Curved surface touch screen and manufacturing method thereof

A technology of a curved touch screen and a manufacturing method, which are applied in the directions of instruments, electrical digital data processing, and data processing input/output processes, etc., can solve the problems of limited reliability, rainbow patterns on the touch screen, and the glass substrate is difficult to meet the curved touch screen, etc. Achieve the effect of good optical reliability and avoid the problem of rainbow pattern

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

other Embodiment approach

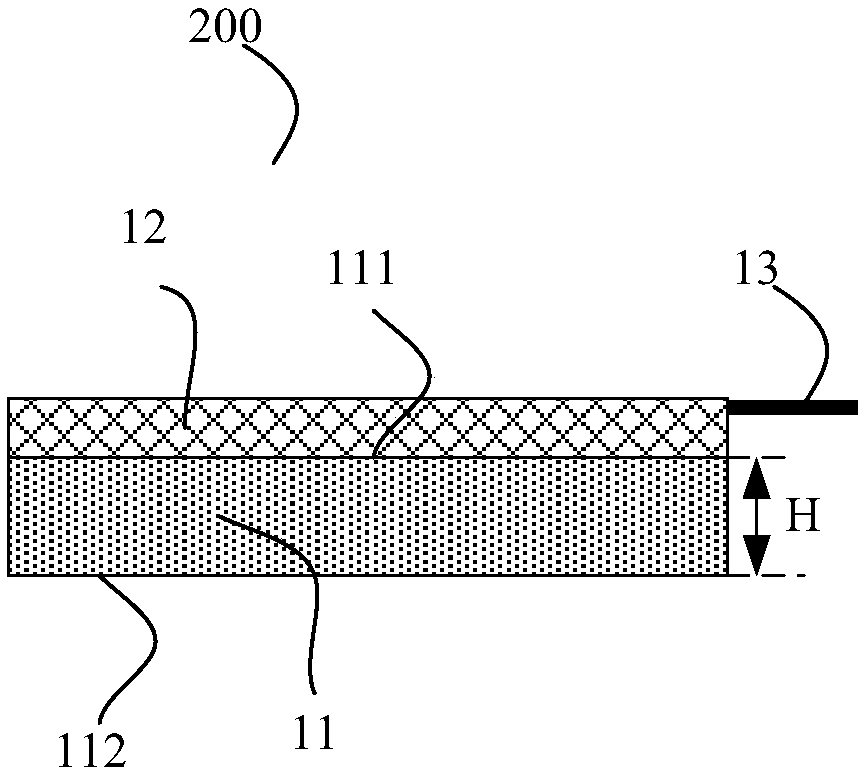

[0084] In other implementation manners, the providing a glass substrate with touch electrodes on its surface includes: directly using a glass substrate with a thickness smaller than the preset threshold to directly form touch electrodes on its surface.

other Embodiment approach

[0085] In other implementation manners, the providing the glass substrate with touch electrodes on the surface includes: providing the glass substrate with a first thickness, and the first thickness is greater than the preset threshold; The two surfaces are thinned so that the thickness of the substrate is less than the preset threshold; the touch electrodes are formed on the first surface of the glass substrate. In this way, the glass substrate is thinned before the touch electrodes are formed. Two glass substrates can be bonded to each other and thinned separately, or the glass substrate can be placed on a carrier substrate for thinning. For the method, reference may be made to the above-mentioned process, which will not be repeated here, and the glass substrate may also be directly thinned. In this way, the requirements for the thinning process are relatively high.

[0086] In the manufacturing method described in the embodiment of the present invention, the preset threshol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com