Tri-state overrunning clutch

An overrunning clutch, outer ring technology, applied in clutches, one-way clutches, mechanical equipment, etc., can solve problems such as affecting service life, heat generation, and wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

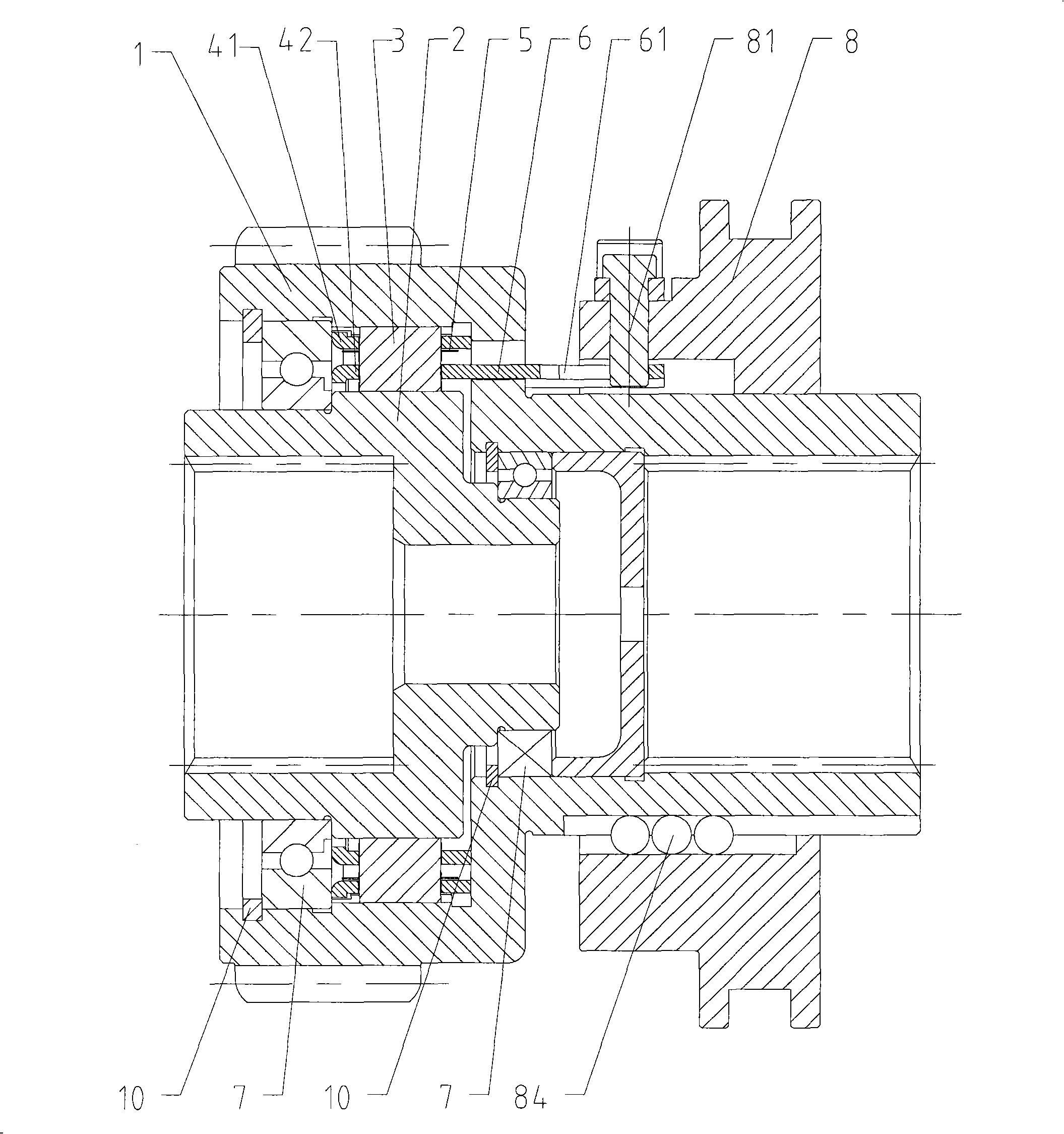

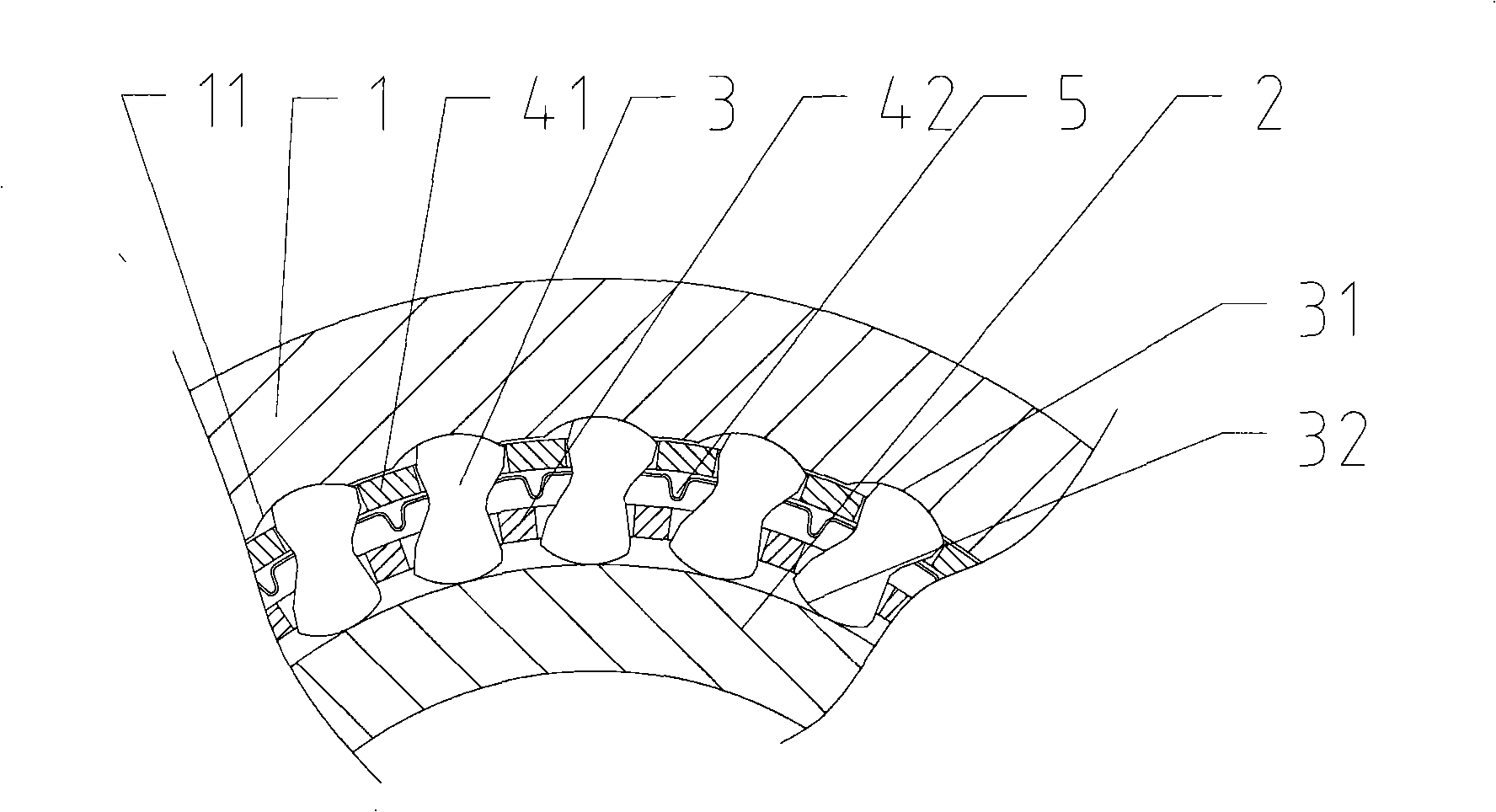

[0018] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

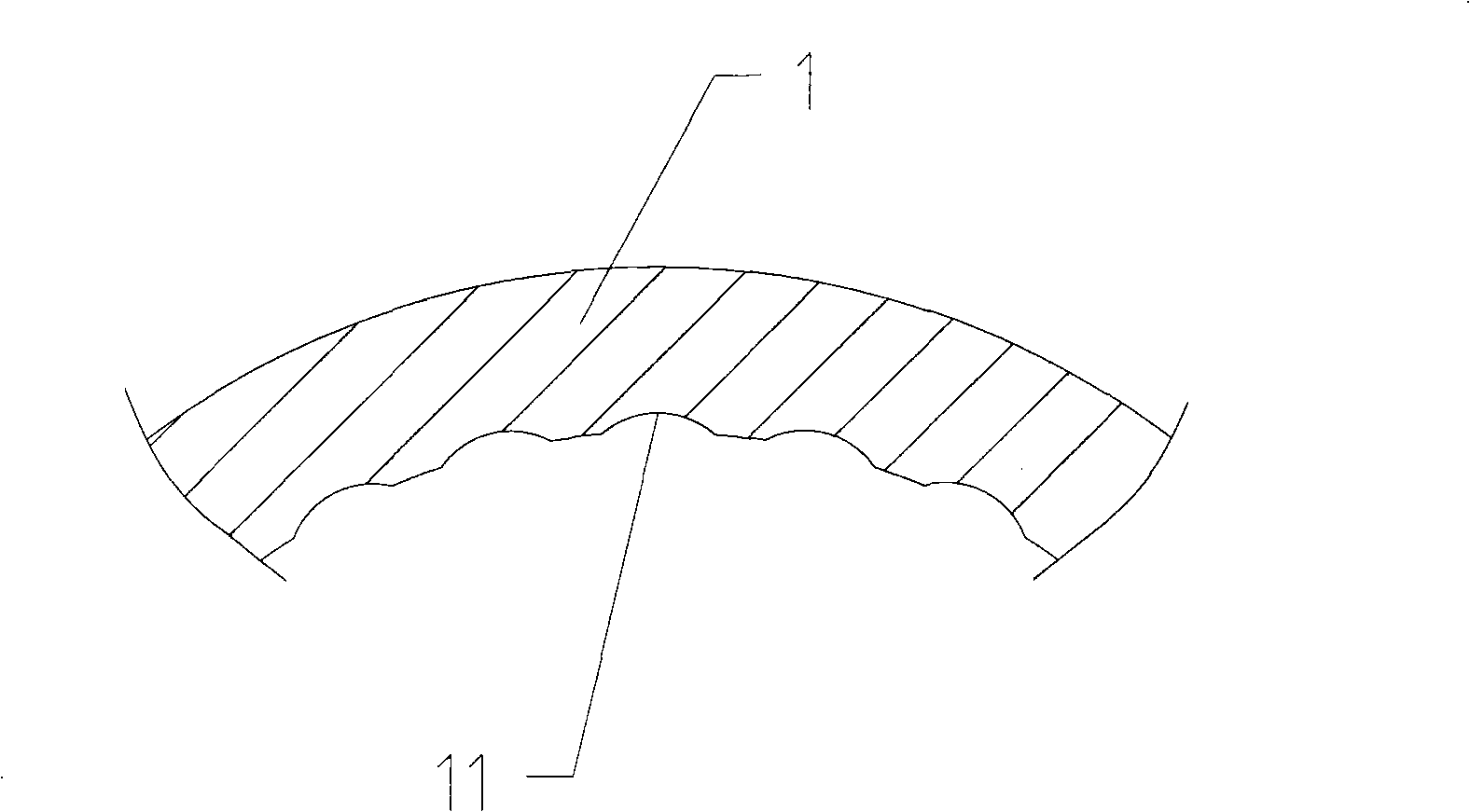

[0019] As shown in the figure, a three-state overrunning clutch provided by the present invention includes an outer ring 1, an inner ring 2, a plurality of sprags 3 located between the outer ring 1 and the inner ring 2, and a plurality of sprags 3 located between the outer ring 1 and the inner ring 2. The outer holder 41 and the inner holder 42 of the plurality of wedges 3 are held between them and for example through holding holes. There are a plurality of arc grooves 11 on the working surface of the outer ring 1, and each arc groove 11 cooperates with a working surface 31 of a corresponding wedge 3, and keeps the working surface 31 on the circle. In the arc groove 11. The inner cage 42 has a plurality of protrusions 6 protruding axially outward, and each protrusion 6 has an oblique hole 61 inclined relative to the axial direction. An axially...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com