A secondary pouring construction device for small structural openings

A secondary pouring and construction device technology, applied in the direction of construction, building structure, formwork/formwork/work frame, etc., can solve problems such as bulging, surface height difference, formwork displacement, etc., to ensure structural strength and construction efficiency The effect of improving and preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

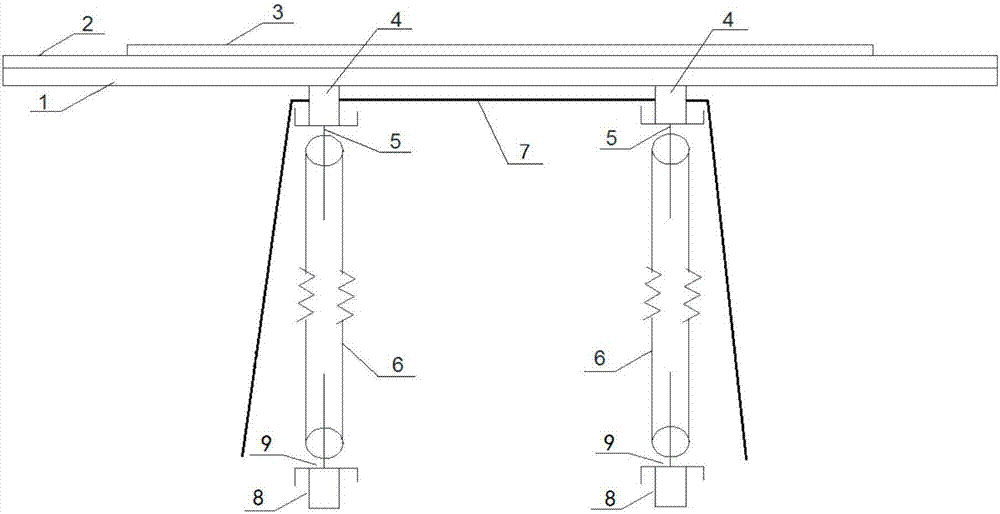

[0015] Such as figure 1 As shown, the secondary pouring construction device of the small structural opening of the present invention includes: wood plywood 1, foam double-sided adhesive layer 2, plastic template working surface layer 3, two wooden square keels 4, two upper supports 5, two A support steel pipe 6, a stay rope 7, two horizontally placed wooden square support beams 8 and two lower jacks 9 inserted in the lower ends of the two support steel pipes 6.

[0016] Among them, the foam double-sided adhesive layer 2 is laid on the upper surface of the wood plywood 1, and the area is equal to the area of the upper surface of the wood plywood 1; the plastic template working surface layer 3 is laid on the foam double-sided adhesive layer 2 above, and the area is smaller than the upper surface area of the wood plywood 1; two wooden square keels 4 are installed below the wooden plywood 1 in parallel; The lower ends of the upper jack brackets 5 are respectively inserted on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com