Pre-bending machine

A technology of pre-bending machine and main machine, applied in the field of pre-bending machine, can solve the problem that the steel pipe cannot reach the diameter and roundness, and achieve the effect of small springback, high efficiency and fast forming speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

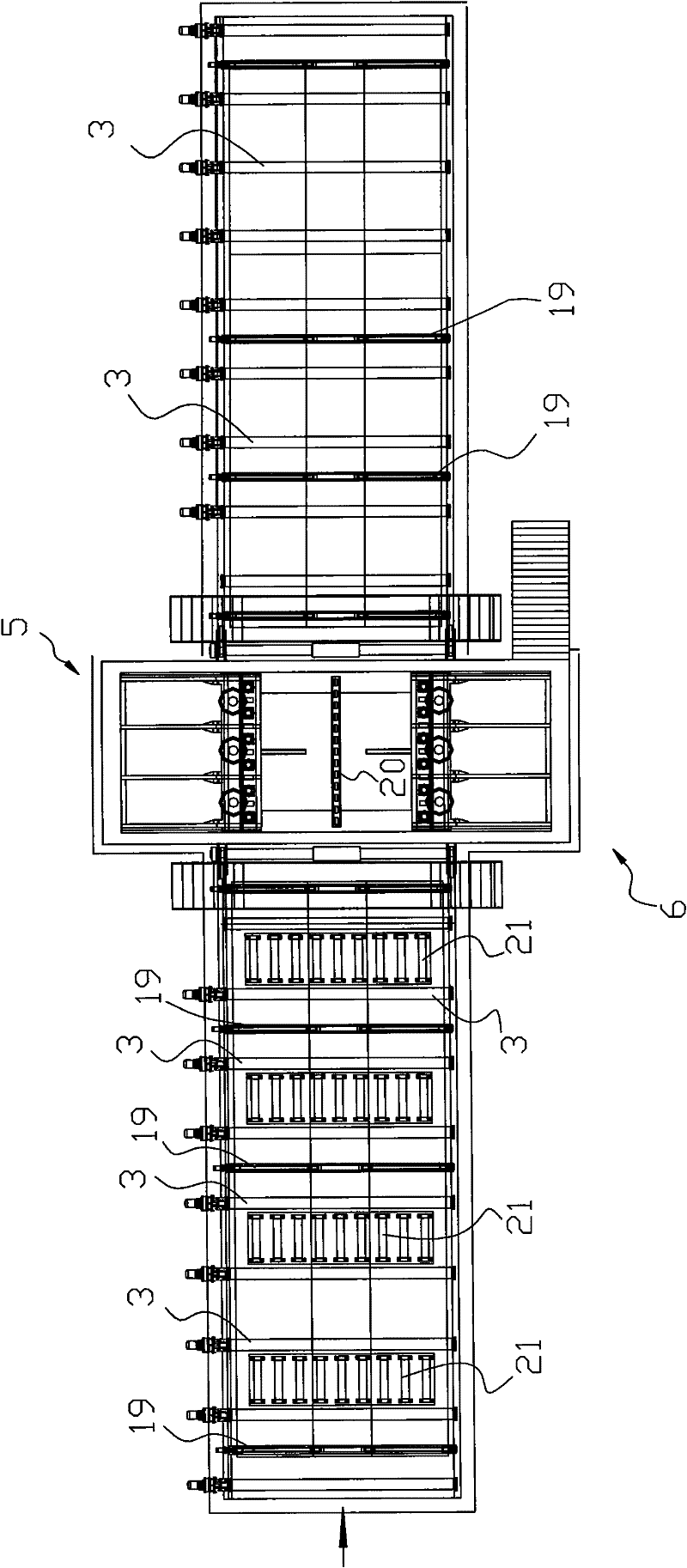

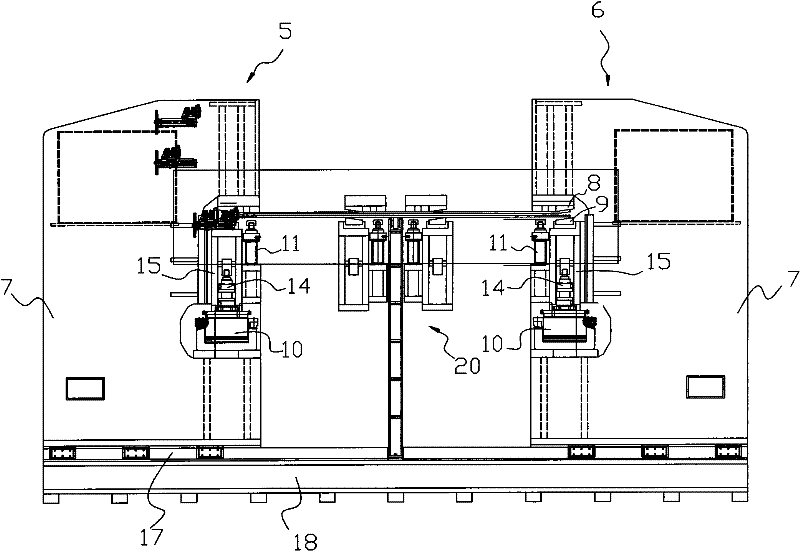

[0018] combine Figure 1 to Figure 5 , a pre-bending machine, including a conveying mechanism, a host, a lubrication system and an electric control system. The conveying mechanism includes a first conveying unit 1 located in front of the main machine and a second conveying unit 2 located behind the main machine. The steel plate workpiece is continuously sent to the main machine by the first conveying unit, and the edge of the steel plate workpiece is continuously pre-prepared by the main machine. After bending, it is continuously sent out by the second conveying unit. The components of the first conveying unit 1 and the second conveying unit 2 can be the same or basically the same, and they all include a conveying roller 3, a centering device and a clamping and feeding device 4 that are arranged in sequence; , the first conveying unit 1 is also provided with a front holding device for holding up the steel plate workpiece, the front lifting device is provided with a plurality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com