Super-flexible intelligent-control photoelectric composite cable for high-speed video transmission

An optoelectronic hybrid cable and video transmission technology, applied in the direction of insulated cables, bendable cables, cables, etc., can solve the problems of many inserted cables, human injury, inconvenient camera moving back and forth, etc., to achieve good tensile strength, cable core, etc. Soft, inconvenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

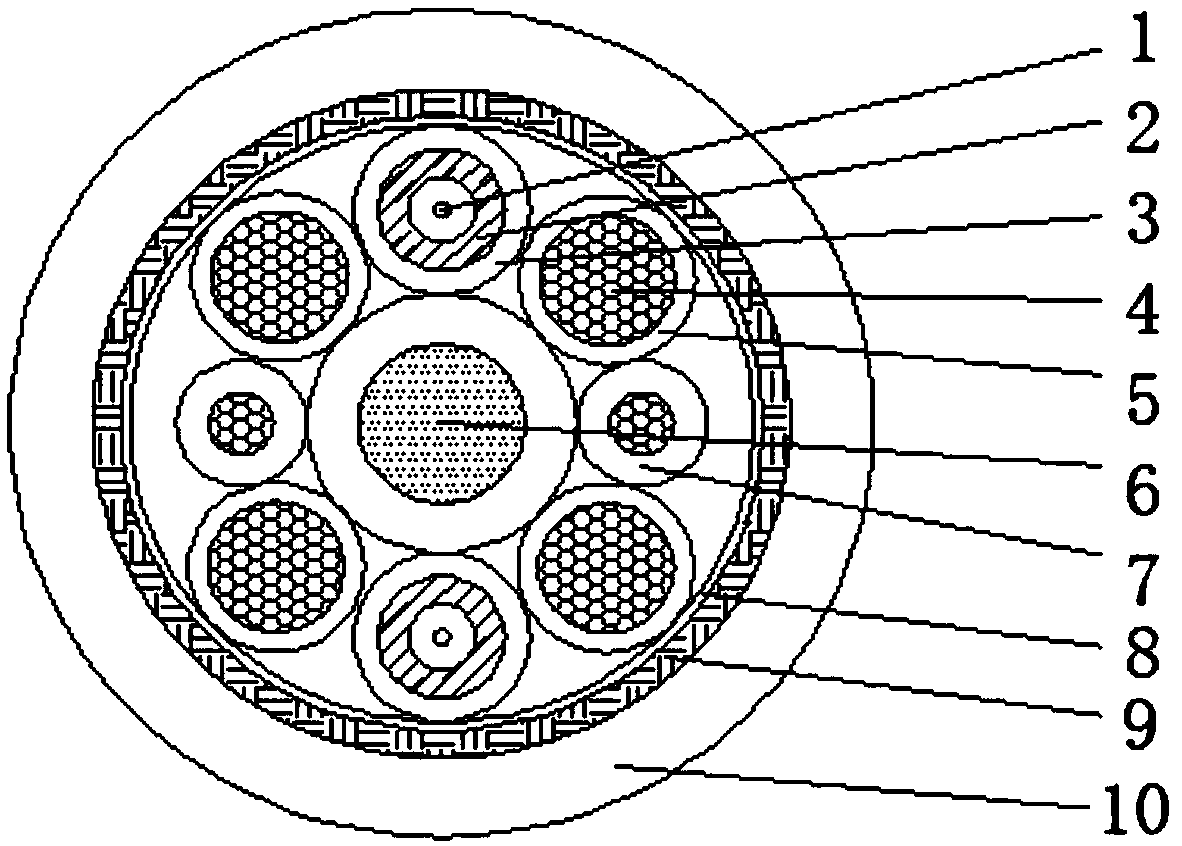

[0027] Such as figure 1 As shown, an ultra-flexible intelligent control photoelectric hybrid cable for high-speed video transmission, including:

[0028] Optical unit: In the hybrid cable, the optical fiber 1 uses two G.657.A2 bending loss insensitive tight-buffered fibers, and the surface of the optical fiber 1 is extruded with a nylon tight-buffered layer. The surrounding of the tight-buffered optical fiber is reinforced with water-blocking aramid fiber 2, and a layer of low-smoke halogen-free polyolefin or other suitable materials (that is, the optical fiber sheath 3) is extruded outside the aramid fiber 2, and the optical cable is distinguished by blue and yellow colors. The optical fiber 1 in the optical unit adopts G.657.A2, which is insensitive to bending loss. The optical fiber 1 has the characteristics of good bending resist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com