Multilayer protective low-smoke zero-halogen flame retardant fireproof control cable and manufacture method thereof

A flame-retardant, fire-resistant, control cable technology, applied in cable/conductor manufacturing, insulated cables, cables, etc., can solve the problems of not meeting the use requirements of multi-layer protection, waterproof and termite prevention, poor resistance to mechanical external force, and short service life. , to achieve good resistance to environmental stress cracking, good mechanical properties, and improved service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

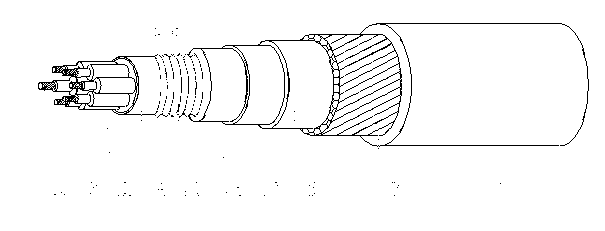

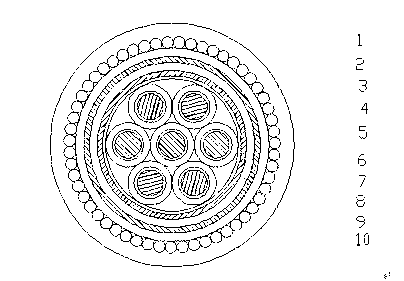

[0016] A multi-layer protective low-smoke, halogen-free, flame-retardant and fire-resistant control cable, including a copper conductor 1, a fire-resistant mica layer 2 and a cross-linked polyethylene insulating layer 3 are arranged on the outside of the copper conductor to form a wire core, and several wire cores form a cable. The cable is provided with polyester film tape 4, metal shielding layer 5, inner sheath I6, inner sheath II7, inner sheath III8, metal armor 9 and outer sheath 10; The fire-resistant mica layer is covered with a calcined mica tape, which can withstand the fire resistance test of 800 ° C; the fire-resistant mica tape is extruded with a 105 ° C irradiated cross-linked polyethylene insulating layer, which improves the temperature resistance level of the cable and makes the resistance required by the standard The temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com