Flexible electronic device and fabrication method thereof

A technology of flexible electronic devices and manufacturing methods, which is applied in the field of flexibility, and can solve the problems of poor energy absorption capacity, damage, and undeveloped wire stretching performance of flexible circuits, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further explain the technical means and functions adopted by the present invention to achieve the intended invention purpose, the detailed description is as follows in conjunction with the accompanying drawings and preferred embodiments.

[0028] The invention provides a flexible electronic device, which can provide better shock resistance for circuits in the flexible electronic device while ensuring the bending performance.

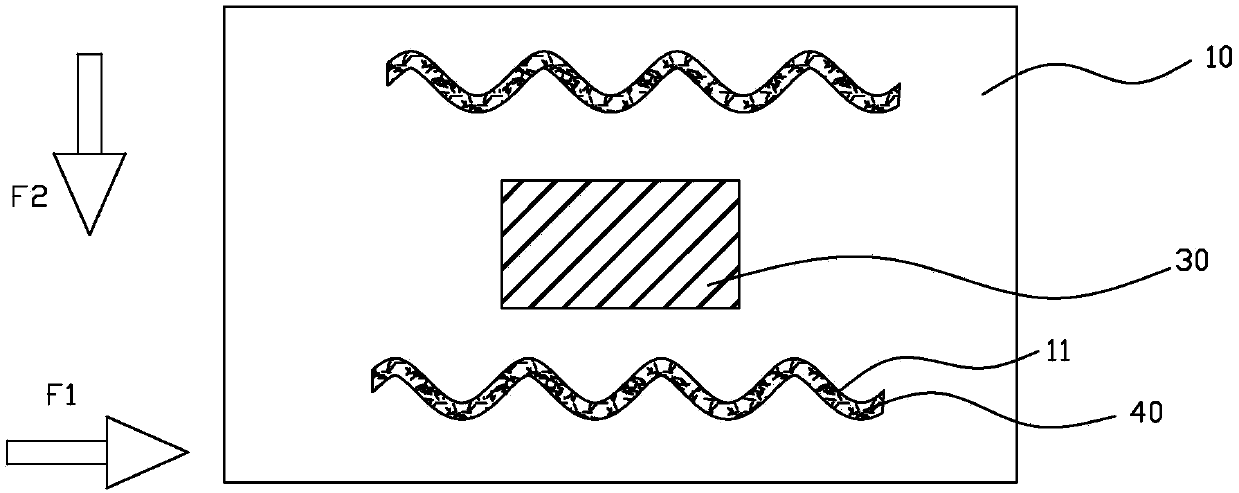

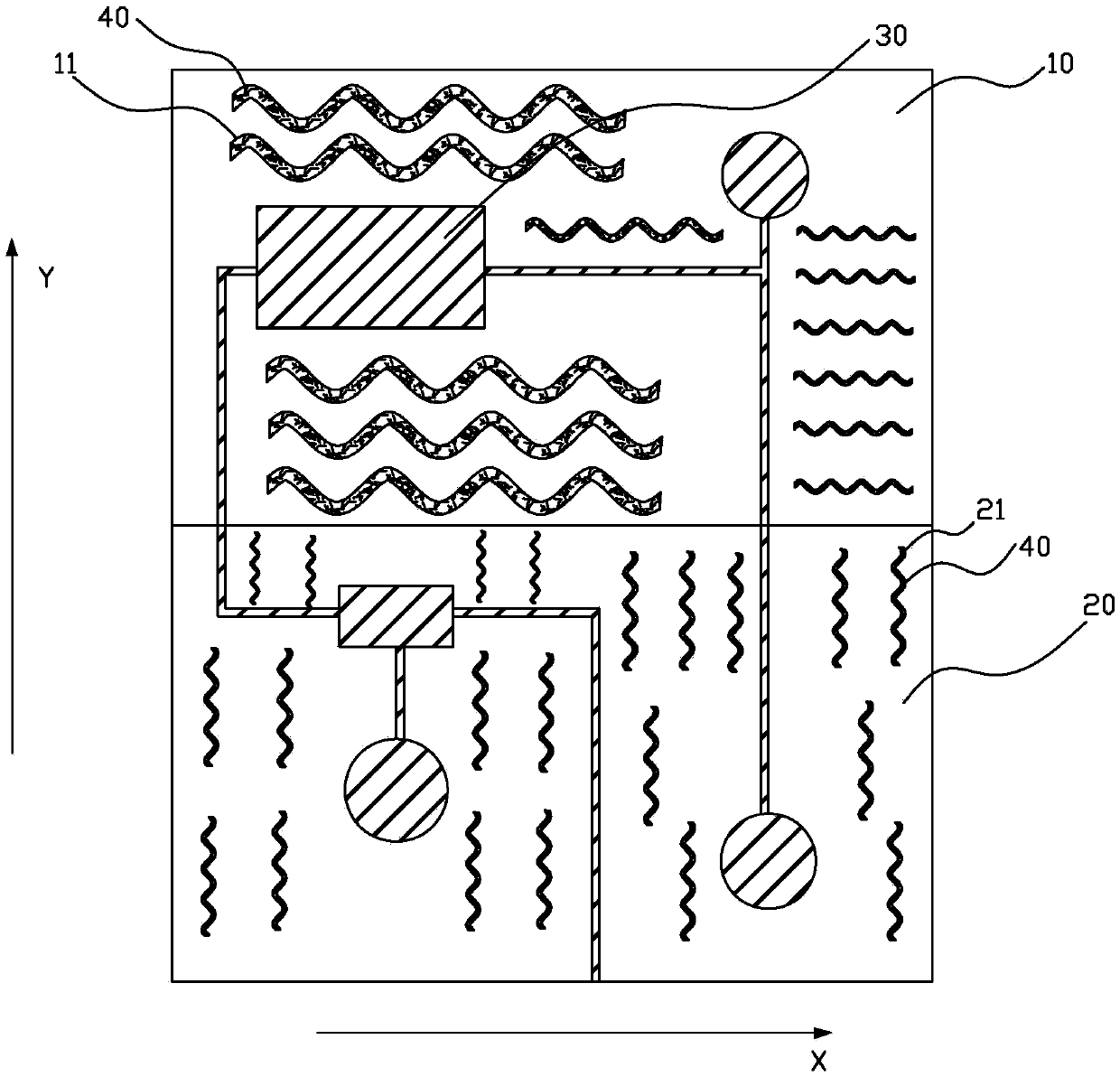

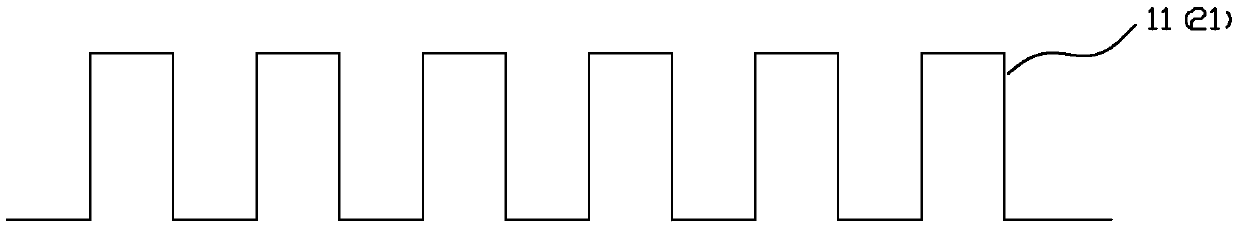

[0029] figure 1 Shown is a schematic diagram of the front structure of the flexible electronic device provided by the first embodiment of the present invention, such as figure 1 As shown, in the first embodiment of the present invention, the flexible electronic device includes a first flexible substrate 10, a circuit 30 and a first flow channel 11 are arranged on the first flexible substrate 10, and the first flow channel 11 extends in a meandering shape. The first flow channel 11 is filled with a non-Newtonian fluid 40 .

[0030] In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com