Steel plate bending device

A technology of bending device and steel plate, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of increasing engineering cost, breaking steel plate, consuming a lot of physical strength and time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is realized through the following technical solutions:

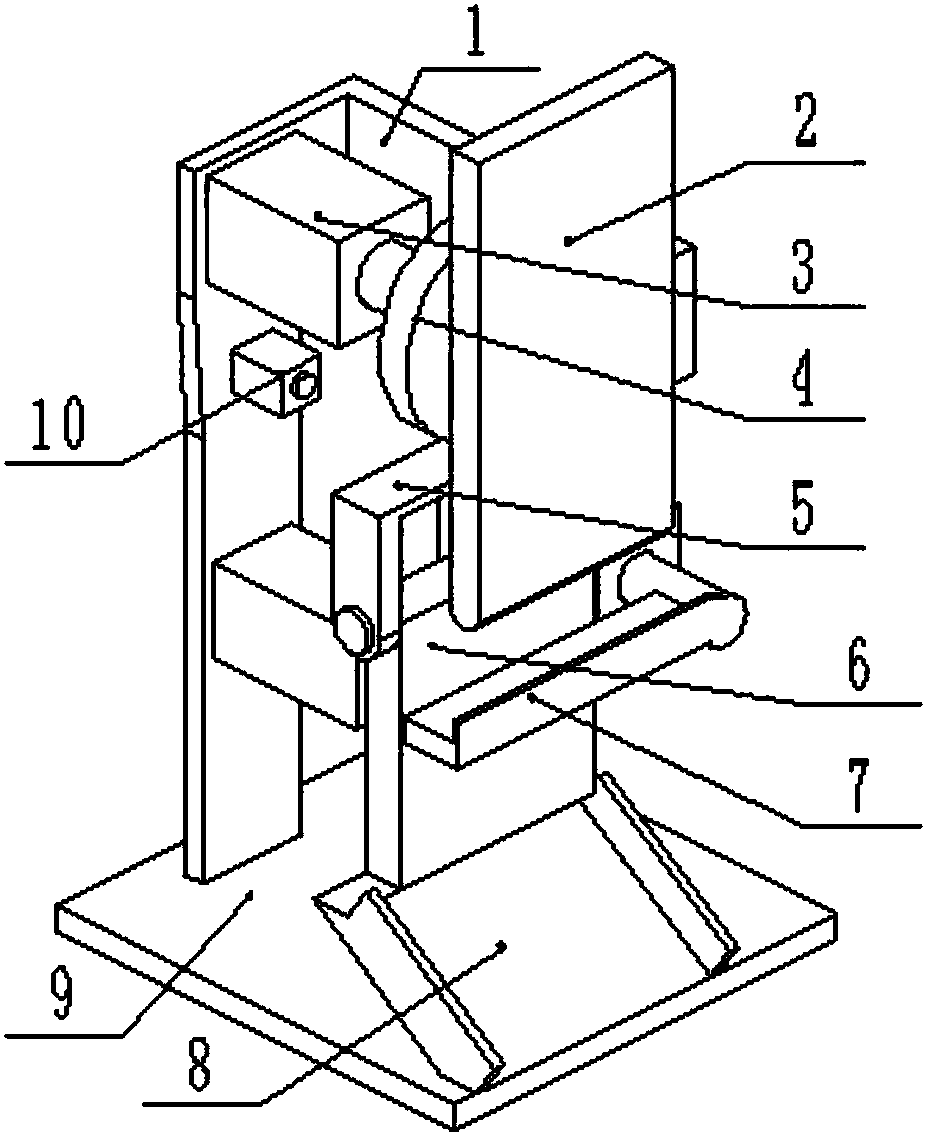

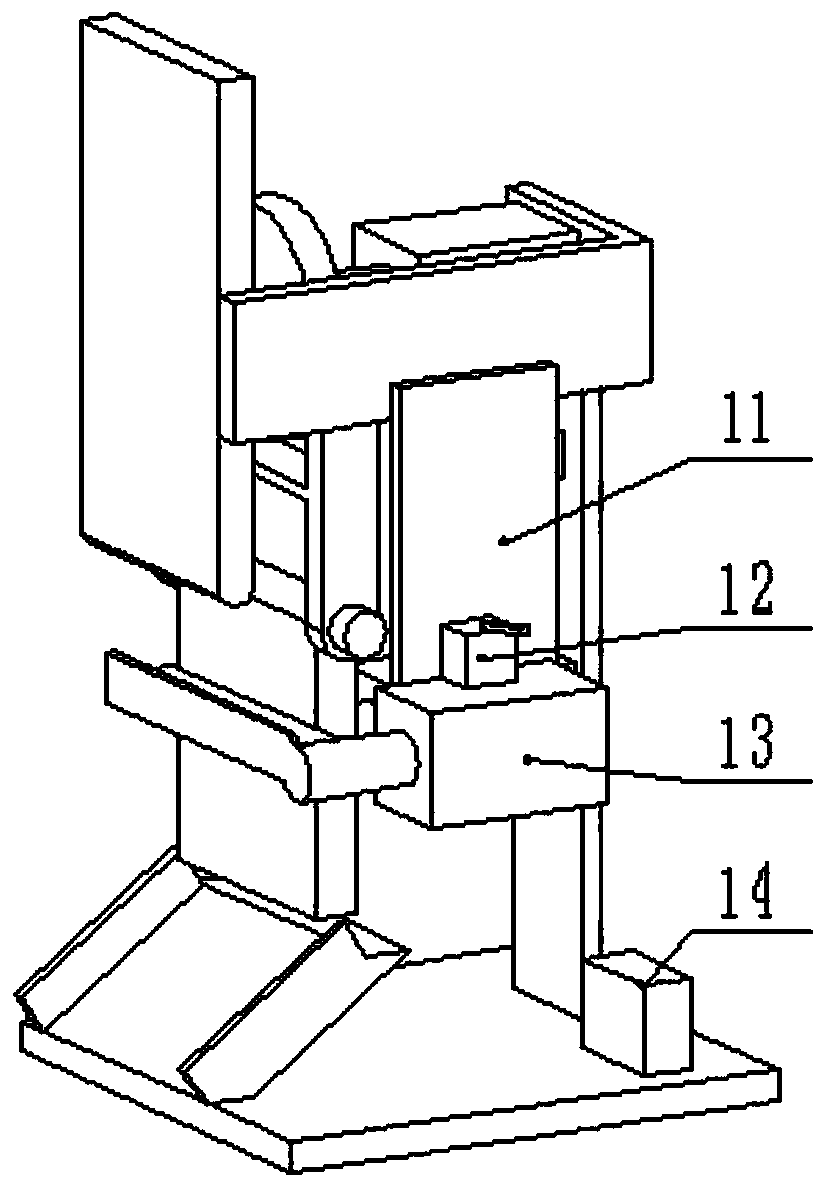

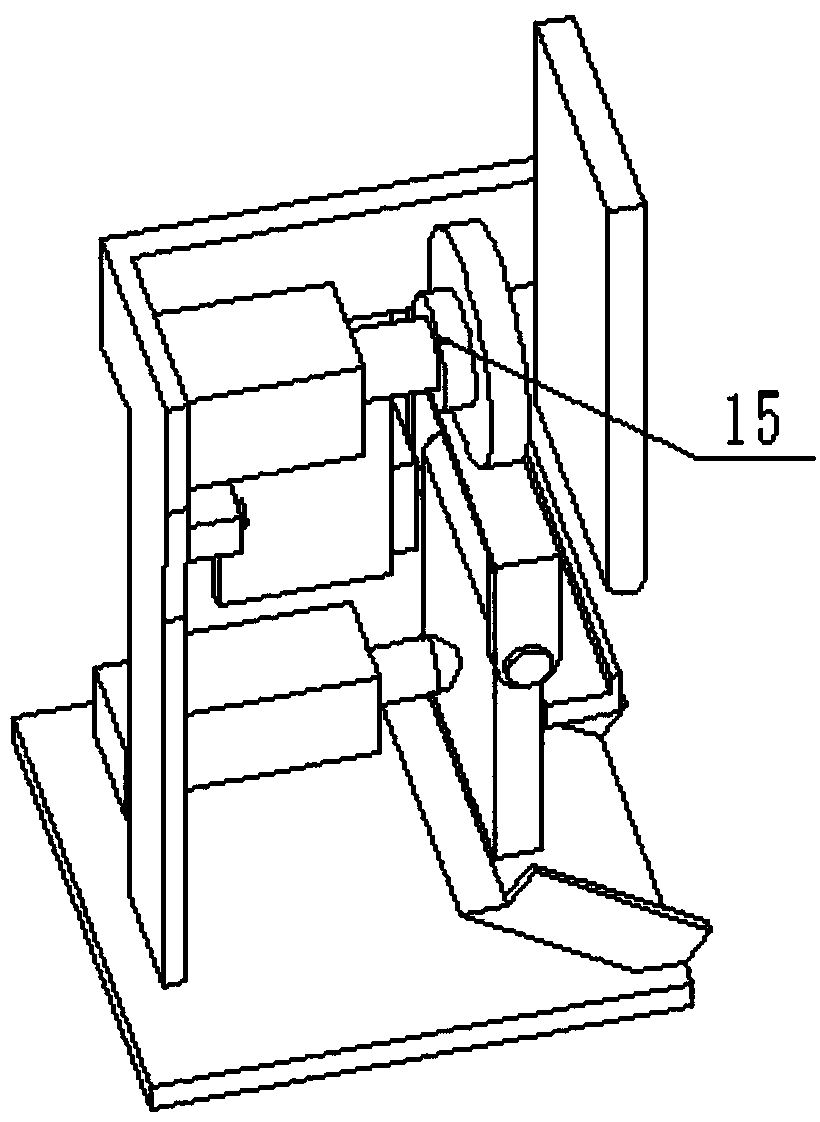

[0017] A steel plate bending device, comprising a support frame 1, a limit plate 2, a first hydraulic cylinder 3, a push plate 4, a first bracket 5, a bending push plate 6, a support plate 7, a discharge plate 8, a workbench 9, Ultrasonic sensor 10, stepper motor base 11, magnetic base 12, stepper motor 13, controller 14, pressure sensor 15 and thrust ball 16, described support frame 1 is fixed on the workbench 9, and described limit plate 2 Fixed on the support frame 1, which is located in front of the push plate 4 and parallel to the push plate 4, the first hydraulic cylinder 3 is vertically fixed on the top of the long side of the support frame 1, and is used to drive the push plate 4 to move forward and fix Hold the steel plate to prevent the movement of the steel plate from affecting the accuracy during the bending operation. The push plate 4 is installed on the main shaft of the first h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com