Leveling method for cross break defects on surface of hot-rolled and acid-pickled plate

A hot-rolled pickling and leveling technology, applied in contour control and other directions, can solve the problems of time-consuming and laborious, high secondary flattening rate of strip transverse fold defects, reduce production costs, eliminate transverse fold defects on the strip surface, and achieve good results. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

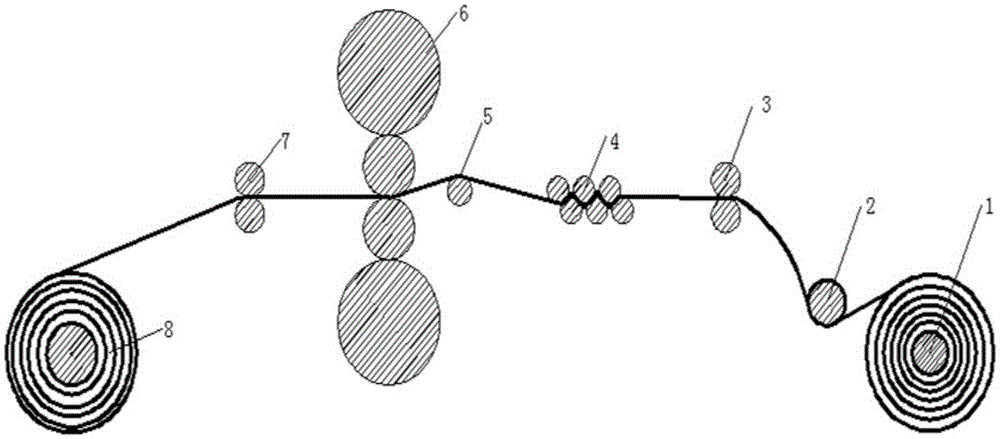

[0022] The embodiments of the present application provide a smoothing method for cross-fold defects on the surface of hot-rolled pickled sheets, so as to solve the technical problems of complex correction of cross-fold defects in the prior art, low efficiency, and high secondary smoothing rate; The leveling efficiency of defects, the technical effect of reducing costs.

[0023] In order to solve the above technical problems, the general idea of the technical solution provided by the embodiment of the present application is as follows:

[0024] A method for smoothing the surface of a hot-rolled pickled sheet for cross-bending defects, comprising:

[0025] The hot-rolling skin pass unit is controlled by constant rolling force, and the skin pass + straightening mode is selected;

[0026] The segmented pressure control strategy of deep bending rolls is adopted, and the pressure of deep bending rolls is adjusted according to the cross-sectional area of the strip;

[0027] Con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com