A special material for high-performance radiation-resistant polypropylene and its preparation method

A technology of irradiated polypropylene and special materials, which is applied in the field of high-performance radiation-resistant polypropylene special materials and its preparation, can solve the problem of not meeting the high requirements for the application performance of medical devices, affecting the safe use of medical devices, and not being scratch-resistant during storage and transportation It can achieve the effects of easy operation and large-scale production, good overall performance, and improved light transmittance and stamping resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

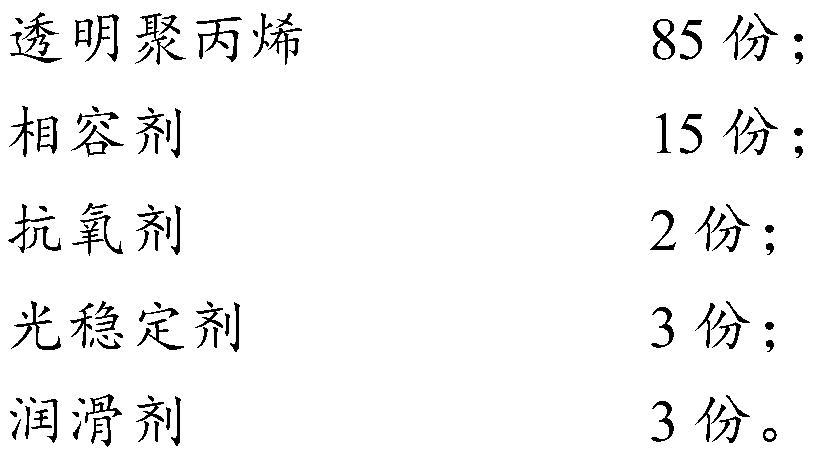

[0050] The modified masterbills added to the present invention are better compatible with the matrix resin, and each component is synergistic, so that the resulting product has higher impact resistance, good radiation resistance, light transmissive performance and scratch resistance performance. The material of the present invention is higher, and other auxiliaries such as transparent and nucleating agents are not needed to add other auxiliaries such as transparers and nucleating agents. Performance loss and small molecules after irradiation. Embodiments of the present invention also provide a method of preparing a high-performance resistant tolerance polypropylene, including the following steps:

[0051] (1) Advertising the raw material of the modified masterbatch according to the weight of the parts, and the high-speed mixer is mixed, and then the twin screw extruder is used for melting, extrusion, granulation, drying, modified masterbatch;

[0052] (2) Prepare transparent polyp...

Embodiment 1

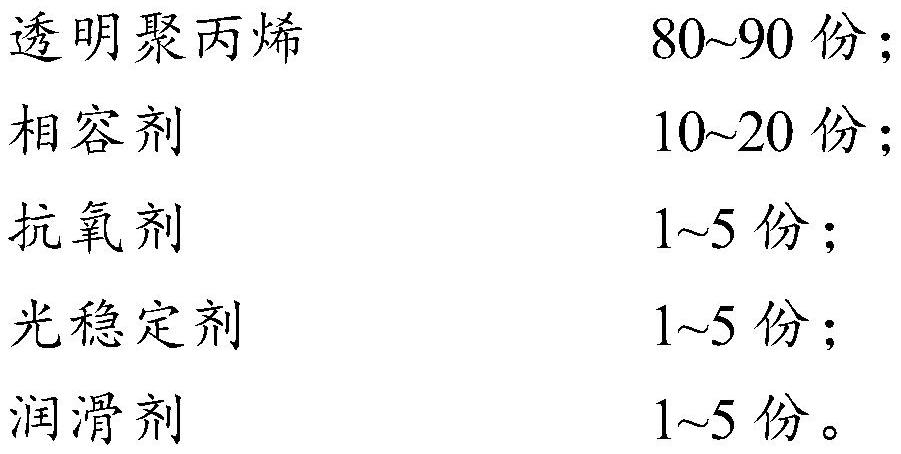

[0059] A high-performance gas resistant to polypropylene special material is prepared from raw material including the following weight:

[0060] Transparent polypropylene 100 parts;

[0061] 10 copies of PoE;

[0062] 10 copies of modified masterbatch.

[0063] Among them, the modified masterbatch is measured by weight, and the raw material groups are:

[0064]

[0065]

[0066] Preparation method of high performance radiation-resistant polypropylene, including the following steps:

[0067] (1) Advertising the raw material of the modified masterbatch according to the weight of the parts, and the high-speed mixer of the rotation speed is 800r / min, and then invested for a long diameter ratio of 40: 1, the twin screw of the rotation speed is 90R / min. In the discharge, the temperature of the feed section is 120 ° C, the melt segment temperature is 150 ° C, the delivery section is 170 ° C for melt, extrusion, granulation, and finally dried at a temperature of 80 ° C for 5 h, re...

Embodiment 2

[0070] The present embodiment is substantially identical to the first embodiment, and the difference is that a high-performance reflective polypropylene special material is prepared from raw materials including the following weight:

[0071] Transparent polypropylene 100 parts;

[0072] 10 copies of PoE;

[0073] 5 copies of modified masterbatch.

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| izod impact strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com