Narrow area ultra-deep channel inclined well back excavation construction method

A construction method and technology for inclined shafts, applied in tunnels, shaft linings, tunnel linings, etc., can solve the problems of deep passage, difficult construction, and narrow construction area, and achieve the effect of small road area, shortened construction period, and less personnel input.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

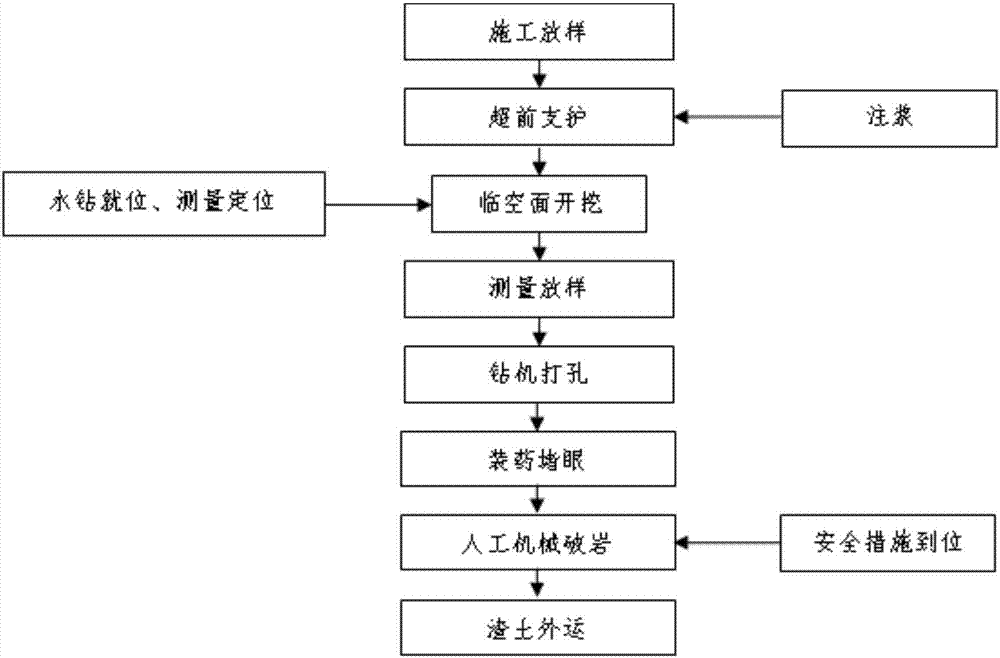

[0039] Embodiment: A back-excavation construction method for an ultra-deep channel inclined shaft in a narrow area, comprising the following steps:

[0040] (1) Construction stakeout: According to the construction drawings, excavate along the outline of the main tunnel arch;

[0041] (2) Advance support: Drill the installed steel soffit in the stratum outside the contour excavated in step (1) and drive into the conduit. Seam steel pipe, one end of the conduit is closed and made into a pointed shape, inserted into the drilled conduit hole, and a reinforcing hoop is welded to the tail of the other end to prevent deformation of the tail end of the conduit during construction; in the middle of the conduit Drill quincunx-shaped small holes with a diameter of 6mm and a spacing of 100mm as grouting holes, and pressurize the grout for cementation into the surrounding rock stratum through the conduit, forming a 0.4-1m thick reinforcement ring outside the contour of the tunnel arch. , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com