Automatic forming shear pin device for electronic parts and components and process of automatic forming shear pin device

An electronic component and automatic molding technology, applied in the field of automation, can solve the problems of small plug-in machine market share and small effect gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

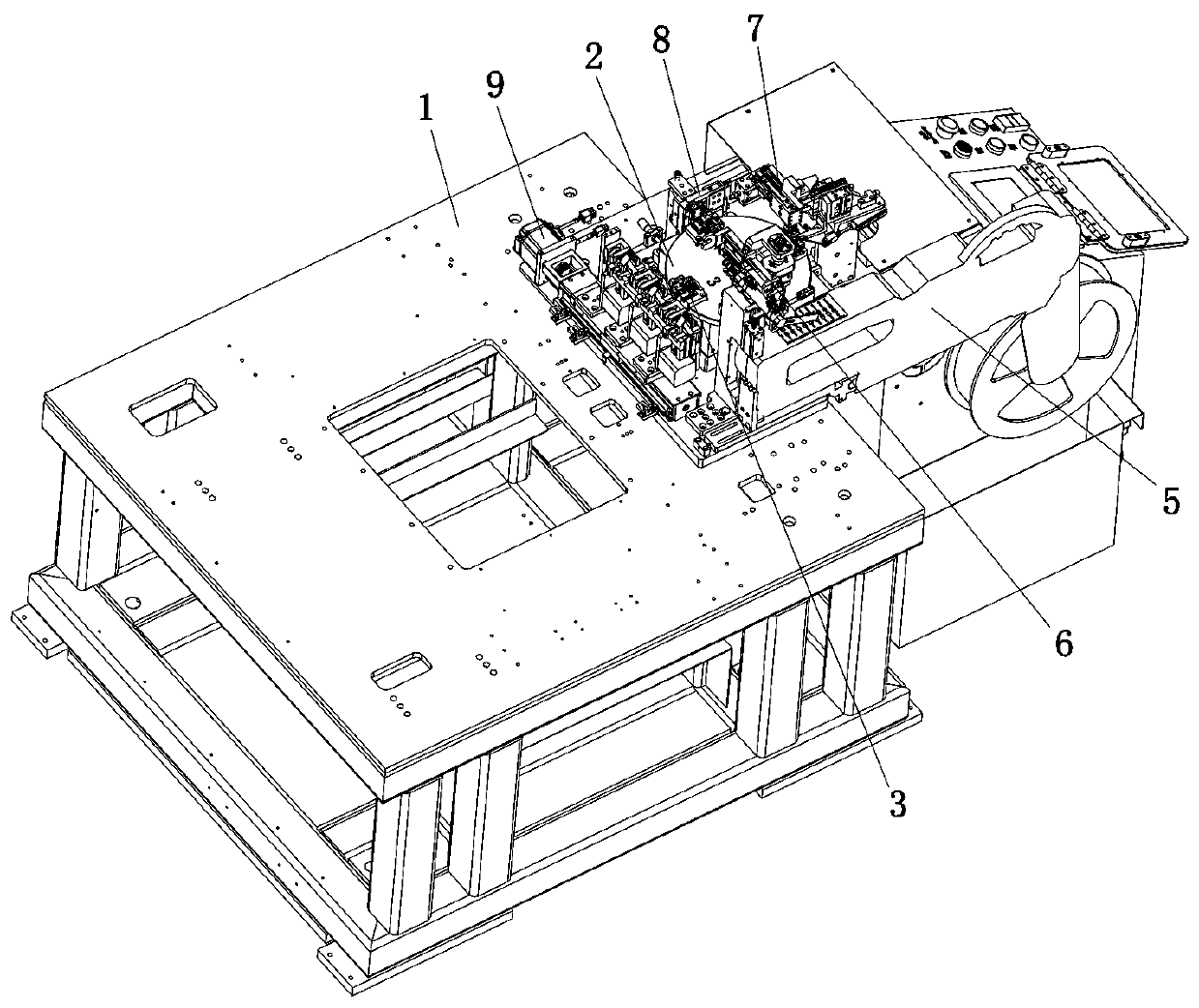

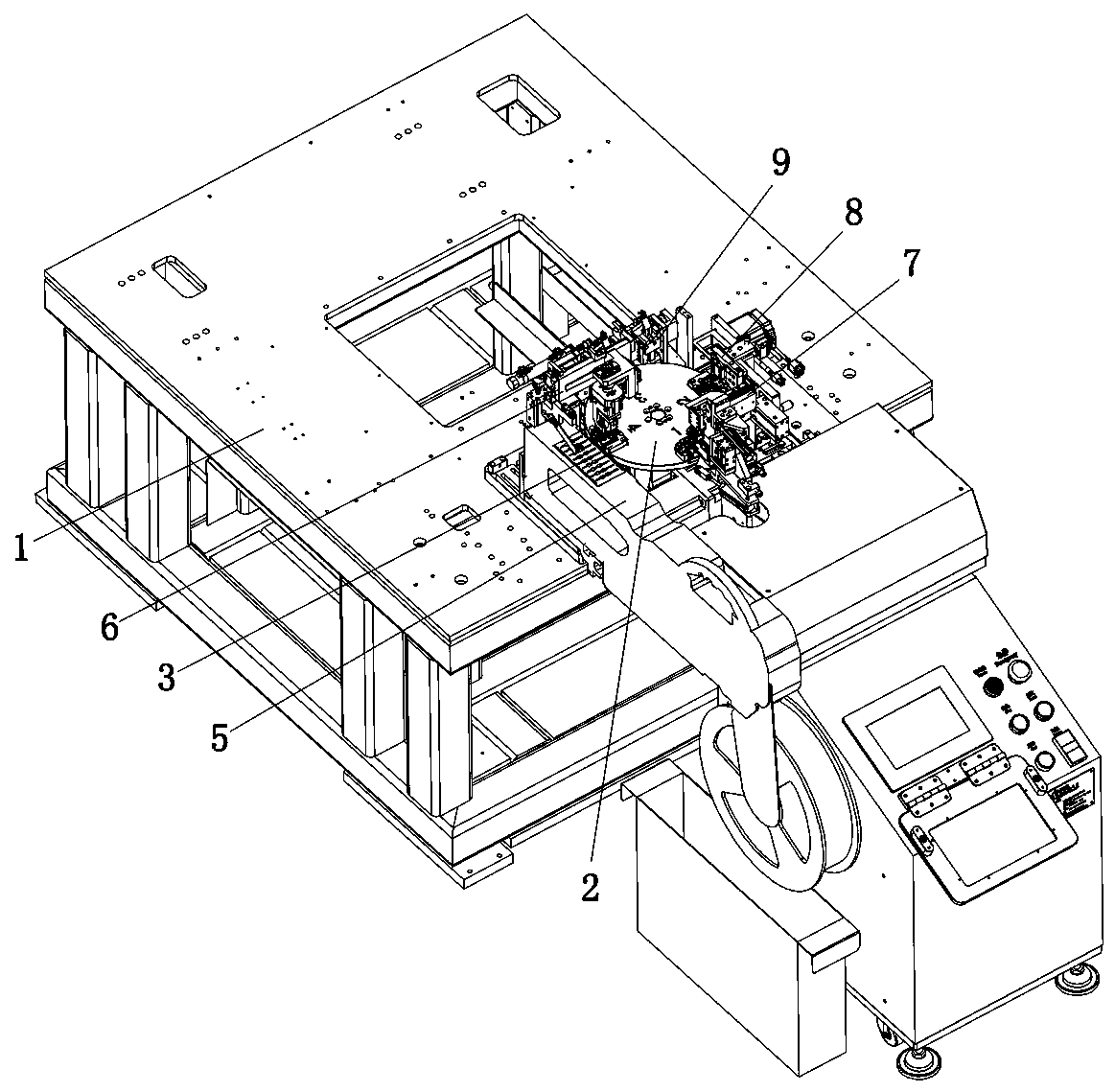

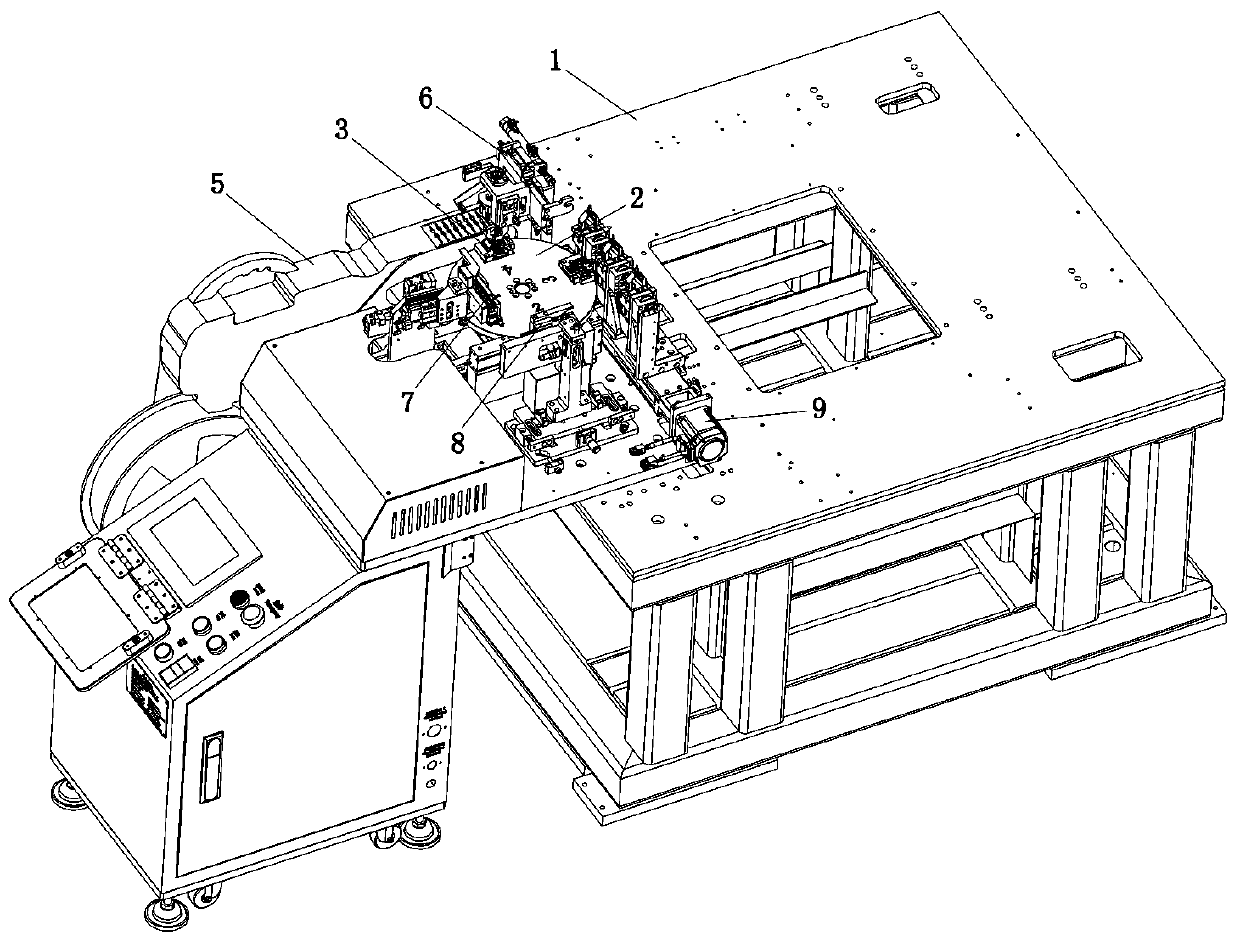

[0064] The present invention will be further described below in conjunction with accompanying drawing:

[0065] Such as Figure 1 to Figure 25 As shown, the technical scheme adopted by the present invention is as follows: an electronic component automatic forming and cutting foot device, including a turntable 2, a jig 3, an opening and closing mechanism 4, a feeding mechanism 5, a feeding mechanism 6, a forming mechanism 7, a cutting mechanism The foot mechanism 8 and the blanking mechanism 9, wherein the above-mentioned turntable 2 is rotatably arranged on the machine platform 1, and at least two processing stations are arranged at intervals along the circumferential direction on the turntable 2; the above-mentioned jig 3 includes at least two sets, The tool 3 is set at the processing station of the turntable 2, and rotates with the turntable 2; there is a storage space in the jig 3, and the component 0 to be processed is placed in the storage space. In the natural state, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com