Experimental machine for evaluating impact-loading type tribological performance of joint bearing

A technology of joint bearings and bearings, which is applied in impact testing, mechanical bearing testing, testing of machine/structural components, etc., to improve experimental efficiency and reduce experimental costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

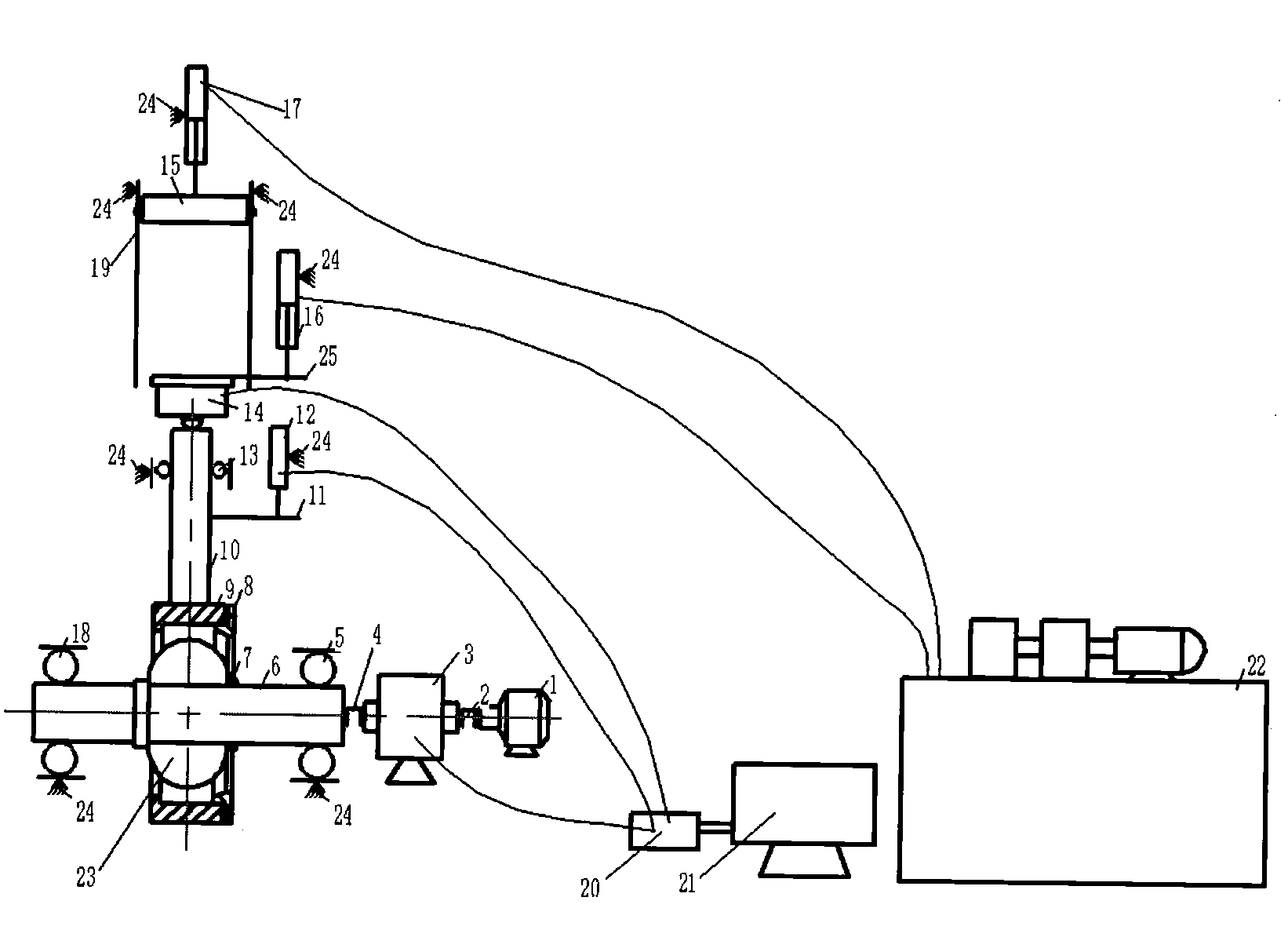

[0014] The composition of this joint bearing impact loading tribological performance evaluation test machine proposed by the present invention includes a transmission device, a loading device, an experimental device, and a detection device, such as figure 1 shown.

[0015] The transmission device is composed of a servo motor 1, a first coupling 2, a torque meter 3 and a friction torque clutch 4. The servo motor 1 is connected to the torque meter 3 through the first coupling 2, and the torque meter 3 is connected to the experimental device through the friction torque clutch 4. The support shaft 6 in the device is connected.

[0016] The loading device is composed of a dowel 10, a second bearing 13, a load sensor 14, an impact weight 15, a stable load loading cylinder 16, an impact weight lifting cylinder 17, a linear guide rail 19, a hydraulic station 22 and a loading rod 25. The upper end surface of the impact weight 15 is fixedly connected with the impact weight lifting cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com