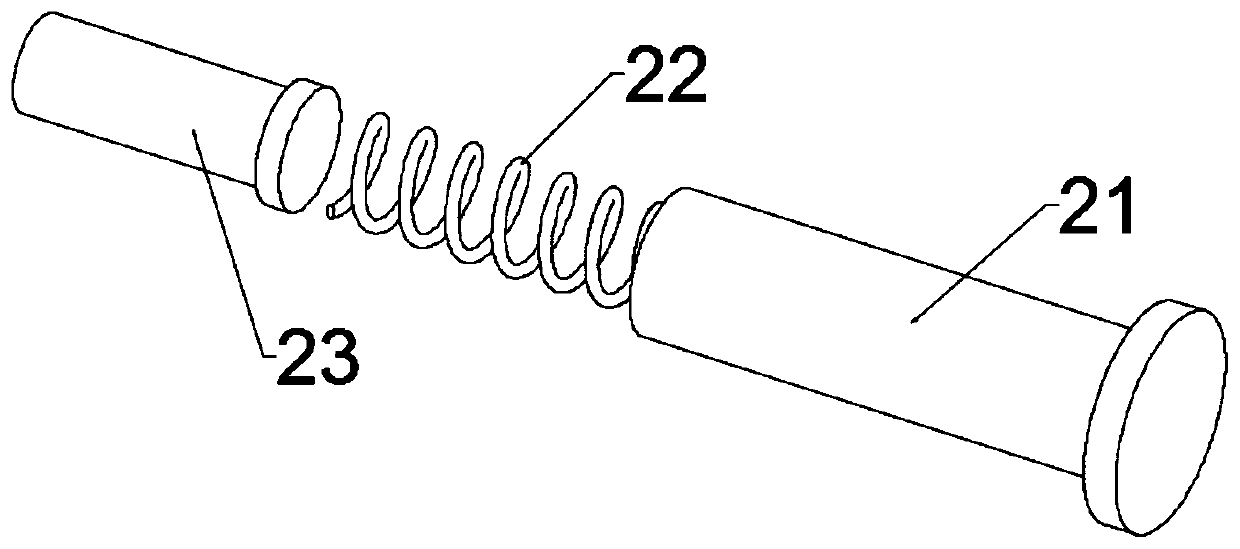

[0027] Preferably, the bottom of the swing plate 7 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com