Method for producing sheath of nylon cable and extrusion die thereof

A nylon sheath and production method technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of low qualified rate of mass production of finished products, poor bending performance of optical cables, obvious yarn binding marks, etc., achieve rapid adjustment of eccentricity, increase peel strength , The effect of solving the problem of yarn tie marks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

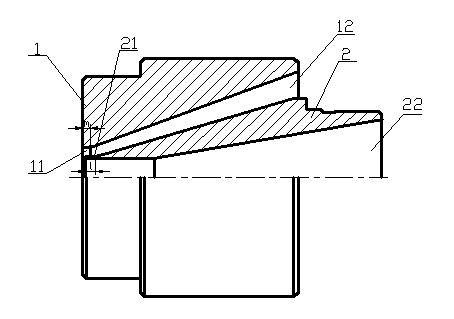

[0020] In the production method of the nylon optical cable sheath of the present invention, a semi-extrusion mold is used to extrude and form a secondary PE sheath, and the mold structure is as follows figure 1 shown. It consists of inner mold 2 and outer mold 1. The front end of the inner mold 2 includes a cone, the constricted front end of the cone is provided with a circular extrusion part 21, the center of the outer mold 1 is provided with a tapered inner mold hole 12 corresponding to the inner mold, and the inner mold 2 passes through The inner die hole 12 passing through the center of the outer die 1 is plugged into the outer die, and the extrusion part 21 and the inner die hole 12 form an annular gap for extruding PE material. The front end of the extrusion part 21 of the inner mold is in the extrusion hole 11 of the outer mold, and the axial length 1 of the extrusion part 21 is not more than 5mm, much shorter than the axial length 15mm of the existing extrusion part....

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com