Multilayer segmented conductor type water-blocking power cable with built-in cable

A technology of split conductors and built-in optical fibers, applied in power cables including optical transmission elements, power cables, bendable conductors, etc., can solve problems such as reducing cable service life, accelerating cable electrical aging, and cable breakdown accidents. The effect of reducing processing difficulty, increasing line loss, and strong water blocking function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the drawings.

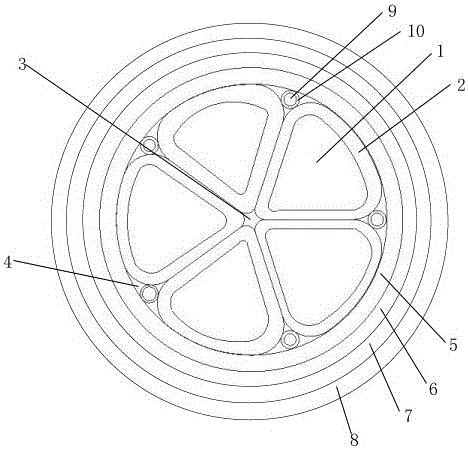

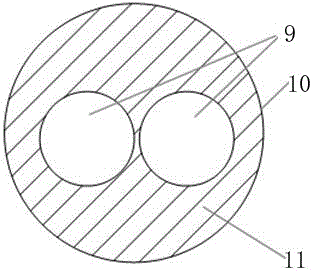

[0021] Such as figure 1 A multi-layer split conductor water-blocking power cable with built-in optical fiber is shown. The center of the cable is provided with a split conductor layer. The split conductor layer is composed of a plurality of divided sector-shaped conductor strands 1 and each sector-shaped conductor strand block. The outer sector-shaped strand water-blocking layer 2 is assembled, and the water-blocking rope 5 is filled in the central gap after the multiple sector-shaped strand water-blocking layers are assembled; each sector-shaped conductor strand is provided with a circle Shaped conductor 3, each round conductor is provided with a circular water blocking layer 4; between the fan-shaped corners of the fan-shaped strand water blocking layer, there are five wire bundles 10 that are directly dragged with the optical fiber unit 9; The gap between the water blocking layer, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com