Optical cable mounting method and mounting fixture

An installation method and fixture technology, applied in the direction of optical fiber/cable installation, etc., can solve the problems of affecting the architectural style, not beautiful enough, strong user resistance, etc., and achieve the effects of saving manpower and material resources, being easy to construct, and avoiding impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0031] A method for installing an optical cable, comprising the steps of:

[0032] A) Determine the installation route, and try to choose a route with fewer corners;

[0033] B) Clean the installation route, use a dry cloth to remove the dust on the surface of the installation route;

[0034] C) fixture is installed, and it comprises the following steps:

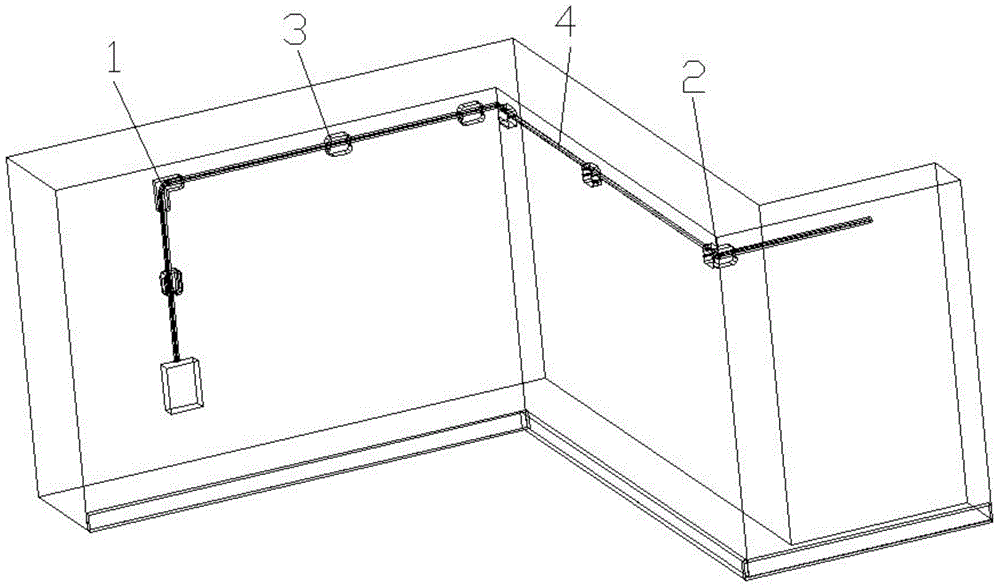

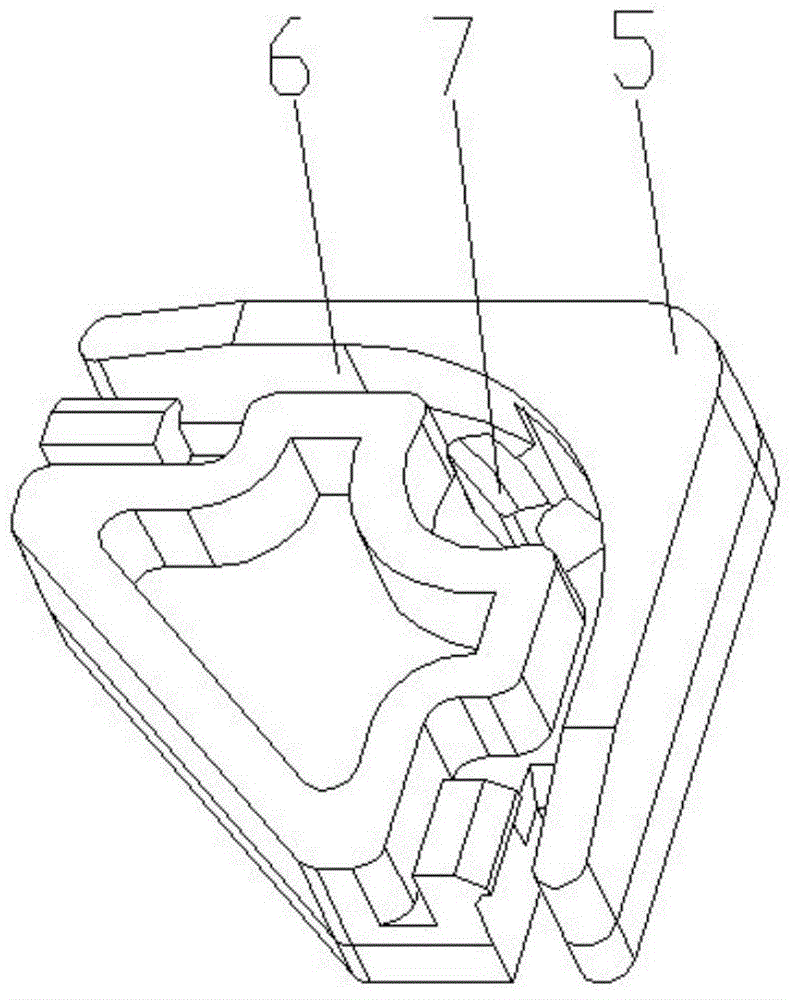

[0035] C1) Install plane turning fixture 1, and plane turning fixture 1 is installed on the plane turning route;

[0036] C2) Install the male corner turning fixture 2, and install the male corner turning fixture 2 on the male corner turning route;

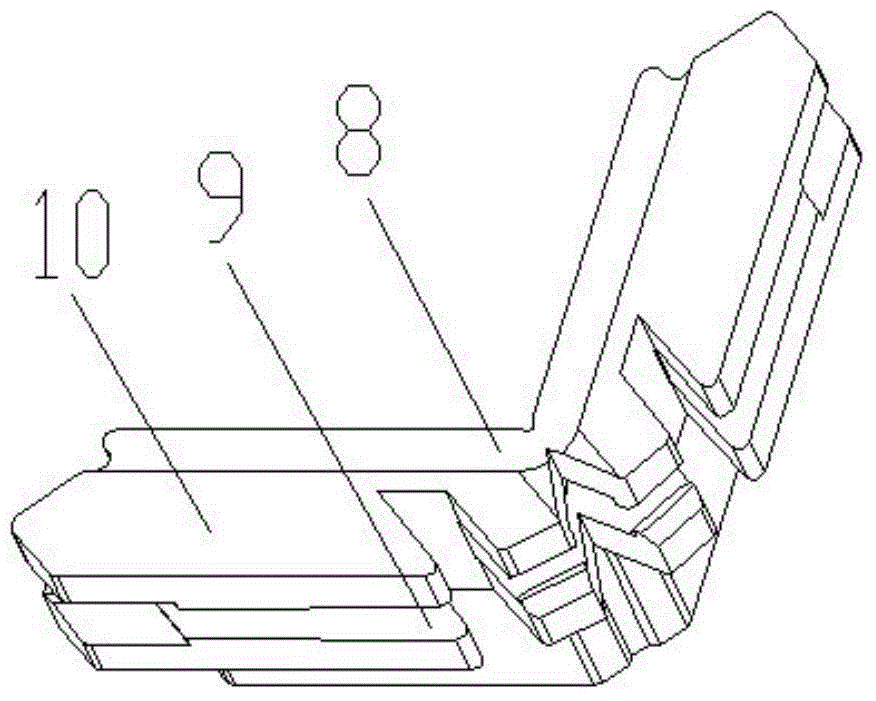

[0037] C3) Install the straight line fixture 3, fold and split the external corner turning fixture along the center line to form two identical straight line fixtures 3, and install the straight line ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com