Sheet bending device

A bending device and thin plate technology, which is applied in the field of thin plate bending devices, can solve the problems of difficult removal of thin plates, high manual labor intensity, and failure to meet product quality requirements, so as to meet the requirements of mass processing and production with low manual labor intensity , Guarantee the effect of plate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

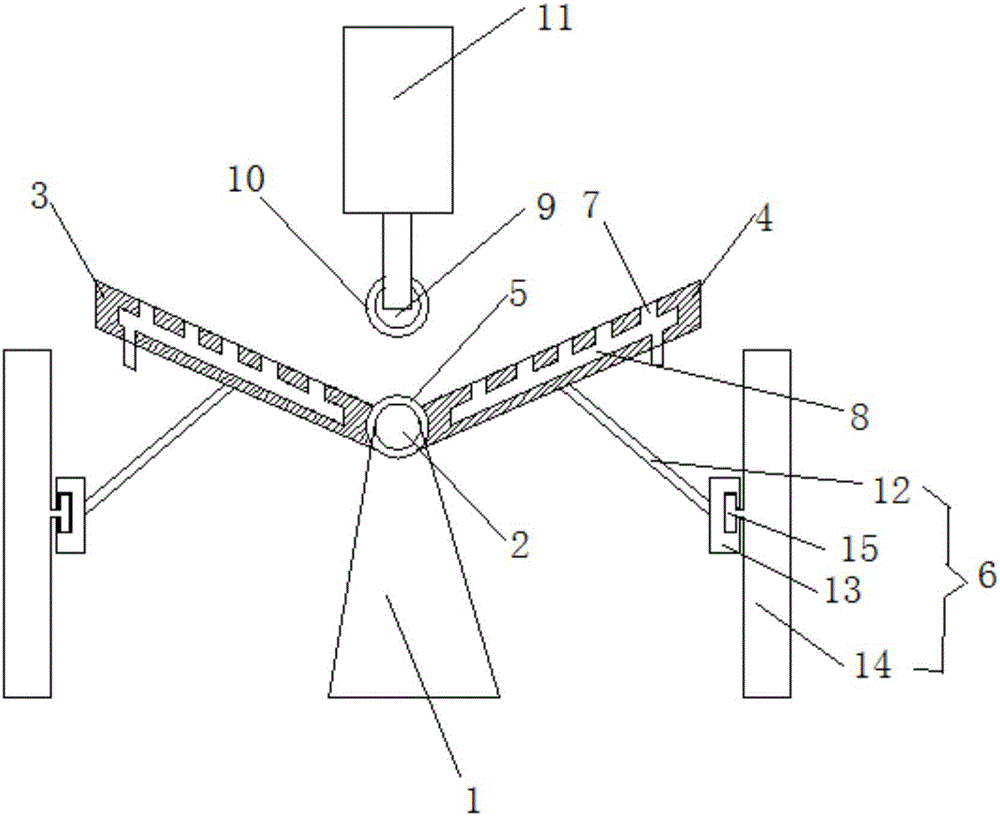

[0017] See attached picture.

[0018] A thin plate bending device, comprising a base 1, a fixed shaft 2 is installed in the middle of the base 1, flip plates 3 and 4 that rotate around the fixed shaft are installed on both sides of the fixed shaft 2, and the inner sides of the flip plates 3 and 4 are provided with The shaft sleeve 5 that cooperates with the fixed shaft 2, and the shaft sleeves of the two flaps 3 and 4 are set at a dislocation interval. A plurality of air outlet holes 7 are distributed, and the air outlet holes 7 extend into the flaps 3 and 4, and are communicated with the vent chambers 8 in the flaps 3 and 4, and the air inlets of the vent chambers 8 are connected with air inlet pipes respectively, and the fixed shaft 2 is erected with finale 9 directly above, and axle sleeve 10 is sleeved on finalist 9, and institute axle 9 is driven by the cylinder 11 of its upper end.

[0019] The guide rod slider mechanism 6 includes a guide rod 12 hinged on the lower end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com