Tunnel sprayed concrete and preparation method thereof

A tunnel shotcrete and concrete technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of poor impermeability and air tightness of shotcrete, unable to meet performance requirements, etc., and achieve enhanced compactness, The effect of increasing strength and resolving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

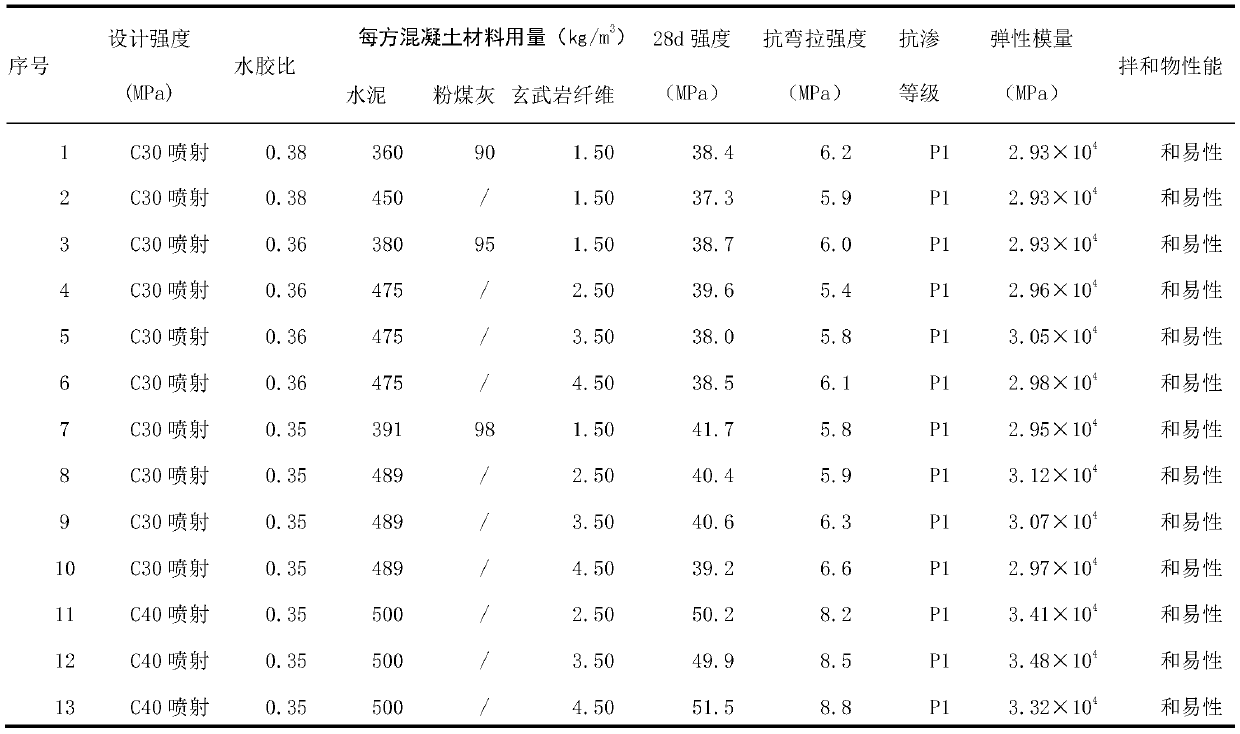

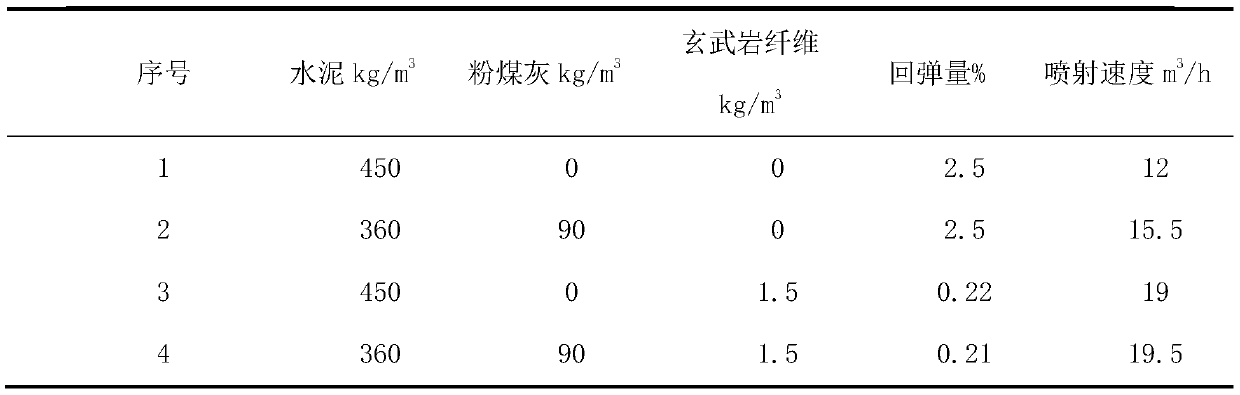

Examples

Embodiment 1

[0022] A tunnel shotcrete, based on the volume of the tunnel shotcrete, including the following components: cement 360kg / m 3 , Coarse sand 818kg / m 3 , Gravel 817kg / m 3 , basalt fiber 1.5kg / m 3 , fly ash 90kg / m 3 , accelerator 8kg / m 3 , water reducer 5kg / m 3 .

[0023] The fineness modulus of the coarse sand is 3.3, and the stone powder content in the coarse sand is 7%; the particle size of the gravel is 5mm.

[0024] The length of the basalt fiber is 10mm.

[0025] The accelerator is an alkali-free accelerator; the water reducer is an air-entraining water reducer.

[0026] A method for preparing shotcrete for tunnels, comprising the following steps: after dry-mixing basalt fibers with cement, coarse sand, crushed stones and fly ash, adding a water reducer and an appropriate amount of water for mixing, and finally adding Accelerator, the dry mixing time is 90s, and the mixing time is 90s.

Embodiment 2

[0028] A tunnel shotcrete, based on the volume of the tunnel shotcrete, including the following components: cement 380kg / m 3 , Coarse sand 836kg / m 3 , Gravel 804kg / m 3 , basalt fiber 2.5kg / m 3 , fly ash 92kg / m 3 , accelerator 10kg / m 3 , water reducer 6kg / m 3 .

[0029] The fineness modulus of the coarse sand is 3.3, and the stone powder content in the coarse sand is 7%; the particle size of the gravel is 7mm.

[0030] The length of the basalt fiber is 15 mm.

[0031] The accelerator is a low-alkali accelerator; the water reducer is an air-entraining water reducer.

[0032] A method for preparing shotcrete for tunnels, comprising the following steps: after dry-mixing basalt fibers with cement, coarse sand, crushed stones and fly ash, adding a water reducer and an appropriate amount of water for mixing, and finally adding Accelerator, the dry mixing time is 100s, and the mixing time is 120s.

Embodiment 3

[0034] A tunnel shotcrete, based on the volume of the tunnel shotcrete, including the following components: cement 425kg / m 3 , Coarse sand 845kg / m 3 , gravel 800kg / m 3 , basalt fiber 3kg / m 3 , fly ash 95kg / m 3 , accelerator 12kg / m 3 , water reducer 8kg / m 3 .

[0035] The fineness modulus of the coarse sand is 3.3, and the stone powder content in the coarse sand is 7%; the particle size of the gravel is 10 mm.

[0036] The length of the basalt fiber is 18mm.

[0037] The accelerator is an alkali-free accelerator; the water reducer is an air-entraining water reducer.

[0038] A method for preparing shotcrete for tunnels, comprising the following steps: after dry-mixing basalt fibers with cement, coarse sand, crushed stones and fly ash, adding a water reducer and an appropriate amount of water for mixing, and finally adding Accelerator, the dry mixing time is 110s, and the mixing time is 120s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com