Iron-doped perovskite type negative temperature coefficient thermal sensitive ceramic material and preparation thereof

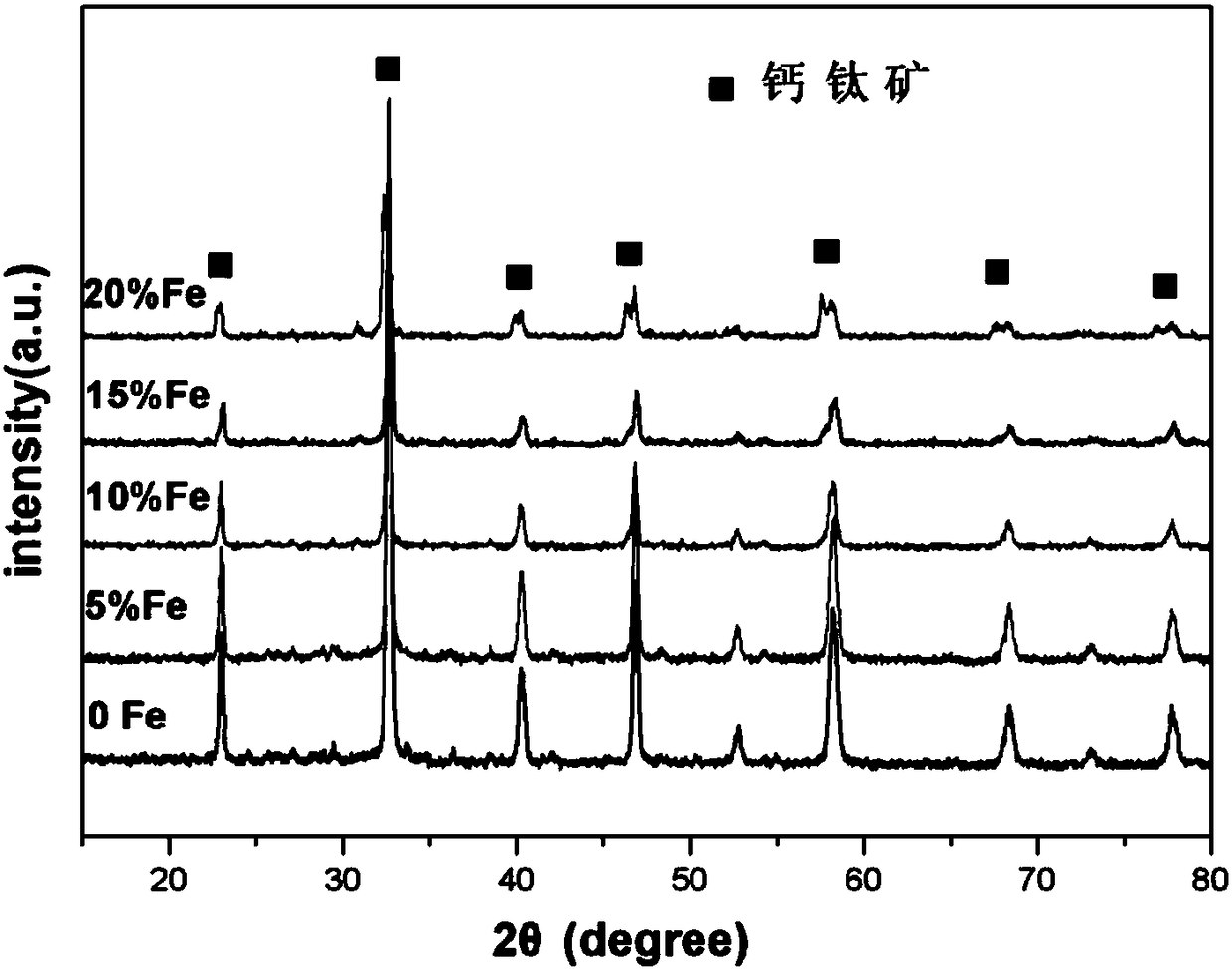

A negative temperature coefficient, perovskite-type technology is applied in the field of preparing iron-doped perovskite-type negative temperature coefficient thermal ceramic materials, which can solve the problems of lack of high precision and low B, and achieve application field expansion and dispersibility. Good, good porcelain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) First use La 2 o 3 、Cr 2 o 3 , Fe 2 o 3 As raw material, according to the perovskite phase (LaCrFe) 2 o 3 The atomic percentage in the middle is La:Cr:Fe=50:45:5 Weigh each oxide and place it in an agate ball milling jar, use agate balls as the ball milling medium and absolute ethanol as the dispersion medium, wet mill for 12 hours, and control the content of each substance in the ball milling jar The mass ratio is: agate ball: material: absolute ethanol = 2.5:1:1, ball milling is carried out alternately clockwise and counterclockwise, with an interval of 30 minutes clockwise and counterclockwise;

[0029] (2) Dry the wet-milled slurry in step (1) in a vacuum drying oven at 80°C, and then grind for 1 hour to obtain a powder;

[0030] (3) Calcining the powder obtained in step (2) at 1000°C for 2 hours to obtain the perovskite phase (LaCrFe) in step a 2 o 3 Powder, the particle size of the powder is 0.154 μm; then it is placed in an agate mortar and ground fo...

Embodiment 2

[0035] (1) First use La 2 o 3 、Cr 2 o 3 , Fe 2 o 3 As raw material, according to the perovskite phase (LaCrFe) 2 o 3The atomic percentage in the middle is La:Cr:Fe=50:40:10 Weigh each oxide and place it in an agate ball mill jar, use agate balls as the ball milling medium and absolute ethanol as the dispersion medium, wet mill for 8 hours, and control the content of each substance in the ball mill jar The mass ratio is: agate ball: material: absolute ethanol = 2.5:1:1, ball milling is carried out alternately clockwise and counterclockwise, with an interval of 30 minutes clockwise and counterclockwise;

[0036] (2) Dry the wet-milled slurry in step (1) in a vacuum drying oven at 80°C, and then grind for 1 hour to obtain a powder;

[0037] (3) Calcining the powder obtained in step (2) at 1100°C for 2 hours to obtain the perovskite phase (LaCrFe) in step a 2 o 3 Powder, the particle size of the powder is 1.534 μm; then it is placed in an agate mortar and ground for 4 hou...

Embodiment 3

[0042] (1) First use La 2 o 3 、Cr 2 o 3 , Fe 2 o 3 As raw material, according to the perovskite phase (LaCrFe) 2 o 3 The atomic percentage in the middle is La:Cr:Fe=50:35:15 Weigh each oxide and place it in an agate ball mill jar, use agate balls as the ball milling medium and absolute ethanol as the dispersion medium, wet mill for 6 hours, and control the content of each substance in the ball mill jar The mass ratio is: agate ball: material: absolute ethanol = 2.5:1:1, ball milling is carried out alternately clockwise and counterclockwise, with an interval of 30 minutes clockwise and counterclockwise;

[0043] (2) Dry the wet-milled slurry in step (1) in a vacuum drying oven at 80°C, and then grind for 1 hour to obtain a powder;

[0044] (3) Calcining the powder obtained in step (2) at 1000°C for 2 hours to obtain the perovskite phase (LaCrFe) in step a 2 o 3 Powder, the particle size of the powder is 1.776 μm; then it is placed in an agate mortar and ground for 4 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com