High temperature resistance extrasoft fluoroplastic insulation branch cable component

A branch cable, fluoroplastic technology, applied in the direction of insulated cables, cable joints, electrical components, etc., can solve the problems of difficult construction, crossover, and inability to improve, and achieve the effect of improving corrosion resistance, good protection, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

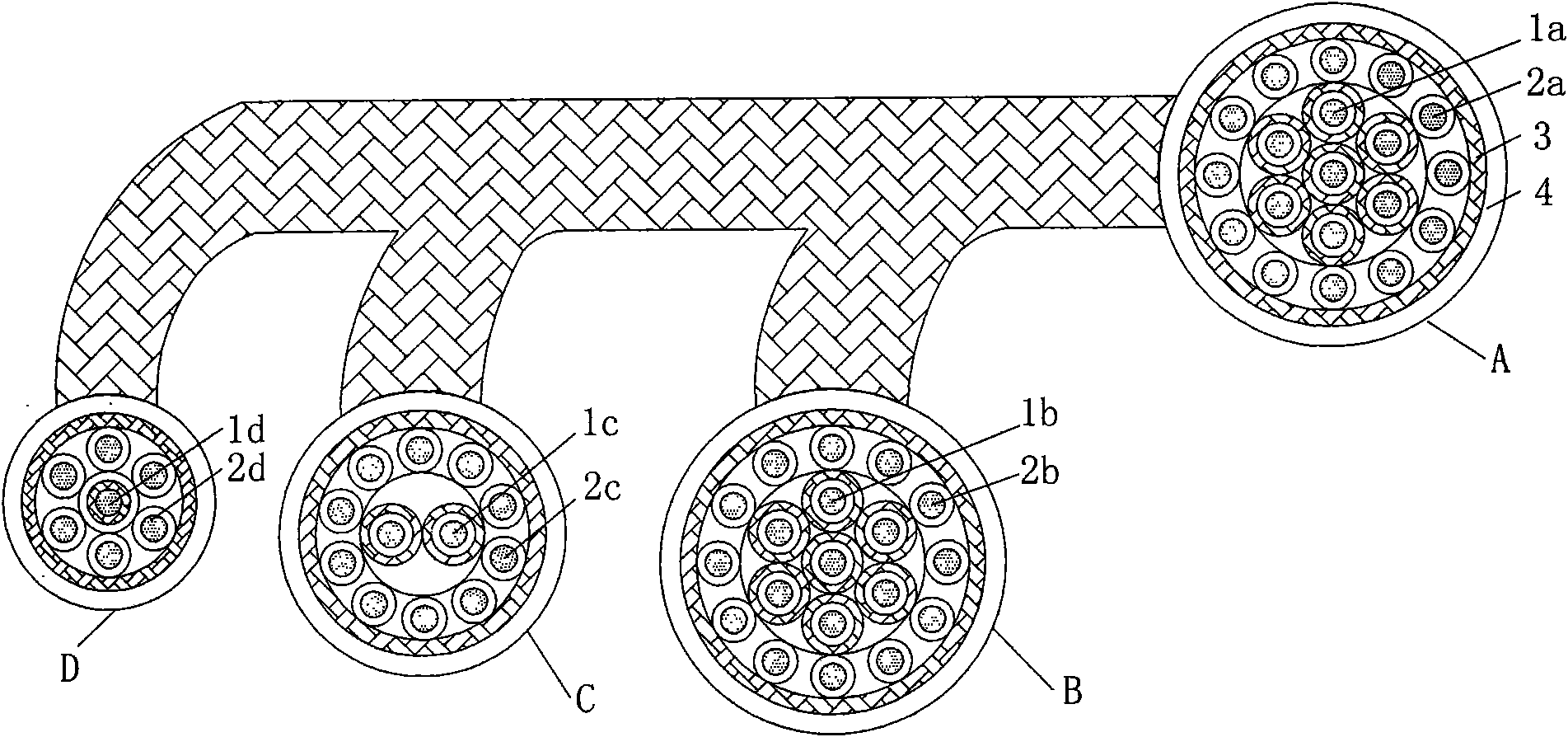

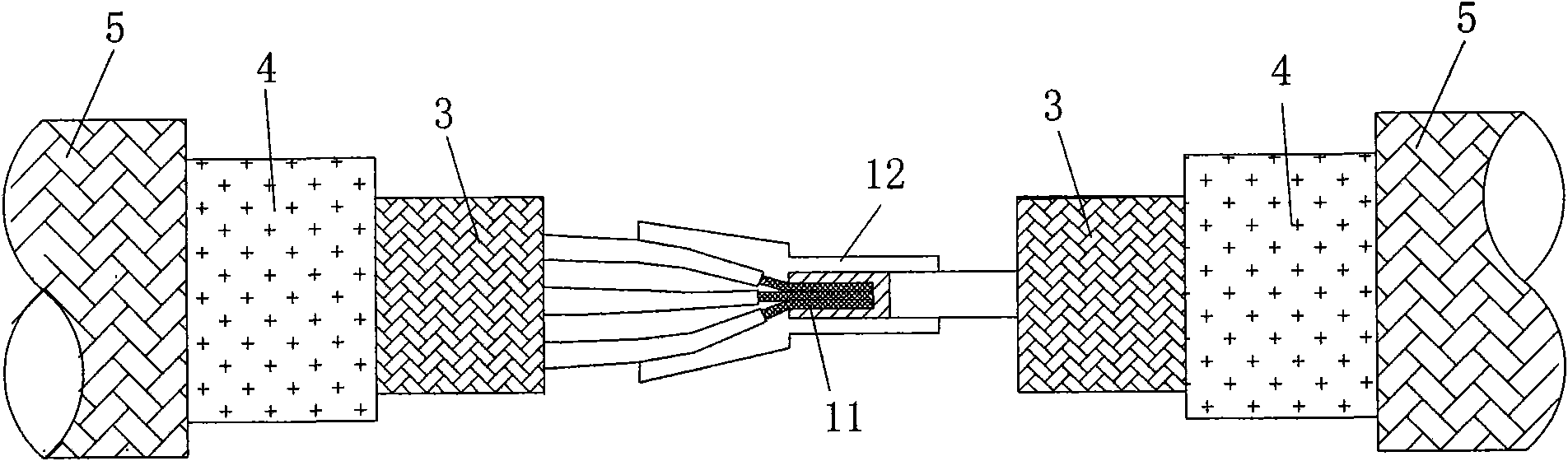

[0025] See figure 1 , figure 2 , Adopts a main control cable and multi-branch cable structure; a main control cable and the conductive core of each branch cable are connected by silver-plated plug, 11, on the outside of the silver-plated connector 11, 180 The temperature-resistant heat-shrinkable tube is the envelope 12, and the outer layer of the envelope 12 sequentially forms a tinned copper wire braided shielding layer, an F4 raw material tape wrapping layer, and a sheath layer made of aramid yarn; a main control cable The cable structure with each branch cable is that the inner ring is the shielded signal wire, the outer ring is the working wire, and the tinned copper wire braided shield layer 3, the F4 raw material tape wrapping layer 4, and the aromatic The sheath 5 is made of Lun silk. The weaving density of the shielding layer formed by weaving tinned copper wire is not less than 90%. The F4 raw material tape is wrapped to play the role of fixing and protecting after tigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com