Liquid crystal alignment composition

A technology of liquid crystal alignment and composition, applied in liquid crystal materials, chemical instruments and methods, chemical recycling, etc., can solve problems such as unevenness, uneven diffusion of alignment films, and film thicknesses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

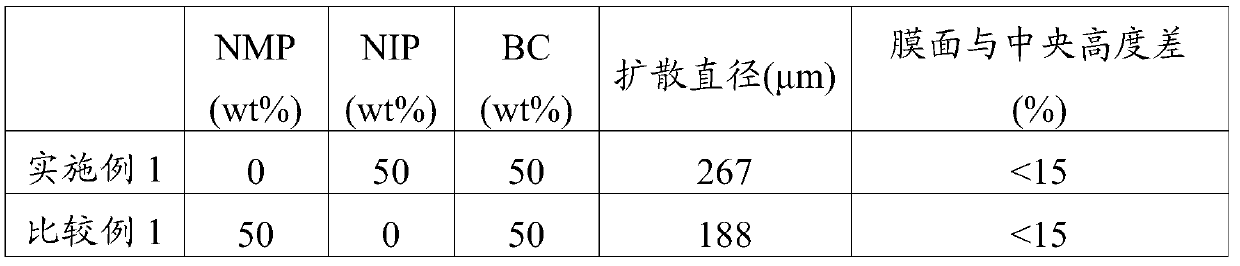

Embodiment 1~4、 comparative example 1~2

[0034] Preparation of liquid crystal alignment composition

[0035] A mixed solvent was prepared by mixing nitrogen-methyl-2-pyrrolidone (NMP), nitrogen-isopropyl-2-pyrrolidone (NIP) and butyl glycol ether (BC) according to the ratios shown in Tables 1 and 2, respectively.

[0036] After the polyamic acid solution RA9002 (sold by Daxing Materials) was drained to remove the original solvent, it was added to the mixed solvent obtained above, and diluted to a polyamic acid concentration of 3.5 wt%, to obtain Examples 1-4 and Comparative Example 1-2 liquid crystal alignment composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com