Formula for special protective film of brushed aluminum plate

A brushed aluminum plate and protective film technology, applied in the formulation field of special protective film for brushed aluminum plate, can solve the problems of processing toughness, weather resistance defects, indentation, sticking and other problems, achieve excellent scratch resistance and corrosion resistance, and form fast Convenience and the effect of improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

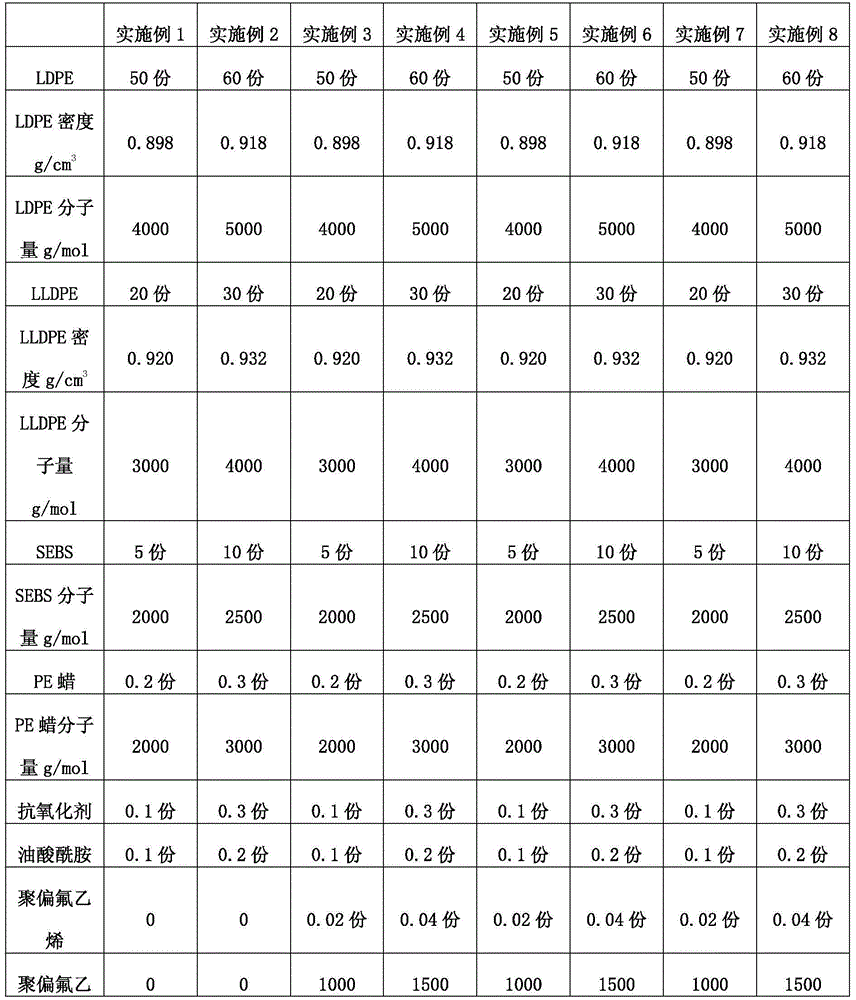

[0023] The present invention will be further described in detail below with reference to the embodiments, so that those skilled in the art can implement according to the description.

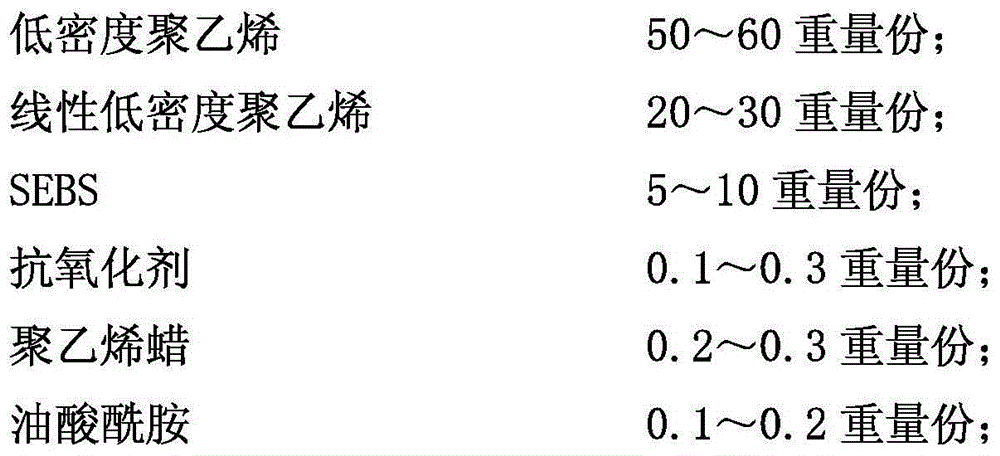

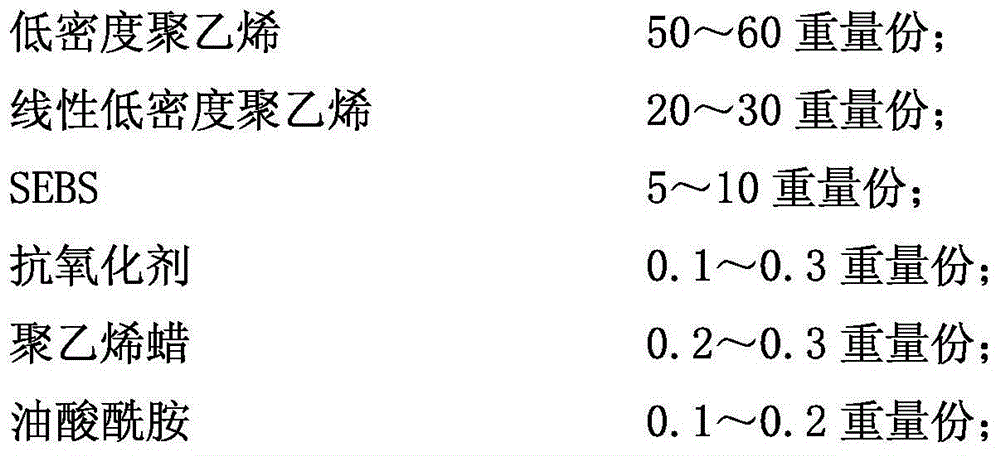

[0024] This case proposes an embodiment of a special protective film formulation for a brushed aluminum plate, which includes the following materials in parts by weight:

[0025]

[0026] Among them, the density of low density polyethylene is 0.898~0.918g / cm 3 , the density of linear low density polyethylene is 0.920~0.932g / cm 3 . In this case, linear low density polyethylene (LLDPE) is not only different from low density polyethylene (LDPE) in terms of density and molecular weight, but also has obvious differences in structure. LLDPE does not have long chain branches in its structure. Although low-density polyethylene may not have long-chain branches in theory, in reality, low-density polyethylene contains a certain amount of long-chain branches. Therefore, in this case, low-density polyet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com