Cement steel bar bending equipment for construction site

A technology for cement steel bars and construction sites, applied in the field of bending equipment, can solve problems affecting the progress of construction construction, low bending efficiency, steel bar bending, etc., and achieve the effect of increasing stability and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

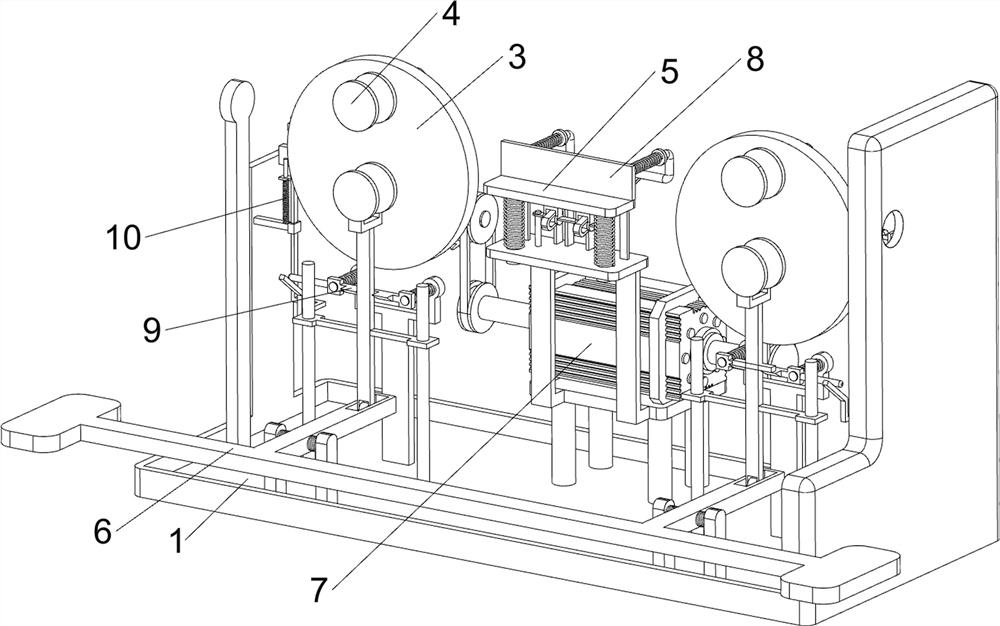

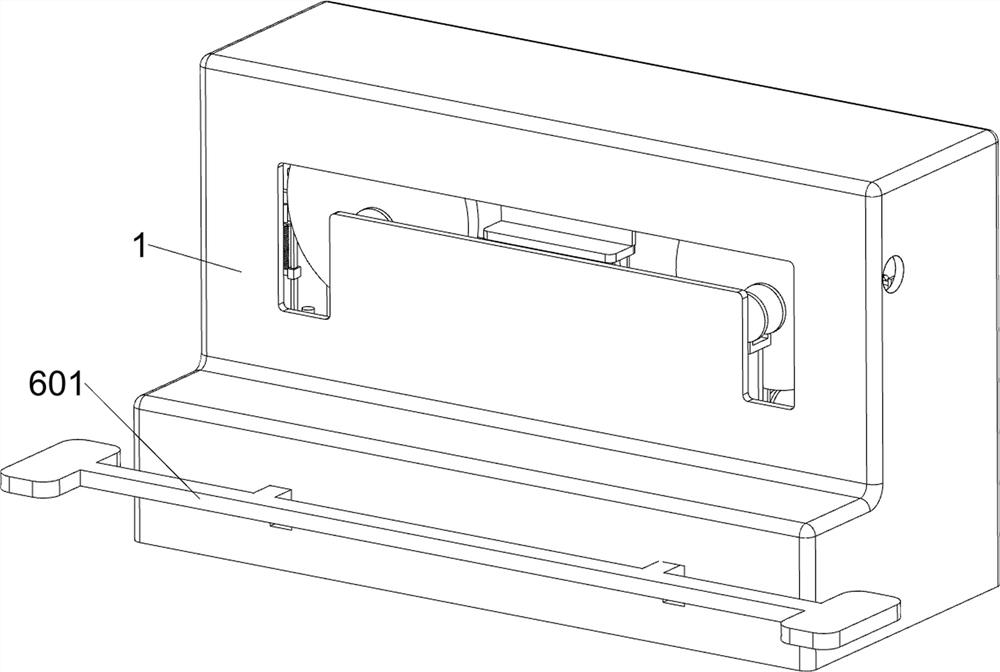

[0028] A cement steel bar bending equipment for construction sites, such as figure 1 , figure 2 , image 3 , Figure 5 and Figure 7 As shown, it includes a box body 1, a first rotating shaft 2, a turntable 3, a bending wheel 4, a buffer assembly 5, a positioning assembly 6 and a driving assembly 7. The inner upper side of the box body 1 is provided with a first rotating shaft 2 symmetrically rotating left and right, A turntable 3 is provided on the first rotating shaft 2, a bending wheel 4 is provided on the front side of the upper part of the turntable 3, a buffer assembly 5 is arranged in the middle of the box body 1, and a positioning assembly 6 is arranged between the turntable 3 and the box body 1, and the first A drive assembly 7 is provided between the rotating shaft 2 and the buffer assembly 5 .

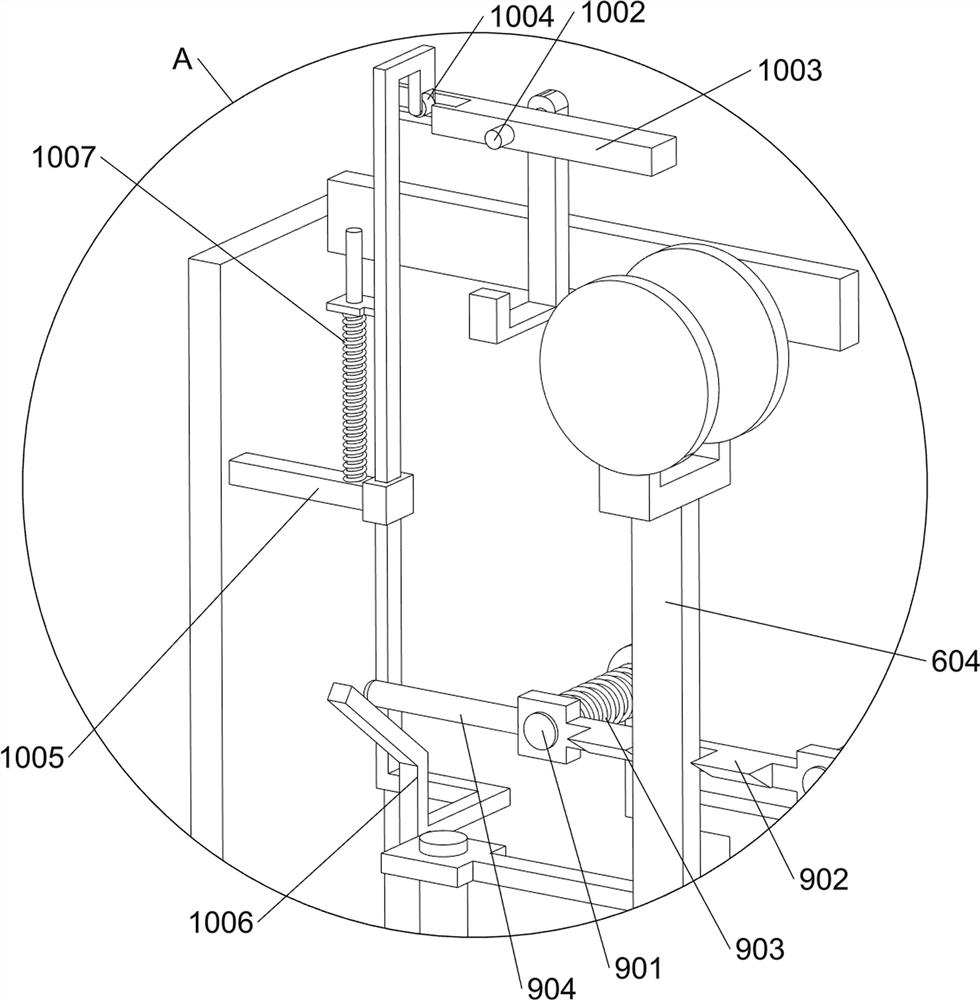

[0029] The buffer assembly 5 includes a support frame 501, a buffer plate 502, a first guide rod 503 and a first spring 504. A support frame 501 is provided in the midd...

Embodiment 2

[0034] On the basis of Example 1, as Figure 4 , Image 6 and Figure 8 As shown, it also includes a pusher assembly 8. The pusher assembly 8 includes a rocker 801, a second guide rod 802, a slider 803, a second slider 804, a pusher plate 805 and a second spring 806. The support frame 501 A second guide rod 802 is provided on the left and right sides of the top, a slider 803 is slidably arranged between the second guide rods 802, and the slider 803 cooperates with the buffer plate 502. The rear side of the top of the support frame 501 is provided with a rocker that rotates symmetrically. 801, the rocker 801 is slidably connected to the slider 803, the top and left sides of the support frame 501 are slidably provided with a second slide 804, the second slide 804 is slidably connected to the rocker 801, and the second slide 804 A pushing plate 805 is provided between the front sides, and a second spring 806 is provided between the pushing plate 805 and the second sliding rod 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com