A kind of anaerobic adhesive for sealing plastic parts and preparation method thereof

A technology for anaerobic adhesives and plastic parts, applied in the field of anaerobic adhesives, which can solve the problems of affecting the sealing effect, low cohesive strength, plastic deformation, etc., and achieve the effects of reducing uneven force, reducing stress, and large torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

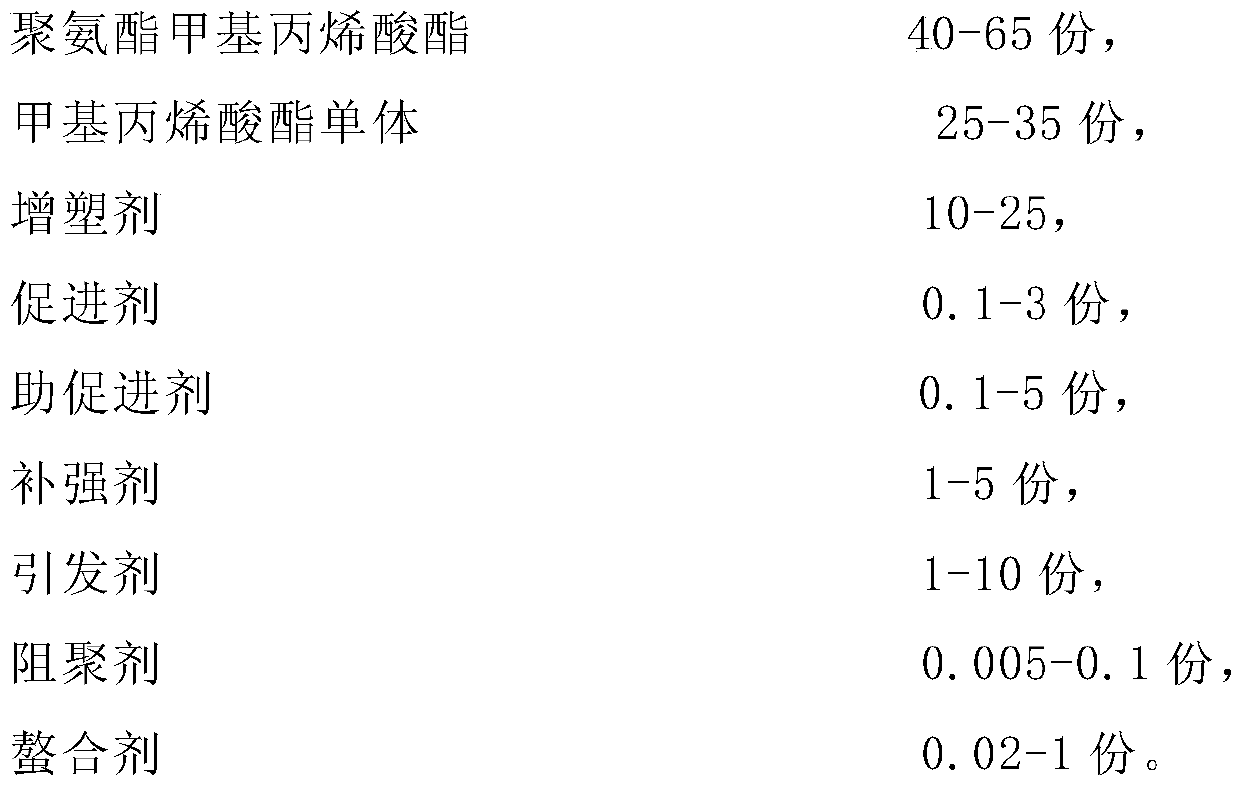

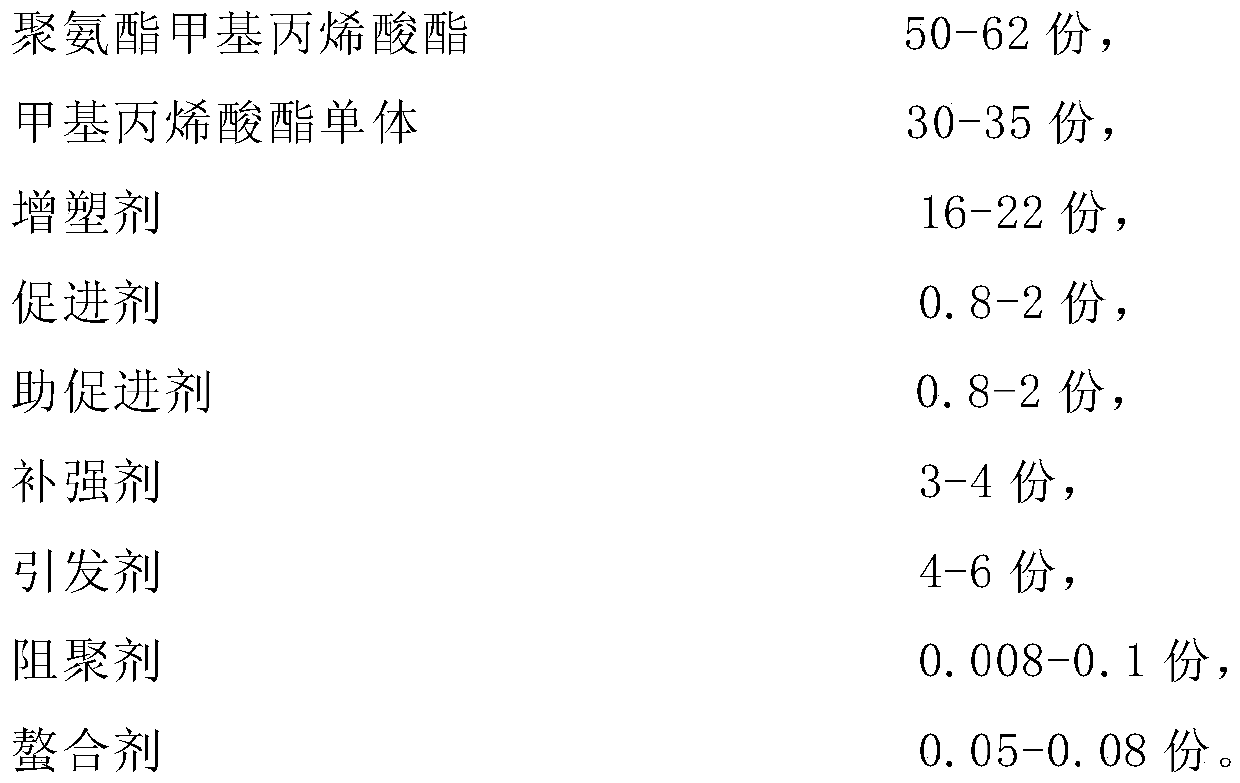

[0039] A kind of anaerobic glue that is used for plastic parts sealing, the proportion by weight of this anaerobic glue component is as shown in table 1 below:

[0040] Table 1

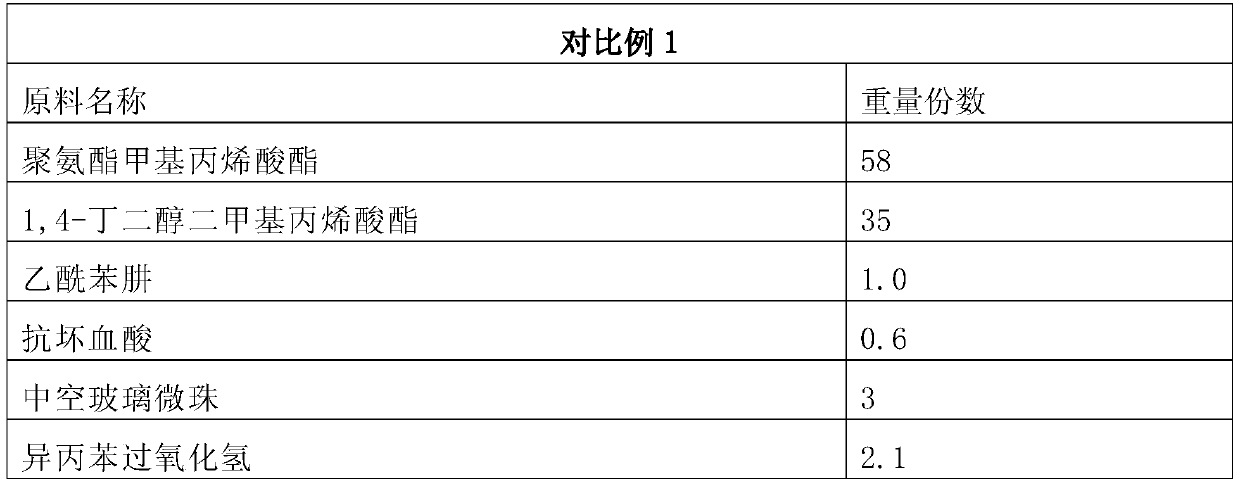

[0041] Example 1 Example 2 Example 3 raw material name parts by weight parts by weight parts by weight polyurethane methacrylate 48 48 48 1,4-Butanediol dimethacrylate 35 30 25 poly(1,2-propylene glycol adipate) 10 15 20 Acetyl phenylhydrazine 1.0 1.0 1.0 ascorbic acid 0.6 0.6 0.6 Hollow glass beads 3 3 3 Cumene Hydroperoxide 2.1 2.1 2.1 Tetrasodium EDTA 0.25 0.25 0.25 p-benzoquinone 0.05 0.05 0.05

[0042] Preparation:

[0043] (1), add polyurethane methacrylate, 1,4-butanediol dimethacrylate, poly-1,2-propylene glycol adipate and tetrasodium ethylenediaminetetraacetic acid into the reaction flask according to the proportion, Stirring at 20-40°C for 1.5 hours to prepare a mixed solution;

[0044] (...

experiment example

[0060] Performance Testing:

[0061] 1. Stability: Put the one-component anaerobic adhesive in a 5ml glass test tube and place it in a water bath at 82°C for 2 hours. If it does not gel, it can be stored at room temperature for 2 years;

[0062] 2. Positioning time: use two Rp3 / 4 and Rp with lengths of 0.112 meters 1 3 / 4 ABS pipe, Rp3 / 4 pipe thread coated with anaerobic adhesive, and then R 1 3 / 4 is put on, record the positioning time from when the pipe is put on to when the two pipes cannot be twisted;

[0063] 3. Air tightness test: According to the standard BS EN 1054 1996, use the above-mentioned ABS pipe, fix it with anaerobic glue and place it for two days to test the air tightness of the interface;

[0064] 4. Stress resistance test: Use the above-mentioned ABS pipe, fix it with anaerobic adhesive, and record the stress failure phenomenon at the interface of each anaerobic adhesive after 3 days.

[0065] Test the stability, positioning time, air tightness, and stress r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com