Air pressure pipe bending machine

A technology of pipe bending machine and air pressure, which is applied in the field of air pressure pipe bending machines, which can solve the problems of high labor intensity of manual pipe bending, damage to the insulation layer of wires in the pipe, and low quality of pipe bending, so as to achieve beautiful installation effect, reduce material loss, and bend good tube quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

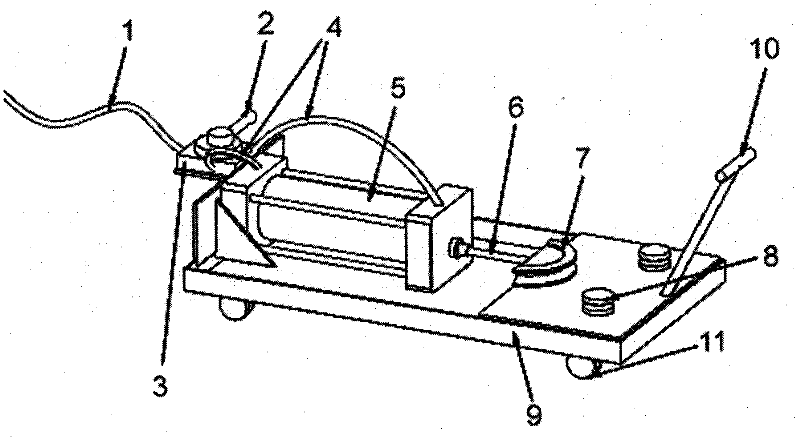

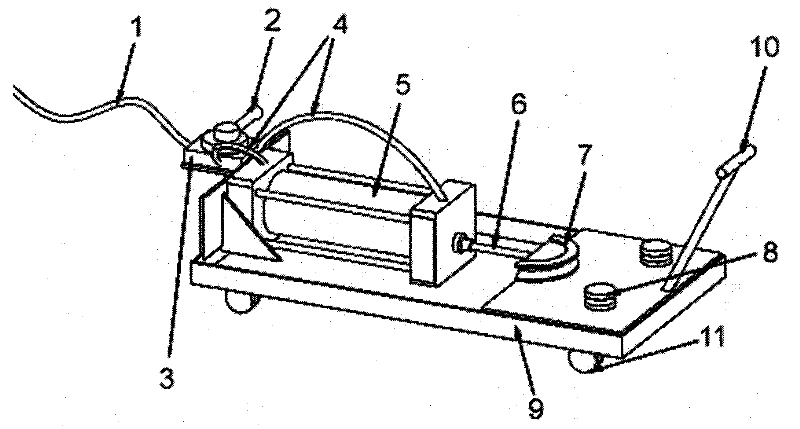

[0024] Example: such as figure 1 As shown, a pneumatic pipe bending machine includes an air intake pipe 1, a joystick 2, an air valve 3, a pneumatic hose 4, a cylinder 5, a telescopic shaft 6, a pipe bending groove 7, a rolling groove 8, a base 9, Drag pull bar 10, drag pulley 11.

[0025] One end of the intake pipe 1 is connected to the air pump, and the other end is connected to the air valve 3. The air valve 3 has two air outlets, and the two ends of the air cylinder 5 are connected by a pneumatic hose 4. When the air pressure hose 4 is connected with the air inlet of the cylinder 5, a sealing ring socket is used.

[0026] The air valve 3 is provided with a control handle 2 to control the air intake direction of the cylinder 5 . The output air pressure of the air pump is usually 8Kg when it is running. When the control handle 2 is turned to the direction of the workbench, the air pressure is loaded on the piston of the cylinder 5, and an air pressure difference is generat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com