Fixed wheel assembly of pipe bending machine

A technology of pipe bending machine and fixed wheel, which is applied in positioning device, metal processing equipment, feeding device, etc., can solve the problems of poor compatibility of pipe fittings, low work efficiency, poor work stability, etc., and achieves low cost, improved work efficiency, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

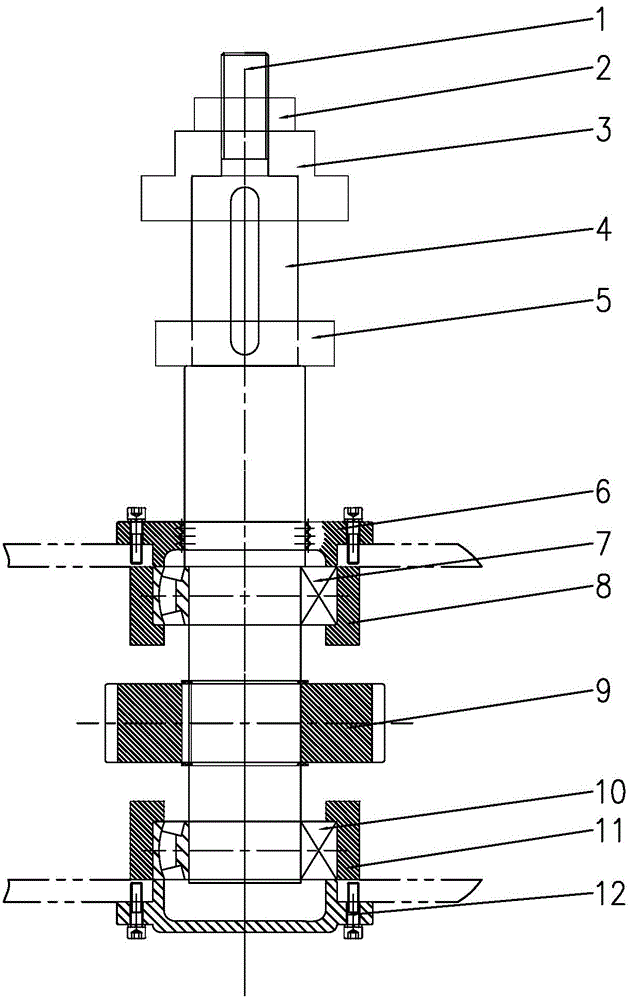

[0014] Such as figure 1 Shown, the present invention mainly comprises fixed wheel shaft 4, and fixed wheel shaft 4 bottoms are provided with fixed gear 9, and when working, drive fixed wheel shaft 4 to rotate by gear transmission.

[0015] The upper part of the fixed wheel shaft 4 is sequentially connected with the upper platen 3 and the lower pallet 5 from top to bottom. hold. By adjusting the distance between the upper platen 3 and the lower pallet 5, the bending requirements of workpieces of different sizes can be met.

[0016] The upper end of the upper pressure plate 3 is connected to the fixed shaft 1, and the fixed shaft 1 is connected to the tightening ring 2, and the upper pressure plate 3 is compressed by the tightening ring 2.

[0017] On the fixed wheel shaft 4, the upper bearing seat 8 and the lower bearing seat 11 are respectively conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com