Patents

Literature

39results about How to "Conductivity recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of hydrogel electrode with high mechanical property and self-healing property

InactiveCN106008799AImprove self-healing abilityConductivity recoveryDiagnostic recording/measuringSensorsWater solubleSelf-healing

The invention discloses a preparation method of a hydrogel electrode with high mechanical property and self-healing property, and belongs to the technical field of biological materials. The preparation method comprises the following steps of firstly, preparing a polydopamine-modified conductive nanometer material in a solution; then, adding a water-soluble monomer into the solution; adding an initiator, a crosslinking agent and an additive, and uniformly mixing; initiating and polymerizing by free radicals to form the hydrogel electrode. The prepared hydrogel electrode has the advantages that the good conductive property and mechanical property are realized; under the non-covalent bond action of polydopamine chains, the self-healing capability is good; the conductivity and mechanical property can be healed by self in short time after accidental damaging; the biocompatibility is good, so that the hydrogel electrode is expected to be applied into modern clinical detection and biomedical measurement.

Owner:SOUTHWEST JIAOTONG UNIV

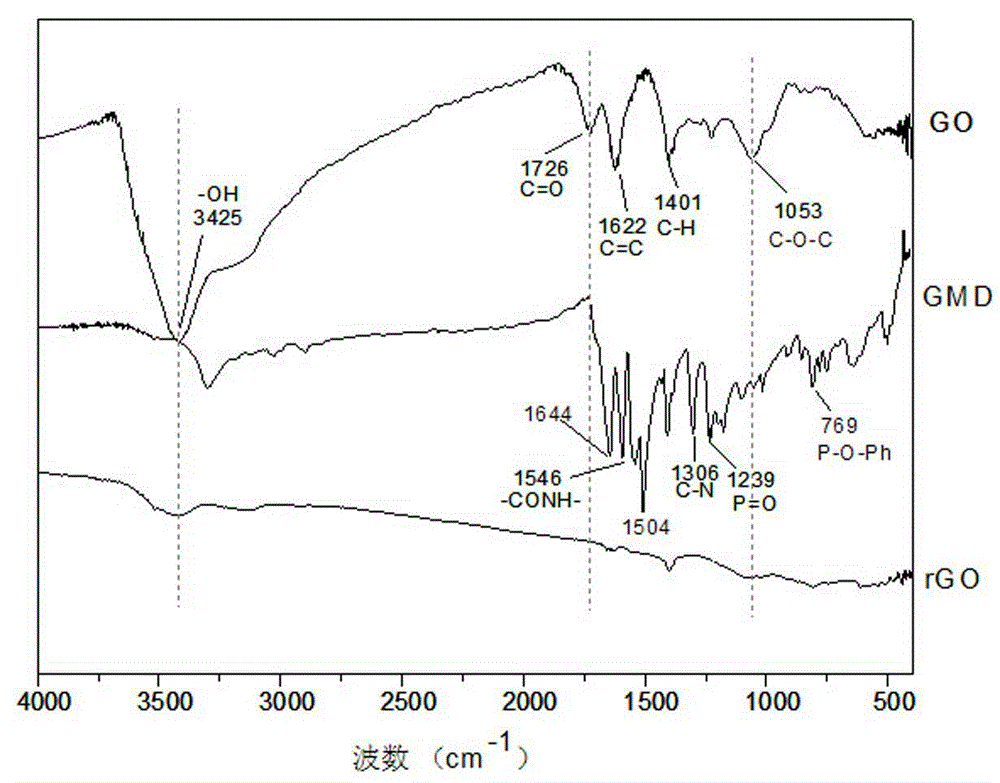

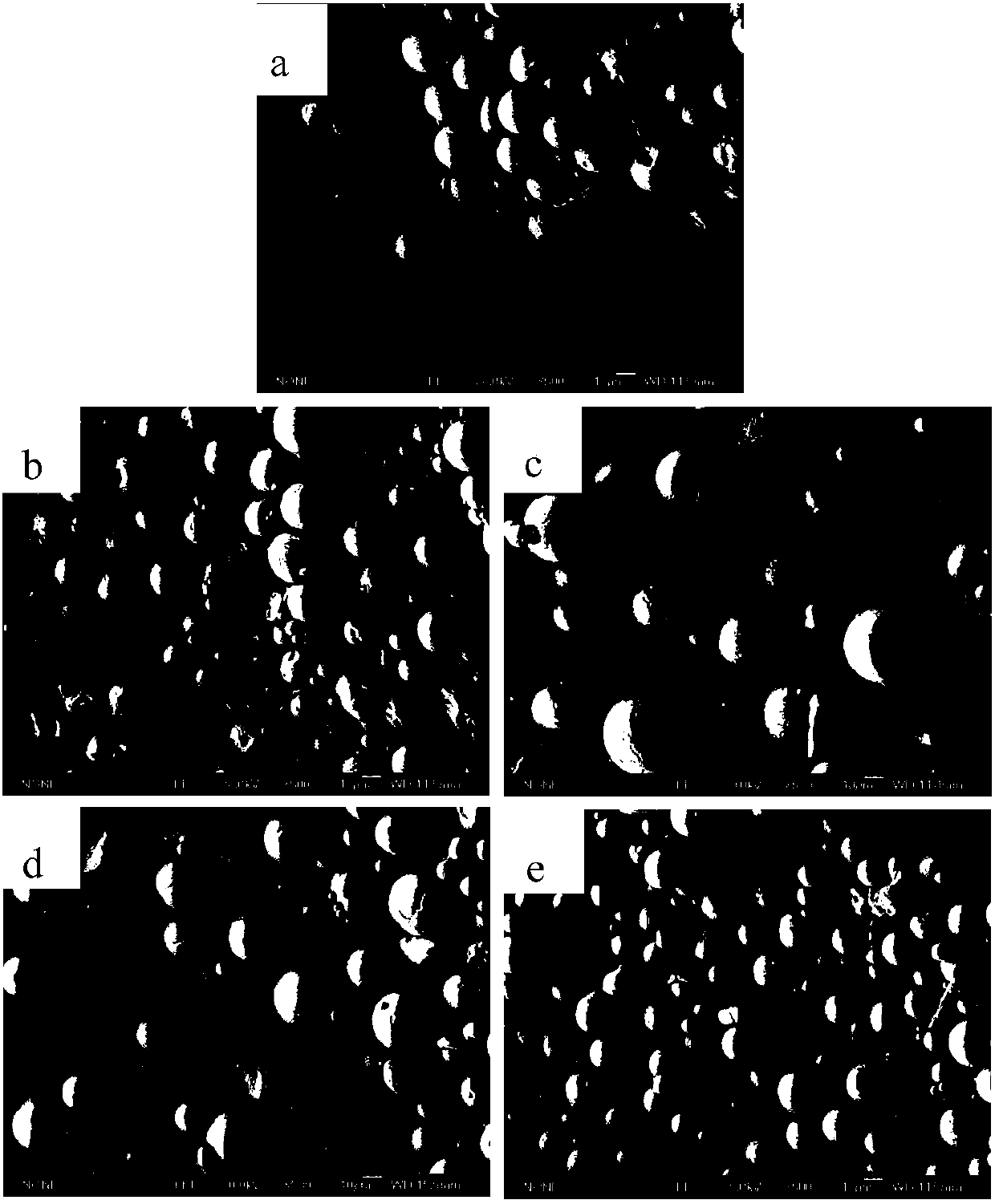

Preparation method and application of modified graphene nano filling material

InactiveCN104804477AConductivity recoveryConductivity is not destroyedPigment treatment with non-polymer organic compoundsPolymer substrateGraphene flake

The invention relates to a preparation method of a modified graphene nano filling material and an application of the modified graphene nano filling material in a nylon 6 material. According to the preparation method, through selection of a reducer and a modifier, optimization of process conditions and the like, graphite oxide is partially reduced, electrical conductivity of the graphite oxide is recovered, and then, residual oxygen-containing groups on the surface of a graphene sheet layer are modified, grafted and endowed with special performance. By comparison with a method adopting first grafting and second reduction in the prior art, compatibility of graphene and polymers can be improved while the graphene conductivity is not damaged, and the modified graphene nano filling material has certain inflaming retarding synergy. When the modified graphene nano filling material is applied to nylon 6, the thermal stability of the nylon 6 material can be improved to a certain extent, the conductivity of a graphene / nylon 6 nanocomposite material is improved by about 4 orders of magnitudes by comparison with that of graphite oxide. Therefore, compared with an existing graphene filling material, the modified graphene nano filling material can improve the conductivity of a polymer substrate, and the anti-static function of the polymer material is improved.

Owner:苏州安鸿泰新材料有限公司

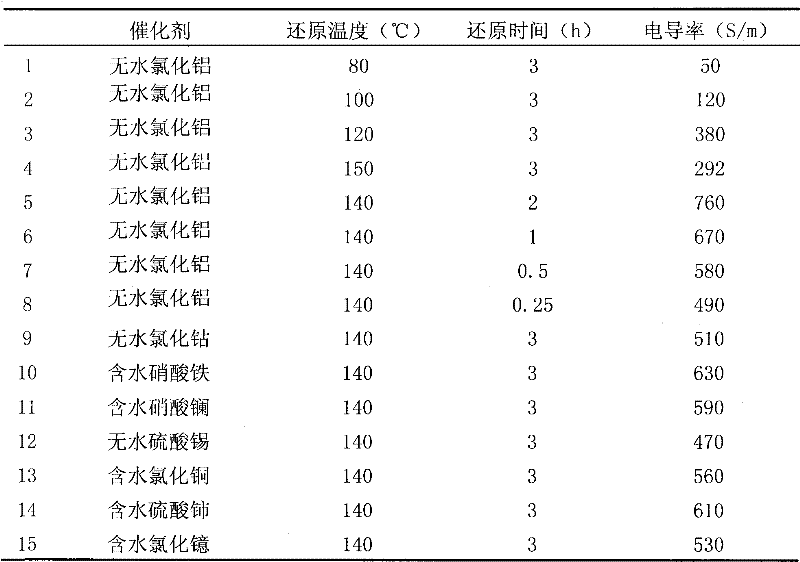

Process for preparing graphene by cryochemical method

ActiveCN102452650AConductivity recoveryLow reduction temperaturePhysical/chemical process catalystsGrapheneEpoxyChemical synthesis

The invention discloses a process for preparing graphene by a cryochemical method, belonging to the technical field of chemical synthesis of graphene. The process uses graphene oxide prepared by chemical oxidation as a raw material, and comprises the step of reducing reaction in which graphene oxide is reduced into graphene. The reducing reaction step implements reduction of the graphene oxide at80-150 DEG C by using sodium borohydride as a reducer by the aid of a catalyst, oxygen-containing functional groups (epoxy group, hydroxy group, carboxy group and carbonyl group) on the graphene oxide are removed, and the electric conductivity of the graphene is thoroughly recovered, thereby preparing the graphene. The process disclosed by the invention is suitable for large-scale industrial production. The process has the advantages of low reduction temperature, mild and controllable reaction, thorough reduction, environment friendliness and the like, and is suitable for industrial production.

Owner:TSINGHUA UNIV

High strength, high electroconductive copper alloy material and preparation tech. thereof

InactiveCN100999793AReduce scatterHigh strengthMetal/alloy conductorsCrystal structureHigh intensity

The present invention discloses one kind of high strength and high conductivity copper alloy material with continuous fiber structure and its preparation process. The copper alloy consists of Be 0.06-0.12 wt %, Ag 0.08-0.15 wt %, and Cu for the rest. The preparation process of the copper alloy includes the following steps: 1. smelting alloy at 1180-1200 deg.c; 2. continuous drawing for directional solidification; and 3. heat treatment at 700-750 deg.c. The copper alloy has homogeneous continuous fibrous crystal structure, cast-state strength up to 240 MPa, strength after machining up to 400 MPa and conductivity up to 86 % IACS. The alloy material may be used in high performance connector, electric switch, IC lead frame, etc.

Owner:焦作市森格高新材料有限责任公司

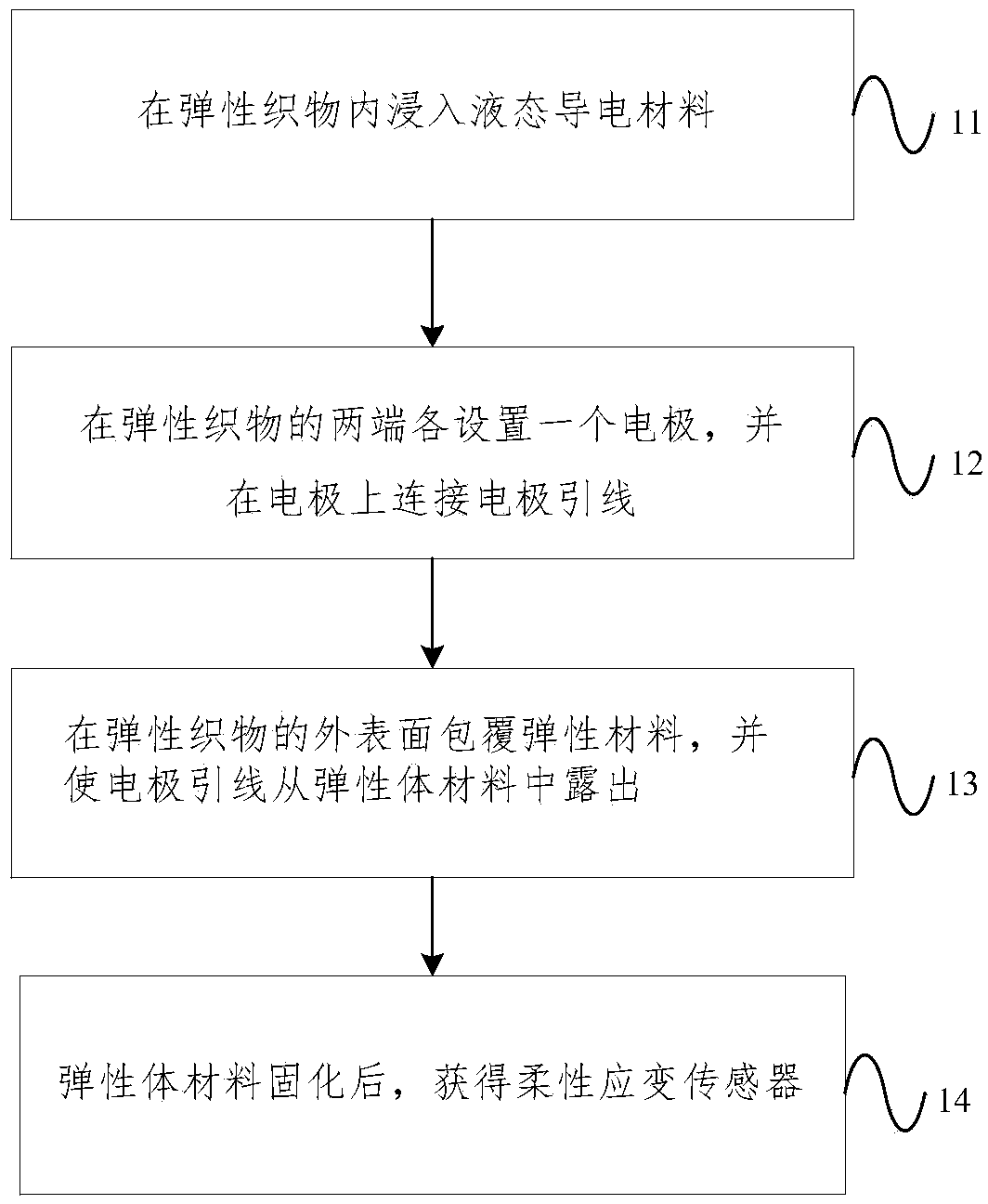

Flexible strain sensor and preparation method

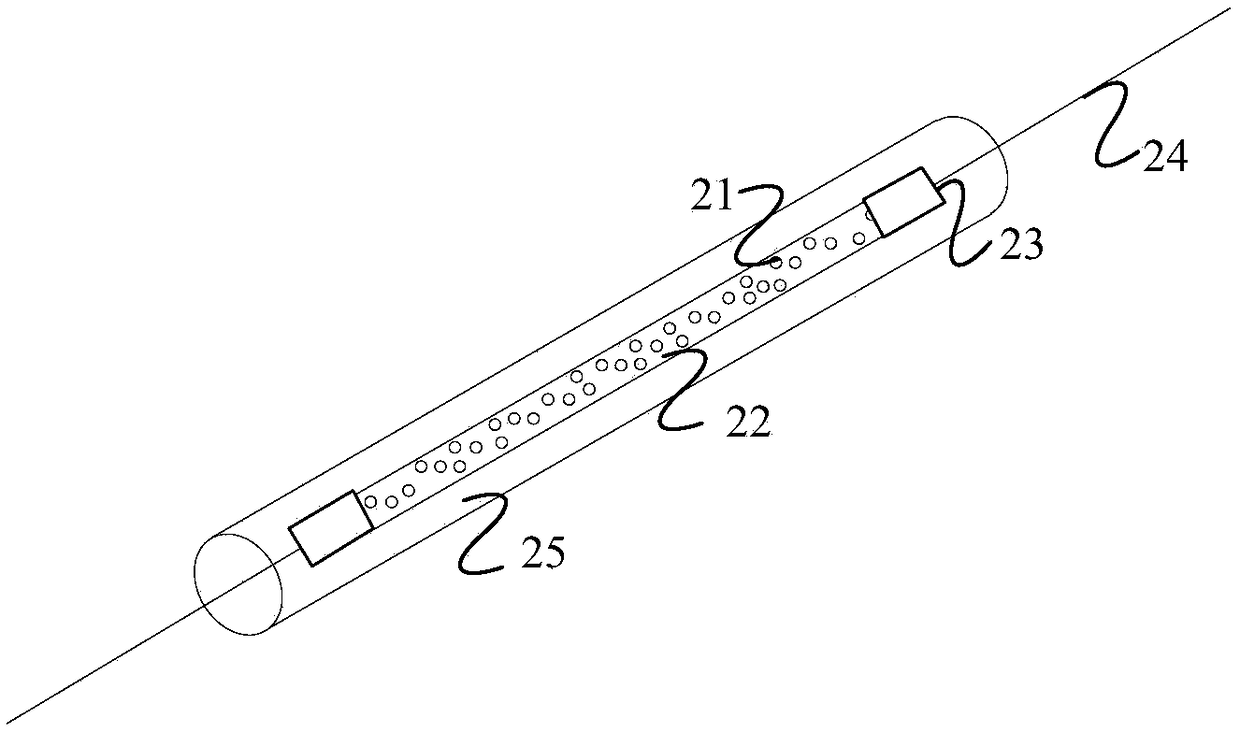

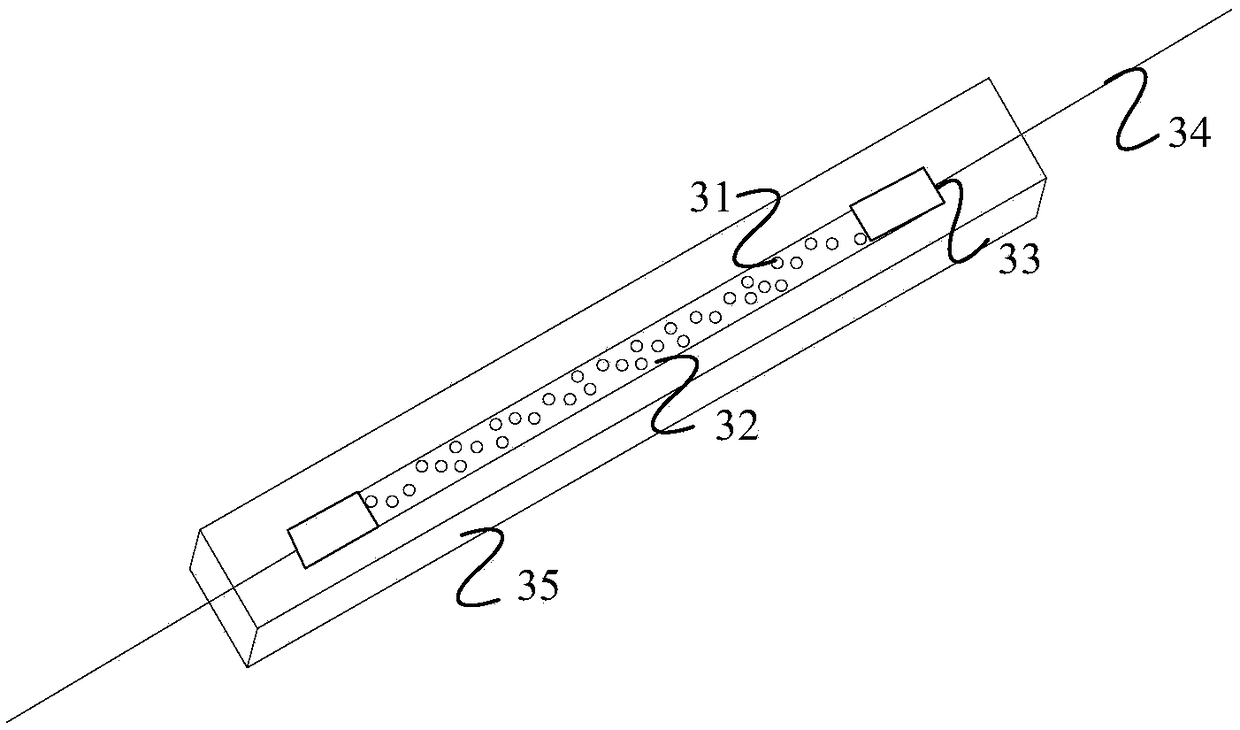

ActiveCN109489539AConductivity recoveryExpand the range of strain perceptionElectrical/magnetic solid deformation measurementElastomerLiquid state

The invention provides a flexible strain sensor and a preparation method thereof. The method includes immersing a liquid conductive material in an elastic fabric; respectively providing two ends of the elastic fabric with an electrode, and connecting electrode leads on the electrodes; coating the outer surface of the elastic fabric with an elastomer material and exposing the electrode leads from the elastomer material; obtaining a flexible strain sensor after the elastomer material is solidified. According to the embodiment of the invention, the elastic fabric is selected as a storage channelof the liquid conductive material, and when tension or pressure is applied to the sensor, the liquid conductive material can flow out of the elastic fabric, so that the electrical conductivity of theelastic fabric can be reduced; after the applied external force is removed, the discharged liquid conductive material flows back to the elastic fabric again, thus the conductivity of the elastic fabric is restored, so that the sensor has the functions of tension sensing and pressure sensing at the same time. Not only does the strain sensing range be widened, but also simplifies the preparation process is simplified.

Owner:BEIJING UNIV OF POSTS & TELECOMM

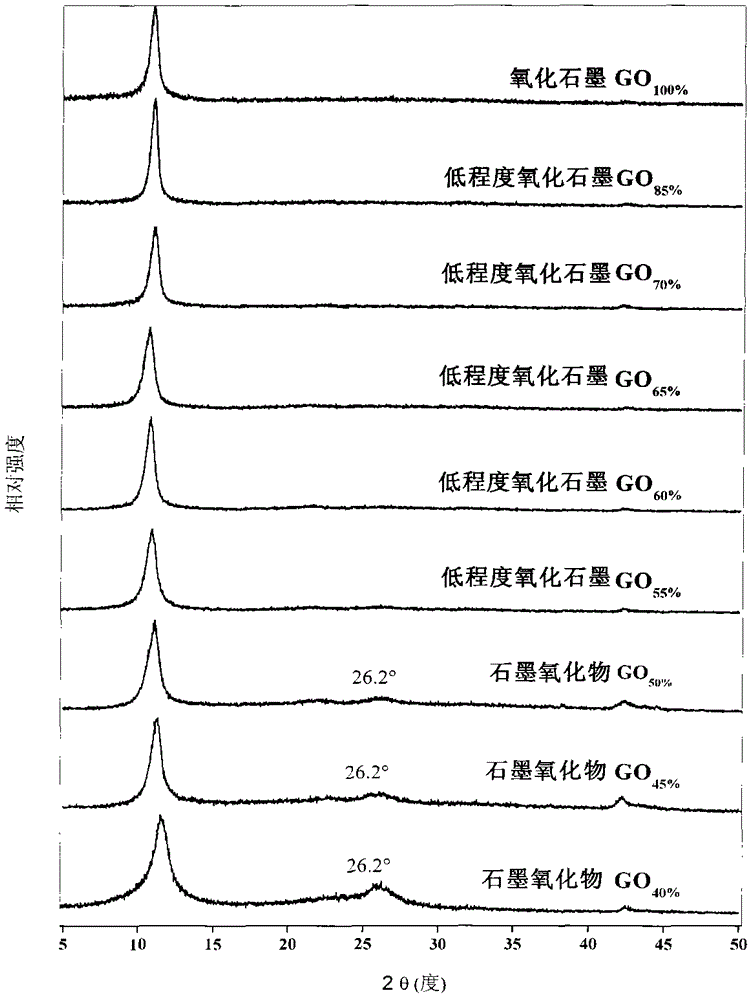

Preparation method of high-electroconductivity graphene

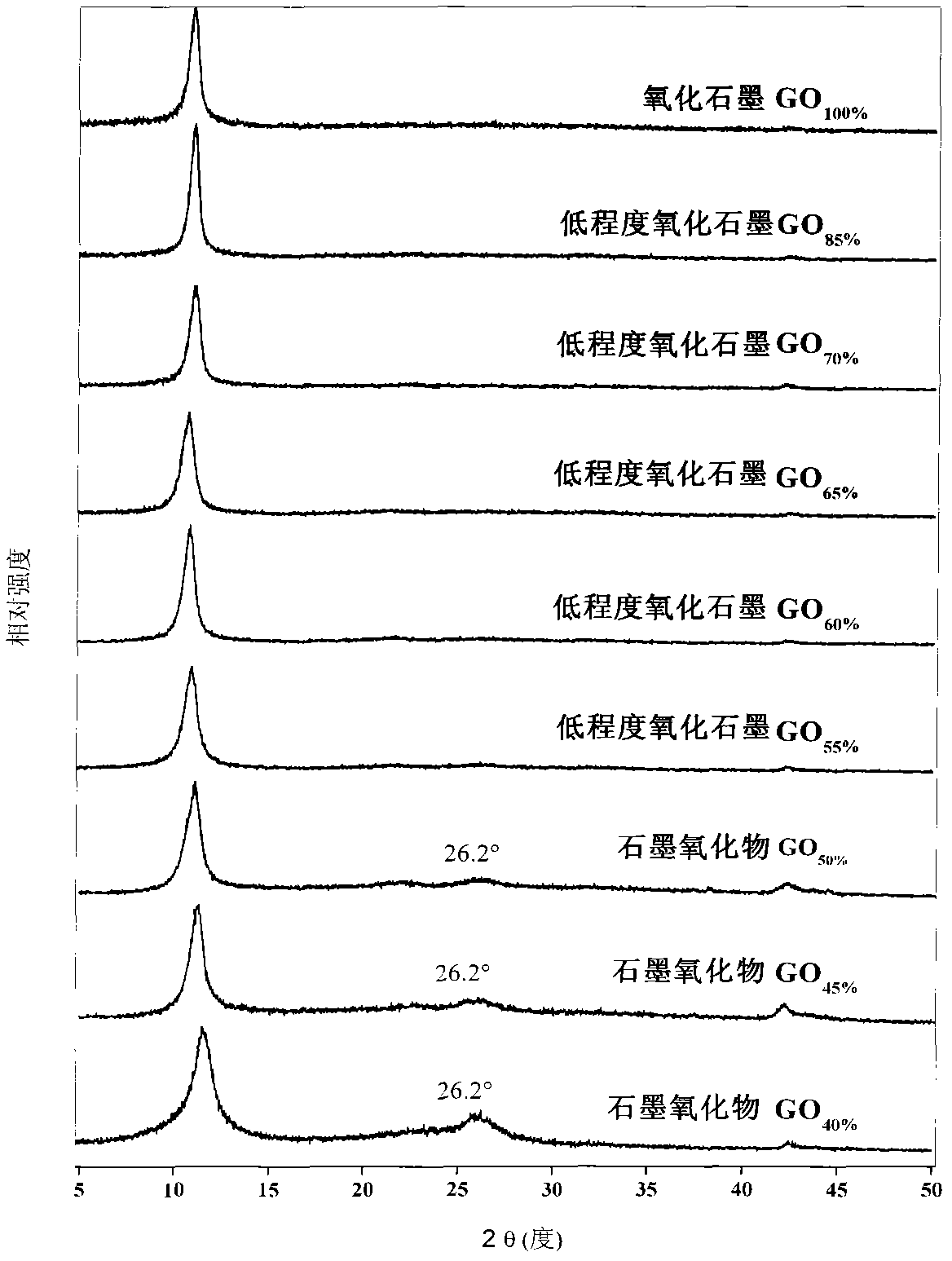

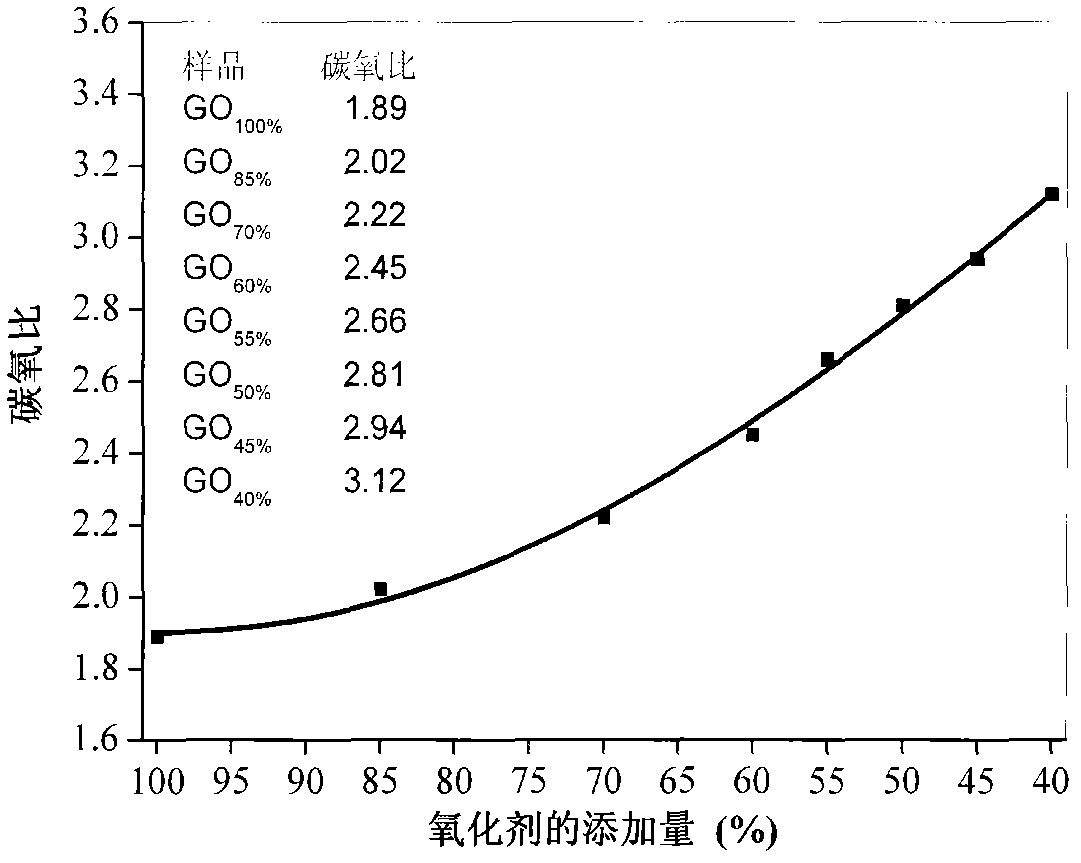

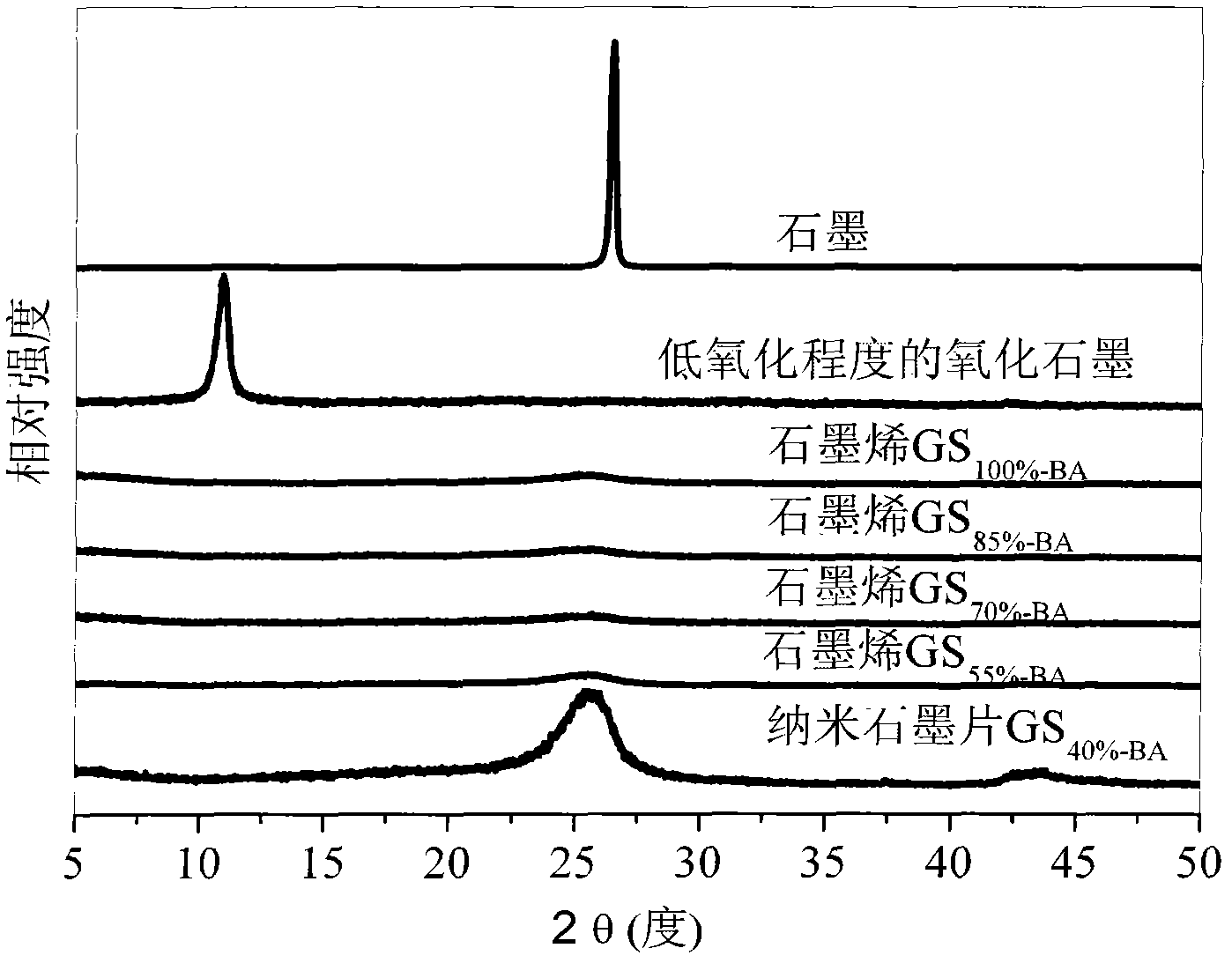

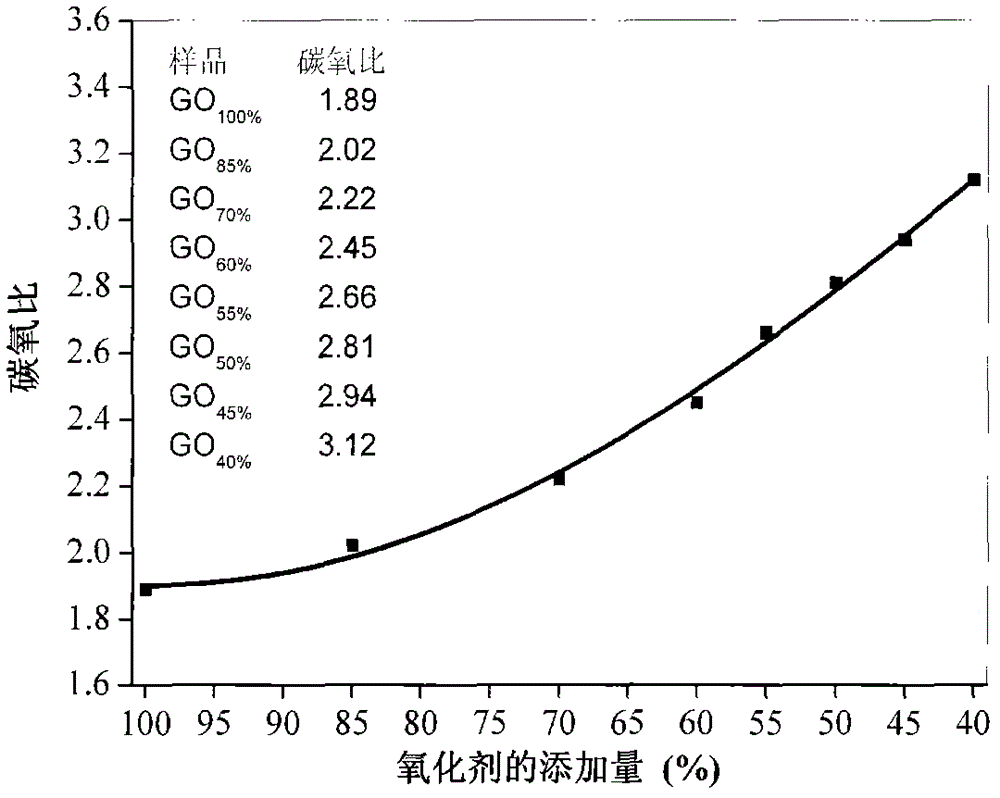

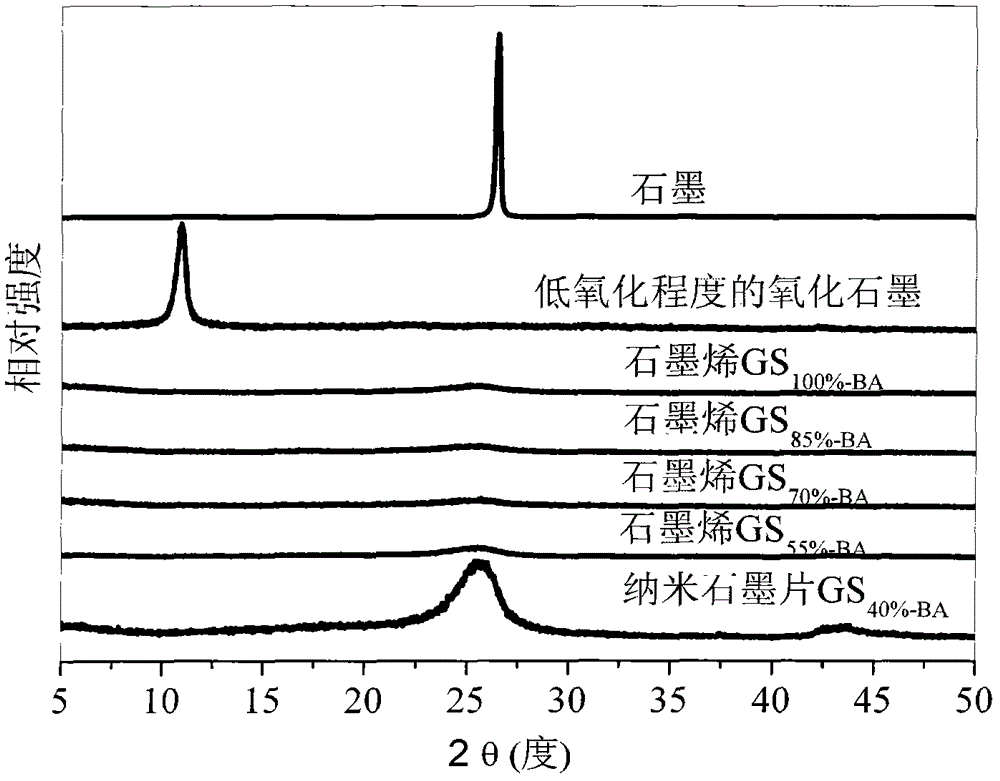

InactiveCN103172055AReduce the degree of oxidationReduce defectsGrapheneX-rayElectromagnetic shielding

The invention discloses a preparation method of high-electroconductivity graphene, belonging to the field of nano graphite electroconductive materials. The method comprises the following steps: dispersing low-oxidation-degree graphite oxide in a solvent containing aromatic alcohol to obtain a low-oxidation-degree graphene oxide dispersion solution, and carrying out solvothermal reduction on the dispersion solution to obtain the high-electroconductivity graphene, wherein the mol ratio of oxygen to carbon in the low-oxidation-degree graphene oxide is lower than 1:2, and the low-oxidation-degree graphene oxide does not have any characteristic diffraction peak in an X-ray diffraction pattern. The preparation method disclosed by the invention has the characteristics of high speed, high efficiency and no toxicity. The graphene disclosed by the invention has high electroconductivity, and is applicable to the fields of battery materials, energy storage materials, electronic devices, electroconductive / thermoconductive materials, electromagnetic shielding materials, antistatic materials and the like.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Method for preparing Cu-Cr alloy powder by means of vacuum gas atomization

The invention discloses a method for preparing Cu-Cr alloy powder by means of vacuum gas atomization. The method comprises the following steps that 1, a smelting chamber and an atomizing chamber in avacuum atomizing furnace are vacuumized; 2, Cu and Cr are put into a graphite crucible in the smelting chamber, N2 is fed into the smelting chamber to serve as protective gas, the graphite crucible isheated, an alloy solution is obtained, heat preservation is conducted to enable the superheat degree of the alloy solution to reach 50 DEG C to 250 DEG C, and then atomization is prepared and started; and 3, the atomization pressure is adjusted to range from 4 MPa to 6 MPa, the alloy solution obtained in the second step is sprayed into the atomizing chamber through a graphite nozzle, atomizationcrushing is conducted, and then the Cu-Cr alloy powder is obtained. The oxygen content of the obtained powder is lower than 0.08% and much smaller than that of powder obtained through ordinary atmospheric atomization; and in the vacuum gas atomization process, the yield of fine powder smaller than 50 micrometers can reach 60% or above.

Owner:XIAN UNIV OF TECH

Novel high-strength heat-resistant aluminium-alloy conductor

InactiveCN103820680AImprove performanceImprove heat resistanceSingle bars/rods/wires/strips conductorsMetal/alloy conductorsHeat resistanceManganese

The invention discloses a novel high-strength heat-resistant aluminium-alloy conductor. According to the invention, commercial-purity aluminium is used as a raw material, and traces of boron, antimony, manganese, copper and zirconium elements are added at 800+ / -10 DEG C. the novel high-strength heat-resistant aluminium-alloy conductor comprises components of, by weight, 0.01-0.30% of boron, 0.05-0.60% of antimony, 0.02-0.80% of manganese, 0.05-2.30% of copper, 0.05-0.90% of zirconium and the balance pure aluminium and unavoidable impurities. The novel high-strength heat-resistant aluminium-alloy conductor is manufactured by a conventional alloy smelting technology. The prepared aluminium-alloy conductor has high strength, good heat resistance and excellent conductivity. Comprehensive performance of the conductor is raised effectively. The aluminium-alloy conductor can be widely applied in national electric transmission lines, especially a long-span long-distance transmission and transformation project.

Owner:GUANGXI DONGXING DINGKANG PLASTIC IND

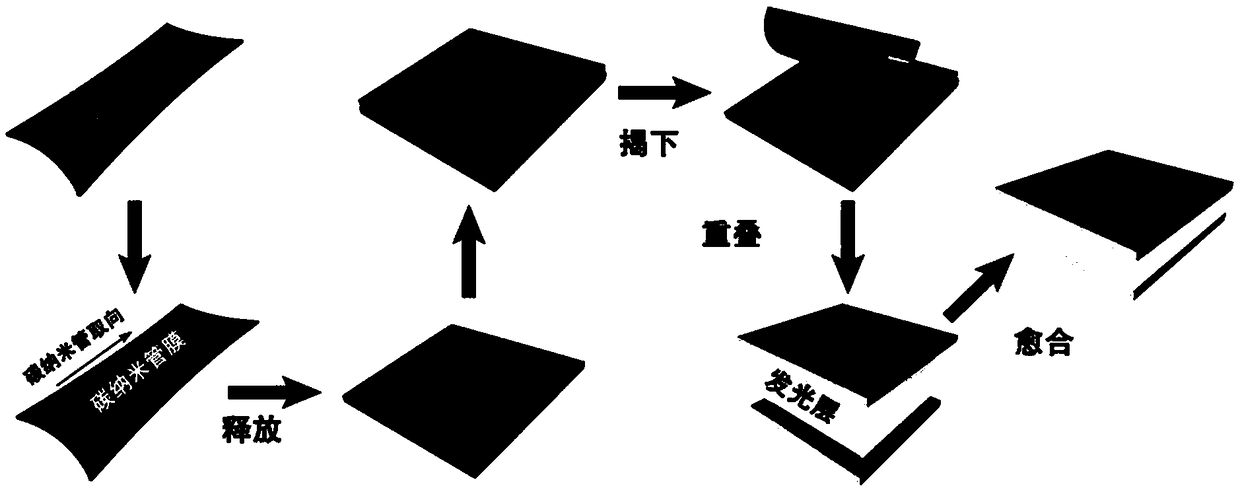

Self-healing stretchable light-emitting device and preparation method thereof

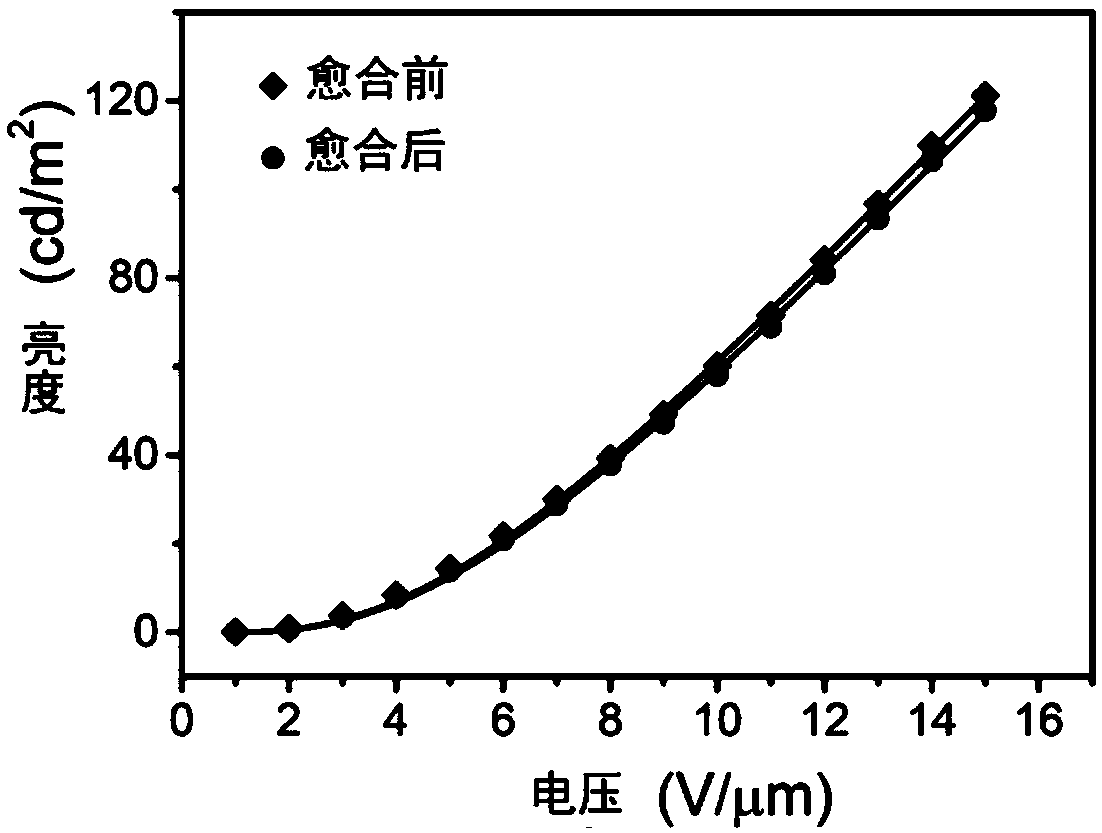

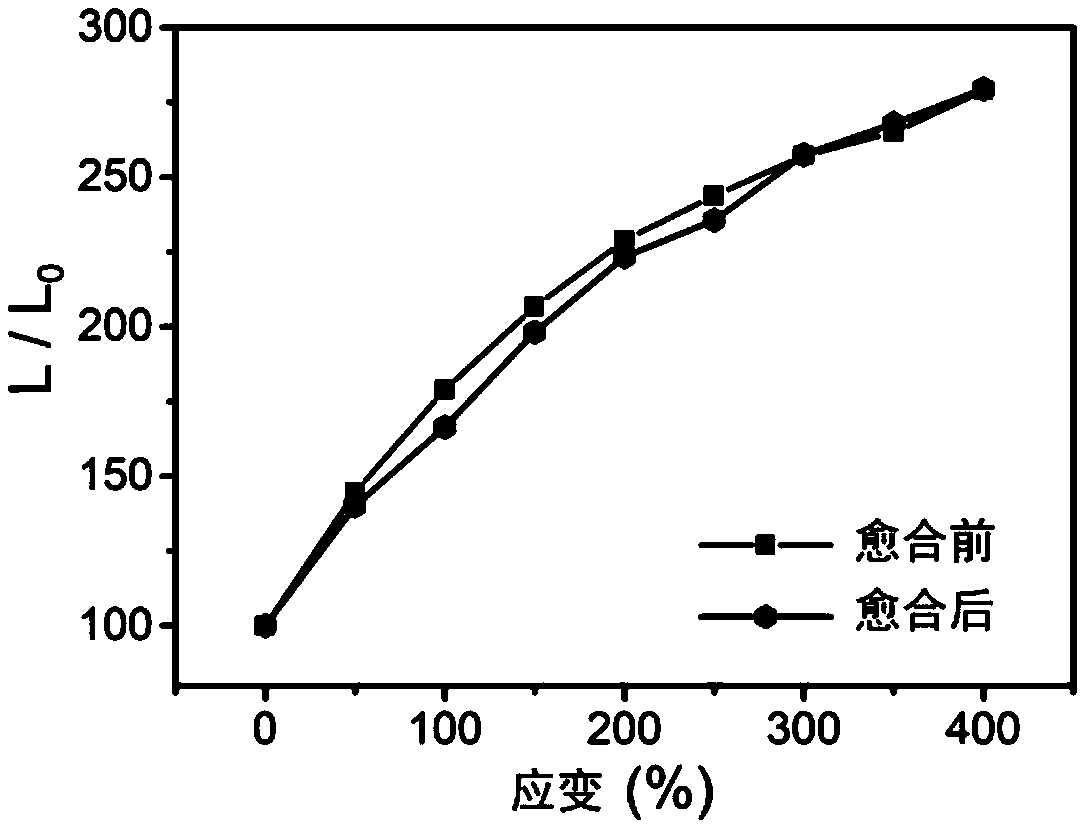

ActiveCN108847454AStable resistanceReduce brightnessSolid-state devicesSemiconductor/solid-state device manufacturingSelf-healingCarbon nanotube

The invention belongs to the intelligent electronic device technical field and relates to a self-healing stretchable light-emitting device and a preparation method thereof. The method of the inventionincludes the following steps that: a light-emitting active layer having a self-healing function and a transparent electrode are prepared by using transparent self-healing polyurethane elastomer as amatrix material; the light-emitting active layer is made of electroluminescent powder, and the unique dispersion structure of the electroluminescent powder allows the healing of the light-emitting layer to be achieved by the healing of the self-healing matrix; and the electrode is made of an oriented carbon nanotube array, and a pre-stretching method is used to make the electrode material have a wrinkle structure when the electrode is in an un-stretched state, such kind of structure can ensure the stability of the resistance of the device during a stretching process, and the interaction of Vander Waals' forces between carbon nanotubes allow the conductivity of the electrode to be better restored. The maximum brightness of the device can achieve 121.2 cd / m<2>; the maximum stretching quantity of the device can achieve 400%; the stability of the device is excellent when the device is stretched cyclically under 200% of strain; and the device can withstand 10 times of cutting and can be finally healed each time with the brightness of the device not attenuated.

Owner:YANTAI TAYHO ADVANCED MATERIALS CO LTD

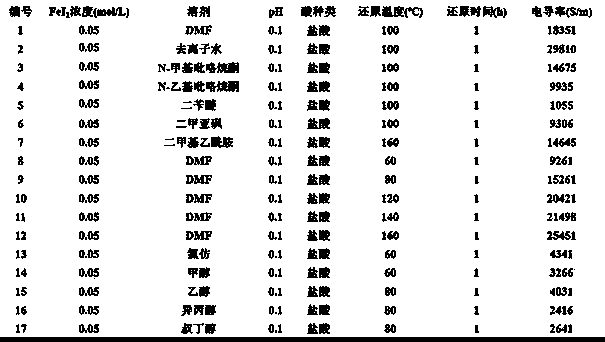

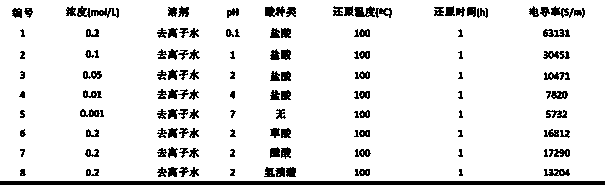

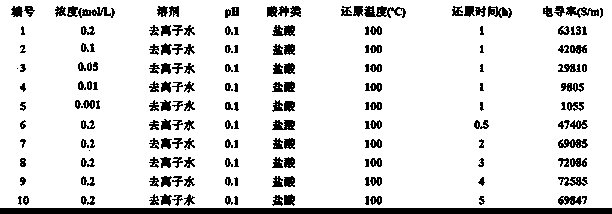

Method for preparing graphene film through reduction of ferrous iodide acid solution

The invention discloses a method for preparing a graphene film through reduction of a ferrous iodide acid solution, belonging to the technical field of chemical synthesis of graphene. A graphene oxide prepared through chemical oxidation is taken as a raw material, and the method comprises a reduction reaction step of reducing the graphene oxide into graphene, wherein the ferrous iodide solution is taken as a reducing agent in the reduction reaction step, rapid reduction of the graphene oxide is realized by controlling the solution concentration, reduction time, reduction temperature, types and pH values of solvents and types of inorganic acids used for pH regulation, oxygen-containing functional groups such as epoxy group, hydroxyl, carboxyl and carbonyl on the graphene oxide are removed, the conductivity of the graphene is completely restored, and the graphene film is prepared. The method is a method for preparing graphene through a low-temperature chemical method suitable for large-scale industrial production. The method has the advantages of low reduction temperature, mild and controllable reactions, complete reduction, environment friendliness and suitableness for industrial production.

Owner:SICHUAN INST OF MATERIALS & TECH

Copper alloy for high-strength and high-conductivity lead and preparation method of copper alloy

ActiveCN104328304AImprove conductivityConductivity recoverySolid-state devicesSemiconductor devicesIngotCopper alloy

The invention discloses a copper alloy for a high-strength and high-conductivity lead and a preparation method of the copper alloy, belonging to the technical field of copper alloy preparation. The copper alloy for the high-strength and high-conductivity lead is prepared from the following components in percentage by weight: 0.05% of lead, 0.7% of iron, 0.04% of magnesium, 0.4-0.5% of chromium, 0.55-0.70% of zirconium and the balance of copper. The preparation method comprises the following steps: mixing and smelting the above components in percentage by weight, casting ingots, thermal-rolling, performing solid solution, cold-rolling and pickling, thereby obtaining the copper alloy. The conductivity of the copper alloy is 91-95% IACS, the ductility of the copper alloy is 12-20%, and the tensile strength of the copper alloy is 620-655MPa. The requirements on properties of a copper alloy material for leads of the electronic industrial field can be relatively well met, and the alloy copper can be also used in the field of copper alloy materials with high requirements on conductivity and ductility and further has the advantages of simple process and low cost.

Owner:SHENZHEN SHENZHOU CABLE

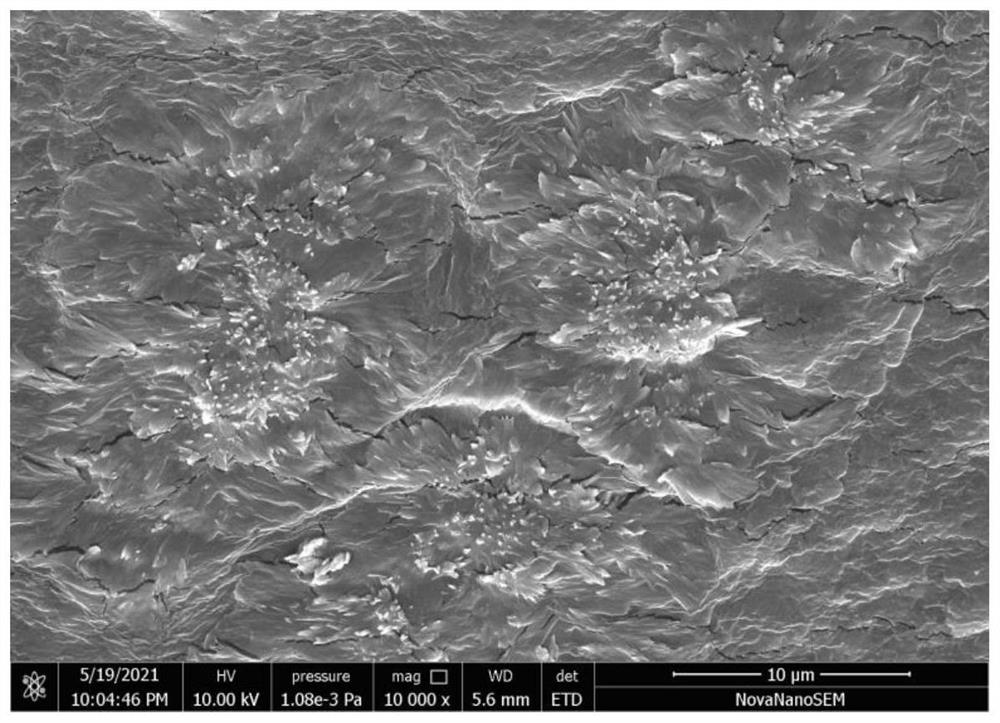

Method for inducing fusion sintering of liquid metal micro-nano liquid drops by utilizing solvent evaporation

ActiveCN111863341AImprove sintering performanceEffective sinteringApparatus for heat treatmentApparatus for manufacturing conducting/semi-conducting layersSolvent evaporationLiquid state

The invention relates to the technical field of liquid metal sintering fusion, and particularly relates to a method for inducing liquid fusion sintering of metal micro-nano liquid drops through solvent evaporation. The method comprises the steps of evaporating and drying a liquid metal micro-nano droplet dispersion liquid or a liquid metal micro-nano droplet dispersion liquid containing an auxiliary agent, and realizing sintering fusion by utilizing capillary acting force generated in the evaporation and drying process. The method for sintering the liquid metal micro-nano liquid drops has theadvantages of being easy and convenient to operate, low in cost, capable of being achieved at normal temperature and normal pressure and the like, and can be applied to the fields of circuit packaging, the 3D printing electronic technology, sensors, drivers, electromagnetic shielding and the like.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Method for preparing graphene and fluorine co-doped tin oxide transparent conductive film

InactiveCN109524170AImprove conductivityImprove stabilityConductive layers on insulating-supportsCable/conductor manufactureChemical compositionTransmittance

The invention relates to a method for preparing a graphene and fluorine co-doped tin oxide transparent conductive film. The method is characterized in that the chemical composition of the graphene andfluorine co-doped tin oxide transparent conductive film is SnO2-x+zFxCy, wherein x=0.1 to 0.5, y=0.2 to 1, z=0.05y to 0.1y, the preparation process includes in-situ reduction of graphene oxide, hybrid sol formulation, hybrid film formation and hybrid film postprocessing, and transparent conductive film glass has the film thickness of 500 to 1200 nm, the visible light transmittance of 82% to 88% and the square resistance of 5 to 20 Omega / square. According to the method, the electrical conductivity, stability, toughness and hydrophobicity of the tin oxide transparent conductive film are improved. The transparent conductive film prepared by using a sol-gel method has the advantages of simple process and equipment, safety and environmental protection, and easy realization of industrialization.

Owner:TIANJIN VOCATIONAL INST

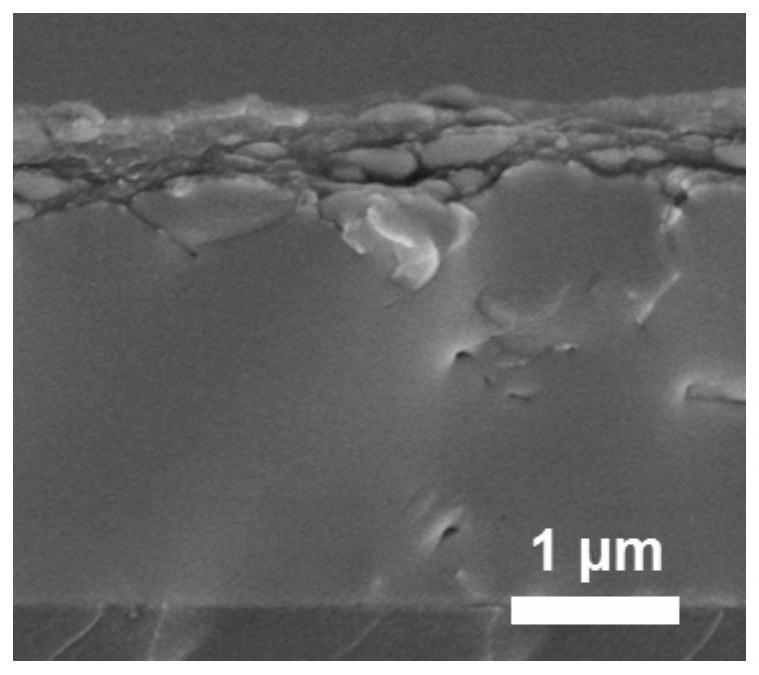

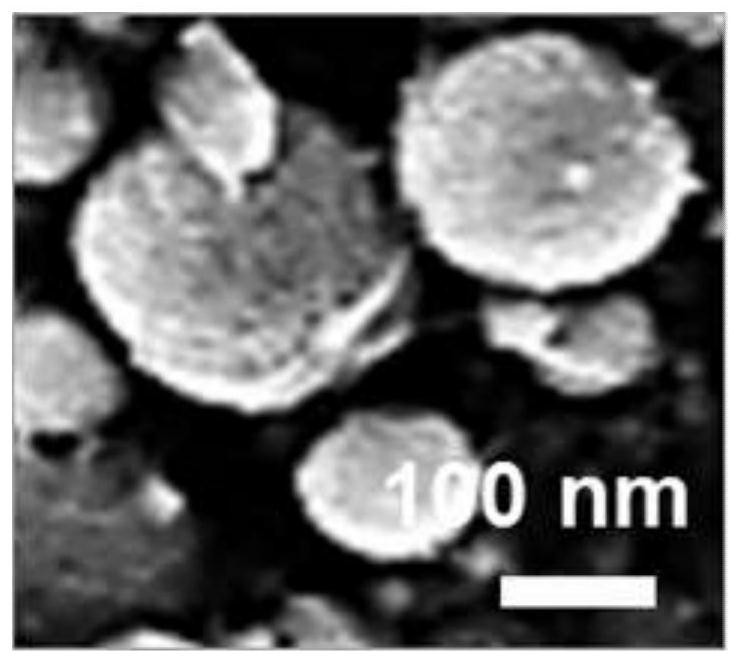

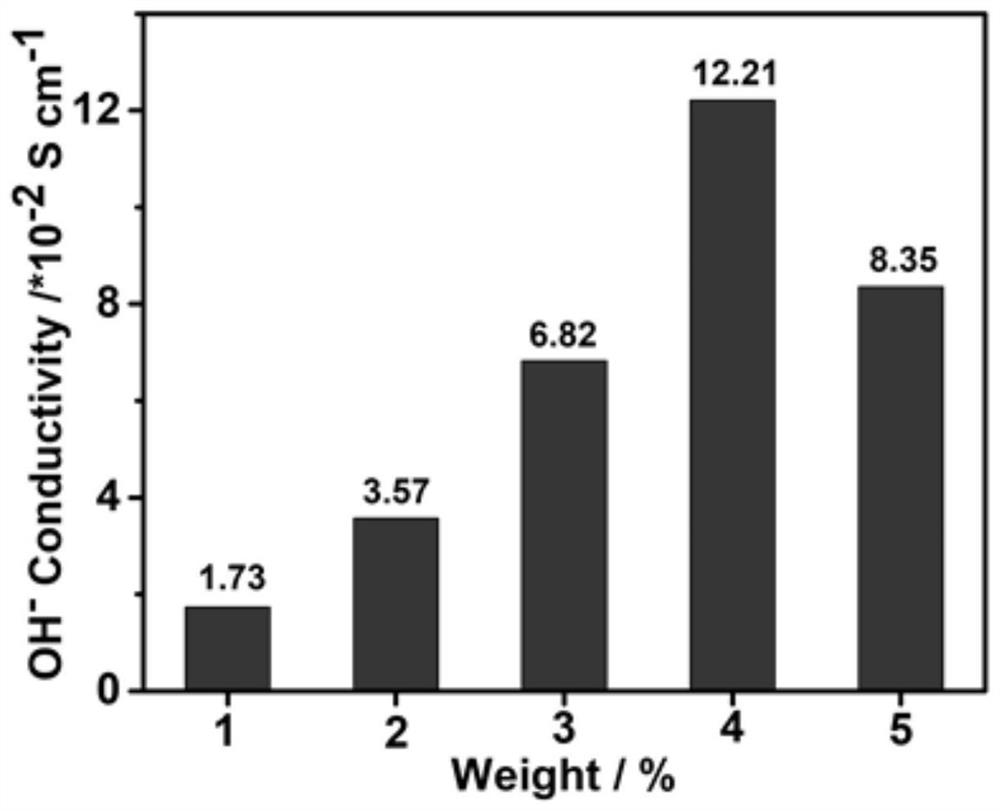

Polymer-metal-MOF-ionic liquid composite alkaline anion exchange membrane and preparation method thereof

PendingCN114292425AMake up for the shortcomings of poor film formationExtended service lifeFuel cellsPhysical chemistryCrystalline materials

According to the polymer-metal-MOF-ionic liquid composite alkaline anion exchange membrane and the preparation method thereof, from the perspective of structural design, the mechanical advantages of a polymer, the structural advantages of MOFs and the combined action of multiple materials are integrated, high-alkali-resistance porous MOF serves as a container, an OH-conduction carrier is introduced into holes of the container, and high OH-conduction is achieved; a high-molecular polymer monomer is introduced as a film forming substrate, the mechanical property of the film is regulated and controlled, the defect that the film forming property of an MOF crystalline material is poor is overcome, and the high OH <-> conductivity with the highest OH <-> conductivity reaching 0.122 S / cm is obtained. And the material can realize rapid recovery of OH <-> conduction performance through a simple copper ion soaking method, breaks through the fate that the performance of an alkaline anion exchange membrane is attenuated along with time and is disposable, and is expected to prolong the service life of a fuel cell.

Owner:YANCHENG INST OF TECH

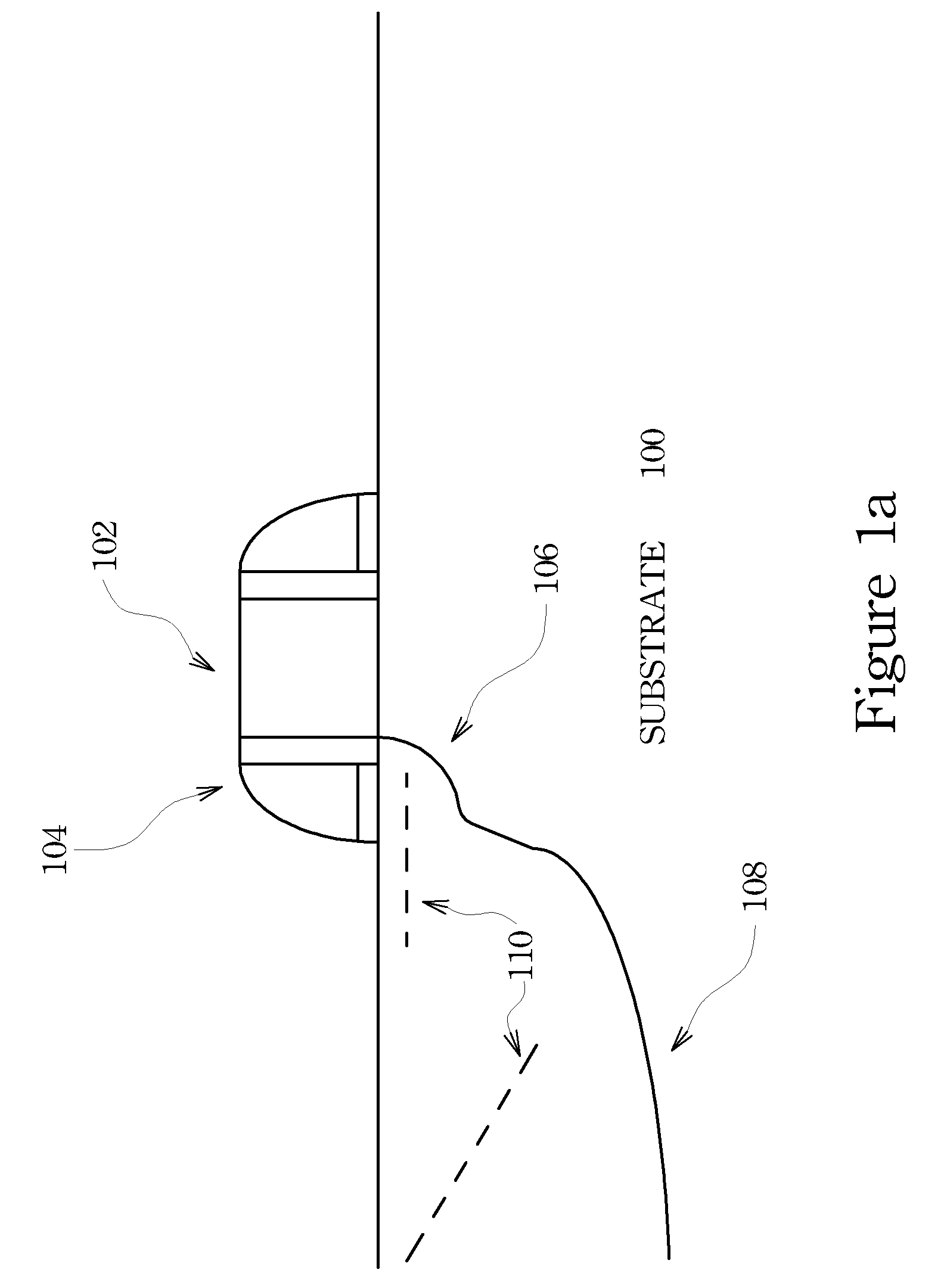

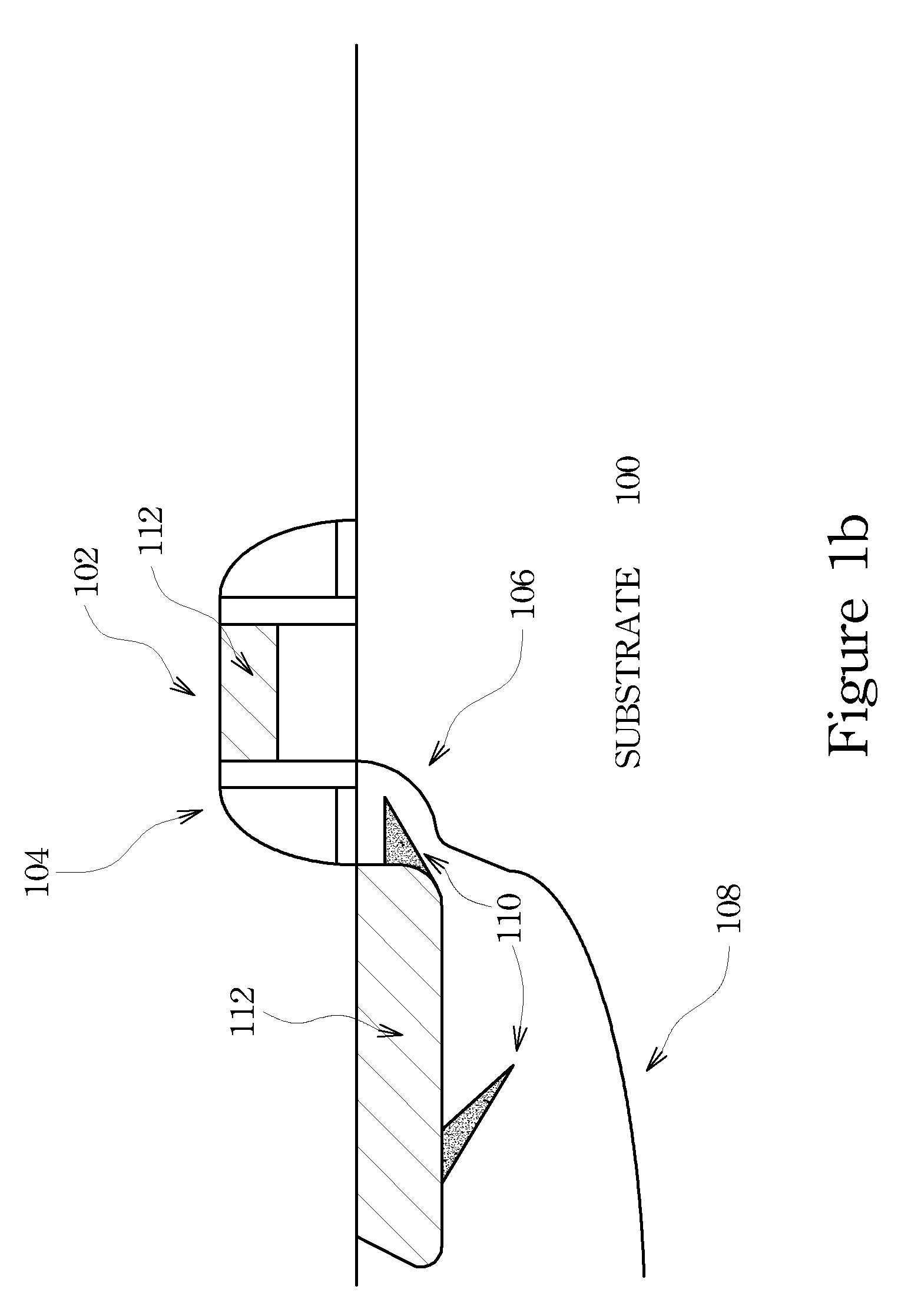

Flash anneal for a PAI, NiSi process

ActiveUS7795119B2Pipe defects and spike structures may be reduced or eliminatedConductivity recoveryTransistorSemiconductor/solid-state device manufacturingMOSFETEngineering

A structure and a method for mitigation of the damage arising in the source / drain region of a MOSFET is presented. A substrate is provided having a gate structure comprising a gate oxide layer and a gate electrode layer, and a source and drain region into which impurity ions have been implanted. A PAI process generates an amorphous layer within the source and drain region. A metal is deposited and is reacted to create a silicide within the amorphous layer, without exacerbating existing defects. Conductivity of the source and drain region is then recovered by flash annealing the substrate.

Owner:TAIWAN SEMICON MFG CO LTD

Preparation method of copper alloy

ActiveCN106498227AImprove conductivityConductivity recoveryConductive materialSolid-state devicesIngot castingSolid solution

The invention discloses a preparation method of a copper alloy and belongs to the technical field of copper alloy preparation. The copper alloy contains the following components in percentage by weight: 0.05% of Pb, 0.7% of Fe, 0.04% of Mg, 0.4-0.5% of Cr, 0.55-0.70% of Zr and Cu in balancing amount. According to the method, the copper alloy is prepared by performing mixed melting, ingot casting, hot rolling, solid solution, cold rolling and pickling treatment of the components in percentage by weight. The electric conductivity of the copper alloy is 91-95% IACS, the elongation of the copper alloy is 12-20%, and the tensile strength of the copper alloy is 620-655 MPa. The copper alloy can well meet the performance requirements of copper alloy materials for wires in the field of electronic industry and can also be used in fields where high-conductivity high-elongation copper alloy materials are required. The preparation method has the advantages of simple process and low cost.

Owner:NINGBO ZHANCI NEW MATERIAL TECH CO LTD

Copper alloy for high conductivity and high elongation wire and preparation method thereof

The invention discloses a copper alloy for a wire with high conductivity and high elongation rate and a preparation method thereof, belonging to the technical field of copper alloy preparation. The copper alloy material for the wire contains 0.04-0.06% lead by weight, 0.6-0.7% iron, 0.06% cerium and the rest is copper. The preparation method is that the components in the above weight ratio are mixed and smelted, ingot-cast, hot-rolled, solutionized, cold-rolled and pickled. Its electrical conductivity is 97-102% IACS, and its elongation is 15-19%. It can better meet the performance requirements of copper alloy materials for wires in the field of electronics industry, and can also be used in the field of copper alloy materials that require high conductivity and high elongation. And it has the advantages of simple process and low cost.

Owner:南通海腾铜业有限公司

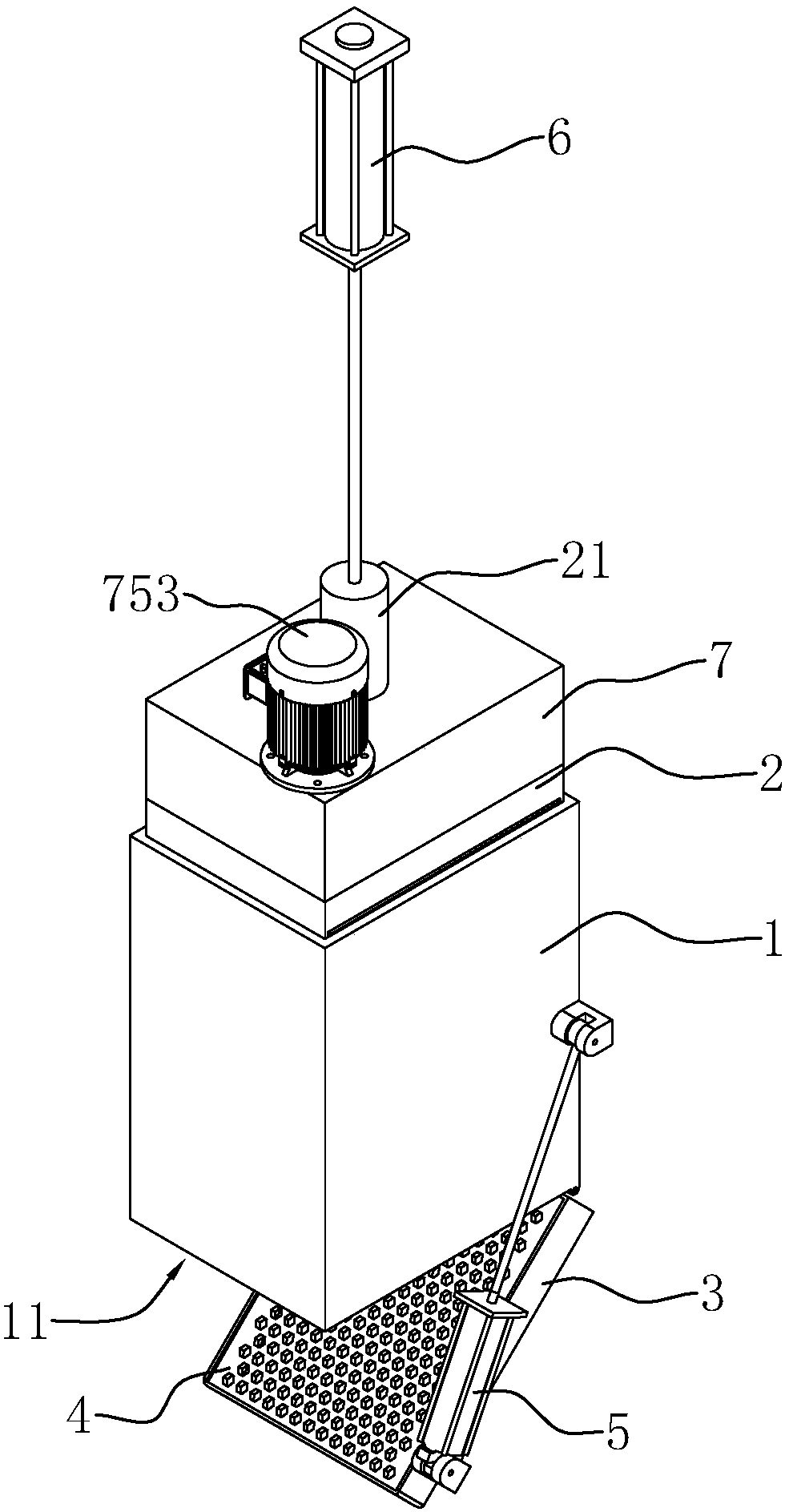

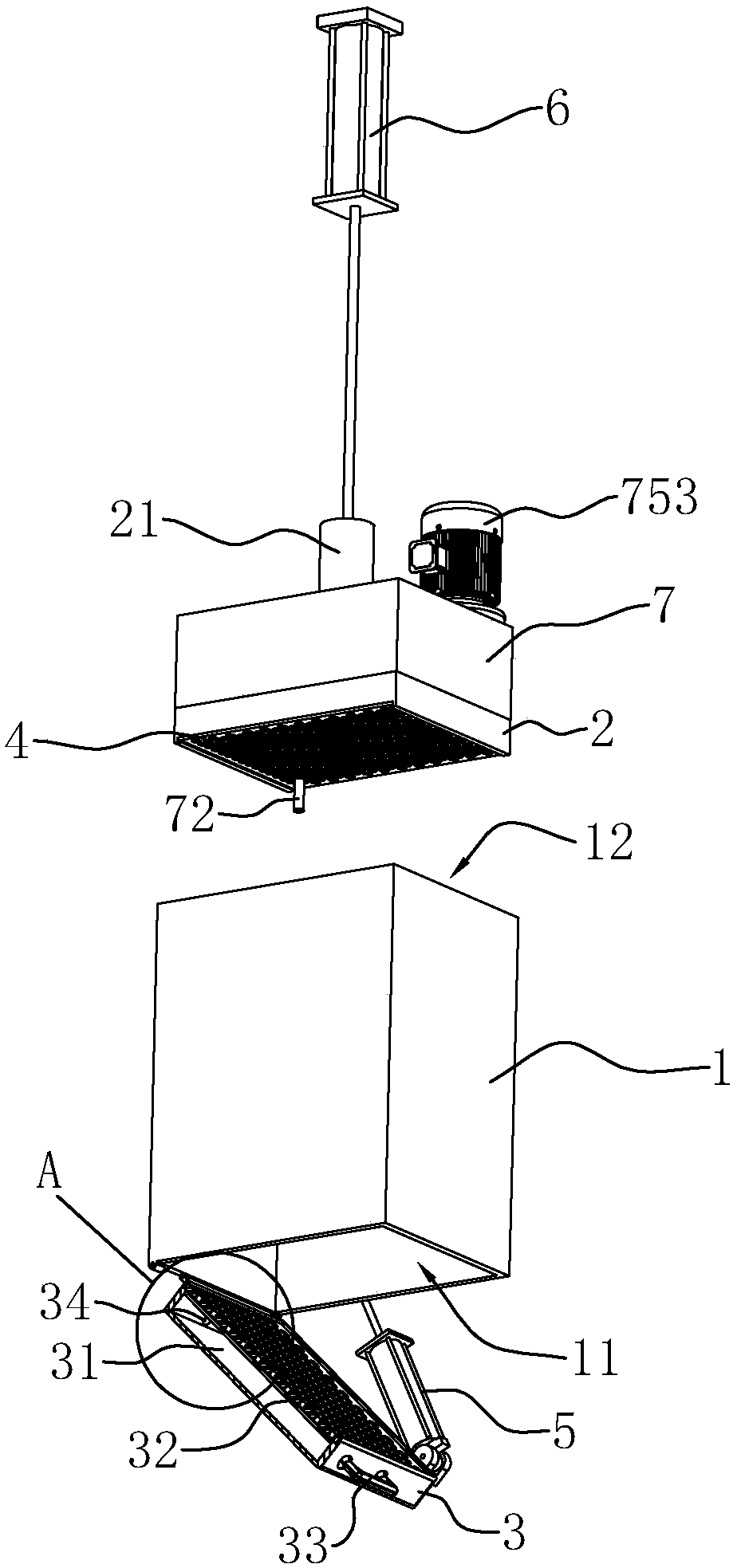

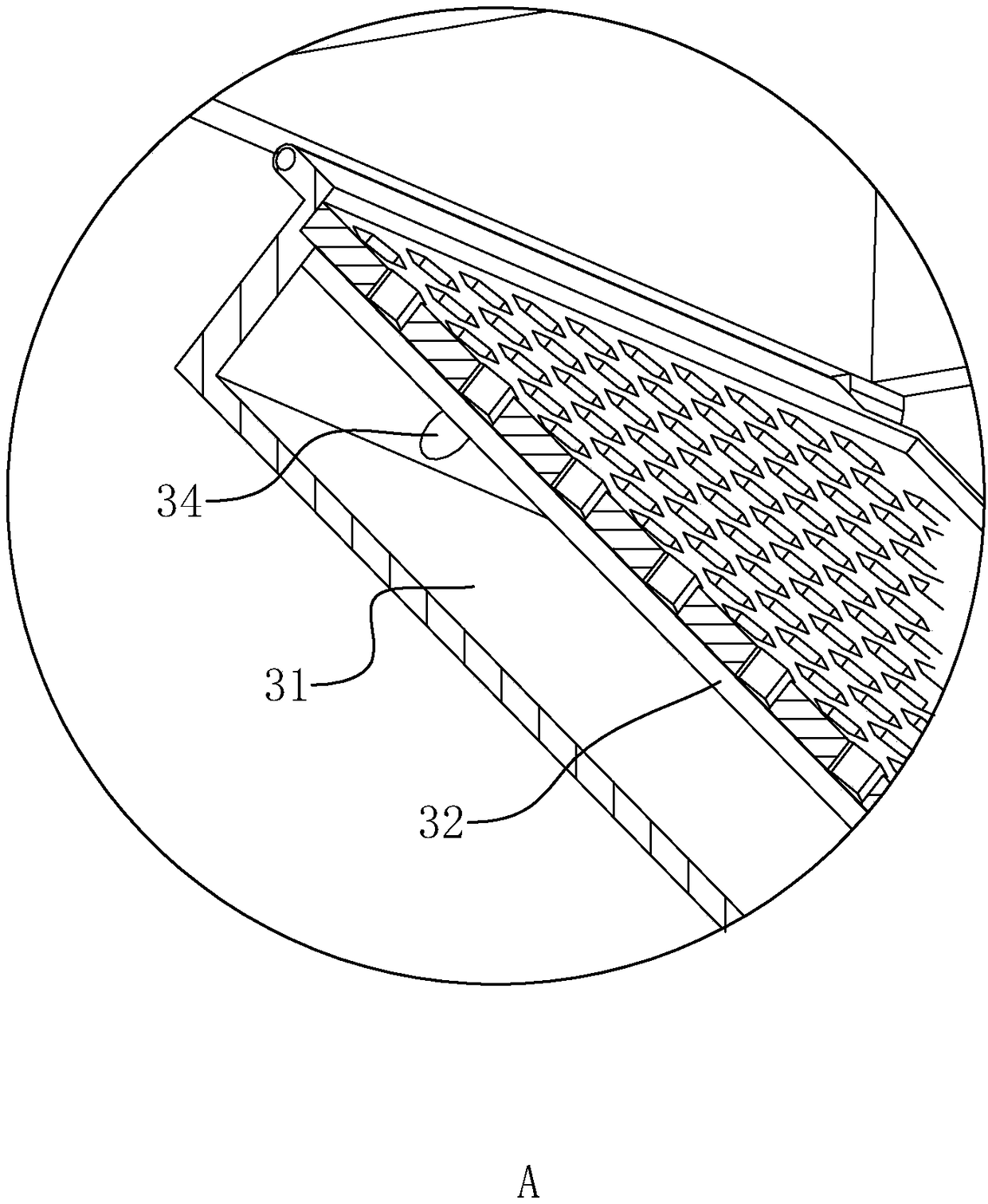

Sludge dewatering container and dewatering method by adopting container

PendingCN109422442ALow conductivityConductivity recoveryWater treatment parameter controlSludge treatment by de-watering/drying/thickeningElectricityEngineering

The invention discloses a sludge dewatering container and a dewatering method by adopting the container. The sludge dewatering container comprises an insulating container body, wherein the insulatingcontainer body comprises container side walls, a bottom, a top, and electrode materials respectively arranged at the bottom and the top, the anode material is arranged at the top, and the cathode material is arranged at the bottom; an alkali adding device is further arranged on the insulating container body, wherein the alkali adding device comprises a detection unit used for detecting electric conductivity of sludge and a liquid outlet for supplying a liquid to the electrode material at the top, the supplied liquid of the liquid outlet is controlled by the detection unit, and every time whenthe electric conductivity of the sludge is reduced by a preset value A, the liquid outlet is opened for liquid supply. The alkali adding device is introduced, and the electric conductivity of the sludge is detected through the detection unit; after electroosmosis is carried out for a period of time, the electric conductivity of the sludge is reduced, and then, a bit of an alkaline solution is added to the electrode material at the top for ensuring the electric conductivity of the sludge and the dewatering effect of electroosmosis.

Owner:杭州渗源环境科技有限公司

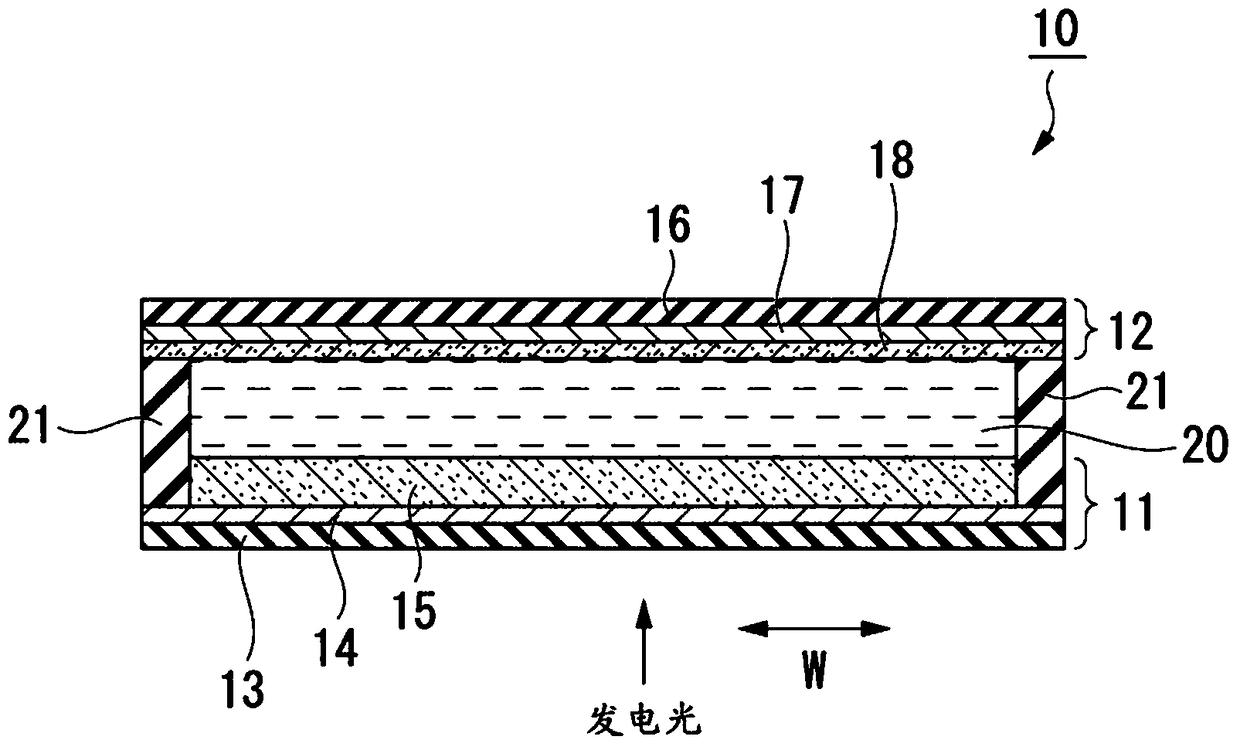

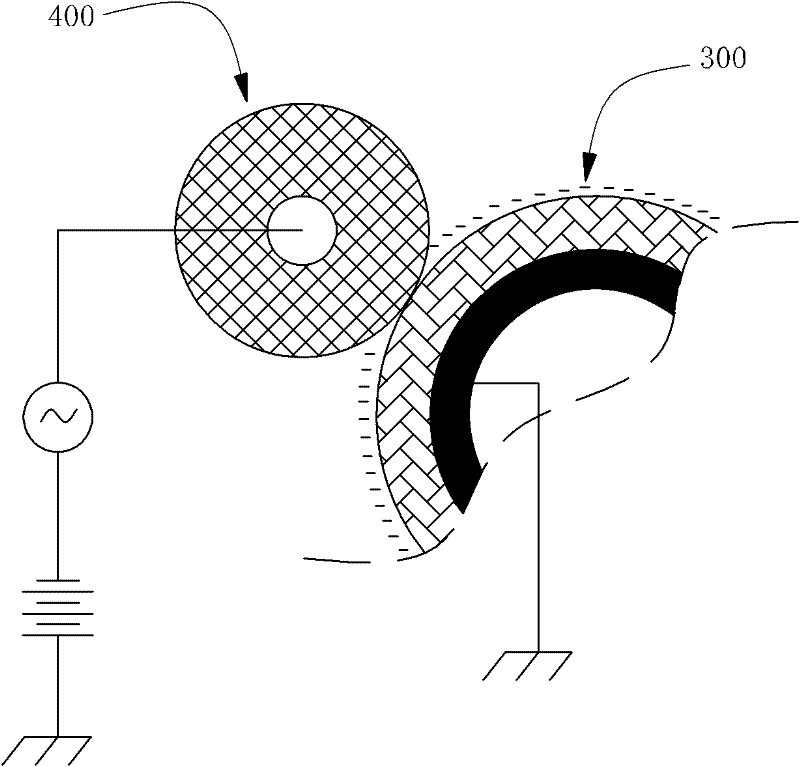

Active material reactivation method, battery regeneration method, catalyst layer, counter electrode

ActiveCN105283936BLow conductivityConductivity recoveryLight-sensitive devicesPhotovoltaic energy generationRedoxEngineering

The object of the present invention is to provide a method for reactivating a counter electrode active material of a dye-sensitized solar cell, a method for regenerating a dye-sensitized solar cell using the method, a catalyst layer of a dye-sensitized solar cell, and a counter electrode. , an electrolyte solution and a dye-sensitized solar cell, wherein the regeneration method of the dye-sensitized solar cell includes regenerating the conductive polymer reduced by the redox pair in the electrolyte solution of the dye-sensitized solar cell, which can temporarily reduce The power generation performance of the dye-sensitized solar cell is restored to the initial performance, and the reduction of the power generation performance of the dye-sensitized solar cell can be prevented. The invention is a method for reactivating the counter electrode active material of a dye-sensitized solar cell, which is a method for reactivating the counter electrode active material of a dye-sensitized solar cell. The dye-sensitized solar cell has at least More than one kind of conductive polymer is used as a counter electrode composed of a catalyst layer of the counter electrode active material, and the method includes: reoxidizing the conductive polymer by chemical oxidation or electrochemical oxidation.

Owner:SEKISUI CHEM CO LTD

A kind of preparation method of high conductivity graphene

InactiveCN103172055BReduce the degree of oxidationReduce defectsGrapheneX-rayElectromagnetic shielding

The invention discloses a preparation method of high-electroconductivity graphene, belonging to the field of nano graphite electroconductive materials. The method comprises the following steps: dispersing low-oxidation-degree graphite oxide in a solvent containing aromatic alcohol to obtain a low-oxidation-degree graphene oxide dispersion solution, and carrying out solvothermal reduction on the dispersion solution to obtain the high-electroconductivity graphene, wherein the mol ratio of oxygen to carbon in the low-oxidation-degree graphene oxide is lower than 1:2, and the low-oxidation-degree graphene oxide does not have any characteristic diffraction peak in an X-ray diffraction pattern. The preparation method disclosed by the invention has the characteristics of high speed, high efficiency and no toxicity. The graphene disclosed by the invention has high electroconductivity, and is applicable to the fields of battery materials, energy storage materials, electronic devices, electroconductive / thermoconductive materials, electromagnetic shielding materials, antistatic materials and the like.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

A high-strength heat-resistant aluminum alloy wire

InactiveCN103820680BLow content of impurity elementsInhibition of recrystallizationSingle bars/rods/wires/strips conductorsMetal/alloy conductorsHeat resistanceManganese

The present invention disclosed a high -strength heat -resistant aluminum alloy wire, with industrial pure aluminum as raw materials, adding trace boron, cricket, manganese, copper, and cricket elements at 800 ± 10 ° C.0.30%boron, 0.05 ~ 0.60%锑, 0.02 ~ 0.80%manganese, 0.05 ~ 2.30%copper, 0.05 ~ 0.90%锆, the balance is pure aluminum and inevitable impurities.manufacture.The aluminum alloy wires made by the present invention have both high intensity and good heat resistance and better conductivity, and the comprehensive performance of the wire has improved significantly.The invention aluminum alloy wires can be widely used in my country's transmission lines, especially in large span and long -distance transmission transmission projects.

Owner:GUANGXI DONGXING DINGKANG PLASTIC IND

A preparation method of a hydrogel electrode with high mechanical properties and self-healing properties

InactiveCN106008799BImprove self-healing abilityConductivity recoveryDiagnostic recording/measuringSensorsSelf-healingBiocompatibility Testing

The invention discloses a preparation method of a hydrogel electrode with high mechanical properties and self-healing property, belonging to the technical field of biomaterials. In the present invention, polydopamine-modified conductive nanomaterials are firstly prepared in a solution, and then water-soluble monomers are added to the solution, and then an initiator, a cross-linking agent and an auxiliary agent are added to mix evenly, and the hydrogel is formed by free radical polymerization. electrode. The hydrogel electrode prepared by the invention does not have good electrical conductivity and mechanical properties; and due to the non-covalent bond between polydopamine chains, the hydrogel electrode has good self-healing performance. The hydrogel electrode prepared by the invention has the ability to heal spontaneously in a short period of time after accidental damage; combined with its good biocompatibility, the self-healing hydrogel electrode prepared by the invention It is expected to be applied to modern clinical detection and biomedical measurement.

Owner:SOUTHWEST JIAOTONG UNIV

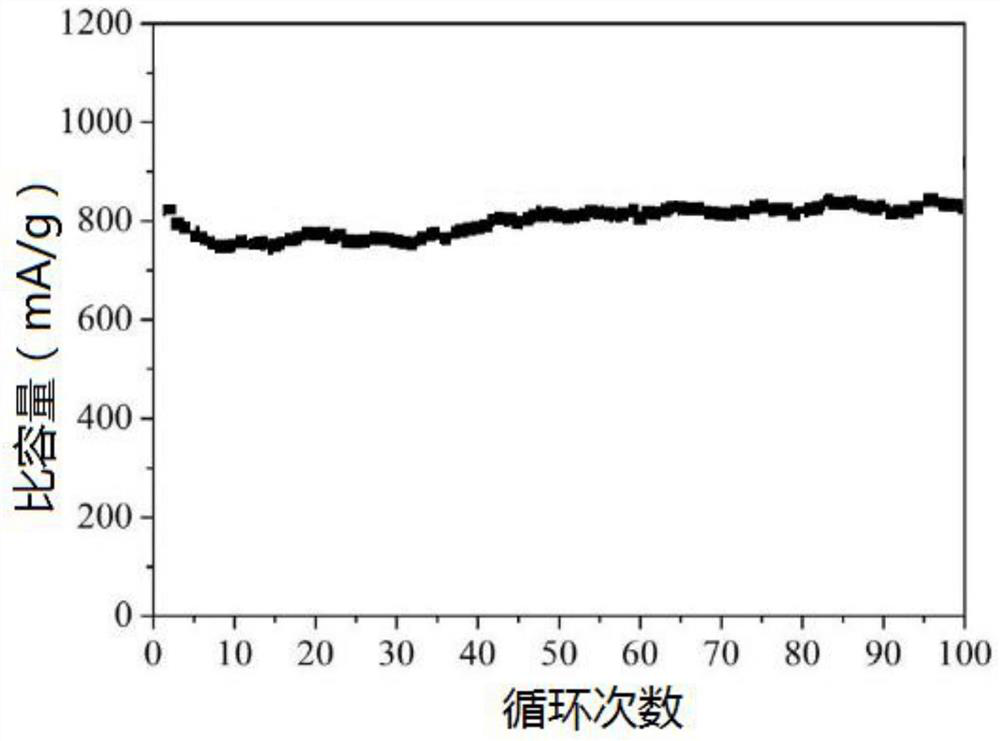

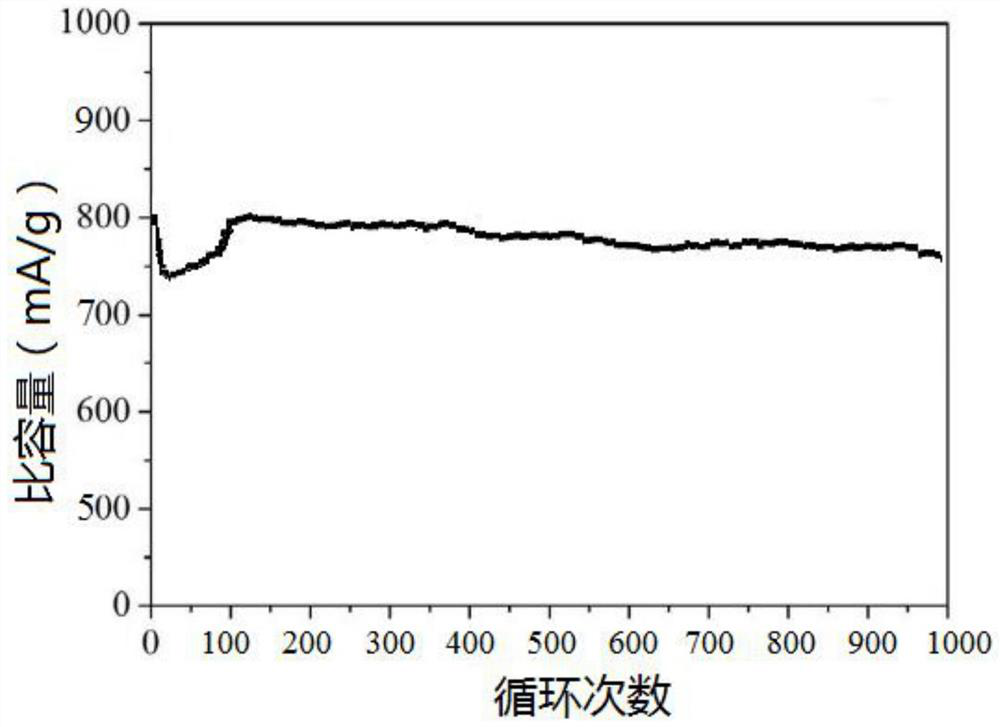

NiS/graphene and carbon composite material as well as preparation method and application thereof

The invention relates to the technical field of lithium ion battery electrode materials, in particular to a NiS / graphene and carbon composite material and a preparation method and application thereof. Nickel sulfide, graphene oxide and a carbon source are compounded, porous carbon is obtained after gel carbonization, the porous carbon has a large specific surface area, and attachment of graphene oxide and nickel sulfide is achieved; the porous carbon has a cross-linked pore structure, and after the porous carbon is compounded with the nickel sulfide, the nickel sulfide is attached to the porous carbon, so that the synergistic effect of the nickel sulfide and the porous carbon is improved, and the conductivity is further improved; the porous carbon is adopted to replace graphene, under the combined action of the reduced graphene oxide, the nickel sulfide and the porous carbon, the conductivity of the electrode material is close to that of a NiS-graphene material, and then the electrode material with excellent conductivity is obtained while the use amount of the graphene is reduced and the cost is saved to a certain extent.

Owner:TAIYUAN UNIV OF TECH

Manufacturing method of aluminum alloy material special for high-voltage power transmission and transformation

The invention discloses a manufacturing method of an aluminum alloy material special for high-voltage power transmission and transformation. The method involves the following raw materials comprising,by mass, 2%-10% of silicon, 0.1%-1.5% of manganese, 0.1%-0.3% of zirconium, 0.2%-0.6% of copper, 0.1%-1.5% of rare earth alloy, 0.2%-0.6% of graphene and the balance industrial pure aluminum alloy. The method includes the following specific operating steps that first, the industrial pure aluminum alloy is added into a melting furnace for fusion, and the temperature is kept to be 800 DEG C; then the silicon raw material is added into molten aluminum after being ground, stirring is conducted continuously in the adding process, and the temperature is kept to be continuously stirred for 30 minutes after the silicon is added; and afterwards, the temperature is lowered to 780 DEG C. According to the manufacturing method, the internal structure of the aluminum alloy is changed by adding the raremetal and graphene materials; Compared with the prior art, the overall performance of the aluminum alloy material manufactured through the method is remarkably improved, and particularly the electrical conductivity, the heat dissipation performance and the flexibility are remarkably improved.

Owner:绵阳市优泰精工科技有限公司

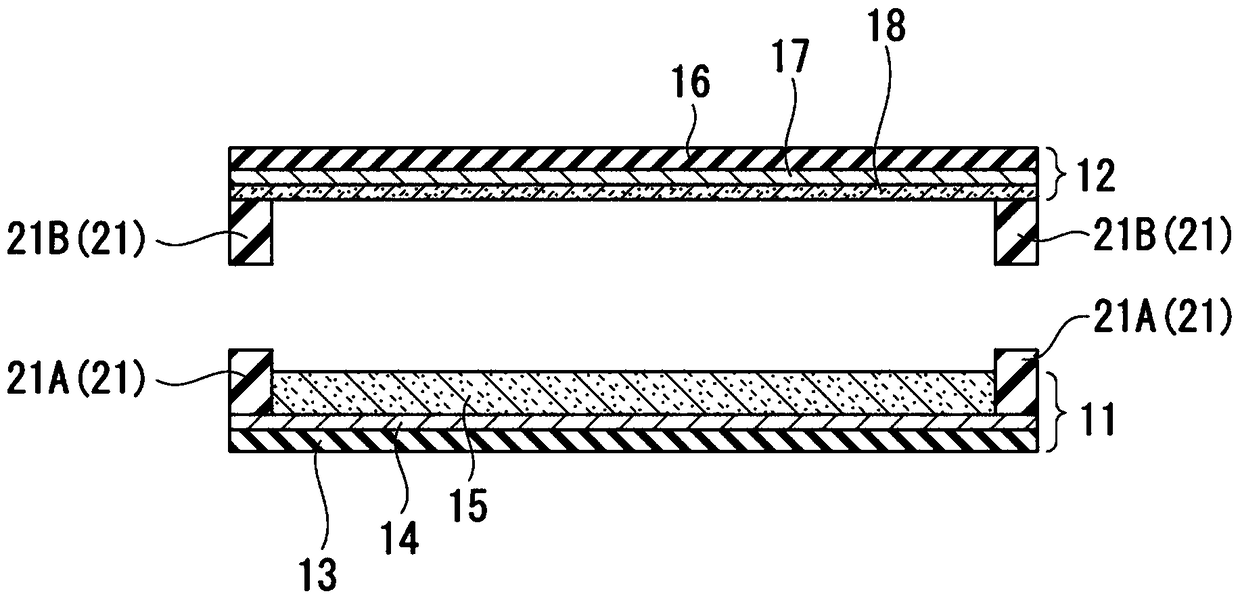

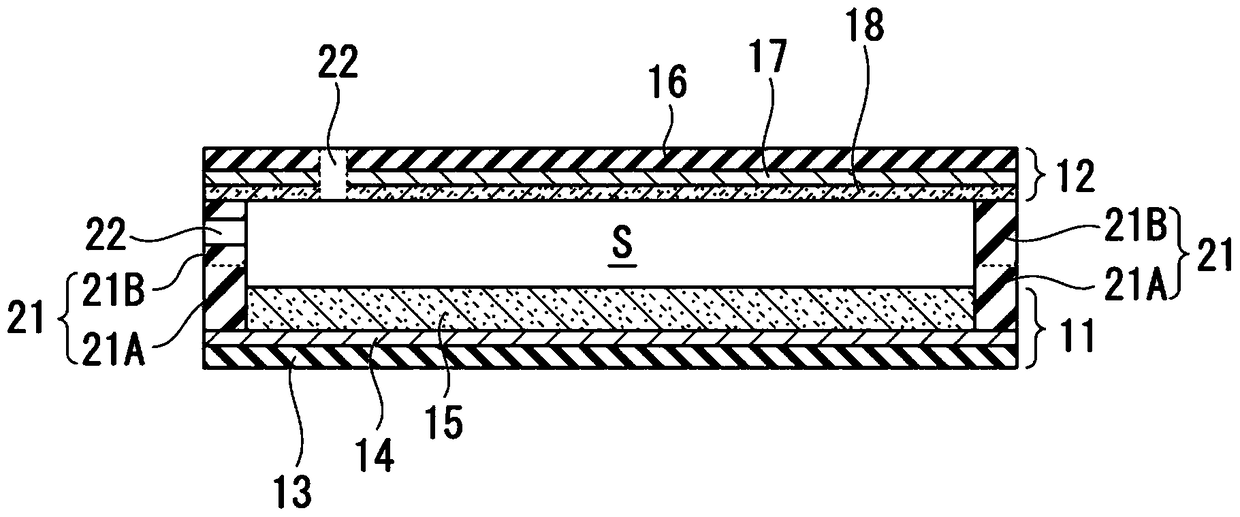

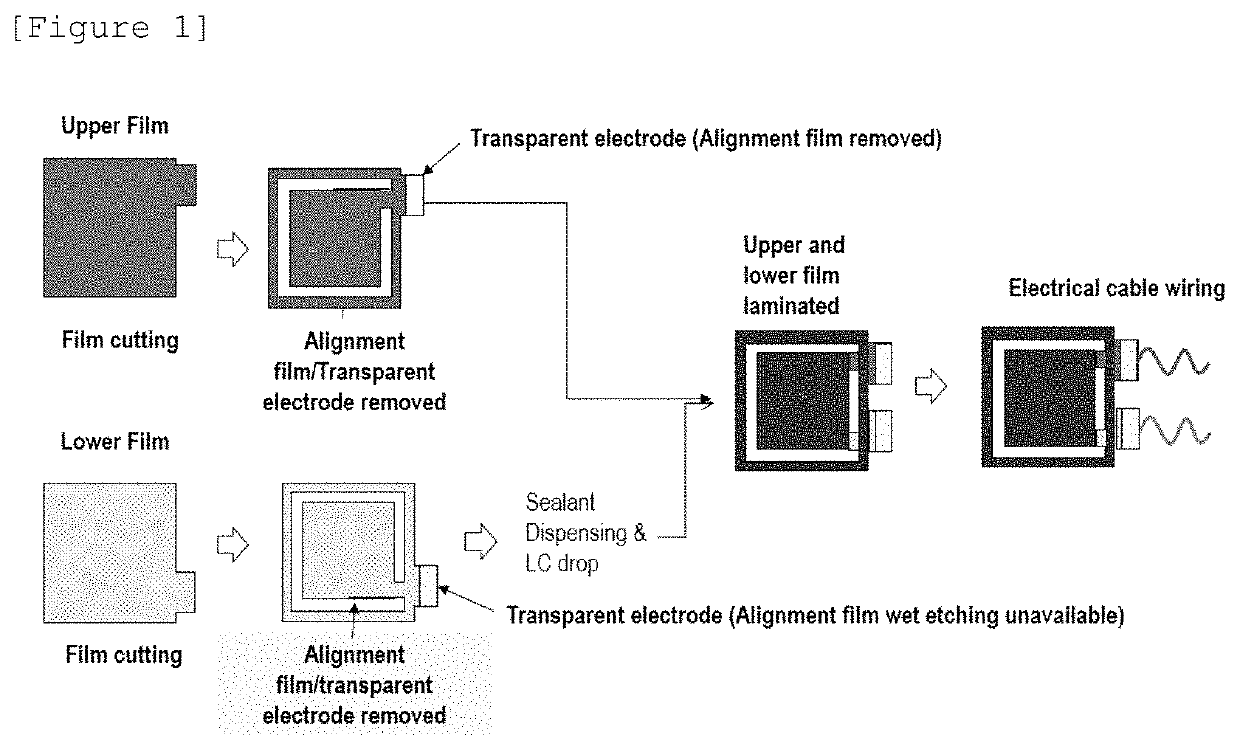

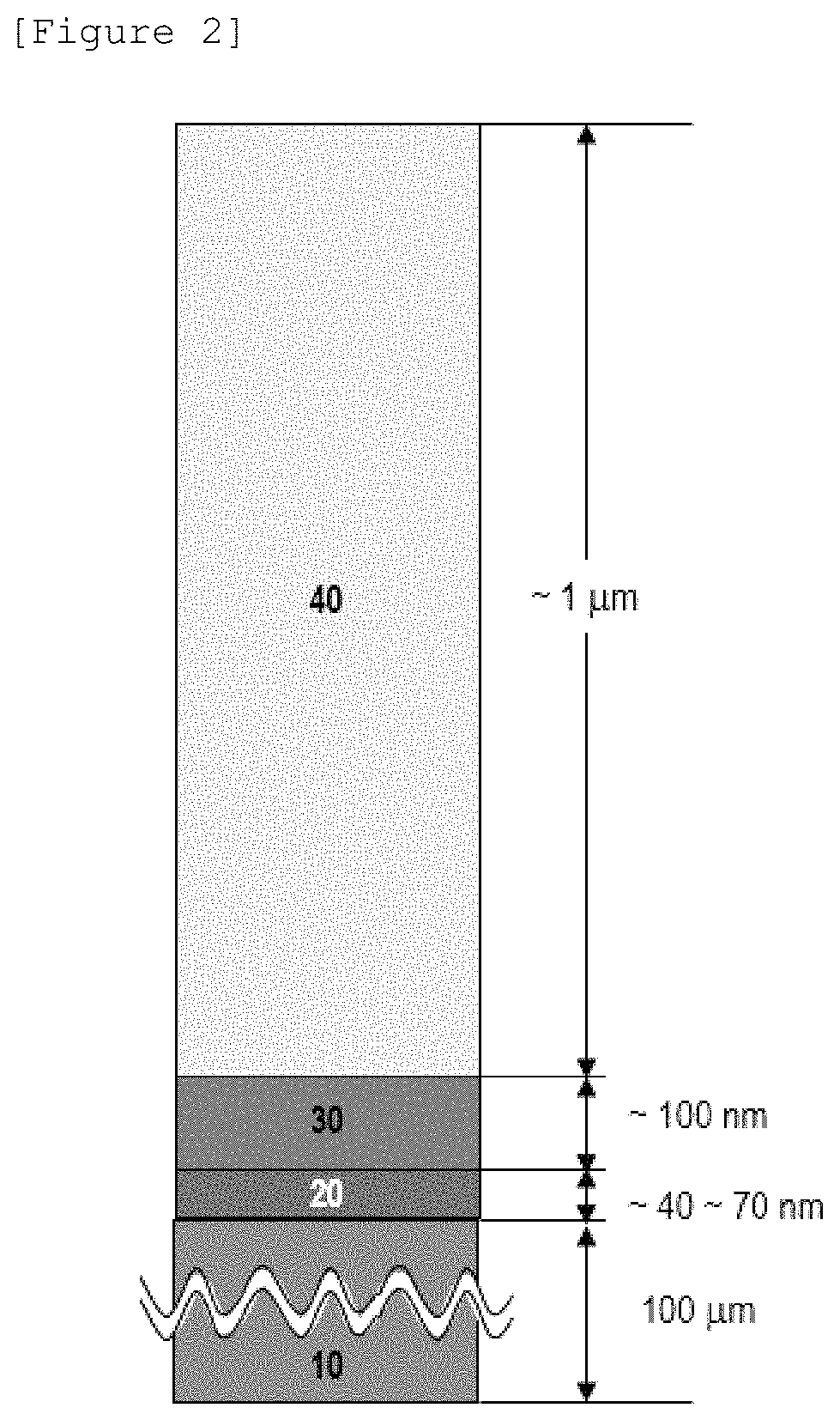

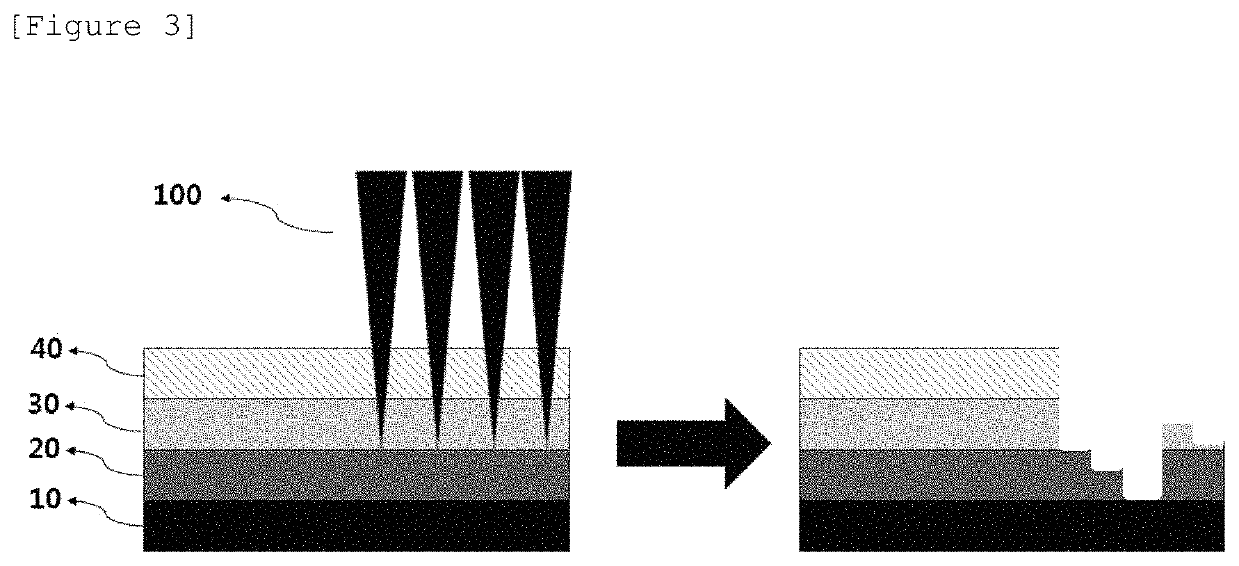

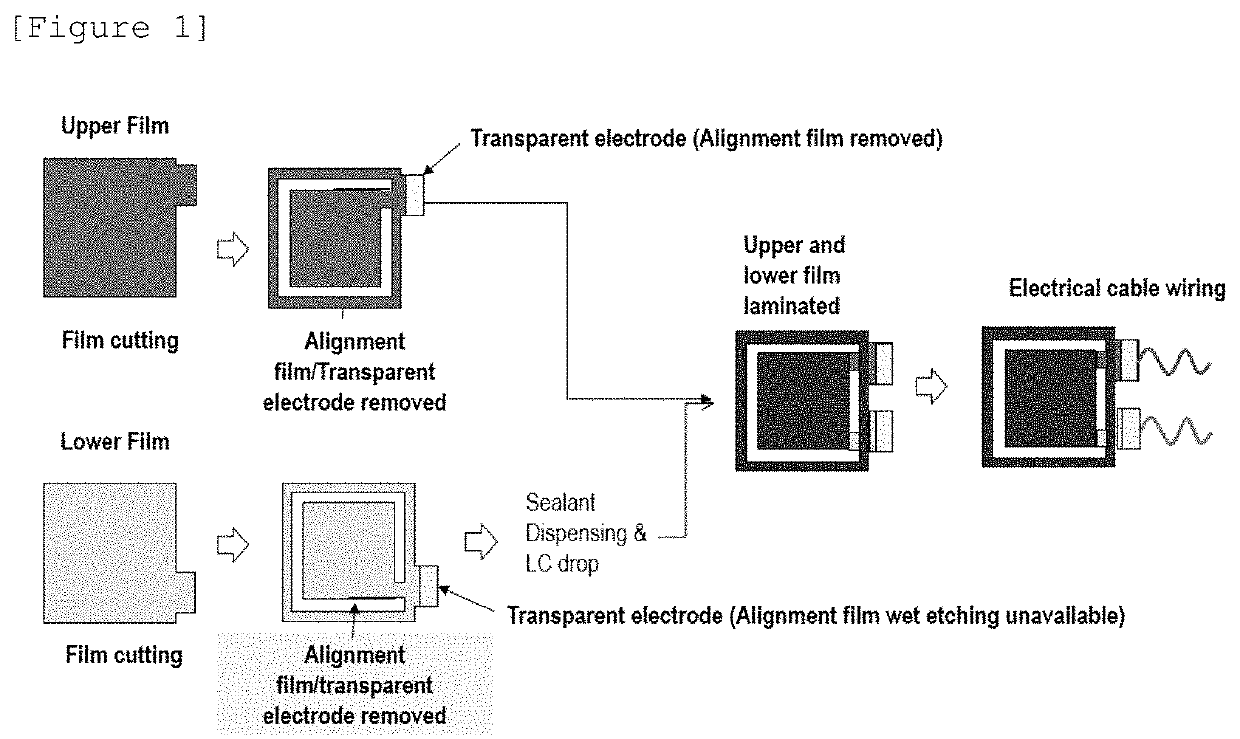

Method for forming wire portion of liquid crystal chromic device and liquid crystal chromic device

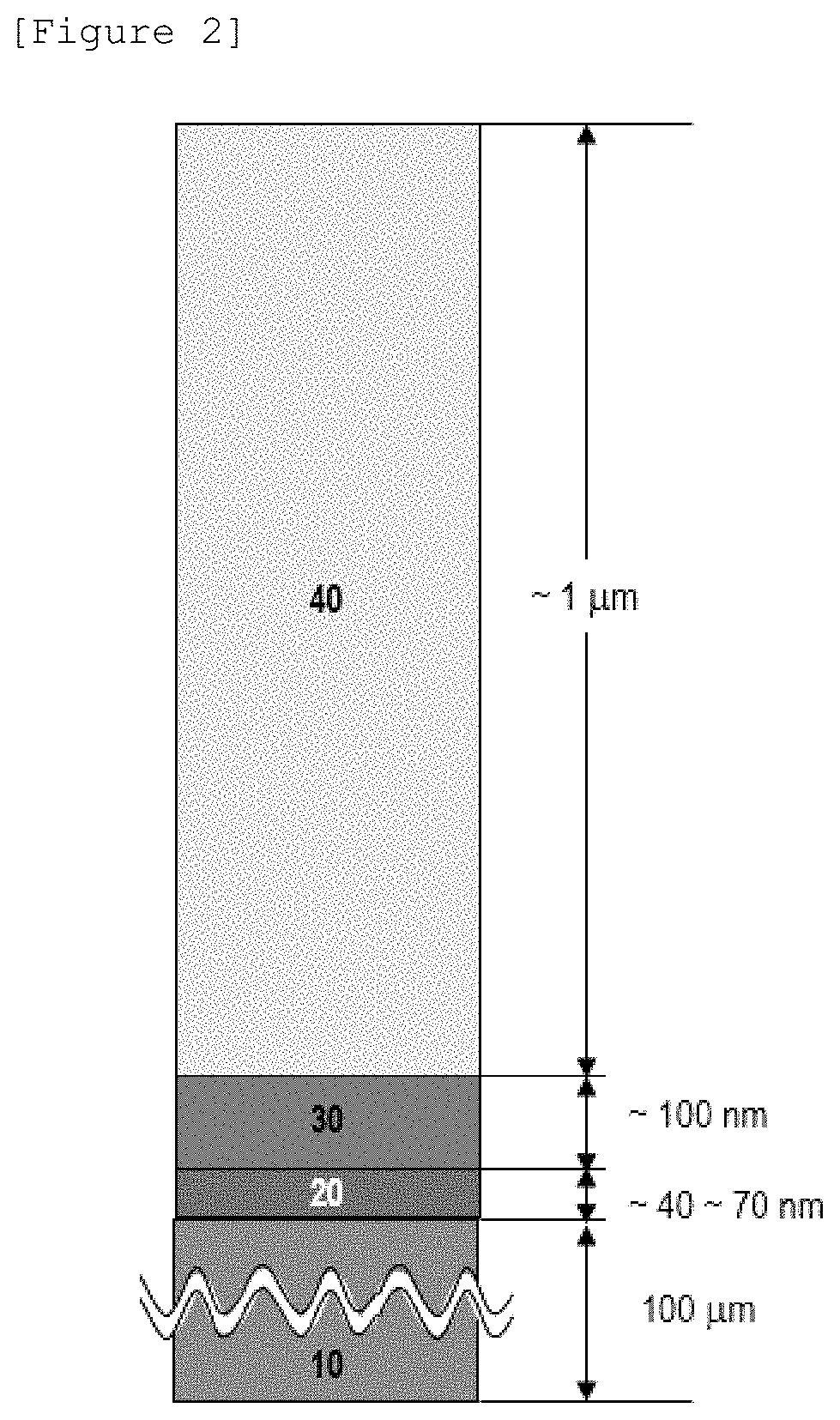

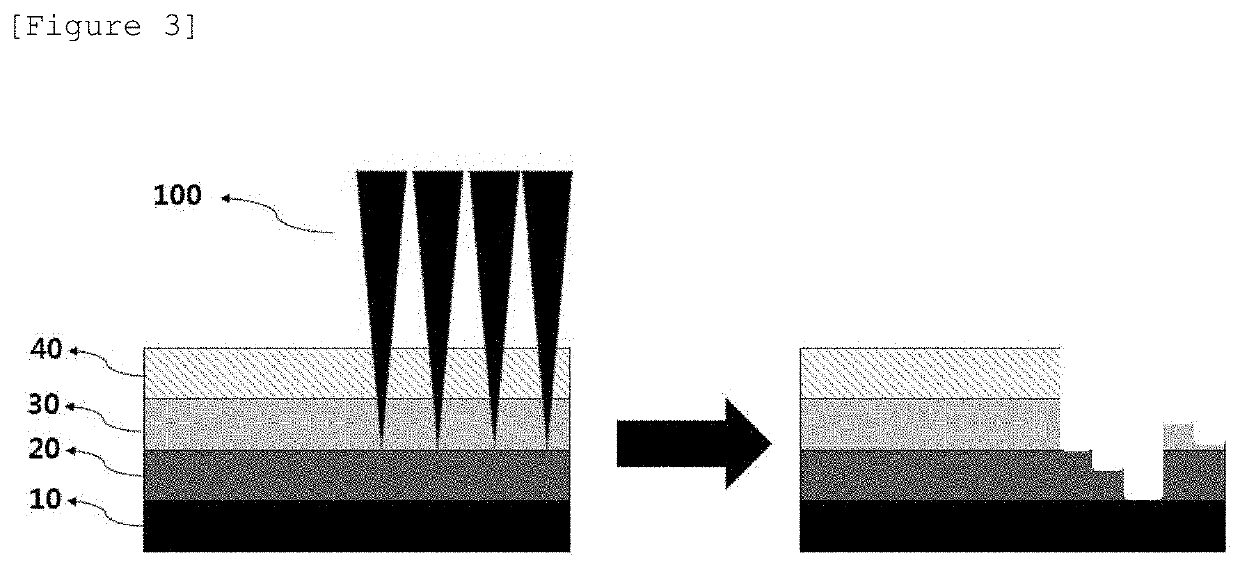

ActiveUS10782578B2Conductivity damageConductivity recoveryLiquid crystal compositionsLaser detailsCrystallographyConductive paste

Owner:LG CHEM LTD

Copper alloy for guide wire with high conductivity and high elongation and preparation method of copper alloy

The invention discloses copper alloy for a guide wire with high conductivity and high elongation and a preparation method of the copper alloy, belonging to the technical field of copper alloy preparation. The copper alloy material for the guide wire comprises the following components in percentage by weight: 0.04-0.06% of lead, 0.6-0.7% of iron, 0.06% of cerium and the balance of copper. The preparation method of the guide wire with high conductivity and high elongation comprises the following steps: mixing and melting the components in percentage by weight, then, ingoting, thermally rolling, performing solid solution treatment, performing cold rolling and pickling to obtain the guide wire with high conductivity and high elongation. The guide wire has conductivity of 97-102% IACS and the elongation of 15-19%. The copper alloy disclosed by the invention can be used for meeting the performance needs of the guide wire in the electronic industrial field on the copper alloy material very well, and also can be used for the field of copper alloy materials with high requirements, high conductivity and high elongation. The copper alloy disclosed by the invention further has the advantages of simple process and low cost.

Owner:南通海腾铜业有限公司

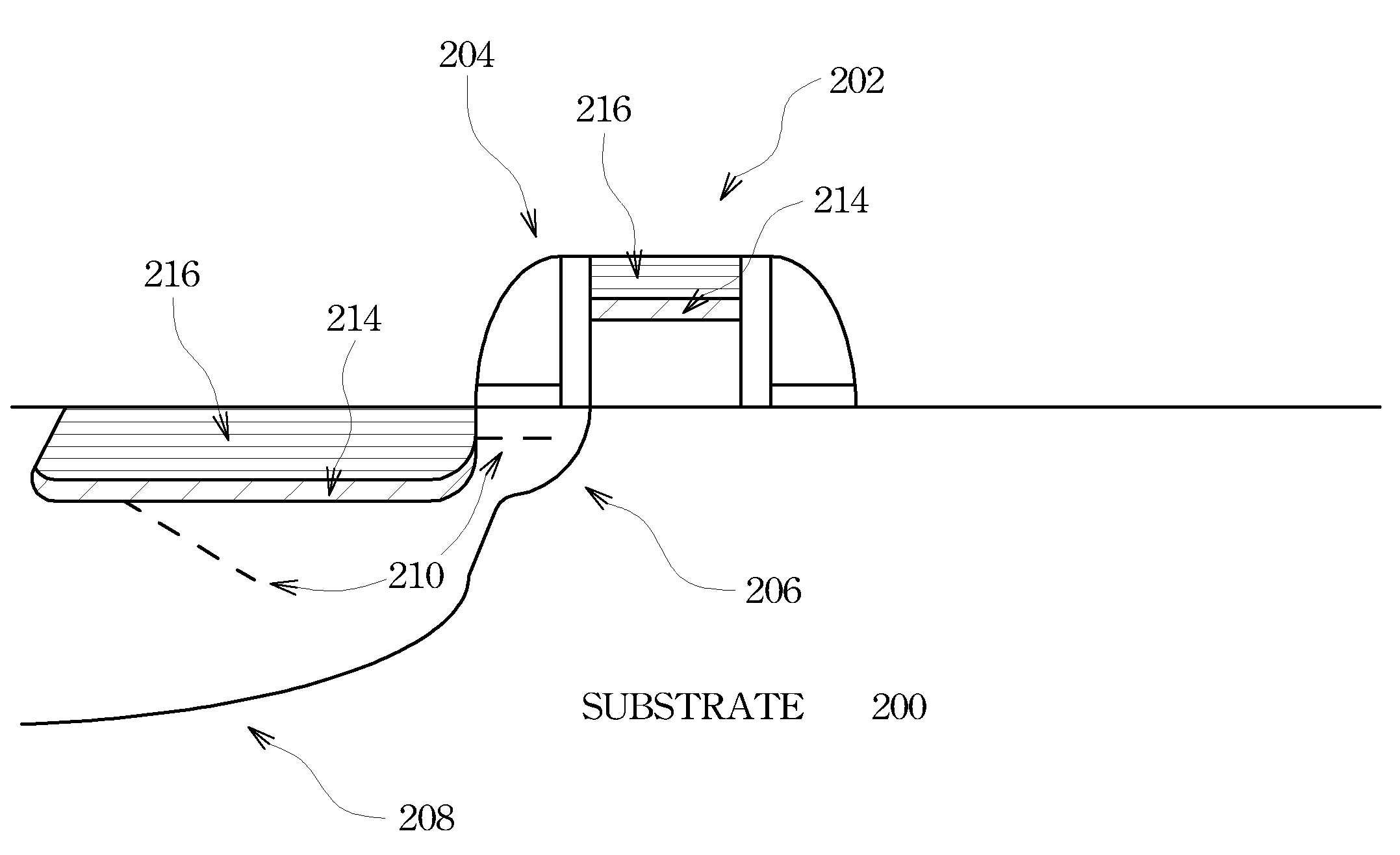

Method for forming wire portion of liquid crystal chromic device and liquid crystal chromic device

ActiveUS20200050067A1Conductivity recoveryImprove productivityLiquid crystal compositionsLaser detailsCrystallographyConductive paste

A method for forming a wire portion of a liquid crystal chromic device. The method includes: a) preparing a liquid crystal chromic device by forming a transparent electrode on a substrate, and forming an alignment film on the transparent electrode; b) forming two or more etching lines spaced apart by a constant interval by irradiating the alignment film with a laser; and c) applying a conductive paste to a valley region of each of the two or more etching lines. The liquid crystal chromic device includes: a substrate; a transparent electrode provided on the substrate; an alignment film provided on the transparent electrode; and two or more etching lines provided on the alignment film. The two or more etching lines are spaced apart by a constant interval, and a valley region of each of the two or more etching lines is coated with a conductive paste.

Owner:LG CHEM LTD

A Method of Using Solvent Evaporation to Induce Fusion and Sintering of Liquid Metal Micro-nano Droplets

ActiveCN111863341BImprove sintering performanceEffective sinteringApparatus for heat treatmentApparatus for manufacturing conducting/semi-conducting layersChemical physicsSolvent evaporation

The invention relates to the technical field of liquid metal sintering and fusion, in particular to a method for inducing fusion and sintering of liquid metal micro-nano droplets by solvent evaporation. Evaporate and dry the liquid metal micro-nano droplet dispersion or the liquid metal micro-nano droplet dispersion containing additives, and use the capillary force generated during the evaporation and drying process to achieve sintering and fusion. The method for sintering liquid metal micro-nano droplets of the present invention has the advantages of simple operation, low cost, and can be realized at normal temperature and pressure, and can be used in many fields such as packaging circuits, 3D printed electronic technology, sensors, drivers, and electromagnetic shielding.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

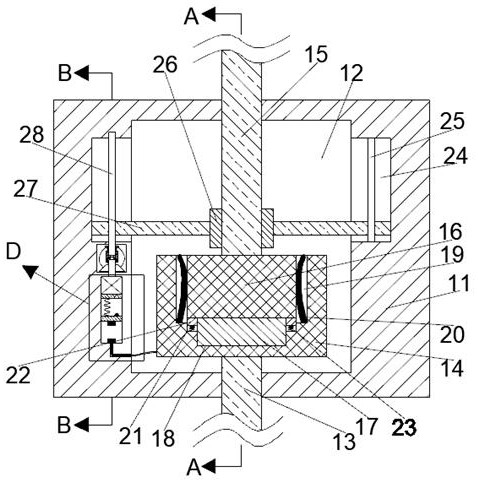

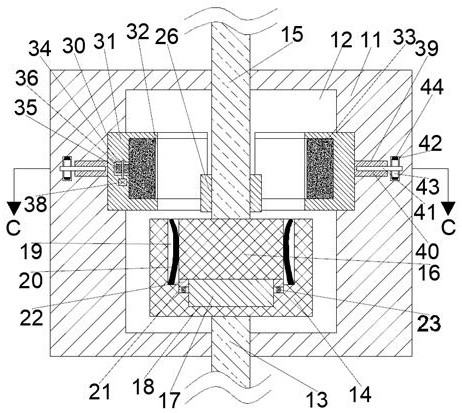

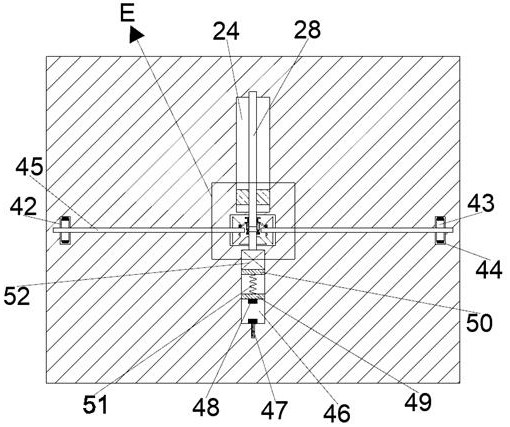

Protection device capable of detecting and repairing conductive contact

InactiveCN111987552AConductivity recoveryLine connector maintainanceMeasurement instrument housingHemt circuitsEngineering

The invention discloses a protection device capable of detecting and repairing a conductive contact. The protection device comprises a protection cover; a protection cavity is formed in the protectioncover; a contact electric wire is connected into the upper wall of the protection cavity in an up-and-down sliding manner; the upper end of the contact electric wire extends to the upper side of theprotection cover; a base electric wire of which the lower end extends to the lower side of the protection cover is fixedly arranged in the lower wall of the protection cavity; a conductive base is fixedly arranged on the upper end surface of the base electric wire; a connecting cavity with an upward opening is formed in the conductive base; a conductive contact is fixedly arranged on the lower endsurface of the contact electric wire; the conductive contact can enter the connecting cavity; whether the conductive contact works normally or not can be judged according to the current of a circuit,when the current is small, the contact and the base can be automatically separated, then polishing treatment is conducted, an oxide layer is obtained by removing the surface of the contact, and the conductive performance of the contact is recovered.

Owner:DONGYANG ZONGTIAN ELECTRONICS TECH CO LTD

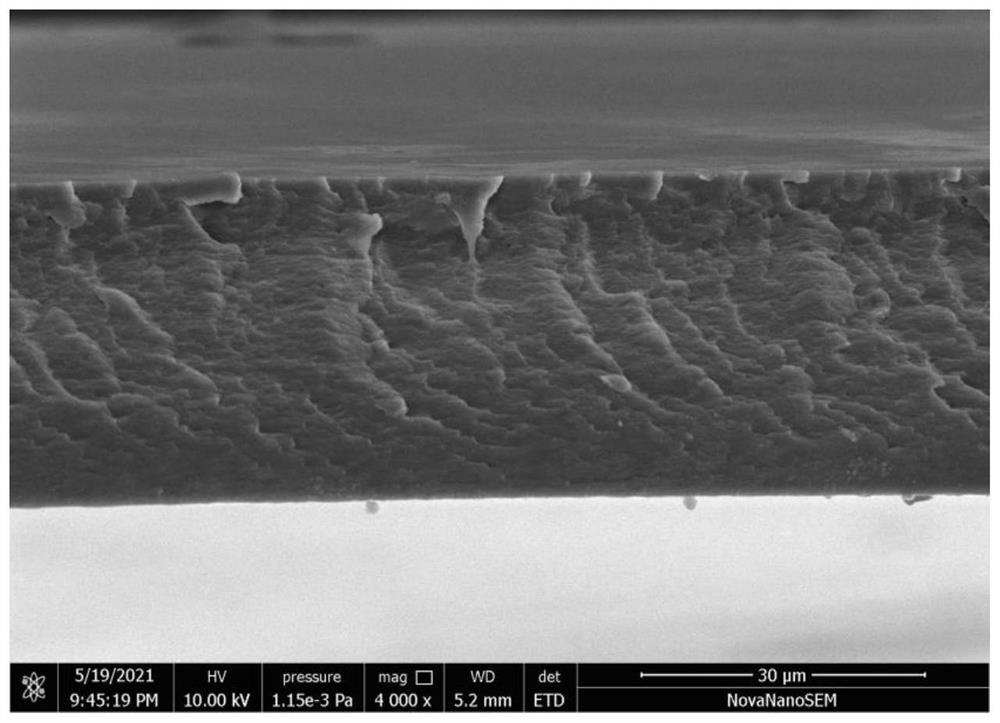

Regeneration method of charging roller of laser imaging processing box

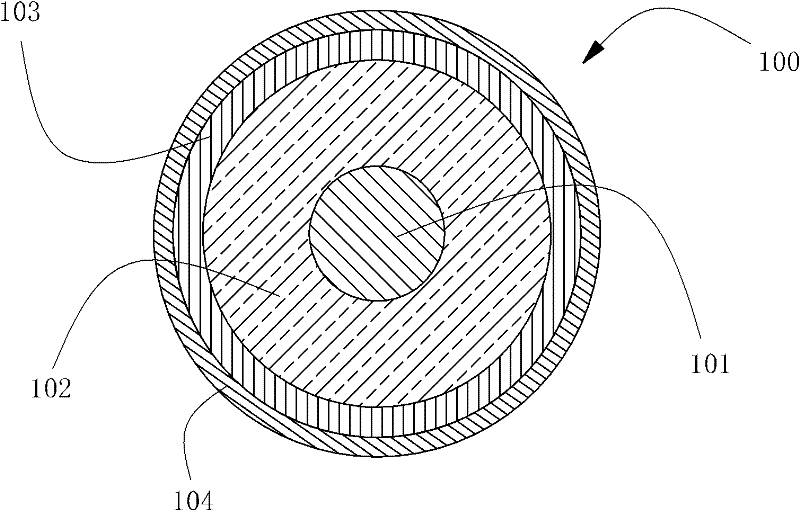

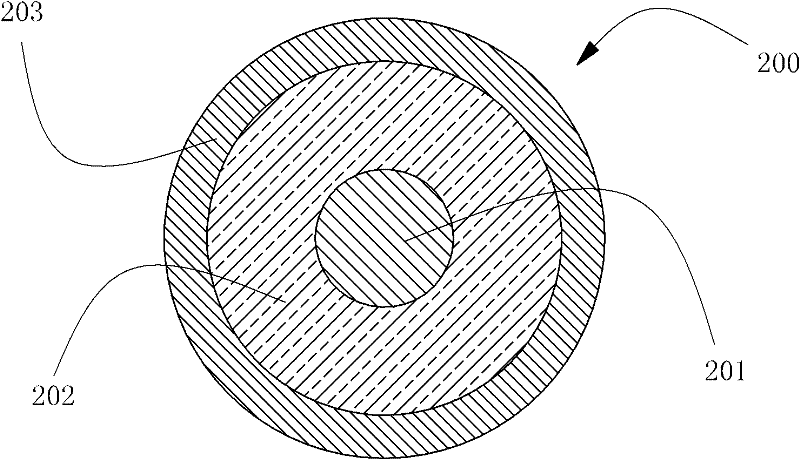

ActiveCN101893840BEliminate bottom ash phenomenonImprove qualityElectrography/magnetographyBottom ashWork period

The invention relates to a regeneration method of a charging roller of a laser imaging processing box, wherein the charging roller works for at least one work period. The cross section structure of the charging roller at least comprises a mandrel, an insulating layer coated on the mandrel and a conducting layer coated on the insulating layer. The regeneration method comprises the following processing steps in sequence: (1) removing the coatings on the periphery surface of the insulating layer; (2) using high-pressure airflow to wash the insulating layer through blowing, wherein the high-pressure airflow dispersedly flows past pores of the insulating layer; and (3) coating original functional layers at least comprising a new conductive layer, wherein the periphery surface of the new conductive layer is exposed. The method is simple and practicable, has the characteristics of high efficiency and low cost, and can be used for effectively recovering the conductivity of the conductive roller and simultaneously eliminating bottom ash which occurs on a work surface and is caused by the charging roller when the image is printed, thus the reproduced product has favorable quality.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com