A kind of modification method of oxidized polyethylene wax and obtained product and application

A technology for modifying oxidized polyethylene wax, which is applied in the field of modification of oxidized polyethylene wax, can solve the problems of aggravated pressure analysis and limit the use of oxidized polyethylene wax, so as to reduce the defective rate and prolong the continuous production time of the machine , The effect of low precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

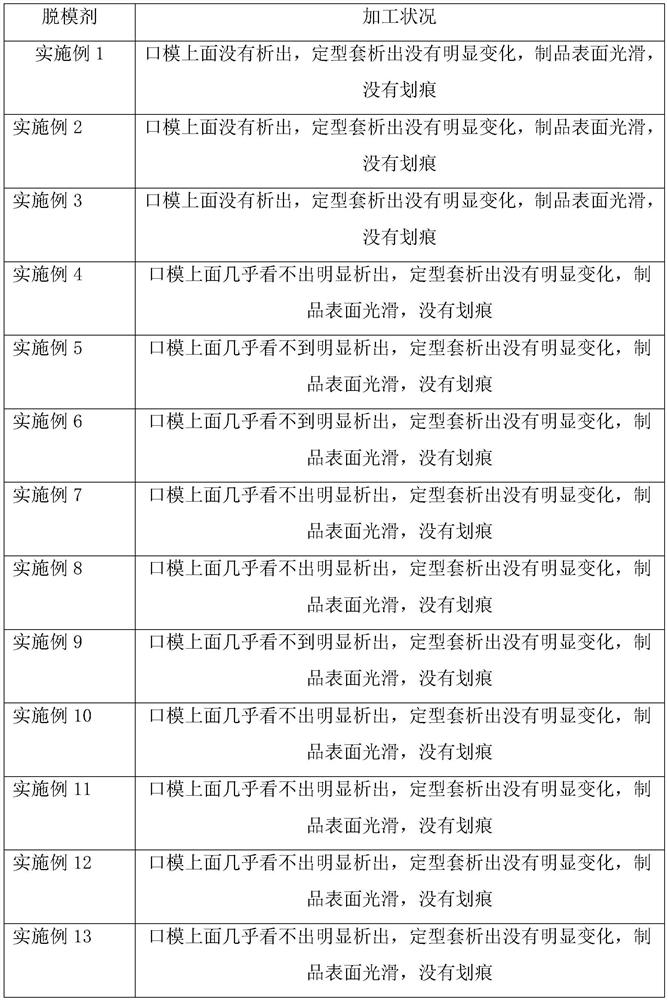

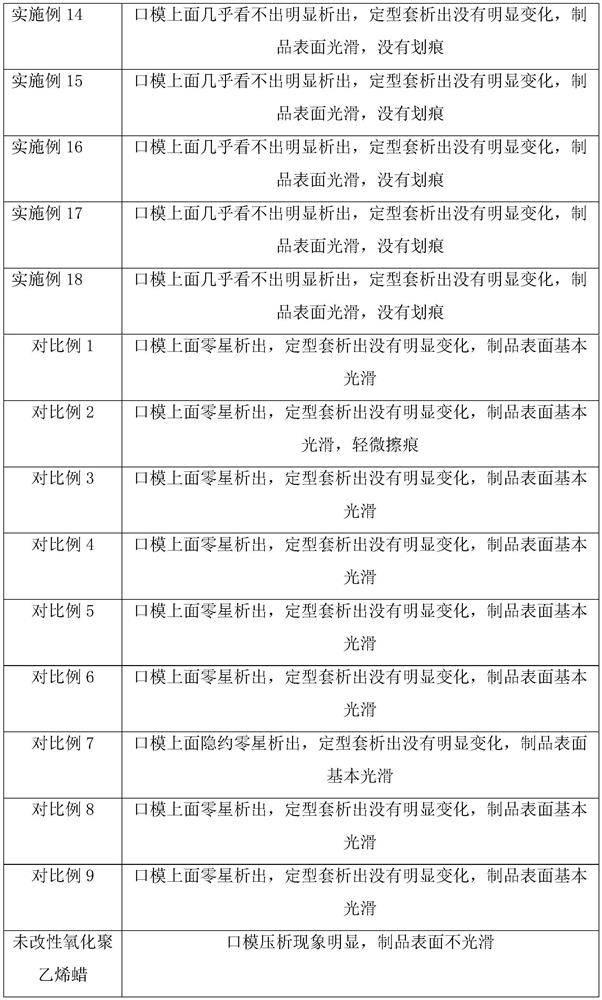

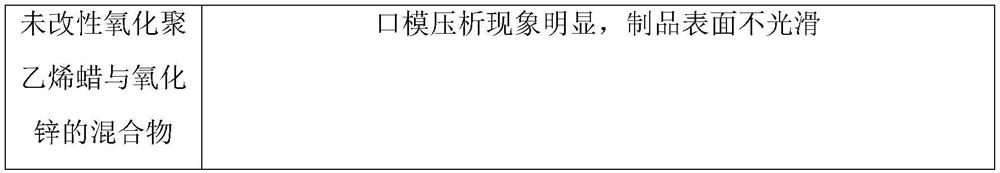

Examples

Embodiment 1

[0036] 1. Weigh the raw materials: 150 g of oxidized polyethylene wax, 4.01 g of calcium hydroxide, and 3.68 g of ammonia water.

[0037] 2. Add 600g of water to the autoclave, continue to add 150g of oxidized polyethylene wax and 4.01g of calcium hydroxide, add 3.68g of ammonia water as an initiator, seal the autoclave, and introduce nitrogen from the nitrogen port to discharge the air in the autoclave. After the air was fully exhausted, 1.0 MPa nitrogen was introduced into the kettle, and the temperature was raised to 100 °C to carry out a closed reaction. The reaction time was 6 h. After the reaction, suction filtration, drying and pulverization were carried out to obtain 150 g of modified oxidized polyethylene wax with a yield of 97.4%.

Embodiment 2

[0039] 1. Weigh the raw materials: 100 g of oxidized polyethylene wax, 3.21 g of calcium hydroxide, and 2.95 g of ammonia water.

[0040] 2. Add 600g of water to the autoclave, continue to add 100g of oxidized polyethylene wax and 3.21g of calcium hydroxide, add 2.95g of ammonia water as an initiator, seal the autoclave, and introduce nitrogen from the nitrogen port to discharge the air in the autoclave. After the air was fully exhausted, 1.5MPa nitrogen was introduced into the kettle, and the temperature was raised to 140°C to carry out a closed reaction, and the reaction time was 4h. After the reaction, suction filtration, drying and pulverization were carried out to obtain 94 g of modified oxidized polyethylene wax with a yield of 91.1%.

Embodiment 3

[0042] 1. Weigh the raw materials: 150 g of oxidized polyethylene wax, 6.68 g of calcium hydroxide, and 6.13 g of ammonia water.

[0043] 2. Add 600g of water to the autoclave, continue to add 150g of oxidized polyethylene wax and 6.68g of calcium hydroxide, add 6.13g of ammonia water as an initiator, seal the autoclave, and introduce nitrogen from the nitrogen port to discharge the air in the autoclave. After the air was fully exhausted, 2.0 MPa nitrogen was introduced into the kettle, and the temperature was raised to 140 °C to carry out a closed reaction, and the reaction time was 3 h. After the reaction, suction filtration, drying and pulverization were carried out to obtain 149 g of modified oxidized polyethylene wax with a yield of 95.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com