Steel bar bending machine

A machine and steel bar technology, applied in the field of steel bar bending machines, can solve problems such as low work efficiency and high safety hazards, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

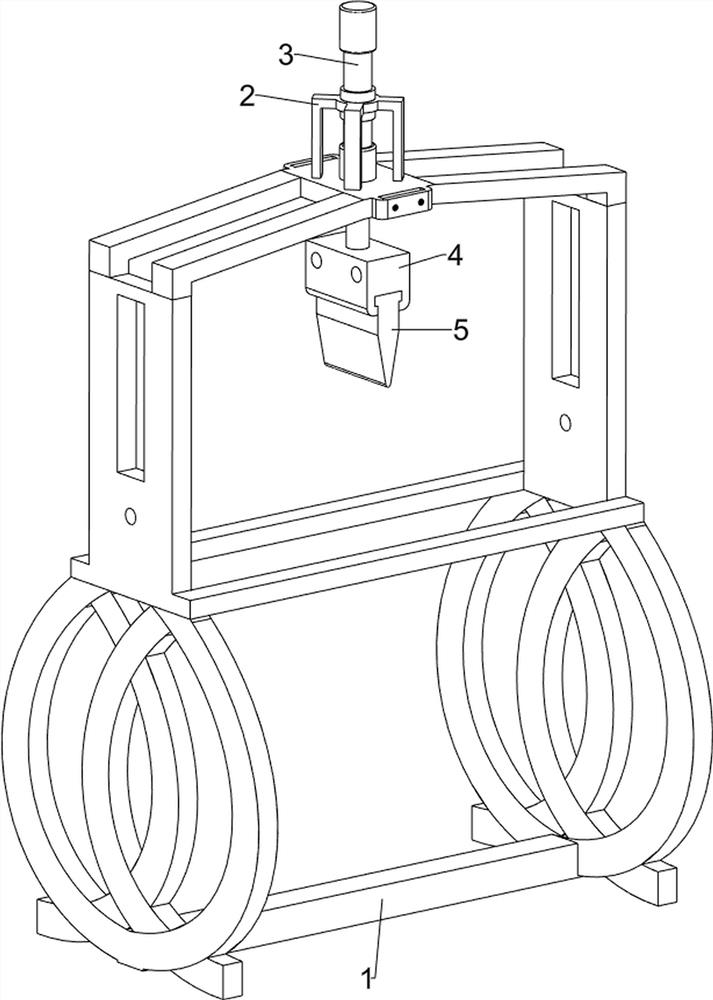

[0027] A steel bending machine, such as figure 1 , figure 2 and image 3 As shown, it includes a support frame 1, a first fixed frame 2, a first cylinder 3, a fixed block 4, a limit plate 5, a guide mechanism 6 and a clamping mechanism 7, and the top of the support frame 1 is provided with a first fixed frame 2, The first cylinder 2 is provided with a first cylinder 3 inboard, the piston rod of the first cylinder 3 is provided with a fixed block 4, the bottom of the fixed block 4 is provided with a limit plate 5, and the inner side of the support frame 1 top is provided with a guide mechanism 6, and the guide mechanism 6 is provided with clamping mechanism 7.

[0028] When it is necessary to bend the steel bar, people place the steel bar at the clamping mechanism 7, then start the first cylinder 3, and under the action of the piston rod of the first cylinder 3, drive the fixed block 4 and the limit plate 5 to move downward , so that the guide mechanism 6 drives the clampin...

Embodiment 2

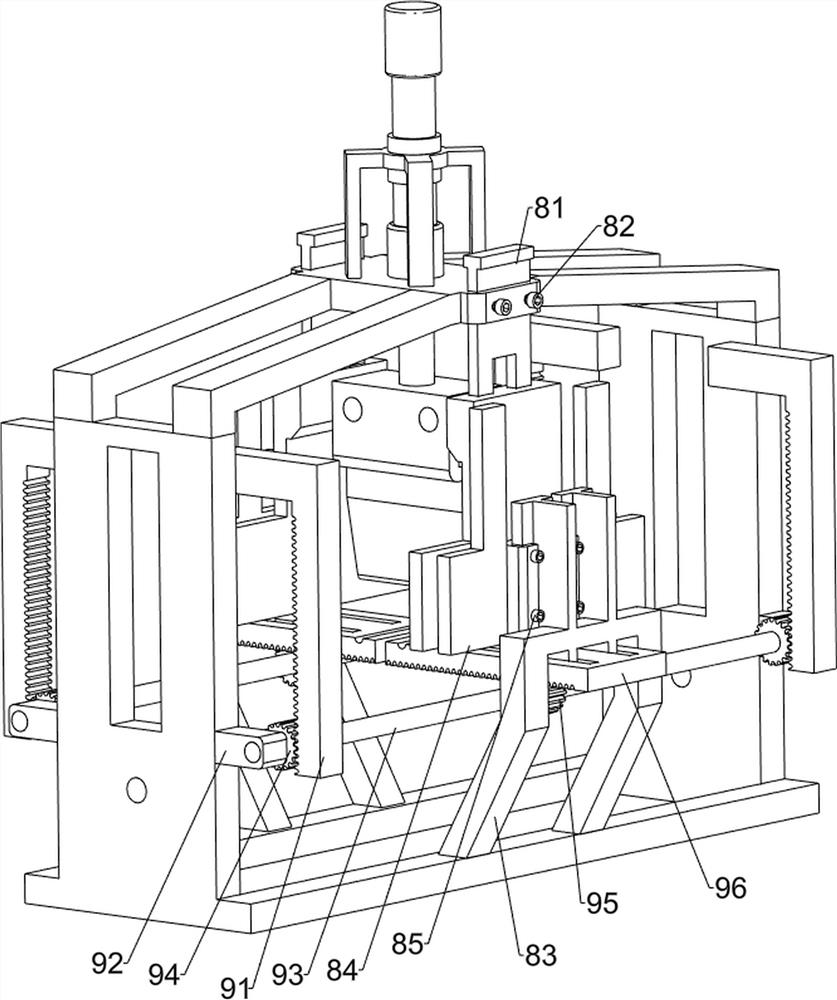

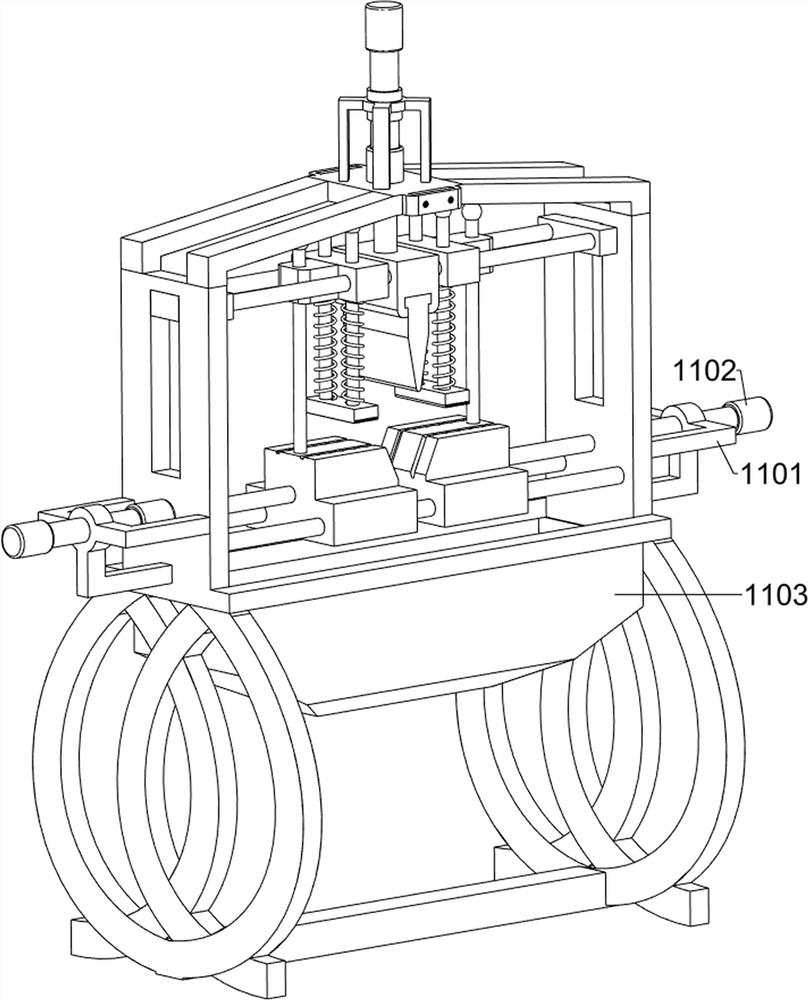

[0033] On the basis of Example 1, such as Figure 4 , Figure 5 , Figure 6 and Figure 7As shown, an adjustment mechanism 8 is also included. The adjustment mechanism 8 includes a first baffle plate 81, a first stop nut 82, a bracket 83, a second baffle plate 84 and a second limit nut 85. The side sliding type is provided with the first baffle plate 81, the front and rear sides of the top of the support frame 1 are symmetrically provided with the first stop nut 82 through threads, the front and rear sides of the middle part of the support frame 1 are provided with supports 83, and the inner sides of the upper part of the support frame 1 are all slidingly designed. There is a second baffle 84 , and the second baffle 84 is provided with six second limit nuts 85 through threads, and the second limit nuts 85 are all matched with the bracket 83 .

[0034] Also include feed mechanism 9, feed mechanism 9 includes first tooth bar 91, the 3rd limit block 92, transmission shaft 93, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com