Method for improving copper precipitation defects in aluminum wires

A technology of copper precipitation and aluminum wire, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., can solve problems such as overheating of silicon wafers, and achieve the effect of avoiding high temperature and reducing the risk of copper precipitation in aluminum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

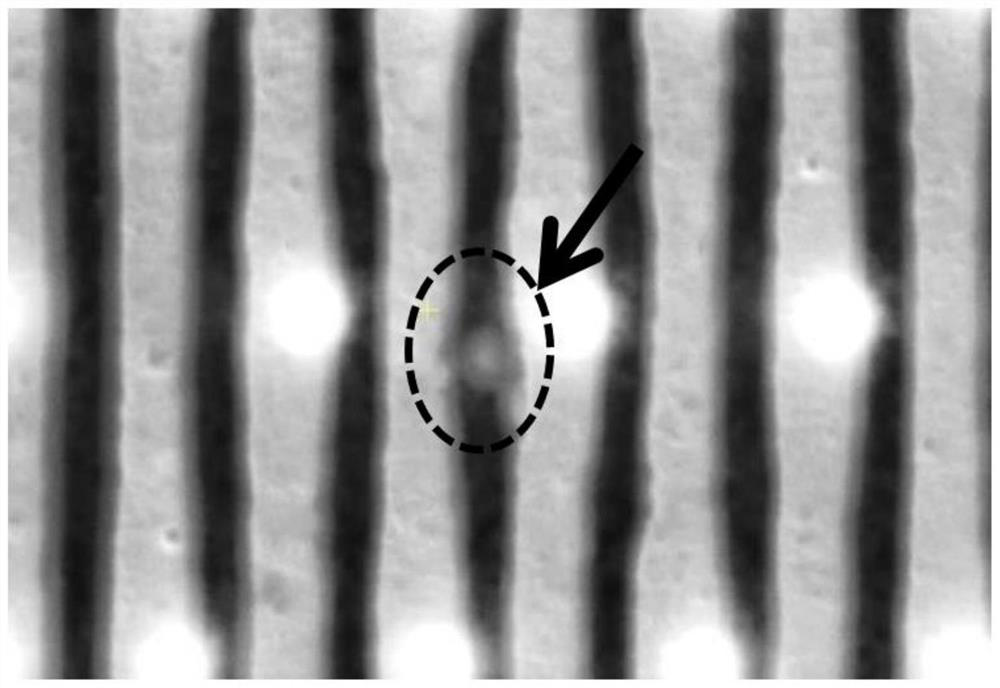

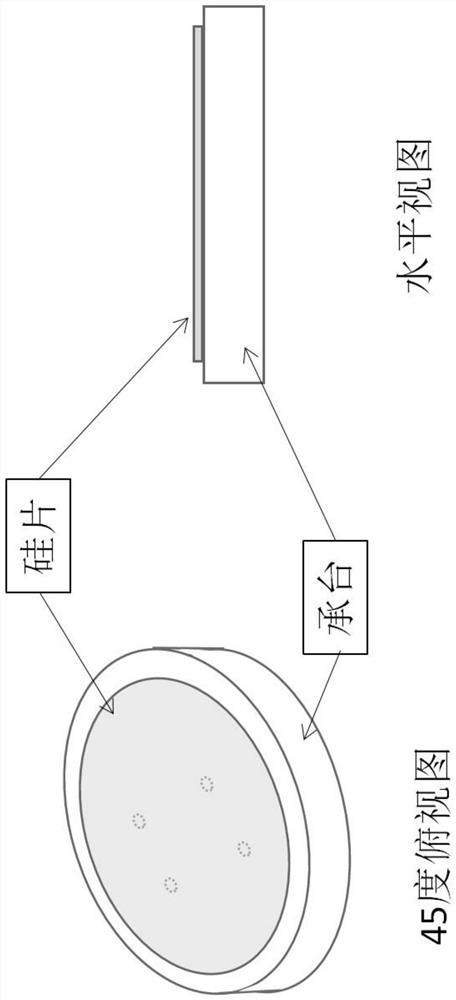

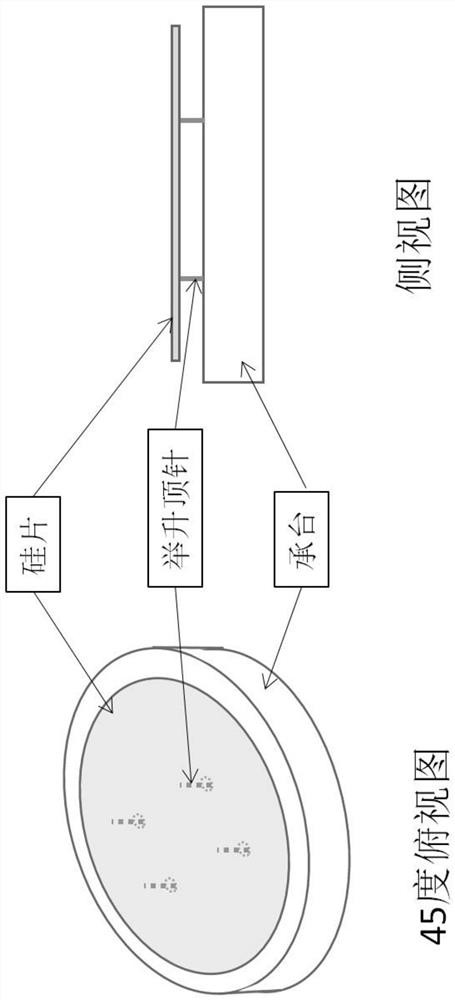

[0016] The method for improving copper precipitation defects in aluminum wires described in the present invention is aimed at the wafers that have completed the aluminum wire or aluminum film process, that is, the wafers after the aluminum deposition has been completed, when the machine stops running due to an abnormal alarm , The high temperature of the machine makes the wafer stay at a long-term high temperature, and the copper doped in the aluminum wire or aluminum film on the wafer will precipitate out, resulting in the formation of defects. Therefore, the design concept of the present invention is that when the equipment used after aluminum deposition, such as metal sputtering equipment, metal etching equipment, dry deglue equipment, chemical vapor deposition equipment, etc., is abnormal and needs to be stopped , try to reduce the risk of the wafer being in a long-term high temperature state. The operating temperature of these machines can reach above 200 degrees Celsius,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com