Design method for elbow used for dredging engineering conveying pipeline and elbow designed by design method

A technology for conveying pipelines and design methods, applied in the direction of elbows, pipes/pipe joints/fittings, pipes, etc., can solve problems such as gaps, improve service life, improve wear resistance and impact resistance, and have superior wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

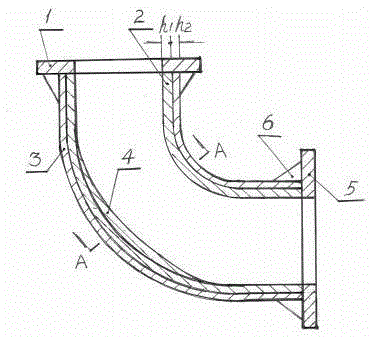

[0029] A method for designing an elbow used in dredging engineering delivery pipelines according to Embodiment 1 of the present invention, including the overall design of the elbow body and the flange and the specific design of each component, the elbow described in Embodiment 1 The design method is to meet the technical requirements of the 90° bending degree of the pipeline used in dredging projects. The cast steel pipe made of wear-resistant high-chromium cast iron material added with rare earth elements is used as the inner steel pipe of the elbow. The outer side of the steel pipe is covered with an elbow pipe body composed of an outer layer steel pipe processed by low-carbon steel plate through batching, pressing, and welding processes; the flange plate is a connecting joint welded at both ends of the pipe body. The inner diameter of the flange matches the outer diameter of the outer steel pipe, and four reinforcing ribs are evenly distributed at the longitudinal junction o...

Embodiment 2

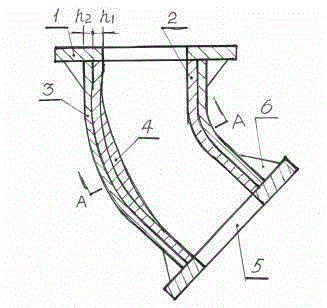

[0039] A method for designing an elbow used in dredging engineering delivery pipelines according to Embodiment 2 of the present invention includes the overall design of the elbow pipe body and the flange and the specific design of each component. The elbow described in Embodiment 2 The design method is to meet the technical requirements of the 135° bending degree of the pipeline used in dredging projects. The cast steel pipe made of wear-resistant high-chromium cast iron material added with rare earth elements is used as the inner steel pipe of the elbow. The outer side of the steel pipe is covered with an elbow pipe body composed of an outer layer steel pipe processed by low-carbon steel plate through batching, pressing, and welding processes; the flange plate is a connecting joint welded at both ends of the pipe body. The inner diameter of the flange matches the outer diameter of the outer steel pipe, and 10 reinforcing ribs are evenly distributed at the longitudinal junction...

Embodiment 3

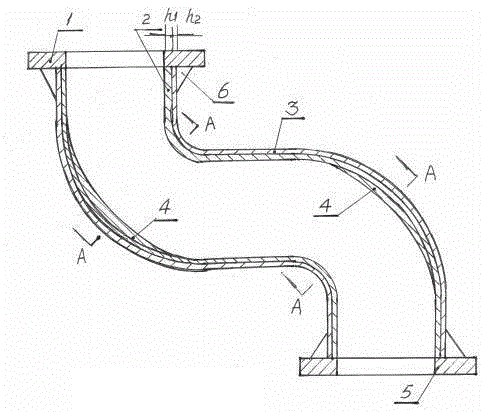

[0049] A method for designing an elbow used in dredging engineering delivery pipelines according to Embodiment 3 of the present invention includes the overall design of the elbow pipe body and the flange and the specific design of each component. The design of the elbow described in this embodiment The method is to meet the technical requirements of the 180° bending degree of the pipeline used in dredging projects. The cast steel pipe made of wear-resistant high-chromium cast iron material added with rare earth elements is used as the inner steel pipe of the elbow. The inner steel pipe The outer side is covered with an elbow pipe body composed of an outer steel pipe processed by low-carbon steel plate through batching, pressing, and welding processes; the flange plate is a connecting joint welded at both ends of the pipe body. The inner diameter of the flange matches the outer diameter of the outer steel pipe, and 16 reinforcing ribs are evenly distributed at the longitudinal c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com